What is a devoré fabric?

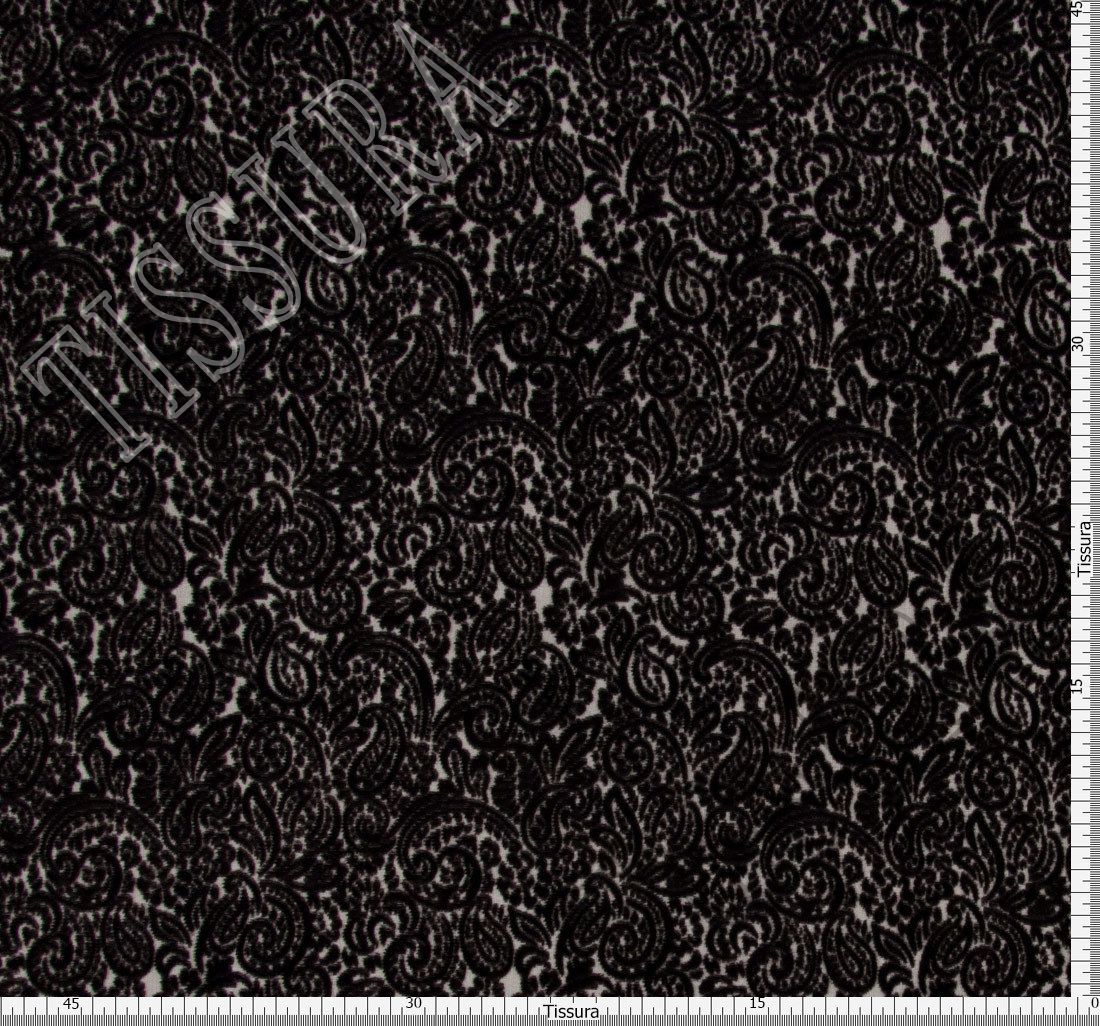

Devoré is a fabric technique used on mixed fibre material where a paste is used to burn through cellulose fibres, leaving woven fabric behind in a pattern or design.

How is devoré made?

You can create devore (from the French devorer – meaning to devour) by using a devorant paste on a mixed fibre fabric. The devorant destroys (burns out) viscose and plant (cellulose) fibres such as cotton, linen etc and leaves other fibres such as polyester and animal fibres, like silk and wool, intact.

What is devoré paste?

Devore is a technique whereby patterns are chemically cut away on fabrics which are made up of a blend of cellulose and synthetic, or cellulose and protein fibres. It gives excellent results on viscose/silk velvet where the backing is silk (protein) and the pile is viscose (cellulose).

What is silk devoré?

Silk devore fabric is a silk fabric with original effects obtained by chemical treatment. The applied chemicals affect only viscose fibers and do not destroy the structure of silk fibers. Silk devore is renowned for its durability, resistance to sunlight and hypoallergenicity.

What is burnt velvet?

Burned Velvet Fabric BV is a designer fabric that starts its life as an all-over velvet and then undergoes an etching process called devoré (or burnout) to create the chosen pattern, leaving sheer sections where the etching has occurred. The fabric is also dyed which allows for the use of lots of awesome colours!

How is velvet burnout made?

Burnout velvet is, quite simply put, beautiful. The fabric is created by cutting away surface pile from velvet in specific areas, leaving a sheer backing visible behind the outer velvet design. The velvet design of the fabric may be floral, geometric, or abstract.

What is burnout print?

This procedure is sometimes referred to as “Burn Out”. A cotton / polyester blended fabric can be printed with a print paste containing the burn out chemicals, and after fixation, the cotton portion is destroyed and only the polyester remains. This allows a patterned lacey design to be imparted to the fabric.

What is unique about burnout fabric?

Burn-out fabrics feature a sheer ground with opaque, often textured motifs. The name comes from the traditional technique for creating the velvet-on-silk variety, a blended textile in which the ground fabric is a different fiber type than the pile.

What does burnout dress mean?

What is burnout? It's a technique that gives fabric different textures by literally burning out a layer of the fabric with a chemical. The French call this process “broderie chimique” – which means “chemical embroidery.” By burning away part of a fabric, the look can mimic embroidery.

What is the most luxurious silk?

The highest-quality silk is mulberry silk, which is made from silkworms who eat from the leaves of the mulberry tree.

What are the 3 grades of silk?

Note: Spider silk can also be known as Muga silk and it is the costliest Silk fabric. There are three main grades of silk namely A, B and C. The grade A silk can be the best quality.

What is the highest quality of silk?

Mulberry SilkMulberry Silk The highest quality silk available comes from silkworms produced from the Bombyx mori moth. They're fed an exclusive diet of mulberry leaves, which is why the luxurious fabric is known as mulberry silk.

How is Bogolanfini made?

The cotton base cloth of bogolanfini is created in a distinctively West African technique known as narrow-strip weaving. Individual strips of cloth are woven by men on treadle looms, then sewn together to make a larger textile.

How is Algiknit made?

The process of making Algiknit yarn starts with powered seaweed made into a monofilament or multifilament; this is then spun into a coagulation bath. From there, yarn spinning commences, and the yarns are spun into cones. Textile construction can then begin to be knit and turned into garments.

How is Nanofabric made?

A nanofiber is produced by the electrospinning method and split spinning process. Nano-fibers possess multifunctional properties such as good filtration, high surface area, high permeability, small fiber diameter, and thin layers.

How is Brocatelle made?

A brocatelle is woven with two silk warps of differing weights for tension purposes and two wefts; one of silk and one of linen. The Speaker's State Bed at the Palace of Westminster, London is a good example of a brocatelle fabric.