What is GRP material?

What is GRP Material? GRP is an acronym for Glass Reinforced Plastic or Glass Reinforced Polymer. It is also often referred to as fibreglass (fiberglass in the US) or glass fibre composite and belongs to a family of products known as FRP or Fibre Reinforced Plastics. GRP has many desirable properties which include:

What is the difference between GRP and FRP?

GRP is Glass Reinforced Plastic, FRP is Fiber Reinforced Plastic. Both terms are now interchangeable in the industry. Resin is the material you add either a catalyst or an activator to, which starts the chemical reaction and the cure process.

What is the full form of GRP?

The full form of GRP is glass-reinforced plastic. The fibers are usually glass, but can also be carbon or aramid. The plastic matrix is typically polyester, vinylester, or epoxy. GRP refers to glass-reinforced plastic, a composite material made of fiberglass reinforcement and polyester or epoxy resin.

What is GRP roofing?

GRP refers to glass-reinforced plastic, a composite material made of fiberglass reinforcement and polyester or epoxy resin. The fiberglass is usually in the form of woven fabric or rovings, while the resin is either polyester or epoxy. GRP has a good strength-to-weight ratio, impact resistance, and thermal insulation properties.

What is the difference between fibreglass and GRP?

As fibreglass is used in these composite materials, many people still refer to the final product as being 'fibreglass'. But – and this is the important bit – it's not. And, if plastic has been mixed with the fibres, then what you're actually talking about is glass reinforced plastic – GRP.

What are the disadvantages of GRP?

Disadvantages.They cost more. When you compare it to rubber materials, GRP costs more. ... They're not for large roofs. It's not always the best option for larger roof areas, and the expansion rates can be high.They're picky.

What does GRP mean on boats?

Glass reinforced plastic (GRP) is a composite material commonly known as fibreglass.

What can fibreglass resin be used for?

Fibreglass is a common repair and building material used across many industries including Boat, Construction, Roofing, Automotive, Surfing and Artmaking to name but a few! Fibreglass can also be referred to GRP or Glass Reinforced Plastic.

Is GRP stronger than steel?

Pound for pound GRP can be stronger than steel. Due to being so light, this makes it easy to transport and install, requiring less man power than if steel was used instead. GRP has virtually no maintenance, or maintenance cost, involved.

How strong is GRP?

Strong and Durable GRP has a high strength to weight ratio and high flexural strength, this means it is a lightweight material that is also super strong. Pound for pound GRP can be stronger than steel! GRP also has high resistance to: ultraviolet light.

How long does a GRP hull last?

Good GRP hulls can also last a lifetime – and without any special treatment. Many fibreglass yachts built 60 years ago are still happily cruising the world's oceans today and the materials we use in our Sirius hulls are much stronger and longer-lasting than the basic GRP that those boats were built with.

What happens to old GRP boats?

Old scrap fibreglass boats are most often pulverised and buried in landfills. Fibreglass is tough, durable, and long lasting – a wonderful material for building boats. Many boats built in the 1960s and 70s are still with us but most eventually reach a point where the time, effort, or money to refit them just runs out.

Which hull material is best?

Steel hulls have the best ability to withstand a collision. Even if they hit a floating object, the chance to keep floating without a crack in the hull is higher than the rest of the hull materials.

What are the three 3 types of commonly used resin?

Understanding the types of resins available and the properties of each type should help you both in the process of product selection and making high performance composites. There are three widely used resin types: polyester, vinyl ester, and epoxy.

What is the difference between epoxy and fiberglass resin?

The key difference between epoxy and fiberglass resin is that epoxy resins are made mainly from the reaction between epichlorohydrin and bisphenol A whereas fiberglass resin is made from the combination of alcohols and organic acids.

Can fiberglass resin be used alone?

Suitable for a tremendous range of projects, Bondo® Fiberglass Resin can stand alone or be used with backing strips, tape, cloth or fiberglass mat for jobs where you need reliable strength.

What are the disadvantages of Fibre reinforced polymers?

However, FRP composites also have disadvantages, such as their relatively high cost, low elastic modulus, linear-elastic brittle behaviour, and poor fire resistance.

Is GRP cheap?

Affordable – GRP is cheap to design, manufacture and install, making it an affordable option to meet your needs. Long Lasting – As the material is very durable, it requires a lot less upkeep and is extremely low maintenance. GRP can last up to 40 years or more without any measurable deterioration.

What is an advantage of using glass reinforced plastic?

High corrosion resistance Offering exceptional corrosion resistance, GRP is highly tolerant of the most aggressive of environments. Its total resistance against chloride ion attacks demonstrates its durable nature and ability to withstand harsh conditions.

Why are the properties of GRP useful in boat hulls?

Glass reinforced polyester (GRP), as a thermoset polymer composites, dominates boat building industry with its several advantages such as high strength/weight ratio, cohesiveness, good resistance to environment.

What is GRP Material?

GRP stands for Glass Reinforced Plastic. It is also called fibreglass, composite plastic or FRP. It is strong, extremely light and highly versatile. GRP behaves differently to the conventional thermoplastics that are used in everyday items. This means that it has properties that are useful for a range of applications within many industries.

What is GRP composite?

GRP is a moulded product, meaning it must be placed in or around the shape of the item it is required to take. GRP composite incorporates aluminium oxide aggregate surface, which is diamond hard, and offers a high resistance to long-term wear.

What are the properties of GRP?

GRP has a number of valuable properties , making it extremely useful in industries all over the world. These properties include:

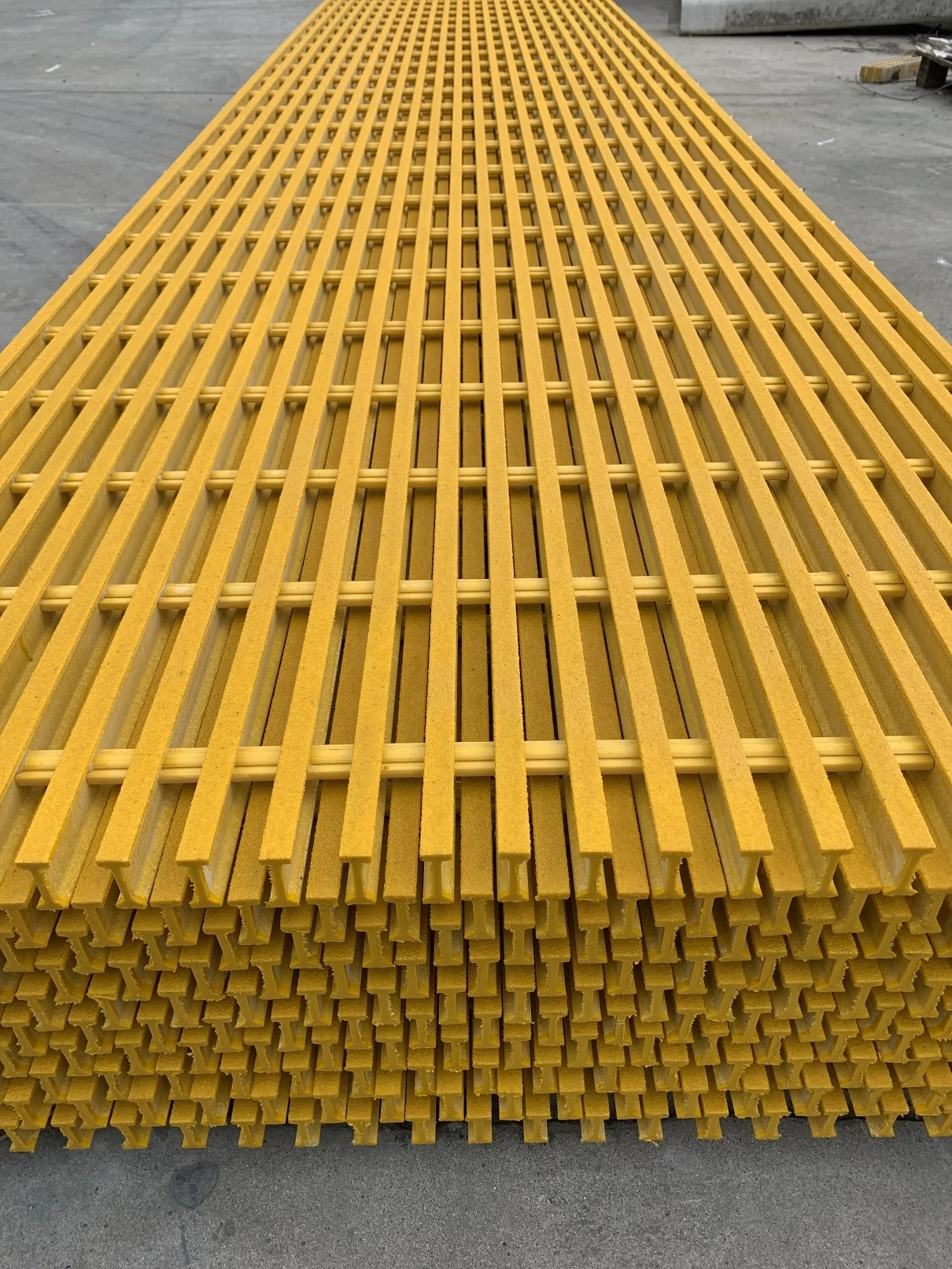

What is GRP Pultrusion?

Pultrusion is a manufacturing process for producing continuous lengths of reinforced polymer structural shapes with constant cross-sections.

What is pultruded GRP made of?

Pultruded GRP structural shapes are made from densely packed continuous fibreglass, which is wrapped by a layer of fibreglass mat.

How is GRP grating made?

GRP grating is produced through a moulding method, whereas GRP handrailing and pultruded profiles are produced by the pultrusion method.

What is FRP in construction?

What is FRP? FRP stands for Fibre-Reinforced Polymer. FRP is a composite material formed of polymer matrix reinforced with fibres. Although the fibres used are usually glass fibre, as in GRP, others such as carbon, aramid or basalt are also utilised.

What is GRP plastic?

Glass Reinforced Plastic - GRP or fibreglass for short - is a popular and relatively cheap material often used for car repairs and , in some cases, construction. Polyester resin is supplied as a thick liquid, and has a shelf life of approximately six months - it becomes thicker and gel-like as it ages and eventually becomes unusable.

What is laying up resin?

The resin supplied in these kits is what would usually be called ‘laying up’ resin - it is a general purpose resin which sets quickly when mixed and is dry to touch when cured. Car body repairs using GRP are ideal candidates for these kits.

Can you use GRP for car body repair?

Car body repairs using GRP are ideal candidates for these kits. Rusted or holed panels (not structural) can be cleaned back to shiny metal, tapped down a little, and any holes bridged using resin and grp matting. A stiff brush is all that is needed to stipple the resin thoroughly into the matting.

What is the difference between GRP and FRP?

GRP is Glass Reinforced Plastic, FRP is Fiber Reinforced Plastic. Both terms are now interchangeable in the industry. Resin is the material you add either a catalyst or an activator to, which starts the chemical reaction and the cure process.

What is the strongest resin?

Weakest on the usual suspect list are the polyester resins, followed by vinylester resin, with epoxy being the strongest and most waterproof.

Do vinylester resins need a catalyst?

Generally the polyester and vinylester resins will require a catalyst, while the epoxies need an activator. The differences between the different chemical combinations can get pretty complicated, so I'll leave it at that. Simply put, both activators and catalists are hardners, though they work differently in the chemical process of the cure.