What is a kanban and why is it used?

Kanban visualizes both the process (the workflow) and the actual work passing through that process. The goal of Kanban is to identify potential bottlenecks in your process and fix them so work can flow through it cost-effectively at an optimal speed or throughput.

Where are kanban cards used?

Nowadays, the Kanban method is widely spread across various industries: manufacturing, IT, software development, marketing, finances, etc. This is because any team will work better and smarter when it is aware of its challenges and those of the whole organization.

What is kanban card in agile?

A kanban board is an agile project management tool designed to help visualize work, limit work-in-progress, and maximize efficiency (or flow). It can help both agile and DevOps teams establish order in their daily work.

What are the two types of kanban?

They often take two forms: internal or interprocess kanban (for withdrawal from an internal process) and supplier kanban (for withdrawal from an external supplier). In their original application around Toyota City, cards commonly were used for both purposes.

What are the benefits of kanban?

Advantages of Using the Kanban SystemFlexibility.Focus on continuous delivery.Reduction of wasted work / wasted time.Increased productivity.Increased efficiency.Team members' ability to focus.

Is kanban Lean or agile?

Kanban is a visual-based agile framework with a focus on optimizing the flow of work in a continuous delivery manner.

What is Kanban board vs scrum?

Kanban is a project management method that helps visualize tasks, while Scrum is a method that provides structure to the team and schedule. Kanban and Scrum are project management methodologies that complete project tasks in small increments and emphasize continuous improvement.

How do I setup my kanban card?

There are five main steps to implementing a Kanban system:Visualize your current workflow.Apply Work-in-Process (WIP) limits.Make policies explicit.Manage and measure flow.Optimize iteratively with data.

What is kanban card used to signal?

Kanban cards are a key component of kanban and they signal the need to move materials within a production facility or to move materials from an outside supplier into the production facility. The kanban card is, in effect, a message that signals a depletion of product, parts, or inventory.

How does kanban work in manufacturing?

The Kanban board is split into columns that track each stage of a project, e.g., Requested, In Progress, Done. Each project is split into individual tasks, which are placed as 'cards' in the Requested column. Each card represents one work item. In manufacturing, one card usually equates to one customer order.

What are the reasons to use kanban pull method in production planning?

Which one of the following is a reason to use the Kanban “pull” method in production planning? Choice-1: It supports the use of long term accurate planning by producing maximum throughput. Choice-2: It optimizes the use of resources. Choice-3: It makes the requirement of long term accurate planning almost obsolete.

What is the name of the card used in a one card kanban system?

In the single Kanban(s)card system, each workstation has only out-bound inventory, and each container is assigned a Kanban, known as a conveyance Kanban or with drawal Kanban. When a container is withdrawn by the succeeding stage, the conveyance Kanban is detached and becomes a production order for the preceding stage.

What is a Kanban card?

A Kanban card represents an individual work item, which allows teams to view important work information. A Kanban card is a sticky note on that board. Each Kanban card, or sticky note, represents one work item. But a Kanban card can contain far more information than a simple sticky note – it can include descriptions, attachments, links, comments, ...

What is the purpose of Kanban cards?

The Purpose of Kanban Cards. The purpose of a Kanban card is to represent a work item and communicate its status as it moves through the work flow. Often, teams track work in one place, and communicate status in another – Kanban boards allow teams to communicate status while tracking their work.

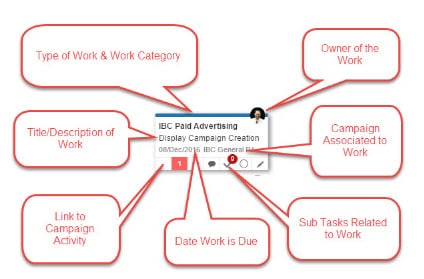

What information should be included in a Kanban card?

Cards can include information such as card assignments, due dates, attachments / links, work type, and work priority. By looking at the position of a Kanban card on the board, teams can tell where the card is in the process.

How many Kanban cards can a team create per week?

For example, if a team works on three to four projects a week and each project has around sixteen tasks, using a card template can save the team from creating 64 new cards per week. Whether physical or digital, Kanban cards give enhanced visibility into the status of work and help team members effectively communicate about work items.

What are the attributes of a Kanban card?

Core Attributes of a Kanban Card. There a few core attributes of a Kanban card that differentiate it from a humble sticky note: Kanban cards represent actionable work items. Card titles will typically include a verb. Kanban cards move on a Kanban board from left to right.

Why create a Kanban card template?

Creating a Kanban card template can ensure that the team remembers perform each of the tasks involved in that work without creating a new card from scratch each time. Once a card template is created, teams can simply duplicate it, edit details as needed, and begin work.

Why is it important to record card metrics?

Accurately recording card metrics helps teams realize the full value of their Kanban system.

What is Kanban in software?

Kanban is a workflow management method for defining, managing, and improving services that deliver knowledge work. It aims to help you visualize your work, maximize efficiency, and improve continuously. Originating from manufacturing, it later became a territory claimed by Agile software development teams.

What is Kanban in business?

Kanban is a workflow management method for defining, managing, and improving services that deliver knowledge work. It aims to help you visualize your work, maximize efficiency, and improve continuously. Learn more.

How to Use Kanban for Project Management?

To use Kanban for project management, all teams involved should use Kanban boards to manage their work. Therefore, all these team boards have to be considered a network of services through which the project work flows. This is the foundation of each value delivery system.

Why is Kanban a service oriented approach?

Through the use of regular reviews of the network of services and assessment of the applied work policies, Kanban encourages the improvement of the delivered results.

How to visualize a Kanban process?

To visualize your process with a Kanban system, you will need a board with cards and columns. Each column on the board represents a step in your workflow. Each Kanban card represents a work item. The Kanban board itself represents the actual state of your workflow with all its risks and specifications.

Why is Kanban discouraged?

In general, sweeping changes are discouraged because they usually encounter resistance due to fear or uncertainty.

What does Kanban mean?

The Japanese word “kanban”, meaning “visual board” or a “sign”, has been used in the sense of a process definition since the 1960s. The systems Toyota used to limit their work in progress have been called “kanban systems”.

What Is Kanban?

Kanban is an inventory control system used in just-in-time (JIT) manufacturing. It was developed by Taiichi Ohno, an industrial engineer at Toyota, and takes its name from the colored cards that track production and order new shipments of parts or materials as they run out. Kanban is the Japanese word for sign, so the kanban system simply means to use visual cues to prompt the action needed to keep a process flowing.

What is Kanban in Japanese?

Kanban is the Japanese word for sign, so the kanban system simply means to use visual cues to prompt the action needed to keep a process flowing.

What is Kanban system?

The kanban system can be used easily within a factory, but it can also be applied to purchasing inventory from external suppliers. The kanban system creates extraordinary visibility to both suppliers and buyers. One of its main goals is to limit the buildup of excess inventory at any point on the production line.

What does it mean when inventory is exceeded?

Whenever a limit of inventory is exceeded, it points to an inefficiency that needs to be addressed. As containers of parts or materials are emptied, cards appear, color-coded in order of priority, allowing the production and delivery of more before a hold-up or shortage develops. A two-card system is often used.

Where is the Kanban placed on conveyor belt?

For example, if a worker is bagging product on a conveyor belt, a kanban may be placed in the stack above the last 10 bags. When the worker gets to the card, he gives the floor runner the card to bring more bags. A station further from the supply room might have the kanban placed at 15 bags and a closer one at five. The flow of bags and the placement of cards are adjusted to make sure no station is left bag-less while the belt is running.

Which companies use Kanban?

Toyota, Ford Motor Company and Bombardier Aerospace are among the manufacturers that use e-kanban systems. These electronic systems still provide visual signals, but the systems are also usually enabled to automate parts of the process, such as transport through the factory or even filing purchase orders.

Who is Clay Halton?

Clay Halton is an Associate Editor at Investopedia and has been working in the finance publishing field for more than three years. He largely writes and edits personal finance content, with a focus on LGBTQ+ finance.

What does Kanban mean in Japanese?

TRIVIA – Kanban, also spelt “ kamban ” in Japanese, translates to “Billboard” (“signboard” in Chinese) that indicates “available capacity (to work)”. Kanban is a concept related to lean and just-in-time (JIT) production, where it is used as a scheduling system that tells you what to produce, when to produce it, and how much to produce.

Why is Kanban important?

The aim is to achieve higher throughput with lower delivery lead times. Over time, Kanban has become an efficient way in a variety of production systems.

What is Kanban system?

A Kanban system ideally controls the entire value chain from the supplier to the end consumer. In this way, it helps avoid supply disruption and overstocking of goods at various stages of the manufacturing process. Kanban requires continuous monitoring of the process.

How does Kanban help a business?

If you follow these principles and practices, you will successfully be able to use Kanban for maximizing the benefits to your business process – improve flow, reduce cycle time, increase value to the customer, with greater predictability – all of which are crucial to any business today.

Why was Kanban created?

It was created as a simple planning system, the aim of which was to control and manage work and inventory at every stage of production optimally . A key reason for the development of Kanban was the inadequate productivity and efficiency of Toyota compared to its American automotive rivals.

How to implement Kanban?

Visualize the flow of work: This is the fundamental first step to adopting and implementing the Kanban Method. You need to visualize – either on a physical board or an electronic Kanban Board, the process steps that you currently use to deliver your work or your services. Depending on the complexity of your process and your work-mix (the different types of work items that you work on and deliver), your Kanban board can be very simple to very elaborate. Once you visualize your process, then you can visualize the current work that you and your team are doing.

What is a kanban?

K anban is a visual system for managing work as it moves through a process. Kanban visualizes both the process (the workflow) and the actual work passing through that process. The goal of Kanban is to identify potential bottlenecks in your process and fix them so work can flow through it cost-effectively at an optimal speed or throughput.