What are the 4 most common weld joints?

- Edge Joint Welding. Edge joints are usually used when two pieces of sheet metal have flanging edges.

- Corner Joint Welding. The sheet metal sector loves this type of joint. Lap Joint Welding.

- Butt Joint Welding. What are various welding joints? There are five types of joints referred to by the American Welding Society: butt, corner, edge, lap, and tee.

What are the 5 basic welding joints?

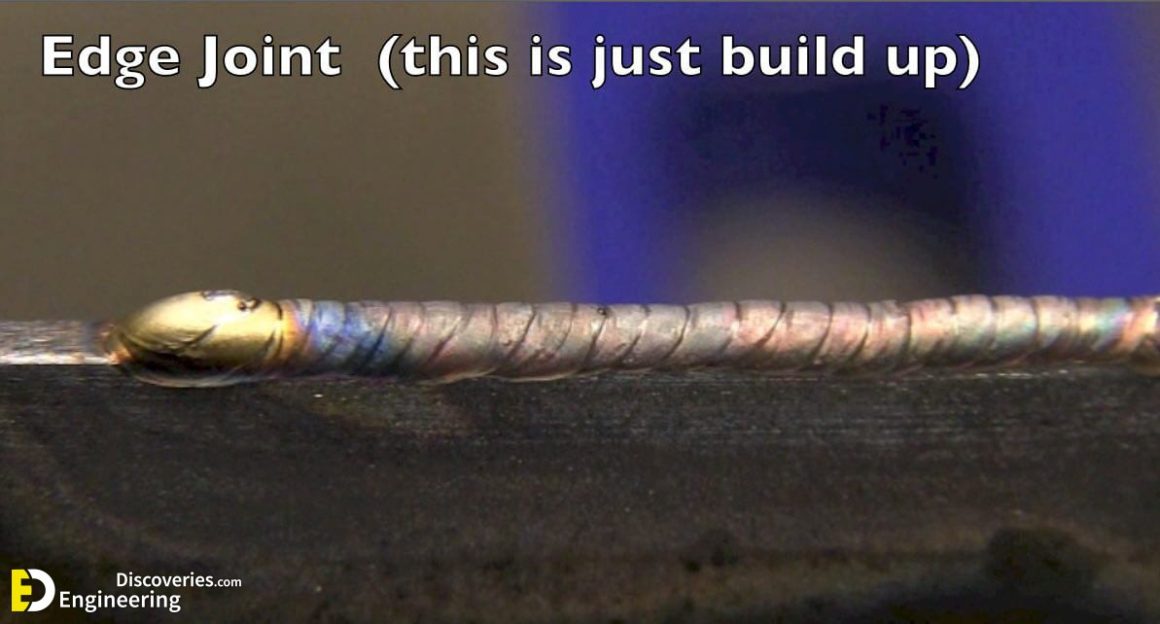

Jan 07, 2020 · Edge welding Joints are often applied to sheet metal parts that have flanging edges or are placed at a location where a weld must be made to attach to adjacent pieces. Being a groove type weld, Edge Joints, the pieces are set side by side and welded on the same edge.

What are the basic types of welding joints?

Sep 02, 2020 · Edge Joint Welding. In an edge joint, the metal surfaces are placed together so that the edges are even. One or both plates may be formed by bending them at an angle. The purpose of a weld joint is to join parts together so that the stresses are distributed.

What is flange edge Weld?

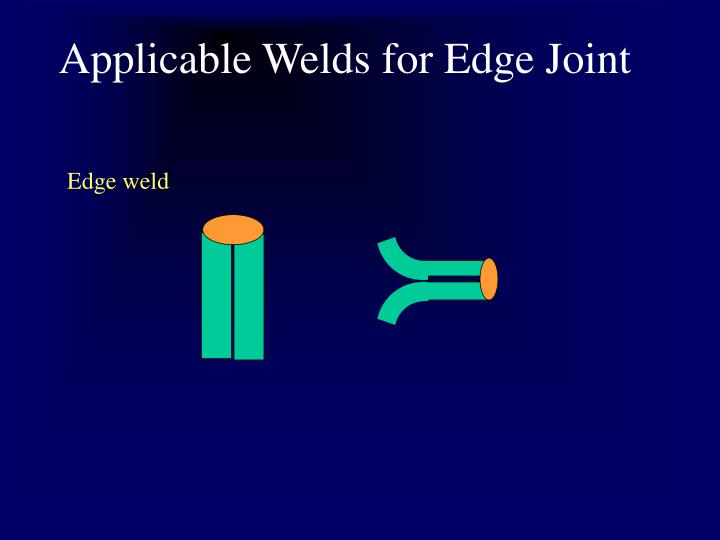

Edge Joint: An edge joint or simply called parallel joint is a weld joint configuration by laying two-member parallel to each other. Edge joint are not very commonly used in structures. Take your time to get familiar with different types of edge joint weld configurations. shown below: Figure: Types of corner joints.

What is joint welding?

Edge welding Joints are often applied to sheet metal parts that have flanging edges or are placed at a location where a weld must be made to attach to adjacent pieces. Being a groove type weld, Edge Joints, the pieces are set side by side and welded on the same edge.

What are types of welding joint?

What are the welding joints and edge preparation?

What is a lap joint welding?

What are the edges of the weld called?

What are the 5 welding joints?

- Butt joint.

- Tee joint.

- Corner joint.

- Lap joint.

- Edge joint.

What are the methods of edge preparation?

Proper edge preparation and fit-up are essential to achieve a good quality welds. There are two main steps of edge preparation, a) cleanliness of faying surface and b) cutting of faying surface of base metal to be welded by fusion arc welding process.

What is the difference between butt welding and lap welding?

What are the 3 types of welding?

Where are lap joints used?

Should you weld both sides?

What are the types of fillet joints?

- Full fillet weld – is a weld where the size of the weld is the same as the thickness of the thinner object joined together.

- Staggered intermittent fillet weld – refers to two lines of intermittent welding on a joint.

The 5 Different Types of Welding Joints

Different jobs need different types of welds. Different types of welding joints are made to stand up to the needs and forces of each individual app...

A Brief Word on Welding Safety

If you’re just learning or even if you’ve done welding for years it can’t be said enough that it’s critical to be fully aware of your surroundings...

Ways Welding Is Better Than Riveting

1. Welding can be done anywhere on the structure. Edges can be welded to edges without having to overlap. Riveting needs to have a certain amount o...

Need Welding Services in Mesa, Arizona?

Why not leave it to the professionals at Cliff’s Welding? You will be able to rest assured that the pros have handled your job, big or small to the...

What is a corner joint?

Corner Joint: A corner joint is a Connection between the ends or edges of two parts making an angle to one another of more than 30 but less than 135 degree in the region of the joint. They are having two types mainly: Closed corner joint. Open corner joint.

What is a T joint?

What is T Joints or Fillet Joint? 2. T joint or fillet joint is a Connection between the end or edge of one part and the face of the other part. As the name suggest, two plates or pipe are 90 degree to each other forming the letter T shape.

What is double barrier?

In the American Bureau of Shipping Rules for Steel Vessels, cruciform joints may be considered a double barrier if the two substances requiring a double barrier are in opposite corners diagonally. Double barriers are often required to separate oil and seawater, chemicals and potable water, etc.

What is edge welding?

Edge welding Joints are often applied to sheet metal parts that have flanging edges or are placed at a location where a weld must be made to attach to adjacent pieces. Being a groove type weld, Edge Joints, the pieces are set side by side and welded on the same edge.

Can you welded to edges?

Welding can be done anywhere on the structure. Edges can be welded to edges without having to overlap. Riveting needs to have a certain amount of clearance from the edges to be joined. Welding saves weight in the construction process.

What is a tee joint?

Tee Joints are considered a type of fillet weld, and can also be made when a pipe or tube is welded onto a base plate. Extra care is required to ensure effective penetration into the roof of the weld.

What is welding and riveting?

Welding and riveting are two ways to join metal to metal. They both have their particular pros and cons. Different situations call for one or the other. Neither is best for every possible situation. We’ll take a look at the different strengths and weaknesses of both metal joining systems.

Why is welding important?

Welding saves weight in the construction process. Since metal is actually joined to metal, gussets or other connecting hardware is not needed. Even the rivets themselves have weight, so being able to join the metal together without having to use them saves a bunch of weight.

Why is welding better than riveting?

Welded joints are better many times because the material on both sides of the weld is actually physically joined. Welding can easily join sections of metal column or pipe. Trying to join these items with rivets can be difficult or impossible given certain situations. Welding is a faster way of joining metal.

What is a butt weld?

Being the universally accepted method for attaching a pipe to itself it’s also used for valves, flanges, fittings, and other equipment. A butt welding joint is also known as a square grove weld. It’s the easiest and probably the most common weld there is. It consists of two flat pieces that are side by side parallel.

What is edge joint welding?

Edge Joint Welding. Edge joints are usually used when two pieces of sheet metal have flanging edges. Other applications tend to be in places where a weld is the only way to attach pieces that are next to each other. Typically, the metal parts will be side-by-side and then welded on the same edge. Edge Joint Weld.

What is welding joints?

Welding joints is the procedure of connecting a couple of pieces of metal (or plastic) at an edge or a point. Numerous factors come into play here including the shape of the materials, and certain geometrical aspects.

What is plug welding?

Plug welding is a style used when spot welding can’t be done. Most of the time, rally car builders love to use this since a spot welder can’t fit into the crevices.

Which side of the plate is the vertical plate?

The vertical plate (i.e. the “stem” of the “T” shape) will be bevelled either on the right side or the left side. If you do it correctly, you should see a diagonally ascending gap from the base plate to the vertical plate.

When to use flare bevel groove weld?

Flare bevel groove weld tends to be used when you’re trying to create a corner joint (which we’re going to talk about later). Having said that, they are used for tee joints too — particularly when you are attaching a round bar to a flat base plate.

What is lap joint?

If you need to join two pieces of metal that are different thicknesses, a lap joint is the one for you. As you may have gathered by the name, the metal parts are overlapped to create the lap joint.

What is a bend test?

Bend Tests. This is the most popular test and it’s used to test the skill and integrity of you, the welder. To tell you the truth, it’s common because it is quick and simple to do. No advanced tools are needed so basically any welder can perform a bend test.

What is welding joint?

A welding joint is referred to an arrangement or configuration of two metal plates that will be fit together. The purposes of welding are infinite, and different processes require different types of welds and joints.

What is corner joint welding?

Corner joint welding. 1. Butt Joint Welding. These types of welding joints form when the two metal pieces are placed end to end together in the same plane surface, it is known as but t joint welding. In welding, this is the most common type of joint.

What is lap welding?

It is basically a modification of butt welding, in which the two metal plates are placed in an overlapping position that is on top of each other, it is known as lap joint welding. The lap joint welding is applied for welding two metal plates that are different in their thickness.

What is a tee joint?

It is known as tee joint welding. These types of welding joints are considered the use of fillet welds mounted on both sides. It is formed when a pipe is welded over a base metal. Commonly, tee joints are prepared with grooves, until the base metal is thick.

How is a tee joint formed?

It is formed, when the two metal plates are intersected to an angle of 90° with one plate is lie on the center of the other plate like a “T” shape. It is known as tee joint welding. These types of welding joints are considered the use of fillet welds mounted on both sides.