Is autoclave example of dry heat Sterlization?

This type of sterilizer is particularly useful when sanitizing metal instruments because it does not rust the equipment nor dull metal edges. Steam sterilizers, or autoclaves, like dry heat sterilizers use very high temperatures to destroy harmful microorganisms, but they also use pressure over a specific amount of time to disinfect.

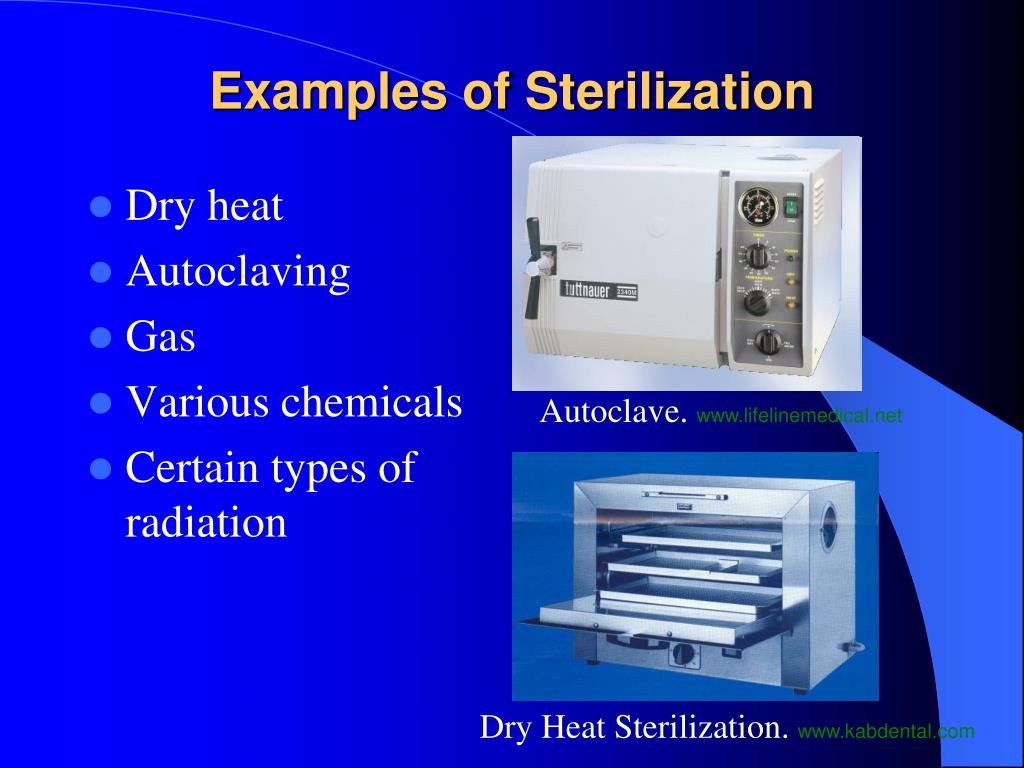

What are the different methods of sterilization?

- i. Physical Control with Heat: The Citadel is novel by A.J. ...

- ii. Direct Flame: Perhaps the most rapid sterilization method is the direct flame method used in the process of incineration.

- iii. Hot-Air Sterilizer: The hot-air-sterilizer utilizes radiating dry heat for sterilization. ...

- iv. ...

- v. ...

- vi. ...

- vii. ...

- i. ...

- ii. ...

- iii. ...

What is the dry heat method of sterilization in microbiology?

Dry heat sterilization. Dry sterilization is the process of removing microorganisms by applying moisture-free heat which is appropriate for moisture-sensitive substances. The dry heat sterilization process is based on the principle of conduction; that is the heat is absorbed by the outer surface of an item and then passed onward to the next layer.

What are types of sterilization?

What are the three types of sterilization?

- WET HEAT (Autoclaving)

- DRY HEAT (Flaming, baking)

- FILTRATION.

- SOLVENTS.

- RADIATION.

What is dry heat sterilizing used for?

Dry heat sterilization processes Dry heat is primarily used to sterilize instruments and heat-resistible glass and instrument parts. The heat transfer by dry heat is less effective than by airless, saturated steam, because steam is able to transport the heat quicker than by condensation just air.

What items can be sterilized using dry heat?

Things such as glassware, metal instruments, paper wrapped things and syringes are effectively sterilized through dry heat. The materials used in these things are heat resistant or it can be said that they are heat stable.

What's an advantage of using a dry heat sterilizer?

Advantages of dry heat sterilization are that it's inexpensive, it doesn't pollute or cause toxic fumes, and it doesn't corrode or rust metal objects. Disadvantages are that it's relatively slow and that many objects can't withstand the high temperatures.

What are two types of dry heat sterilization?

There are two types of dry-heat sterilizers: the static-air type and the forced-air type. The static-air type is referred to as the oven-type sterilizer as heating coils in the bottom of the unit cause the hot air to rise inside the chamber via gravity convection.

Which of the following is an example of dry heat?

Examples of dry-heat methods include: Roasting and Baking. Grilling and Broiling. Sautéeing and Pan-Frying.

What temperature is required for dry heat sterilization?

The most common time-temperature parameters for dry heat sterilization are 170°C (340°F) for 60 min, 160°C (320°F) for 120 min, and 150°C (300°F) for 150 min.

What is the difference between dry heat sterilization and an autoclave?

There are a number of differences between dry heat sterilization and steam sterilization, the most obvious difference being that autoclaves use steam, vacuum, and pressure to clean tools and cages, while dry heat sterilization simply uses hot air.

Why dry heat sterilization is better than moist heat sterilization?

The main advantage of dry heat sterilization is that it will not corrode or dull instruments. It's also perfect for instruments that will be damaged by moist heat, such as powders, sharp instruments and even petroleum products.

What is sterilization dry heat sterilization?

Dry heat ovens are used to sterilize items that might be damaged by moist heat or that are impenetrable to moist heat (e.g., powders, petroleum products, sharp instruments). Sterilization is defined as killing or removal of all microorganisms, including bacterial spores.

Does autoclave use dry heat?

There are a number of differences between dry heat sterilization and steam sterilization, the most obvious difference being that autoclaves use steam, vacuum, and pressure to clean tools and cages, while dry heat sterilization simply uses hot air.

Which is example of moist heat sterilization?

Moist heat sterilization is the sterilization technique using high-pressure steam. Based on the temperature of sterilization ,moist heat sterilization is classified as : Temperature below 100 C Example: Pasteurisation ; Pasteurised milk.

Which of the following materials Cannot be sterilized by hot air oven?

Examples of items that aren't sterilized in a hot air oven are surgical dressings, rubber items, or plastic material. Hot air ovens use extremely high temperatures over several hours to destroy microorganisms and bacterial spores.

How long does it take to dry sterilize?

30 minutes. Dry heat sterilization is used on items that cannot get wet and for glassware, oils, powders, metal instruments, and items wrapped in paper. There are several different types of dry heat sterilization such as:

How long does it take to sterilize a hot air oven?

The hot air oven is the most commonly used form of dry heat sterilization. It is a large container that holds several objects. Once the oven is filled, it is closed and secured for the allotted time it will take to sterilize. For example, the oven is set at 160 degrees Celsius so it will not be opened until 60 minutes have passed. A hot air oven does not harm any of the objects that are being sterilized and it is non-toxic to the environment. However, it's time consuming and requires extremely high temperatures.

How does Kathy test a hot air oven?

She completes the tests herself. Kathy begins by making sure all of the parts of the instrument are accounted for and in place. She then checks that everything is in working order. She sets up data loggers in the oven and turns it on to test the temperature in various areas of the oven. It all looks good. The final test is the biological indicator, which was successful. She documents the validation tests and sends them to the appropriate companies. The operating room is successfully using sterile equipment from the hot air oven dry heat sterilization instruments.

Why does a static air oven take so long to heat?

The oven has coils on the bottom to heat the oven. It takes a long time for the temperature to be reached because the hot air has to rise through convection. This also means that the temperature may not be uniform throughout the oven.

Does the hospital use forced air ovens?

Kathy finds out that the hospital uses forced air hot air ovens. The machines appear to be in good condition and are working correctly. She is ready to see if they are successful at completing the sterilization process.

What is dry heat sterilization?

Dry heat sterilization. Dry heat sterilization of an article is one of the earliest forms of sterilization practiced. It uses hot air that is either free from water vapor or has very little of it, where this moisture plays a minimal or no role in the process of sterilization.

How is dry heat sterilization accomplished?

The dry heat sterilization process is accomplished by conduction; that is where heat is absorbed by the exterior surface of an item and then passed inward to the next layer. Eventually, the entire item reaches the proper temperature needed to achieve sterilization.

Why should sterilization be dry?

Items should be dry before sterilization since water will interfere with the process. Dry heat destroys microorganisms by causing denaturation of proteins. The presence of moisture, such as in steam sterilization, significantly speeds up heat penetration. See also: Moist heat sterilization.

How long does it take to dry a sterilizer?

The proper time and temperature for dry heat sterilization is 160 °C (320 °F) for 2 hours or 170 °C (340 °F) for 1 hour or in the case of High Velocity Hot Air sterilisers 190°C (375°F) for 6 to 12 minutes. Items should be dry before sterilization since water will interfere with the process. Dry heat destroys microorganisms by causing denaturation ...

How does heat affect microorganisms?

Effect on microorganisms. Dry heat lyses the proteins in any organism, causes oxidative free radical damage, causes drying of cells, and can even burn them to ashes, as in incineration.

How Dry-Heat Sterilization Works

Dry air is blown onto the object that is to be sterilized, passing energy to it through conduction (forced air). Alternatively, an oven could use heated coils instead of fans (static air), but the forced air type is preferable as it delivers the heat load to the object with better homogeneity.

Advantages of Dry-Heat Sterilization

The heat can go deeply into thick objects, achieving an in-depth sterilization effect. Even objects inside packaging can be sterilized this way.

Disadvantages Compared to Other Processes

The dry heat can take much more time to achieve sterilization than what is required with steam, flaming, chemical sterilization, or radiation.

Common Applications of Dry Heat Sterilization

There is a wide range of materials that can handle dry heat well, and that is why this method is so popular and widely used. Examples include metals of all kinds, powders that can’t be compromised by moisture or chemical agents, anhydrous oils and fats, and glassware.

What Is Dry Heat Sterilization?

After working in the sterile processing department of his community hospital for 15 years, he is considered an essential part of the infection control team.

What is the use of a hot plate or tray in which items to be sterilized are placed on the surface?

Conductors: Employ the use of a hot plate or tray, in which items to be sterilized are placed on the surface for heat transfer and sterilization

How long does it take for sterilization to be done?

Once the space designated for sterilization reaches 180 degrees Fahrenheit, it must remain at this temperature for a period of time depending on the sterilization equipment being used. An hour of consistent high heat is effective in killing germs that are known to be especially strong and resistant to heat.

Is moist heat safe for rust?

While moist heat is highly effective at sterilizing or completely disinfecting environments and tools in short periods of time, it may not be appropriate to use in some instances. For example, substances like powder medication or tools susceptible to rust will rely on dry heat techniques.

Is dry heat sterilization effective?

As Fred reviews common uses of dry heat sterilization, Phil begins to see the overall impact that proper sterilization has on stopping the transmission of infection. Despite the fact that the dry heat sterilization process may take a considerably longer amount of time, it is highly effective in disinfecting critical equipment.

How is dry heat sterilization performed?

As mentioned above, sterilization by dry heat is performed in cabinet ovens or conveyor tunnels. In these systems, temperature, time, and blower speed are controlled during sterilization. In cabinet ovens, HEPA filtered air flows across the load, moved by a blower. Though HEPA filters remove most particulates, there is always a risk that particulate matter generated from the heat source could collect on the sterilized load. In order to prevent particulates from entering the cabinet and consistent temperature during sterilization, the cabinet dryer door must be appropriately sealed before sterilization. Note that the size of the cabinet oven chamber is limited. Limited chamber size, along with manual loading and unloading, reduces the processing rate for dry heat sterilization. Dry heat sterilization processing rates are much higher for tunnel sterilizers. Tunnel sterilizers are dry heat conveyor systems. In the conveyor system, items are sterilized and depyrogenated as they move from heating zones through cooling zones. The heat source for a dry heat sterilization tunnel is either convection or radiant heat. Cooling zones contain vertical laminar airflow units under HEPA filtration. Tunnel sterilizers contain a stainless-steel conveyor belt. The conveyor belt often moves nonsterile containers through the dry heat sterilization cycle and onto a collection table for immediate sterile product filling. Tunnel dry heat sterilizers are primarily used to sterilize glass containers and are part of a sterile fill system. Tunnel sterilizers, like cabinet ovens, may generate particles from the heating source. Where tunnel sterilizers provide advantages in dry heat sterilization loading and unloading speeds, tunnel sterilizers are more challenging to validate than cabinet ovens, as it is tricky to control uniform heating throughout the entire conveyor system.

What items can be sterilized by dry heat?

Items typically sterilized by dry heat are glassware, metal parts, oils, and some dry powders.

How do thermal sterilization methods work?

Heat-based sterilization methods kill microorganisms by denaturing proteins within the cells.

How does dry heat depyrogenation work?

Dry heat depyrogenation uses air first to heat and then to cool items. Due to the heat capacity of dry air, loaded items are slowly heated and cooled during dry heat treatment. Items in the dry heat ovens must be placed in the same locations every time for depyrogenation cycles to be valid due to the limited heat capacity of air. Indeed, varying load mass and product distribution can result in dry heat processing variability. Dry heat depyrogenation, like dry heat sterilization, uses a combination of temperature sensors and thermocouples to regulate temperature and dwell time to the levels needed to kill the endotoxin load on incoming materials. By convention, the z-value for dry heat depyrogenation ranges from 45°–55°C. This z-value is the rate at which the depyrogenation destruction rate varies as a function of temperature change.

What temperature is used for depyrogenation?

Dry heat depyrogenation depends upon time and temperature. Depyrogenation processes are performed at temperatures ranging from 170°C up to about 400°C. Understanding the total thermal input makes it possible to predict the depyrogenation efficacy of dry heat processes at various times and temperatures. Since bacterial endotoxins are more resistant to the effects of dry heat than bacterial spores, depyrogenation methods also sterilize the materials they depyrogenate.

How hot does it have to be to sterilize?

Sterilization by dry heat uses exceptionally high temperatures, 170◦C at minimum, to inactivate microorganisms. Dry heat kills microorganisms by oxidation (cell bursting) because of the high temperatures experienced during sterilization.

What is the process of sterilization?

Sterilization is any process that removes, kills, or deactivates all forms of life. Sterilization is related to the term sterile, which means a complete absence of viable microorganisms or viruses that have the potential to reproduce. Thus, sterile products that undergo sterilization are often chemical, heat or radiation sterilized. Sterilization kills any microorganisms inside the products obtained during manufacturing. Sterilization occurs after the product is placed in its final packaging for chemical, heat, or radiation sterilization. The last sterilization process after manufacturing is known as terminal sterilization.

How long does it take to sterilize a sterilizer?

The most common time-temperature relationships for sterilization with hot air sterilizers are 170°C (340°F) for 60 minutes, 160° C (320°F) for 120 minutes, and 150°C (300°F) for 150 minutes.

How is hydrogen peroxide used in sterilization?

One method for delivering VHP to the reaction site uses a deep vacuum to pull liquid hydrogen peroxide (30-35% concentration) from a disposable cartridge through a heated vaporizer and then, following vaporization, into the sterilization chamber. A second approach to VHP delivery is the flow-through approach in which the VHP is carried into the sterilization chamber by a carrier gas such as air using either a slight negative pressure (vacuum) or slight positive pressure. Applications of this technology include vacuum systems for industrial sterilization of medical devices and atmospheric systems for decontaminating for large and small areas 853. VHP offers several appealing features that include rapid cycle time (e.g., 30-45 minutes); low temperature; environmentally safe by-products (H 2 O, oxygen [O 2 ]); good material compatibility; and ease of operation, installation and monitoring. VHP has limitations including that cellulose cannot be processed; nylon becomes brittle; and VHP penetration capabilities are less than those of ETO. VHP has not been cleared by FDA for sterilization of medical devices in healthcare facilities.

What is the survival kinetics of thermal sterilization?

The survival kinetics for thermal sterilization methods, such as steam and dry heat , have been studied and characterized extensively, whereas the kinetics for sterilization with liquid sterilants are less well understood 921. The information that is available in the literature suggests that sterilization processes based on liquid chemical sterilants, in general, may not convey the same sterility assurance level as sterilization achieved using thermal or physical methods 823. The data indicate that the survival curves for liquid chemical sterilants may not exhibit log-linear kinetics and the shape of the survivor curve may vary depending of the formulation, chemical nature and stability of the liquid chemical sterilant. In addition, the design of the AOAC Sporicidal Test does not provide quantification of the microbial challenge. Therefore, sterilization with a liquid chemical sterilant may not convey the same sterility assurance as other sterilization methods.

What is static air sterilizer?

The static-air type is referred to as the oven-type sterilizer as heating coils in the bottom of the unit cause the hot air to rise inside the chamber via gravity convection.

What is the microwave used for?

Microwave. Microwaves are used in medicine for disinfection of soft contact lenses, dental instruments, dentures, milk, and urinary catheters for intermittent self-catheterization 925-931. However, microwaves must only be used with products that are compatible (e.g., do not melt) 931.

How is ozone used in water?

Ozone has been used for years as a drinking water disinfectant. Ozone is produced when O 2 is energized and split into two monatomic (O 1) molecules. The monatomic oxygen molecules then collide with O 2 molecules to form ozone, which is O 3. Thus, ozone consists of O 2 with a loosely bonded third oxygen atom that is readily available to attach to, and oxidize, other molecules. This additional oxygen atom makes ozone a powerful oxidant that destroys microorganisms but is highly unstable (i.e., half-life of 22 minutes at room temperature).

What temperature do glass beads sterilize?

Glass bead “sterilization” uses small glass beads (1.2-1.5 mm diameter) and high temperature (217 °C -232°C) for brief exposure times (e.g., 45 seconds) to inactivate microorganisms. These devices have been used for several years in the dental profession 938-940. FDA believes there is a risk of infection with this device because of potential failure to sterilize dental instruments and their use should be discontinued until the device has received FDA clearance.

What Are the Advantages of Dry Heat Sterilization?

The main advantage of dry heat sterilization is that it will not corrode or dull instruments. It’s also perfect for instruments that will be damaged by moist heat, such as powders, sharp instruments and even petroleum products.

What Are the Best Dry Heat Sterilizers?

The RapidPro line of dental sterilizers offers the unique combination of complete sterilization with cycles varying from six minutes to 12 minutes depending upon whether or not the instruments are wrapped. This represents the fastest FDA-cleared sterilization technology.

How Do Moist Heat Sterilizers Work?

Moist heat sterilizers are heated to create a saturated steam that destroys microorganisms. You should follow your manufacturer’s instructions diligently, but in general, how long and how hot the temperature should be depends upon the BAR pressure.

Is dry heat sterilization good?

If you’re looking for a method of sterilization that is easy, effective, and won’t damage your delicate instruments then dry heat sterilization may be a good choice for you.

Do you have to dry instruments before sterilizing?

However, you have to be sure that the instruments are completely dry before they are placed in the sterilizer.

Can steam sterilization cause corrosion?

But it’s important to realize that moist heat (steam) sterilization can cause corrosion on orthodontic and dental handpieces.

Overview

Dry heat sterilization of an object is one of the earliest forms of sterilization practiced. It uses hot air that is either free from water vapor or has very little of it, where this moisture plays a minimal or no role in the process of sterilization.

Process

The dry heat sterilization process is accomplished by conduction; that is where heat is absorbed by the exterior surface of an item and then passed inward to the next layer. Eventually, the entire item reaches the proper temperature needed to achieve sterilization. The proper time and temperature for dry heat sterilization is 160 °C (320 °F) for 2 hours or 170 °C (340 °F) for 1 hour, and in the case of High Velocity Hot Air sterilisers, 190°C (375°F) for 6 to 12 minutes.

Instruments used for dry heat sterilization

Instruments and techniques used for dry heat sterilization include hot air ovens, incinerators, flaming, radiation, and glass bead sterilizers.

Effect on microorganisms

Dry heat lyses the proteins in any organism, causes oxidative free radical damage, causes drying of cells, and can even burn them to ashes, as in incineration.

See also

• Sterility assurance level