Exploring types of manufacturing systems

- Custom manufacturing system. Custom manufacturing describes the production of bespoke products, made to order, usually...

- Intermittent manufacturing system. Intermittent manufacturing can also be thought of as batch production—limited runs of...

- Continuous manufacturing system. Otherwise known simply as ‘mass manufacture’,...

What are some of the different types of manufacturing systems?

Types of Manufacturing Systems

- Intermittent Manufacturing Systems. The intermittent manufacturing system allows companies to make different types of goods using the same production line.

- Continuous Manufacturing Systems. Continuous manufacturing systems are designed to enable the mass production of a single product. ...

- Flexible Manufacturing Systems. ...

What are the different types of manufacturing processes?

- Embossing

- Stretch forming

- Blanking (see drawing below)

- Drawing (manufacturing) ( pulling sheet metal, wire, bar, or tube Bulging Necking Nosing

- Deep drawing (sinks, auto body)

What are the different types of manufacturing companies?

Types of Manufacturing Industries

- Food Industry. This is what most manufacturing industries in Nigeria set up to do. ...

- Textile Mill Industry. ...

- Clothing and Apparel Industry. ...

- Metal Industry. ...

- Chemical Industry. ...

- Leather Industry. ...

- Paper Industry. ...

- Rubber and Plastic Industry. ...

- Wood and Furniture Industry. ...

- Breweries Industry. ...

What are the different types of manufacturing equipment?

Manufacturing equipment is used in the creation or assembly of a wide range of goods. In general, there are three types of manufacturing equipment: machines that create items, machines that assemble items and machines that aid human operators in creating or assembling items.

What are the manufacturing systems?

A manufacturing system can be defined as a combination of humans, machinery, and equipment that are bound by a common material and information flow. The materials input to a manufacturing system are raw materials and energy.

What are the 4 types of manufacturing systems?

According to the book Handbook of Design, Manufacturing, and Automation by Richard C. Dorf and Andrew Kusiak, there are four types of manufacturing systems: custom manufacturing, intermittent manufacturing, continuous manufacturing and flexible manufacturing.

What are the three types of manufacturing systems?

There are three common types of basic production systems: the batch system, the continuous system, and the project system.

What are the two basic types of manufacturing system?

What are the two basic types of production systems? Automated and manual.

What are the 5 manufacturing process types?

Five types of manufacturing processesRepetitive manufacturing.Discrete manufacturing.Job shop manufacturing.Process manufacturing (continuous)Process manufacturing (batch)

What are the 6 different types of manufacturing processes?

The Six Types of Manufacturing – Complete GuideRepetitive Manufacturing.Discrete Manufacturing.Job Shop Manufacturing.Continuous Process Manufacturing.Batch Process Manufacturing.3D Printing.Related Articles.

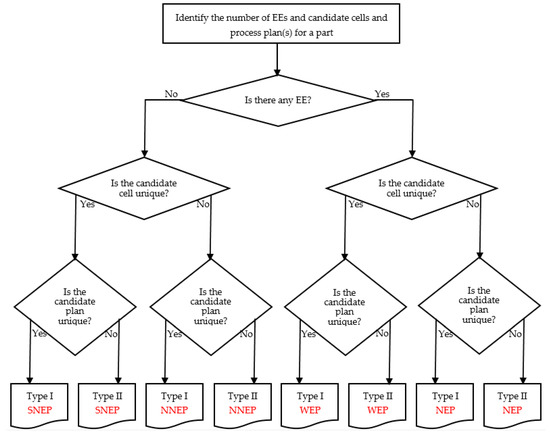

How are manufacturing systems classified?

Production systems can be classified as Job-shop, Batch, Mass and Continuous production systems. Job-shop production are characterized by manufacturing one or few quantity of products designed and produced as per the specification of customers within prefixed time and cost.

What are the types of manufacturing industry?

Here are five types of manufacturing industries that are predominant in the market today:Apparel and Textiles. ... Oil, Chemicals, and Plastics. ... Gadgets, Computers, and Transportation. ... Food Production. ... Metal Manufacturing.

What are the types of flexible manufacturing system?

Types of flexible manufacturing systemSequential FMS. This type of FMS is similar to a small batch flexible transfer line. ... Random FMS. ... Dedicated FMS. ... Engineered FMS. ... Modular FMS.

What is a manufacturing system name the four components of a manufacturing system?

Answer: As listed in the text, the four components are (1) production machines plus tools, fixtures, and other related hardware, (2) a material handling system, (3) a computer system to coordinate and/or control the preceding components, and (4) human workers to operate and manage the system. 3.

How are manufacturing systems classified?

Production systems can be classified as Job-shop, Batch, Mass and Continuous production systems. Job-shop production are characterized by manufacturing one or few quantity of products designed and produced as per the specification of customers within prefixed time and cost.

What is a manufacturing system name the four components of a manufacturing system?

Answer: As listed in the text, the four components are (1) production machines plus tools, fixtures, and other related hardware, (2) a material handling system, (3) a computer system to coordinate and/or control the preceding components, and (4) human workers to operate and manage the system. 3.

What are the three characteristics of manufacturing system?

Three main characteristics are comprised of competitiveness, production process, and business growth. Keywords: small and medium manufacturing industry, ACFTA, exploratory factor analysis, performance.

What is continuous manufacturing?

In a continuous manufacturing system, a product moves along an assembly line, with various specialized workers performing actions to assemble the product at stations along the way.

Why is continuous manufacturing important?

Continuous manufacturing allows for higher output and lower unit costs, but requires a large capital investment due to the amount of labor and machinery you need, and so are more often found in larger operations.

What is intermittent manufacturing?

Intermittent Manufacturing System. In an intermittent manufacturing system, the company produces multiple identical items at the same time. The nature of the system means the products must be standardized and there is little or no allowance for customization.

What are the characteristics of flexible systems?

Characteristics of flexible systems usually include robots or other automated devices that replace or augment human labor. Like continuous management systems, the initial cost of machines can be quite high — but these systems allow you to produce more goods with fewer labor requirements.

How many types of manufacturing are there?

According to the book Handbook of Design, Manufacturing, and Automation by Richard C. Dorf and Andrew Kusiak, there are four types of manufacturing systems: custom manufacturing, intermittent manufacturing, continuous manufacturing and flexible manufacturing.

What are the benefits of manufacturing?

Having the appropriate manufacturing system for your product can yield a variety of benefits, including the ability to maintain the high quality of your goods, being more efficient in your production processes ...

What is manufacturing in manufacturing?

Contact Us. Manufacturing is the production of goods through the use of labour, machinery, tools and biological or chemical processing or formulation. Manufacturing can either mean transforming raw materials into finished goods on a large scale, or the creation of more complex items by selling basic goods to manufacturers for the production ...

What are the three types of manufacturing processes?

There are three types of manufacturing production process; make to stock (MTS), make to order (MTO) and make to assemble (MTA). These three manufacturing types work as follows: 1. Make-To-Stock (MTS) In this system a factory produces goods that are held in stock at stores and showrooms.

What is additive manufacturing?

Additive manufacturing (AM) or additive layer manufacturing (ALM) is the industrial production name for 3D printing, a computer controlled process that creates three dimensional objects by depositing materials, usually in layers.

Why is manufacturing important?

Why it is Important. Manufacturing is not only important in producing and delivering goods to the marketplace, but it is also important for economic reasons. In the United States, for example, manufacturing makes up 15% of the economic output.

How did manufacturing begin?

Manufacturing has existed for centuries and was originally carried out by skilled artisans, sometimes working with assistants, with the skills being passed down through apprenticeships. Manufacturers may have joined guilds who would protect the trade secrets and privileges of these artisans. Alternatively, manufacturing could take place on a less organised scale, often in rural areas, where craftspeople would supplement agricultural subsistence through home-based manufacturing. These manufacturing households were sometimes organised into joined-up enterprises through the putting-out system.

Why do manufacturers use make to order?

This makes it much easier to manage inventories and react to market demand. However, customers will need to wait for their products to be produced and the manufacturer will need a steady stream of orders to keep the factory in production and profitable.

What does it mean when a manufacturer is ready to fulfil customer orders?

This means that the manufacturer is ready to fulfil customer orders as they arrive, but can leave the manufacturer with a stock of unwanted parts if there is no demand. As shown above, all of these types of manufacturing have their own risks related to supply and demand.

What is manufacturing system?

The manufacturing systems are the different processes of transformation and production of a material or raw material through the use of tools, machinery, energy and work. The term manufacture is of Latin origin: manus means"hand"and Facts it means"done".

What are the characteristics of traditional manufacturing systems?

However, there are still many companies with traditional manufacturing systems, whose main characteristics are: - They are designed for specific products. - The flow is online, by the way in which the machines are arranged in a row. - The process ends in the last machine in the row. - The inventory of products in the production chain is low.

What is the manufacturing system of a single piece?

The manufacturing system"piece by piece"consists in the organization of the manufacture of products based on the continuous flow or production of a single piece , which is not grouped in batches but passes from one station to another as it is being manufactured.

What does "manufactured by hand" mean?

Thus, the word"manufacture"means"made by hand", but by extension it is applied to the current productive process, which involves techniques, machines and people. Manufacturing systems are fundamental in society for the manufacture of products or parts, efficiently and with quality.

What is flexibility in manufacturing?

The term flexibility is used to define an attribute that allows a manufacturing system - flexible or mixed - to deal with a certain level of variation in the styles of products or parts. This is achieved without implying the interruption of the production process while making the changes between models.

What are the characteristics of continuous process?

Continuous process. Its main characteristic is the production of batches of products by quantity or weight, whose evaluation is carried out through a group of variables of continuous range. These variables are physical or chemical, such as weight, strength, volume, color, time, density, conductivity, elasticity, viscosity and transparency, ...

What is Ford's assembly line?

The Ford system (the assembly line) is based on increasing the division of labor, increasing the control of productive work of the worker, mass production, reducing costs and increasing the movement of goods, in other aspects.

What is custom manufacturing?

Custom manufacturing describes the production of bespoke products, made to order, usually by a skilled craftsperson. It is a relative rarity in modern society, usually reserved for high-end variants of common products. Tailored suits, handmade furniture, and wedding cakes are all good examples.

What is intermittent manufacturing?

Intermittent manufacturing can also be thought of as batch production—limited runs of similar products, usually to fulfill specific orders. Although machinery is often utilized, intermittent manufacturers commonly rely on skilled workers able to switch between different products.

What is mass customization?

Mass customization delivers individually customized products on a mass scale and production lines may be designed to accommodate simple customization. However, the convergence of digital design and manufacturing may allow customers to design highly complex customizations themselves that are automatically relayed to automated production lines, capable of adapting with no changeover time. As customers increasingly expect personalization—and the technology becomes more capable—mass customization is rapidly becoming the preferred method of production in many sectors.

How many types of manufacturing processes are there?

Six types of manufacturing processes. Depending on your type of business or product, one manufacturing process might work better than another for your company. Here are six types of manufacturing processes used in industries worldwide today:

What is manufacturing process?

A manufacturing process is how a company builds or creates a product. It can be a complex activity that involves a range of machinery, tools and equipment with many levels of automation using computers, robots and cloud-based technology. A business establishes its own manufacturing process to produce goods specifically for its customers.

Why do companies use repetitive manufacturing?

Because there is such little changeover and setup, you can match operation speeds to customer demand or client requirements to make more or fewer items. Many companies that make electronic goods, automobiles or durable consumer goods like refrigerators and clothes dryers use the repetitive manufacturing process.

What is batch process manufacturing?

Batch process manufacturing shares similarities with discrete and job shop manufacturing processes, driven by customer demand or the availability of ingredients and raw materials. One manufacturing run might produce a batch enough to fill client needs, so you finish production, clean the equipment, and resume when you need another batch.

What is repetitive manufacturing?

Repetitive manufacturing is appropriate when making repeat production at a committed production rate. This manufacturing process has dedicated production lines all working on the same product or component all day, every day year-round. Because there is such little changeover and setup, you can match operation speeds to customer demand or client requirements to make more or fewer items.

What is job shop manufacturing?

Job shop manufacturing uses production areas instead of an assembly line and is most often used for small-batch, custom products that are made-to-order for certain clients or customers. These workstations might focus on one particular product or a handful of them, like a custom shoemaker or commercial printing press, and easily offer the ability to customize the final product. Many machine shops also use this type of manufacturing to make local industrial machinery, ship components or specialized parts for the aviation industry.

What is the purpose of machining?

Machining. Machining uses power-driven tools to shape solid materials and metals by removing extra materials from the piece, usually by trimming. Machining is the foundation of the industry and includes things such as presses, chip-making tools and modern machinery.

What is flexible manufacturing system?

A flexible manufacturing system is a systematic arrangement of machine which is interconnected through a transport system. In this, the desired transporter helps in carrying different jobs or works to the machine on pallets.

What is FMS in manufacturing?

The FMS becomes one of the efficient manufacturing concepts for mid-variety and mid-volume part production with this information. In this system, numerous configurations can provide striking features, for example, kinds of operation, the number of machines, and the efficacy of flexibility into the system.

What is FMS used for?

These applications are based upon different aspects. The following are some of them: FMS, in general, can be used for different sets of manufacturing operations. The different processes, such as machining or forging, can also be used, which makes flexible automation a challenge.

What are the components of FMS?

There are three main components of FMS that will make us understand the whole system of flexible manufacturing. The core components of FMS are: Workstations.

Why are FMSs more prevalent?

FMSs are more predominant for non-rotational parts because they can handle non-rotational parts as efficiently and less expensive. FMS is a system that can be used for bulk production; for example, it is used to make aircraft components consisting of vivid sets and numbers of components.

What is FMS in assembly?

While in an assembly operation, the FMS involves the joining of two or more material parts. It provides a new product which is known as an assembly. Some of the standard processes are soldering, rivets, press fitting, expansion fits, brazing, welding, and many more.

Why is FMS flexible?

The term flexible in FMS is because it can provide execution and control to different art styles in a specific time lap while also controlling the workstation. With this, we can easily change the get a hold of quantity and workstation in production, calibrating or changing as per the demand regime.

The 2 T Major Types of Manufacturing Systems

- Manufacturing engineering classifies or divides these processes into two categories: continuous and discrete.

Main Characteristics of Traditional Manufacturing Systems

- To become more efficient and competitive, currently productive organizations have had to adopt new technologies, improve their systems and production methods and adapt to markets. The particularities of the manufacturing systems are very varied in terms of density, shape, size, aesthetics or strength. These systems are used in the field of industry. However, there are still m…

Flexible Manufacturing Systems

- The term flexibility is used to define an attribute that allows a manufacturing system - flexible or mixed - to deal with a certain level of variation in the styles of products or parts. This is achieved without implying the interruption of the production process while making the changes between models. This feature is very desirable in all manufacturing systems. These types of systems are …

world-class Manufacturing

- World-class manufacturing is a concept created by manufacturing consultant Richard Schonberger. Its main objective is to enhance the human and technological resources towards the manufacture of products more efficiently, by increasing its operability and speed. The category of world-class manufacturing involves a process of adaptation to production procedur…

References

- Pérez Gaona, Oscar Eduardo: Manufacturing Systems - Tesoem (PDF). Retrieved on February 8, 2018 from tesoem.edu.mx.

- Types of manufacturing systems (PDF). Recovered from sistemasmanufactura.files.wordpress.com

- Advanced manufacturing - Cepal. Consulted by cepal.org

- Pérez Gaona, Oscar Eduardo: Manufacturing Systems - Tesoem (PDF). Retrieved on February 8, 2018 from tesoem.edu.mx.

- Types of manufacturing systems (PDF). Recovered from sistemasmanufactura.files.wordpress.com

- Advanced manufacturing - Cepal. Consulted by cepal.org

- Robles, José Orozco: Advanced manufacturing systems and their potential application to the Mexican industry. Degree thesis, Autonomous University of Nuevo León. eprints.uanl.mx