What is the meaning of lean production?

Definition of Lean Production. The terms "lean manufacturing" and "lean inventory" refer to an approach to production that eliminates waste and shortens the time between receiving and delivering orders. Lean accounting is geared toward streamlining accounting processes in comparable ways.

What is lean accounting and how does it support manufacturing?

Assembling and organizing this information often involves rethinking the assumptions embedded in traditional accounting systems. Lean accounting is a financial management approach that supports the streamlined processes of lean manufacturing. What Is Lean Accounting?

What are the positive and negative aspects of Lean Accounting?

The positive includes accounting, control, measurements, and decision-making processes that actively support their lean strategy. The negative is to remove the harmful impact of traditional accounting. Lean accounting also eliminates waste within the accounting processes by stripping them down to the minimum amount of work.

What is the difference between traditional accounting and lean accounting?

Traditional accounting measures also use standard costing, which can lead to inaccurate information for decision makers who put Lean tools and techniques into place. Rather than using a traditional approach, Lean accounting uses a method that categorizes costs by value stream rather than by department.

What does lean mean in accounting?

The term Lean accounting describes the financial reporting practices used by a company that embraces Lean thinking: focusing on the value delivered to the client and on waste elimination through better workflow and material management.

What is lean manufacturing in accounting?

Lean manufacturing. A strategy designed to achieve the shortest possible production cycle by eliminating waste. The goal is to reduce inventory and produce only to meet customer demand. Benefits include lower costs, higher quality and shorter lead times.

What are the 4 components of lean production?

These are:The key aspects of lean production that you should be aware of are:Time based management.Simultaneous engineering.Just in time production (JIT)Cell production.Kaizen (Continuous improvement)Quality improvement and management.

What is an example of lean production?

1. Cable Manufacturing. A cable manufacturing company wanted to reduce set-up times and shorten lead time to market. A lean team found ways to streamline machine set-up and changeover requirements.

Why is lean accounting important?

An important purpose of Lean Accounting is to reduce the work required for the routine accounting, control, and measurement system so as to free up the time of the accountants (and others) so as to give them time to work on more strategic activities that drive the company forwards.

What are the benefits of lean accounting?

Benefits of Lean AccountingThe financial impact of any decision is based on the impact on total value stream profitability. Value streams are the profit centers of a lean enterprise and all financial analysis should be performed at this level. ... Using cost allocations is costing you money. ... Eliminating waste creates time.

What are the 5 principles of lean?

According to Womack and Jones, there are five key lean principles: value, value stream, flow, pull, and perfection.

What are the 5 steps of lean?

The Five Steps of Lean ImplementationStep 1: Specify Value. Define value from the perspective of the final customer. ... Step 2: Map. ... Step 3: Flow. ... Step 4: Pull. ... Step 5: Perfection.

What is purpose of lean production?

The purpose of lean manufacturing is to minimize waste, which in turn reduces costs and maximizes productivity. Waste in this context is any action or process step that adds to costs but doesn't add value for the customer.

Who uses lean production?

Some well-known companies that use lean include Toyota, Intel, John Deere and Nike. The approach is based on the Toyota Production System and is still used by that company, as well as myriad others. Companies that use enterprise resource planning (ERP) can also benefit from using a lean production system.

What are the characteristics of lean production?

What are characteristics of lean manufacturing?One-piece flow.Machines in order of process.Small, inexpensive and dedicated equipment.Multi-process handling workers.Easy moving/standing operations.Production paced to task time.Pull production.Standard operations defined.More items...

What are the key components of lean accounting?

Components of lean accounting Lean concepts: ideas for improving accounting processes, the flow of information, and financial documentation. Lean culture: encouraging a productive work environment by streamlining communication and teamwork.

What companies use lean accounting?

Some well-known companies that use lean include Toyota, Intel, John Deere and Nike. The approach is based on the Toyota Production System and is still used by that company, as well as myriad others. Companies that use enterprise resource planning (ERP) can also benefit from using a lean production system.

What does lean mean in business?

Simply stated, a Lean business is a business that maximizes value while minimizing waste. A Lean business model focuses on improving processes across the value stream in order to eliminate waste and deliver optimized value to the customer.

What are the disadvantages of lean manufacturing?

Disadvantages of Lean Manufacturing (and How to Make Lean Work in Your Firm)Lack of Strategic Focus. ... Lack of Proper IT Systems. ... The Time Factor. ... The Human Factor. ... Cutting Things Too Fine. ... Harnessing Lean Manufacturing for Success.

What is lean accounting?

Lean accounting includes making financial statements easier to understand and relevant to specific activities within a business. It also involves applying lean principles to the accounting department to ensure that processes are completed consistently in an easier to understand way.

Why is lean accounting different from traditional accounting?

This is because lean accounting suggests new ways of looking at numbers and calculating the health of a business.

Why are lean accounting reports not available?

The reason that lean accounting reports may not be able to completely replace traditional accounting reports is due to the Generally Accepted Accounting Practices which are a set of reporting standards in the UK that establish how financial statements need to be prepared.

What are the disadvantages of lean accounting?

Here are some disadvantages of lean accounting: 1 Difficult to switch from traditional accounting: switching to lean accounting will involve lots of new processes and may be difficult and slow to implement for everyone to be on the same page. 2 High cost of implementation: although lean accounting is all about maximising profits, the cost of implementing lean accounting is high and complex. It will usually need to be done in small steps over a long period of time. 3 Inventory problems: one approach to lean accounting is keeping low amounts of stock to increase short-term profits. This may cause issues if orders increase drastically. 4 Having to do 2 sets of financial reports: lean accounting reports usually cannot replace standard reports under your countries legal requirements. Your accounting department may have to run 2 different sets of reports if lean accounting is implemented. Most accounting software will only be able to create standard financial reports.

What is the difference between lean accounting and overhead accounting?

In traditional cost accounting, overhead costs are assigned to specific products, whereas lean accounting uses value streams to report financial data. Value streams identify all steps from the creation of a product to the delivery to the customer.

What is lean concept?

Lean concepts: ideas for improving accounting processes, the flow of information, and financial documentation. Lean culture: encouraging a productive work environment by streamlining communication and teamwork. Lean planning: connecting the business goals with lean practices that will help achieve these goals.

What is cost control in lean approaches?

Cost control: lean approaches are all about increasing profits and decreasing wasted costs.

Why use Lean accounting?

The general purpose of accounting is to gather, analyze, and communicate a company’s performance, position, and cash reserves - all types of information used to make decisions on how to manage a business well.

How to implement Lean financial management?

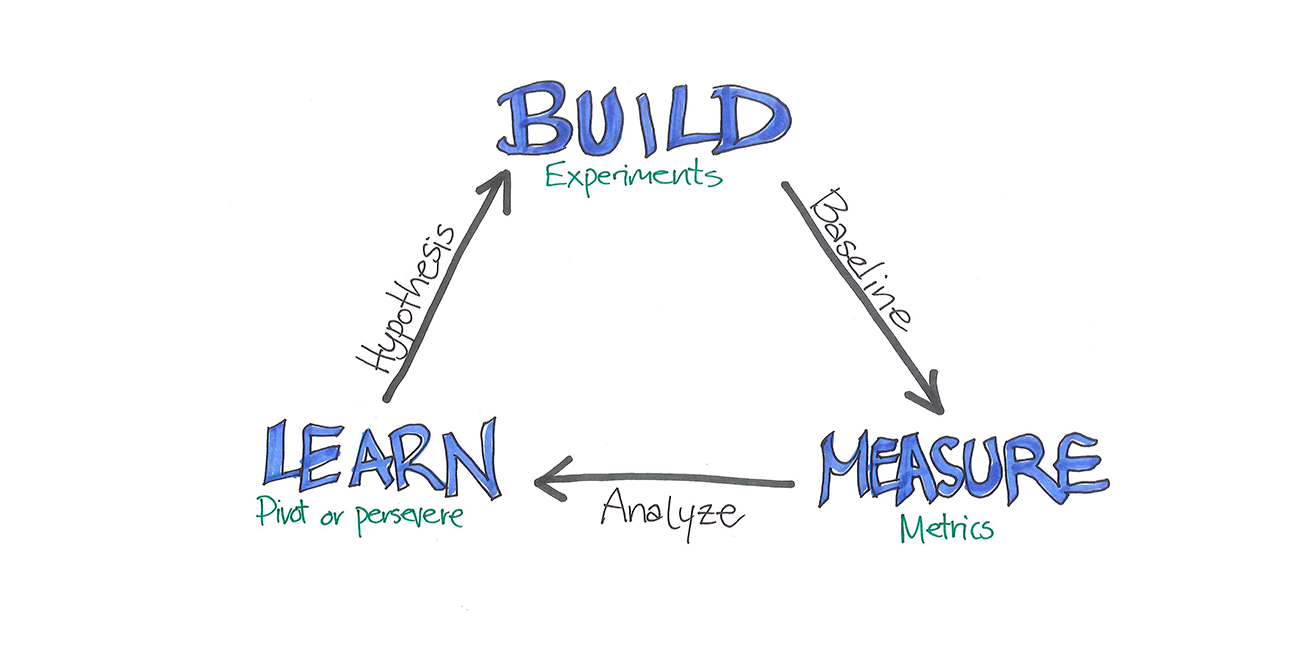

Companies looking to implement Lean financial management first need to adopt Lean ways of operating. Standardizing operations, implementing Kaizen, improving workflows, organizing in work cells all help with adopting Lean thinking and consecutively Lean accounting.

Why is knowing the direct cost of delivering a product line important?

Once done, knowing the direct cost of delivering a product line is, first of all, possible and very useful for planning the organization’s development. Lean companies make it their business to know the value that customers get out of their products. Then, if their processing costs get too high, they can re-engineer the process to keep the market satisfied. Happy customers are the goal for any Lean company. They stand to prove its current state, as well as being a factor in predicting its future.

What is openness in accounting?

Openness to continuous improvements in both the process and accounting.

When did cost accounting shift to information for planning?

As a result of traditional manufacturing processes making accurate cost measurement challenging, in the 1920s, cost accounting focus started to shift from information for planning to information for control. That led to businesses turning to cost allocation rather than cost tracking, which slowly became the new norm.

Can expenditure reporting be automated?

Better yet, ongoing cost amounts can be automated and made available on-demand, as opposed to seasonal bulk financial reporting shared with top-level management only.

Is lean accounting a continuous improvement?

Given that the transformation of your business strategy, preceding any work on accounting methods, will take time, Lean accounting can be challenging for managers hoping to achieve significant results in a short time. A Lean approach to company accounting is a result of continuous improvement, just like all things Lean.

What is lean accounting?

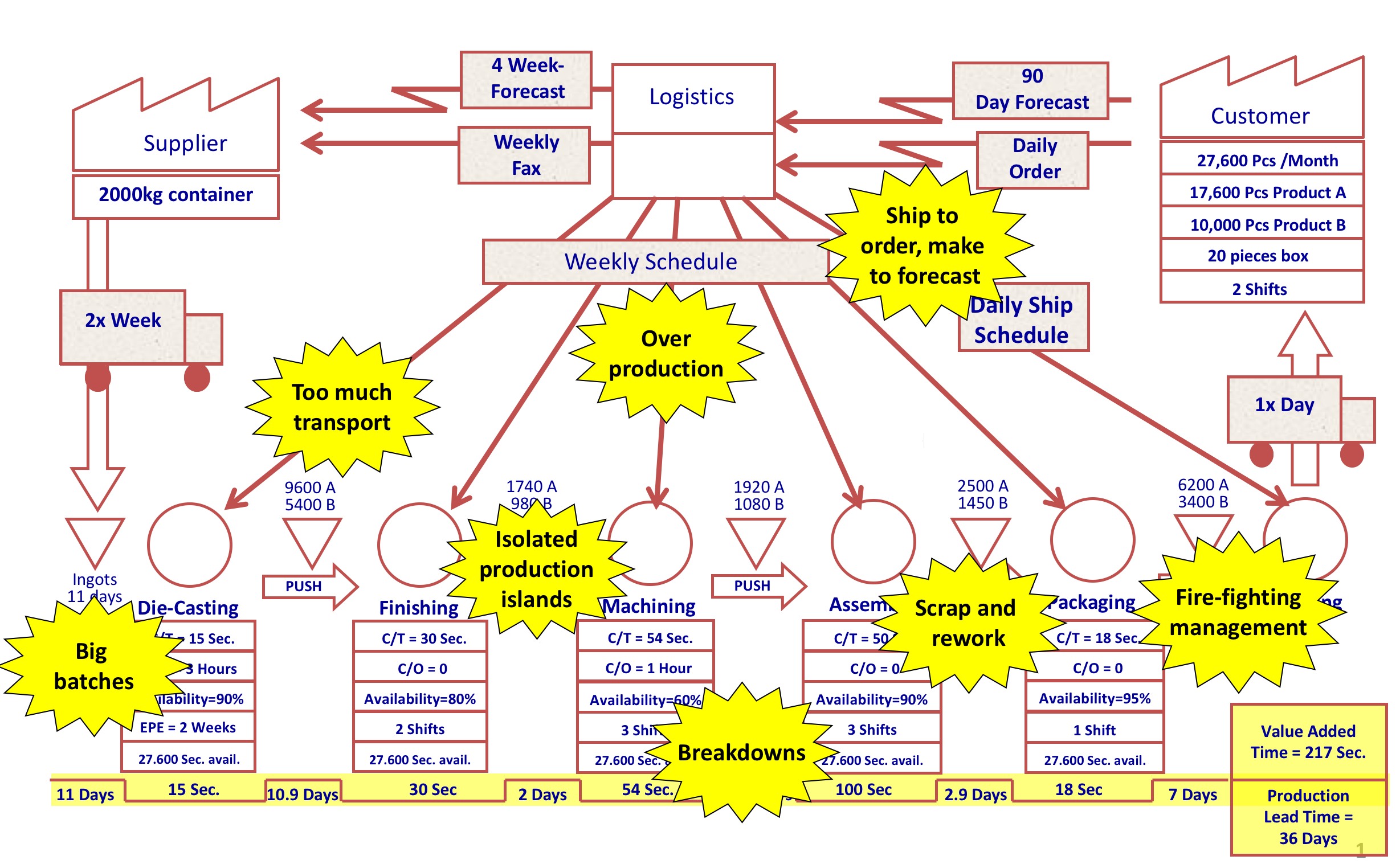

Sometimes called Lean Accounting, it refers to the restructuring of management accounting and controls to accurately report the results of improvements that are continuously being made during a lean transformation. Because current accounting systems were mostly developed in the early 1900s to support large batch manufacturing, traditional accounting systems often send signals that encourage batch processing and silo decision-making.

Why use lean tools?

Use lean tools to eliminate waste from the accounting processes while maintaining thorough financial control

What is lean accounting?

Lean accounting is the collection of principles and processes that provide numerical feedback for manufacturers implementing lean manufacturing and lean inventory practices . When you make changes to operations, such as organizing processes in different ways or shifting the ways you use your workers' time, it may be difficult to tell from simply observing workflow how much of a difference these adjustments have made. Production may seem smoother and easier and customers may seem more satisfied, but quantifying these results provides relevant, high-quality information, allowing managers to actually see the consequences of different approaches to workflow and to compare results. The information you receive from lean accounting can provide the basis for making further changes and adjustments, which your lean accounting system can also measure and evaluate.

How does lean manufacturing work?

Sort: With its strong emphasis on keeping inventory levels to a minimum, lean manufacturing relies on the Kaizen principle of sorting, or identifying items that are no longer useful and getting them out of the way. This practice eliminates clutter and cuts down on the time your team has to spend cataloging and rotating stock that may not even be used. Lean accounting measures the time you save here by evaluating the efficiency of your systems overall once you've gotten unnecessary stock out of the way.

How does lean manufacturing improve efficiency?

Standardize: Every manufacturing operation has elements in common with other operations and elements that are unique to its specifications and processes. Lean manufacturing identifies and standardizes best practices, drawing on general industry knowledge and also proprietary information developed by your staff. By assembling these insights into operations manuals and training staff effectively, you'll lower labor costs by minimizing mistakes and maximizing efficiency. You'll also increase customer satisfaction through increased consistency. Your lean accounting system will capture these improvements with data that shows strong sales and efficient use of labor hours.

Why is lean accounting considered nontraditional?

Lean accounting treats some traditional accounting principles in nontraditional ways because conventional accounting protocols don't fully reflect the value that comes from a lean manufacturing approach.

Why is lean manufacturing important?

Lean manufacturing also emphasizes the principle of short turnaround time. If your business focuses on filling orders as you receive them rather than building up large quantities of particular parts, you'll end up with less waste because the parts you've manufactured in quantity may not be the parts you actually need once the orders start rolling in. Lean accounting quantifies these savings, measuring results in terms of sales relative to inventory and the lead time between a customer placing an order and your company filling and delivering it.

How does lean manufacturing show up on a pro forma cash flow statement?

Lean manufacturing and inventory show up on a pro forma cash-flow statement in the form of lower expenses that result in a less-urgent need for outside operating capital, reflecting a lean approach to finance. If you shorten lead times for producing and delivering orders and you keep less inventory on hand, the cash flow needs on your pro forma (and in your actual operations) will sync more closely with incoming cash. Instead of investing in a glut of inventory that requires a large payment up front but brings in revenue over an extended period of time, a lean operation spends money as closely as possible to when it delivers orders and bills customers.

How does lean inventory affect balance sheet?

The effect of lean inventory on your balance sheet is the most striking example of this discrepancy: Lower inventory levels keep your business running smoothly and profitably, but they show up on a traditional balance sheet as a variable that causes your company to have less value, at least on paper. However, if you're using lean principles successfully, this hit to your balance sheet will be balanced by a corresponding increase in the bottom line of your profit and loss statement, which over time will bounce back to your balance sheet as more cash in the bank.

Why is lean accounting negative?

The negative is to remove the harmful impact of traditional accounting. Lean accounting also eliminates waste within the accounting processes by stripping them down to the minimum amount of work.

How does lean thinking affect business?

There is a maturity path to making these changes. As your company becomes proficient with lean thinking, your processes will come under better control . Much of this control comes from pragmatic, visual tracking by the people in the processes. As your company makes more progress with lean, you will get to the point where the secondary, transactional control systems (ERP/MRP) are increasingly unnecessary and can be largely phased out. ERP systems are valuable tools for any lean company, but they are largely wasteful and we need to eliminate waste from the systems as well as the physical process. Similar, we also simplify and greatly reduce transactions in accounts payable, account receivable, inventory tracking, and other processes.

What is a box score in lean accounting?

Lean Accounting uses a “box score” which is a single page report showing the three aspects of a value stream that determine the operational and financial results. These are the operational performance measurements, the capacity usage, and a summary of the income statement.

Is traditional accounting bad?

Traditional accounting and measurement methods are NOT wrong and bad, but they are the opposite of lean. Traditional measurements like labor efficiency, machine utilization, and others motivate large batches, long lead times, high inventory, shortages, expediting, and crisis management.

Is lean accounting positive or negative?

The purpose of Lean Accounting is both positive and negative.

Is lean accounting a lot of work?

5. Lean Accounting is a Lot Less Work. Lean Accounting does not need the thousands or millions of transactions required to maintain the departmental reporting, the labor tracking, the other so-called control systems traditional companies anguish over. There is a maturity path to making these changes.

How does lean accounting work?

Value streams are the most vital core element of lean accounting. A value stream is everything that goes into getting a product sold. It starts from a sales process and goes all the way to purchasing, production, and shipping.

Why is accounting lean?

Being lean requires the accountants to be efficient in communicating with both external customers and internal customers through making appropriate adjustments to accounting processes.

What is the role of accounting department in a lean business?

The accounting department needs to take an active role in communicating the impact of being lean on the company's bottom line and inventory levels.

What is standard cost accounting?

In short, standard cost accounting values overproduction, which goes against the fundamental goal of lean manufacturing. Furthermore, as the manufacturer produces fewer products, traditional financial statements will indicate an increase in the cost of completing each unit. Labour and overhead are categorised as "deferred costs" as they are not absorbed as quickly. The effect of this is inaccurately priced finished goods, which makes the business less competitive.

Why is lean accounting important?

The lean methodology when applied to the accounting functions also means that it is necessary to eliminate "waste" in accounting processes, such as implementing suitable solutions to accelerate reconciliations, shorten the forecasting and budgeting cycle, close books faster, etc.

What is lean manufacturing?

Lean manufacturing has been around for decades and has been widely adopted by various manufacturing businesses worldwide. In contrast to the traditional mass-production model, where the main goal is to produce as much as possible, lean manufacturing focuses on eliminating waste, reducing inventory levels, maintaining the shortest possible lead ...

How long does it take for lean effect to be visible?

The lean effect will not be visible immediately as it takes time to "digest" the current inventory on-hand until it reaches the desired level.

Components of Lean Accounting

- Lean accounting includes making financial statementseasier to understand and relevant to specific activities within a business. It also involves applying lean principles to the accounting department to ensure that processes are completed consistently in an easier to understand way. Here are some key elements of lean accounting: 1. Lean concepts: id...

Lean Accounting Example

- Lean accounting uses a variety of different concepts and tools to maximise efficiency and profit. Lean accounting involves looking at numbers differently than traditional accounting. One main approach to lean accounting is how inventoryis stored and recorded. A lean company will generally have less stock at any given time to maximise short-term profits. Inventory will also b…

Lean Accounting vs Traditional Accounting

- Several companies have adopted lean principles alongside their standard accounting methods. Lean accounting, however, usually cannot replace traditional accounting and financial reporting methods. Lean accounting financial statements may differ significantly from traditional accounting statements. This is because lean accounting suggests new ways of looking at numb…

The Advantages and Disadvantages of Lean Accounting

- As with most accounting methods, lean accounting has its benefits and downsides. Here are some benefitsof lean accounting: 1. Cost control: lean approaches are all about increasing profits and decreasing wasted costs. 2. Improved company culture: one of the main components of lean accounting is a lean culture, which will encourage teamwork, communication, and improved pro…