Exhaust butterfly valves are a type of actuator used to silence or reduce noise emitted from certain applications. These valves are commonly associated within the automotive industry, as they will often be found working within cars or motorbikes.

What is a butterfly valve?

Butterfly valves are a family of quarter-turn rotational motion valves that are used in pipelines to shut-off flow. It is often said that butterfly valves can be used to regulate the flow.

What is the purpose of the exhaust valves on a car?

Unfortunately, this probably isn’t the real reason; the true purpose of the exup valves is to meet noise regulations. The exhaust valves are partially closed at idle and low rpm to reduce noise, and closed again at the upper RPMs to meet peak noise regulations.

How does a motorcycle exhaust system work?

This motor, which is controlled by the engine control unit, has a pulley on top that rotates the cables to open and close the valve in the exhaust. The cables are used to isolate the motor from the hot exhaust and allow it to be placed in a more convenient place on the bike.

Do I need a gearbox for a butterfly valve?

Fast Acting: A 90° rotation of the handle, or the actuation mechanism, provides a complete closure or opening of the valve. However, with larger butterfly valves, a gearbox is often required as part of the actuation mechanism which reduces the operational torque and simplifies the operation of the valve but comes at the expense of speed.

What is the point of exhaust valve?

An exhaust valve is a valve that releases burned gases from a cylinder. The exhaust valve closes during the initial part of the induction stroke. The inlet valve usually opens a little before top dead center and the exhaust valve remains open a little after top dead center.

What are the three types of butterfly valves?

Butterfly valves are often distinguished by the three main types: zero, double, or triple offset.Zero Offset Butterfly Valves. These valves are designed to solve the tightening problems that can occur between the disc and seat of the butterfly valve. ... Double Offset Butterfly Valves. ... Triple offset butterfly valves.

What does the exhaust valve do on a motorcycle?

The valves allow the intake mixture to enter the combustion chamber, and the spent gasses to exit after combustion. However, the most important job valves do is to seal the combustion chamber so that the intake mixture can be compressed and ignited. That's pretty much it.

Why it is called butterfly valve?

The butterfly valve gets its name from how the movement is similar to a wing for flight. The rod is analogous to a butterfly's body, while the disc moves like a butterfly wing. A butterfly valve's motion is similar to that of a butterfly that has landed with the wings moved up and down with a 90-degree motion.

How does the butterfly valve work?

The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid.

Are exhaust valves heated when open?

Both intake and exhaust valves get hot during operation. This heat must be dissipated and this heat is mainly conducted across the face of the valve, through the valve seat and into the cylinder head, where it is carried away by the flowing coolant.

How hot do exhaust valves get?

When the valve opens and exhaust gas begins to flow out from under it, the valve is heated not only on the top of its head by combustion itself but the back side of it is heated as well by exhaust gas, whose temperature can be as high as 1,700 degrees Fahrenheit.

What is the exhaust valve made of?

According to Larry Carley [4], for exhaust valve, it is made of austenitic stainless steel alloys, 21-4N (21% chromium). Exhaust valve is constantly blasted by hot exhaust gases and usually operates at 650 o C to 788°C or higher. Therefore it needs higher corrosion resistant and heat resistant steel.

How many types of butterfly valves are there?

There are 3 main categories of butterfly valves: Rubber-lined, Plastic-lined, and Metal.

How many types of valves are there?

All of the most common types of automated valves fall into one of three main categories. They are linear, rotary, and self-actuated. There are a variety of valve types within each of these categories each having its own benefits. This training course is focused on rotary and linear actuated valves.

What are the parts of a butterfly valve?

Butterfly valves are a quarter turn valve that is simple in design and easy to use. The components of butterfly valves are made up of four main parts: the body, disk, stem, and the seat.

What is wafer type butterfly valve?

Wafer-Style Butterfly Valve Most wafer-style butterfly valves are engineered with four holes that align with the connected pipeline. The valve is designed to clamp between two flanges in your pipe work. Most wafer butterfly valves fit the majority of flange standards.

What is the function of a butterfly valve?

The main function of the butterfly valve is to close, open or slow the fluid flow. It uses to control the fluid flow in either direction.

What are the types of the Butterfly valve?

The butterfly valve has the following types: Rotary valveConcentric valveLug-style valveWafer valveEccentric valve

What are the components of the Butterfly valve?

The butterfly valve has the following components: BodyStemBushingStem sealing HandwheelPinsDiskBolt threadSeat

What are the characteristics of the Butterfly valve?

The butterfly valve has light weight than the ball valve.It requires very small installation space.It needs less structural support than the ball v...

What is butterfly valve?

Exhaust butterfly valves are s noise reducing type of actuator commonly used in motor vehicle exhausts. In this article, PIF explains how this type of valve functions and provides servicing tips to fix common exhaust butterfly valve issues.

What happens if the butterfly valves are closed?

This adversely affects vehicle performance because the trapped gases prevent fuel from entering the engine. This can be fixed during oil changes by rotating the counterweight that controls the motion of the valve. If the valve shaft is jammed, gently tap repeatedly with a hammer to loosen it.

Why does my engine start slow when the butterfly valves are open?

By comparison, should exhaust butterfly valves remain stuck open, engines will start to slow as the gas-air mixture will be too rich. Unless valves are calibrated to accommodate a balanced fuel mixture, unburned gasoline will slosh around inside the cylinders, causing other vehicle components to foul.

Do you lubricate butterfly valves?

Finally, as a general rule of thumb for servicing exhaust butterfly valves, do not lubricate with any kind of oil. If a lubricant is required, stick to the solution above as even the thinnest oil types will make the valve seize and seal tighter than before, in either open or closed positions.

What is a Butterfly Valve?

A butterfly valve is a quarter-turn valve used to open, close, and regulate fluid flow. It has an easy operation. The 90-degree rotation of the valve handwheel or actuator fully opens or closes the fluid flow.

Working of Butterfly Valve

The working of the butterfly valve is very similar as a ball valve. The butterfly valves are most famous because they have light weight, low cost, easy and quick operation. A butterfly valve has a metal disk that is attached to a stem. This disk always presents in the flow due to that it increases the pressure drop.

Construction of Butterfly Valve

The butterfly valve has an easy and simple construction. It consists of a handwheel/actuator, stem, disk, gasket, and body. The disk is connected to the stem, which further connects to the handwheel.

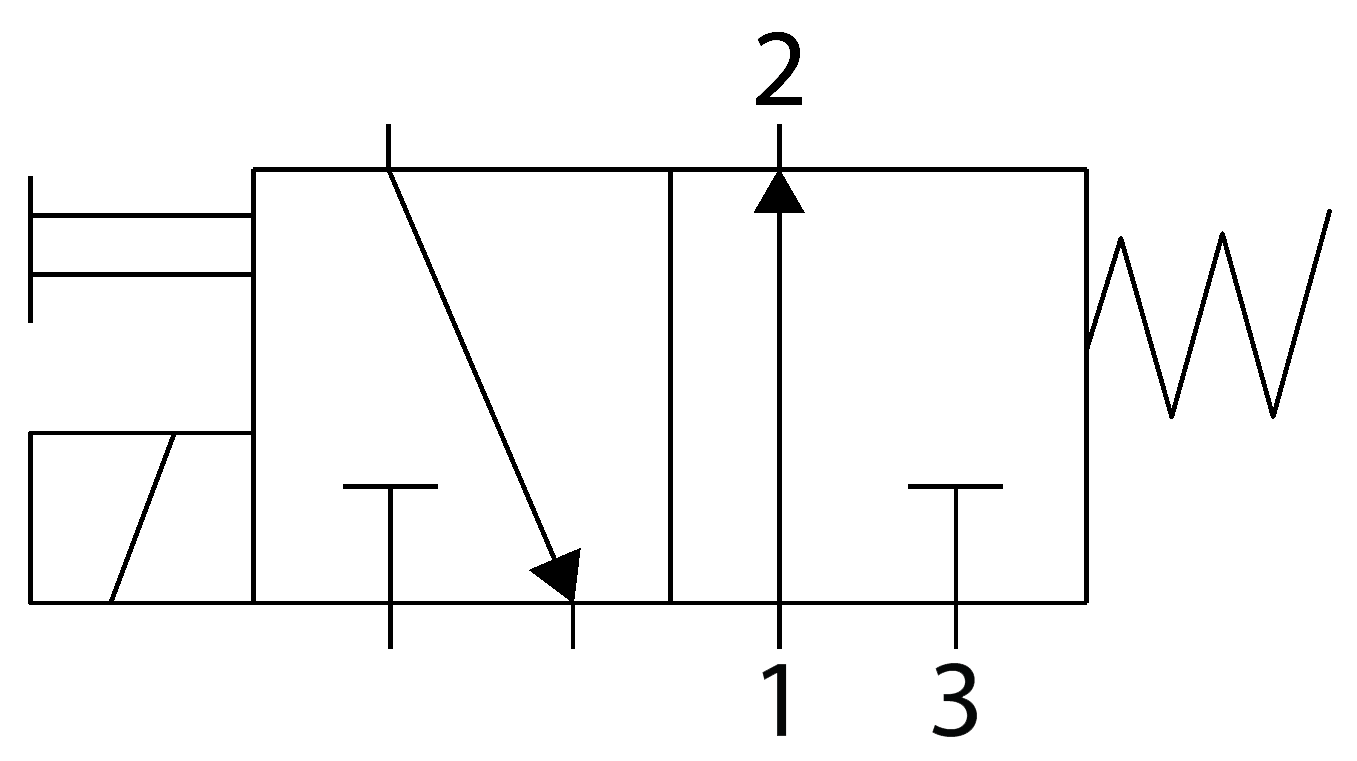

Butterfly Valve Actuation

You can actuate or operate the butterfly valves through different that vary according to the nature of the application. Following are the most common methods to operate butterfly valves:

Construction Materials of Butterfly Valves

Following are the most common materials used for the construction of the butterfly valve:

What is butterfly valve?

Butterfly valves are a family of quarter-turn rotational motion valves that are used in pipelines to shut-off flow. It is often said that butterfly valves can be used to regulate the flow. However, we do not recommend doing this, as it can damage the valve disk and have a negative effect on the sealing properties.

How do butterfly valves work?

The construction of a butterfly valve is relatively simple, with the rotation of the valve disc controlling the fluid flow. In the closed position, the disc blocks the valve bore while in the open position, the disc is oriented perpendicular to the flow direction to allow flow. Butterfly valves generally provide bi-directional flow and shutoff capability. However, they are not full-bore, which renders them unsuitable for pigging or swabbing. The body material is ductile iron with an epoxy powder coat on both internal and external surfaces. The valves are typically operated by handwheels, gears, or actuators, or a combination thereof, according to the specific application requirement and technical specifications. We will be discussing the actuation methods later in the article.

What is the pressure rating of a Hawle butterfly valve?

The Hawle 9881k series double eccentric butterfly valves come in sizes ranging from DN 150 up to DN 1600 with pressure ratings of both PN 10 and PN 16. Additionally, design feature optimizations such as the double offset, or double eccentric (e1 and e2 as seen above) disc further reinforces its advantages of achieving a tight seat seal through full circle sealing, and improves the service life of internal components while lowering operating torque requirements.

Why are actuators less expensive for butterfly valves?

Due to inherently lower torque requirements, sizing and installing actuators are less expensive for butterfly valves compared to others, like gate valves.

How many ways can a butterfly valve be operated?

There are multiple ways to operate, or actuate, a butterfly valve - manual, semi-manual, or fully automatic.

What are the components of a butterfly valve?

Below are the major components of a butterfly valve. Besides, there are smaller more common components such as the bushings, bearings, and fasteners that are part of most other valve constructions as well. Details on some of the components on the actuation end, such as the handle, lever, gearbox, and handwheel will be covered in ...

How are valves operated?

The valves are typically operated by handwheels, gears, or actuators, or a combination thereof, according to the specific application requirement and technical specifications. We will be discussing the actuation methods later in the article. 04.

Why do motorcycles have exup valves?

The purpose of this system according to the motorcycle manufacturers’ marketing departments is to create back-pressure at lower RPM’s to increase torque. Unfortunately, this probably isn’t the real reason; the true purpose of the exup valves is to meet noise regulations. The exhaust valves are partially closed at idle and low rpm to reduce noise, and closed again at the upper RPMs to meet peak noise regulations. The proof of this has been shown on the dyno where removing the valves and retuning the engine creates a flatter better torque curve. Additionally, in the USA, most bikes close the valve again at the upper RPM range, but in Europe they do not (different regulations) and the European bikes typically create a few more HP on the top end as a result.

What is the exhaust code for a Kawasaki?

The exhaust code varies by manufacture but general code descriptions can be found below: Kawasaki ZX6R and Kawasaki ZX10R – Code 34 or 63. Yamaha R1 and Yamaha R6 – Code 17 or 18. Suzuki GSXR-600, Suzuki GSXR-750, and Suzuki GSXR-1000 – Code C46. Honda CBR600RR and CBR1000RR – Code 34 or 35.

Can you bypass an exhaust valve?

Removing or bypassing the valve is quite easy. It can be accomplished as easily as removing the cables that connect the valve to the motor. The valve typically is spring loaded so if disconnected it will hold the valve in the full open position. Additionally, the purchase of a full or slip on exhaust system often eliminates the exhaust valve.

What is a butterfly valve?from quora.com

A butterfly valve is used in pipe systems and air systems where there isn't typically very high pressure, and where variable flow is required. A very common butterfly valve is in the air intake of almost all gasoline and diesel engines, to control the amount of air flowing into the engine as you press in the gas pedal. So you probably have at least 1 for each car or truck you have.

Where is the butterfly valve located?from quora.com

I believe you are speaking of the exhaust butterfly, normally located in the exhaust manifold. These valves are located in the exhaust manifold air flow to force and reroute a portion of it’s hot exhaust gas to heat up and around the intake manifold , carburetor throttle plate area to prevent manifold icing buildup and supply choke heater coil function. Most butterfly valves operate by a small coil spring close to manifold heat to work like a thermostat and relax butterfly plate to full open position after warm up. Some earlier models use vacuum control systems also. Late models today use engi

How does exhaust work?from wikihow.com

An exhaust system connects to your engine and guides the emissions through a pipe under your car. This system helps remove toxic chemicals and reduces noise. If you need to replace your system, you can install a new one from the catalytic converter to the tailpipe with a few tools.

How to tell if intake and exhaust are the same?from quora.com

There are usually ways to discern one from another, even with the engine fully assembled. Look carefully at the alignment of the intake manifold runners with the cylinder heads, then look closely at the alignment of the exhaust manifold the same head. Whether your engine is a V type or in line cylinder configuration the intake and exhaust manifolds are usually on opposite sides of the head. But the alignment of the ports is a conclusive proof of how the intake and exhaust valves are sequenced within the cylinder head casting.

What is the difference between an intake and an exhaust valve?from quora.com

However, Inlet valves are larger (for suction of more air) while exhaust valves are smaller. New design of exhaust valves have vanes or blades around the stem just above the seat. This is for rotation of the valve and for removal of carbon particles that might be accumulated on the valve seats and causing erosion. Intake valves do not have these blades.

Why does exhaust valve clearance need to be greater?from quora.com

The reason exhaust valve clearance needs to be greater is that exhaust valves get hotter than intake valves. Therefore thermal expansion will be greater and might close the gap enough to hold the valve slightly open. That would cause the valve to burn out as it depends on contact with the valve seat to dissipate heat into the cylinder head.

How to replace exhaust system without disturbing engine?from wikihow.com

Start by disconnecting the bolts and wires of the old exhaust system from underneath your vehicle so you can remove it.