What is hydraulic braking system types and how it works?

- Brake pedal or lever

- A pushrod (also called an actuating rod)

- A master cylinder assembly containing a piston assembly (made up of either one or two pistons, a return spring, a series of gaskets / O-rings and a fluid reservoir)

- Reinforced hydraulic lines

Why do car braking systems use hydraulic systems?

- Hydrualic brakes can generate higher forces as compared to air/pnuematic brakes. ...

- No need of compressed air cylinder, or a source of pressurized air for actuation. ...

- Take lesser space as compared to complete air brake system

- Hydraulic brakes give a controlled and smoother braking experience wh

What is the principle behind hydraulic brakes?

Hydraulic brake is a type of braking system which is widely used in the automobiles with the application of the hydraulic fluid. The working principle of hydraulic braking system is purely based upon Pascal’s law, which states that the intensity of pressure exerted inside a closed system by the liquid is always equal in all the directions.

What are the disadvantages for hydraulic brakes?

Disadvantages of Hydraulic Brakes are: If the brake-fluid leak out, then the brake-shoes may be ruined. High moisture in the environment can change the quality of the hydraulic fluid and cause corrosion of the internal components.

What do hydraulic brakes mean?

Definition of hydraulic brake : a brake (as for a motor vehicle) in which the braking force is applied through a mechanism operated like a small hydraulic press.

Where is hydraulic braking system used?

Hydraulic brake systems are used as the main braking system on almost all passenger vehicles and light trucks. Hydraulic brakes use brake fluid to transmit force when the brakes are applied.

What is hydraulic brake types?

There are two brake operation methods for hydraulic brakes: spring actuation (engage) and spring return (disengage): Spring Actuation/Engage—The spring engages during operation and requires power to disengage. Spring-actuated brakes are also called power-off brakes, fail-safe brakes, and safety brakes.

What are the advantages of hydraulic brakes?

Hydraulic disk brakes also provide more braking power because they have a greater contact area, which supports heat dissipation. They also rarely fail, making them reliable at high speeds and work better compared to mechanical brakes in wet and muddy conditions.

What is hydraulic brake example?

An example of a hydraulic brake system In a very simple brake system, with just two cylinders and a disc brake, the cylinders could be connected via tubes, with a piston inside the cylinders. The cylinders and tubes are filled with incompressible oil.

What are 3 examples of a hydraulic system?

Examples of Hydraulic SystemHydraulic Lifts. Hydraulic lifts are used for moving goods or people vertically. ... Hydraulic Brakes. Braking system of the vehicle is an important example of hydraulics. ... Hydraulic Steering. ... Hydraulic Jacks. ... Heavy Equipment. ... Airplanes. ... Hydraulic Shock Absorbers.

What are the 3 types of brakes?

Braking System History In most automobiles, there are three basic types of brakes including; service brakes, emergency brakes, and parking brakes.

What are the 4 types of brakes?

4 Types of Car BrakesDisc Brakes. Disc brakes consist of a brake rotor which is attached directly to the wheel. ... Drum Brakes. Drum brakes consist of a brake drum attached to the inside of the wheel. ... Emergency Brakes. ... Anti-Lock Brakes.

What are the 3 types of brake pads?

These days, drivers typically have a choice between three types of brake pads: ceramic vs. semi metallic vs. organic brake pads.

What are 3 disadvantages of hydraulics?

Disadvantages of hydraulic system:Poor resistance to working fluid pollution;Sensitive to temperature changes;Hidden danger of leakage;Difficult manufacturing and high cost;It is not suitable for long-distance transmission and requires hydraulic energy.

What are 5 Advantages of hydraulics?

Hydraulic System AdvantagesHydraulic systems are easy to control and accurate. ... Hydraulic systems are simpler and easier to maintain because these systems use less moving parts.Only hydraulic systems can deliver constant torque or force regardless of speed changes.Easy to spot leakages of a hydraulic system.More items...•

What are the disadvantages of hydraulic brake?

Disadvantages of Hydraulic Braking System : (a) The whole braking system fails due to leakage of fluid from brake linings. (c) Maintenance is more than other braking systems. (d) Construction is complex.

Where are hydraulics commonly used?

Hydraulics are used extensively in the automotive industry for everything from braking systems to power steering. However, they are also used in construction equipment, manufacturing machinery and aircraft.

Is hydraulic brake used in cars?

Your vehicle's brakes are hydraulic, meaning they use fluid to operate (there are also compressed-air brakes, but they're used on tractor-trailers and other large trucks). When you hit the brake pedal, you're pressing a piston into a brake fluid reservoir called the master cylinder.

What are the five 5 application of hydraulic system?

Hydraulics Applications Plastic processing machinery, steel making and primary metal extraction applications, automated production lines, machine tool industry, paper industries, loaders, crushers, presses, textile industry machinery, etc.

Do modern cars use hydraulic brakes?

When it comes to brakes, all modern cars come equipped with hydraulic system operating brakes on all four wheels. Brakes in the front are seen as more important than rear brakes given that during the braking process, weight is shifted towards the front of the vehicle.

What Is Hydraulic Braking System?

A hydraulic brakes system is a braking mechanism that uses brake fluid to transmit force into the system. The fluid transfers pressure from the con...

Construction of Hydraulic Braking System:

The construction of hydraulic braking systems involves the following part arrangement. Brake pedal or level, a wreath, also known as an actuating r...

Parts of Hydraulic Braking System:

#1. Master Cylinder It is the main part of the entire assembly. It acts as a hydraulic actuator with a piston-cylinder arrangement. It is responsib...

Working of Hydraulic Braking System:

The work of the hydraulic braking system is very simple. To execute the brakes, we have two types of components: a disc brake and a drum brake. The...

Application of Hydraulic Braking System:

Drum type hydraulic brakes - They are used in some low-speed four-wheel vehicles such as Tata Ace. Disc Type Hydraulic Brakes - They are used in al...

What is hydraulic braking system?

Hydraulic braking system is a type of braking system in which unlike the mechanical braking system, hydraulic fluid is used to transmit the brake pedal or brake lever force from the brake pedal or brake lever to the final drum shoes or disc caliper in order to achieve braking. In this type of braking system the mechanical force transmitted by ...

What is a disc caliper?

Disc caliper- It is a small stationary component fitted over a disc just like a clamp, inside which there is a housing of brake shoes and hydraulic cylinder, when the brakes are applied the brake shoes inside the caliper contracts and make frictional contact with the rotating disc in order to provide braking.

What is brake fluid reservoir?

Brake fluid reservoir – it is the simple reservoir tank containing brake fluid which is connected to the master cylinder with the help of brake hose.

What is master cylinder?

Master cylinder – It is the simple cylinder and piston arrangement ( refer to article on master cylinder) which converts the mechanical force from the brake pedal into the hydraulic pressure .

What is brake pedal?

Brake pedal or brake lever- In hydraulic braking system same as other braking brake pedal or brake lever is required by the driver to apply braking, this brake pedal or brake lever is attached with the master cylinder through mechanical rod or connecting rod.

Why is frictional wear and tear so high in mechanical braking systems?

Frictional wear and tear in case of mechanical braking system was very high due to the involvement of many moving parts, which is very well reduced to the optimum level with the introduction of the hydraulic braking system which has very less moving parts as compared to the mechanical one .

Why is maintenance in the case of mechanical braking system high?

The maintenance in the case of mechanical braking system was high due to the involvement of complex and more number of member which is not a problem with the hydraulic braking system as it has a simple design with less moving parts.

What Is Hydraulic Braking System?

A hydraulic brakes system is a braking mechanism that uses brake fluid to transmit force into the system. The fluid transfers pressure from the control mechanism to the braking mechanism. Hydraulic braking systems are widely used in low-speed four-wheelers such as the Tata Ace. It works with the drum type, while the disc type is used in almost all cars.

What happens when high pressure brake fluid enters the wheel cylinder?

When this high-pressure brake fluid o enters the wheel cylinder or drum cylinder due to its high pressure, there is movement in the cylinder piston, which in turn expands the static brake shoe attached to it .

What happens when brake fluid moves inside the master cylinder?

This movement of the pistons inside the master cylinders causes compression of the brake fluid inside the master cylinder, which in turn converts mechanical energy to hydraulic pressure. Thises highly compressed brake fluid from the master cylinders moves inside the brake, and this hydraulic pressure transfers from the master cylinder to the brake drum.

What happens when the driver applies a brake in a vehicle equipped with hydraulic brakes mounted on the drum?

The speed or activation of the brake pedal causes a master cylinder to move a rod connected between the pedal and the piston, which in turn pushes the piston of the master cylinder inside the master cylinder like a medical syringe.

What is thermally conductive brake?

This is known as the caliper piston. A thermally conductive brake is a set of pads and rotors, also known as a brake disc or drum attached to an axle. A glycol-ether-based brake fluid filled the system to force the four wheels. However, other liquids may also be employed.

How many types of brakes are there in hydraulic braking?

The work of the hydraulic braking system is very simple. To execute the brakes, we have two types of components: a disc brake and a drum brake. The initial work is the same for both types, but the execution technique is different.

What is a master cylinder assembly?

The construction of hydraulic braking systems involves the following part arrangement. Brake pedal or level, a wreath, also known as an actuating rod, a master cylinder assembly is carrying a piston assembly. It is composed of one or two pistons, a return spring, a series of gasket or O rings, and a fluid reservoir.

What is the action of a brake lever?

This action first relieves the hydraulic pressure on the caliper, then applies suction to the brake piston in the caliper assembly, moving it back into its housing and allowing the brake pads to release the rotor.

What is hydraulic brake fluid?

A hydraulic brake is an arrangement of braking mechanism which uses brake fluid, typically containing glycol ethers or diethylene glycol, to transfer pressure from the controlling mechanism to the braking mechanism.

Why do you need hydraulic brake hose?

Since the wheels do not maintain a fixed relation to the automobile, it is necessary to use hydraulic brake hose from the end of the steel line at the vehicle frame to the caliper at the wheel. Allowing steel brake tubing to flex invites metal fatigue and, ultimately, brake failure.

What is a brake caliper?

Brake caliper assembly usually consisting of one or two hollow aluminum or chrome-plated steel pistons (called caliper pistons ), a set of thermally conductive brake pads and a rotor (also called a brake disc) or drum attached to an axle.

How does friction affect brakes?

The brake caliper pistons then apply force to the brake pads, pushing them against the spinning rotor, and the friction between the pads and the rotor causes a braking torque to be generated, slowing the vehicle. Heat generated by this friction is either dissipated through vents and channels in the rotor or is conducted through the pads, which are made of specialized heat-tolerant materials such as kevlar or sintered glass .

How do drum brakes work?

Alternatively, in a drum brake, the fluid enters a wheel cylinder and presses one or two brake shoes against the inside of the spinning drum. The brake shoes use a similar heat-tolerant friction material to the pads used in disc brakes.

How to increase brake force?

This force can be further increased by inserting a lever connected between the master piston, a pedal, and a pivot point. If the distance from the pedal to the pivot is three times the distance from the pivot to the connected piston, then it multiplies the pedal force by a factor of 3, when pushing down on the pedal, so that 10 N becomes 30 N on the master piston and 120 N on the brake pad. Conversely, the pedal must move three times as far as the master piston. If we push the pedal 120 mm down, the master piston will move 40 mm and the slave piston will move the brake pad by 10 mm.

What is hydraulic braking system?

A hydraulic brake system is a braking mechanism that uses brake fluid to transmit force to the system. The fluid transfer pressure from the controlling mechanism to the braking mechanism.

What causes the movement of the brake pad?

High-pressure brake fluids enter the disc caliper from the brake lines which then cause the movement in the caliper cylinder’s piston. The caliper cylinder piston causes the movement of the brake pad which is attached to the piston inside the caliper.

What causes the frictional contact between the shoes and drum lining?

The expansion of the brake shoes causes the frictional contact between the shoes and drum lining (the rotating drum part) to converts the kinetic energy of the vehicle into heat energy, which makes the braking happen.

What is a wheel cylinder?

Wheel cylinder: A wheel cylinder in the hydraulic brake system help in converting hydraulic pressure to mechanical pressure. in its working, it pushes the brake shoes towards the drum. The wheel cylinder is categorized into two which include a stepped wheel cylinder and a single-piston wheel cylinder.

What is a drum brake?

Drum brakes are a small round drum designed with a set of brake shoes in it. The brake shoes are supported on a back-plate that is attached to the axle-casing with bolts. It rotates along with wheels and it resists the rotation of the wheel when the brake pedal is pressed.

How does hydraulic pressure work in a master cylinder?

The piston inside the master cylinder compresses the brake fluid, which then offers the conversion of mechanical energy into hydraulic pressure. This highly compressed brake fluid moves inside the brake which then transfers the hydraulic pressure from the master cylinder to the brake drum. As soon as the high-pressure brake fluid enters the drum cylinder or wheel cylinder, the movement of the cylinder piston occurs due to the high pressure. This in turn expands the stationary brake shoes attached to it.

What is a brake pedal?

Brake pedal or level, a pushrod, which is also known as actuating rod, a master cylinder assembly carrying piston assembly. It’s made up of either one or two pistons, a return spring, a series of gaskets or o rings, and a fluid reservoir. The construction of a hydraulic braking system is containing reinforced hydraulic lines and the brake caliper assembly consists of one or two hollow aluminum or chrome-plated steel pistons. It’s known as caliper pistons. There is a set of thermally conductive brake pads and a rotor, which is also known as brake disc or drum attached to an axle.

What is brake hose?

Brake hoses connect the hard brake lines to the brake calipers and to the differential in rear-wheel drive vehicles. They must flex as the suspension moves and are subject to wear from stress at connection points, atmospheric UV light, and ozone.

How does brake fluid move?

Once the brake pedal is depressed, the brake fluid moves through the brake lines and enters the calipers and wheel cylinders, flowing to the pistons inside and actuating the pistons. As the brake caliper or wheel cylinder pistons move, they push the brake friction pads and shoes.

What happens when the brake pedal is depressed?

When the brake pedal is depressed it actuates an arm connected to a part called the Master Cylinder. This master cylinder controls hydraulic pressure across the whole brake system. Between the brake pedal and the hydraulic cylinder it operates, mechanical energy is converted to hydraulic energy.

How do brakes work?

This is how the brakes work like a flexible stilt, as we referenced earlier; rather than a wooden or metal rod being used to apply pressure to the brakes, fluid is moved across a set of tubing lines mounted across the car. These tubing lines are referred to as brake lines, and act as conduits for the hydraulic fluid.

What happens when you brake hydraulically?

What really happens in the hydraulic braking system? The short answer is that the brake pedal moves hydraulic fluid like a flexible stilt between the driver and the brake calipers. The long answer is more complicated, so buckle up-- things are about to get dense.

When did the dual diagonal system become mandatory?

Diagonal split systems (AKA dual diagonal) became mandatory in 1976 and required that the master cylinder split the hydraulics so that even with a hydraulic failure the vehicle could still stop. In a dual-diagonal system the front right and rear left are typically controlled by one hydraulic circuit and the front left and rear right by the other.

When were hydraulic brakes invented?

Hydraulic brakes were first patented around 1917, and have been the standard for braking systems since then. In the simplest form, a single hydraulic circuit from the master cylinder out to the wheels provided pressure that was regulated only by the operator’s foot pressure.

How many pistons are in a brake caliper?

The number of pistons within a caliper or brake can differ. Many hydraulic mountain bike brakes have 2 piston calipers, some may have 4 pistons. Whereas some automobile brake calipers have 6 or even 8 pistons. It is an important note that brake power is not determined by piston quantity.

What is the master cylinder?

The master cylinder, mounted to the handlebar, houses the brake lever and together they produce the input force needed to push hydraulic brake fluid to the slave cylinder (or caliper) and cause the brake pads to clamp the rotor. 1.

How do brake calipers work?

Calipers can be fixed by a rigid mount to the frame or floating. Fixed calipers are combined with a fixed rotor which offers the only way of achieving zero free running drag, one drawback of this design is that it is much less tolerant of rotor imperfections. Floating calipers slide axially and self-centre with each braking application.

Why does brake fluid fade?

Fluid fade is caused by heat induced boiling of the brake fluid in the calipers and brake lines. When used under extreme conditions heat from the pads can transfer to the caliper and brake fluid causing it to boil, producing bubbles in the braking system. Since bubbles are compressible this results in a spongy lever feel and prevents the lever input from being sent to the caliper.#N#The major cause of fluid fade is absorbed water from the air under normal atmospheric conditions which reduces the boiling temperature of the brake fluid. DOT brake fluid has an affinity for absorbing water from the air around it, especially in hot humid conditions. This is the main reason why we replace brake fluid on an annual basis.#N#Fortunately fluid fade has a gradual onset giving the user time to compensate for potential loss of braking.

How to find the amount of multiplication?

The amount of multiplication can be found by comparing the sizes of the pistons at either end. In braking systems for example, the piston driving the fluid is smaller than the pistons operating the brake pads therefore the force is multiplied helping you to brake easily and more efficiently.

What is a closed brake system?

A closed system also utilises a reservoir of brake fluid, however the lack of an internal bladder to compensate for the expansion in brake fluid and also to compensate for pad wear means that any adjustments to the levels of brake fluid within the working system need to be made manually.

Why do hydraulic brakes stop working?

Hydraulic brakes can fail or temporarily stop working for numerous reasons such as a simple (but potentially catastrophic) fluid leak or eventual brake fade after prolonged use. Knowing the causes of brake failure can be valuable knowledge in curing the problem and preventing future episodes.

What happens when the brake pedal is pressed?

As the brake pedal is pressed, the pulls rod of expander pulled out which pulls out the conical wedge. The brake shoe connected to the conical wedge through plunger and steel roller ball pulls outward. Thus braking the wheel. When the pedal is released, spring force brings the brake shoe to its original position.

What causes the upper valve of a control unit to open and lower the valve to close?

As the brake pedal is pressed, the fluid pressure causes the upper valve of a control unit to open and lower the valve to close .

How does a piston work on a brake pedal?

The piston is connected to the brake pedal through the piston rod. From the reservoir, fluid enters the compression chamber through the parts as shown.

What is disc brake?

The disc brake is used in motor vehicles and cars, etc. When the pedal is pressed piston pushes the pad by the pressure of the hydraulic fluid. The diagram is shown below: These friction pad rub against the rotating disc connected to the wheels of the vehicle and thus braking takes place.

How does a hand brake lever work?

The handbrake lever pulls a cable or pair of cables linked to the brakes by a set of smaller levers, pulleys, and guides whose details vary greatly from car to car. A ratchet on the handbrake lever keeps the brake on once it is applied. A push-button disengages the ratchet and frees the lever.

Why is a brake valve fitted?

Brake valve is fitted in order to control the intensity of braking. Thus braking takes place.

Why does the brake pedal slow down the vehicle?

As the brake pedal is pressed cam rotates, which pushes the brake shoes outwards and hence brake lining provided on the outer surface of the shoes rub against rotating the drum and hence slow down or stops the vehicles because the drum is connected to the wheels.

Introduction

Why We Need Hydraulic Braking System

- Prior to the hydraulic braking system the type of braking system used was mechanical braking system, so now the question arise if we already have mechanical braking system so why hydraulic braking system? Let’s just find out. 1. As the braking of an automobile vehicle is a very crucial safety part so the responses from the brake pedal to the final braking must be very quick which …

Types

- Hydraulic braking system are classified on 2 basis- 1. On the basis of frictional contact mechanism- On this basis, hydraulic brakes are of 2 types – (i) Drum brakeor internal expanding hydraulic brakes. (ii)Disc brakesor external contracting hydraulic brakes. 2. On the basis of brake force distribution-on this basis, hydraulic brakes are of 2 types- (i) Single acting hydraulic brake…

Constructional Details

- On the Basis of Frictional Contact Mechanism In drum hydraulic braking system the parts involved are- 1. Brake pedal or brake lever- In hydraulic braking system same as other braking brake pedal or brake lever is required by the driver to apply braking, this brake pedal or brake lever is attached with the master cylinder through mechanical rod or connecting rod. 2. Master cylinder– It is the …

Application of Hydraulic Braking

- Drum Type Hydraulic Brakes- They are used in some low speed four wheelers like Tata Ace.

- Disc Type Hydraulic Brakes- They are widely used in almost all the cars like Maruti Suzuki swift, Hyundai i20 etc and also in bikes like Bajaj pulsar 180, Ktm Duke 390 etc.

- Single Acting Hydraulic Brakes- Front brakes of pulsar 180 is of single acting type.

- Dual Acting Hydraulic Brakes – All the cars mentioned above.

Overview

A hydraulic brake is an arrangement of braking mechanism which uses brake fluid, typically containing glycol ethers or diethylene glycol, to transfer pressure from the controlling mechanism to the braking mechanism.

System operation

In a hydraulic brake system, when the brake pedal is pressed, a pushrod exerts force on the piston(s) in the master cylinder, causing fluid from the brake fluid reservoir to flow into a pressure chamber through a compensating port. This results in an increase in the pressure of the entire hydraulic system, forcing fluid through the hydraulic lines toward one or more calipers where it acts upon one or more caliper pistons sealed by one or more seated O-rings (which prevent leak…

History

During 1904, Frederick George Heath (Heath Hydraulic Brake Co., Ltd.), Redditch, England devised and fitted a hydraulic (water/glycerine) brake system to a cycle using a handlebar lever and piston. He obtained patent GB190403651A for “Improvements in hydraulic actuated brakes for cycles and motors”, as well as subsequently for improved flexible rubber hydraulic pipes.

Construction

The most common arrangement of hydraulic brakes for passenger vehicles, motorcycles, scooters, and mopeds, consists of the following:

• Brake pedal or lever

• A pushrod (also called an actuating rod)

• A master cylinder assembly containing a piston assembly (made up of either one or two pistons, a return spring, a series of gaskets/ O-rings and a fluid res…

The most common arrangement of hydraulic brakes for passenger vehicles, motorcycles, scooters, and mopeds, consists of the following:

• Brake pedal or lever

• A pushrod (also called an actuating rod)

• A master cylinder assembly containing a piston assembly (made up of either one or two pistons, a return spring, a series of gaskets/ O-rings and a fluid reservoir)

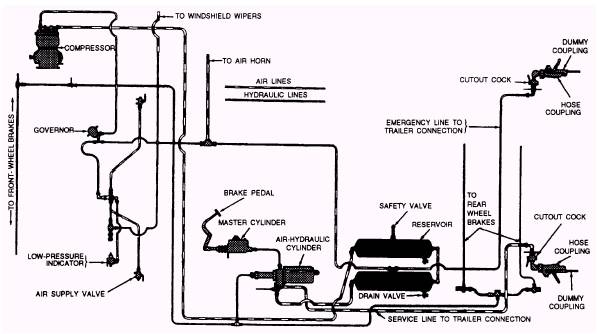

An example of a hydraulic brake system

Hydraulic brakes transfer energy to stop an object, normally a rotating axle. In a very simple brake system, with just two cylinders and a disc brake, the cylinders could be connected via tubes, with a piston inside the cylinders. The cylinders and tubes are filled with incompressible oil. The two cylinders have the same volume, but different diameters, and thus different cross-section areas. The cylinder that the operator uses is called the master cylinder. The spinning disc brake will be …

Component specifics

(For typical light duty automotive braking systems)

In a four-wheel car, the FMVSS Standard 105, 1976; requires that the master cylinder be divided internally into two sections, each of which pressurizes a separate hydraulic circuit. Each section supplies pressure to one circuit. The combination is known as a tandem master cylinder. Passenger vehicles typically have either a front/rear split brake system or a diagonal split brake …

Special considerations

Air brake systems are bulky, and require air compressors and reservoir tanks. Hydraulic systems are smaller and less expensive.

Hydraulic fluid must be non-compressible. Unlike air brakes, where a valve is opened and air flows into the lines and brake chambers until the pressure rises sufficiently, hydraulic systems rely on a single stroke of a piston to force fluid through the system. If any vapor is introduced into the sys…

See also

• Air brake (road vehicle)

• Anti-lock braking system

• Bicycle brake systems

• Brake bleeding

• Brake-by-wire