Is Masonite hard to handle?

While Masonite is a great product and perfect in some temporary floor protection situation, WR-Hardboard is just simply faster, less expensive, and easier to handle. It's 44 mil. heavy duty protection lays flat and lets you make longer runs of floor protection which cuts your install time.

Where can I buy Masonite?

Though are a few online dealers which I know for the Masonite Siding are Hod Supply construction & white industrial cap. It is an online dealer. Now coming to the second one, Green Fiber – it is also an online dealer of the Masonite Siding.

What thickness does Masonite come in?

The typical size for Masonite is 4′ x 8′ (48” x 96”) sheets with a ⅛” thickness. For convenience and ease of use, we also cut Masonite into 4′ x 4′ sheets. The material is paintable but it is not stainable.

Can you still buy Masonite siding?

While Masonite siding is still being used in modern construction, quality building professionals have deemed Masonite siding to be an inferior building product. As a result, The original manufacturer of Masonite siding, named Masonite, is low longer manufacturing the material. Subsequently, question is, how can you tell if siding is Masonite?

What is the difference between hardboard and Masonite?

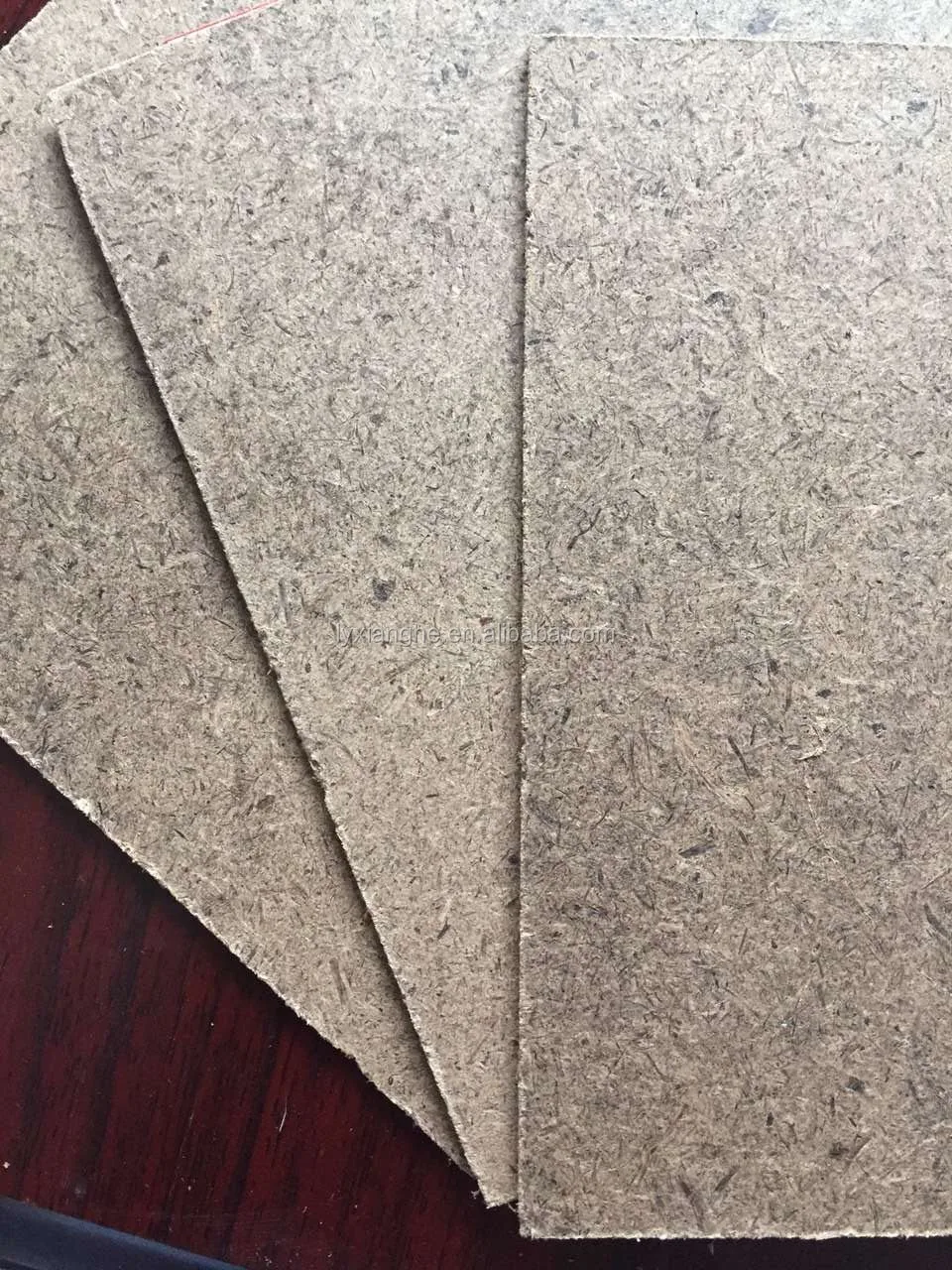

Hardboard (HDF) is produced in one of two ways, either a wet or dry process. Masonite is produced using the wet process only, and the wet process is known as the Mason Method!

What do you use Masonite board for?

Masonite is used extensively in the construction of sets for theater, film and television. It is especially common in theaters as the stage floor, painted matte black. It is considered one of the best materials for making a musical wobble board.

What are the disadvantages of Masonite?

Regardless of what it's called, the material has many common problems that often lead to its replacement.Rotting. Swelling, buckling, and rotting are all really common issues with masonite siding. ... Blistering. Blistering is another common issue with masonite. ... Mold and Mildew. ... Insect Issues. ... Discoloration. ... Bowed Wall Studs.

What is hardboard best used for?

Standard hardboard receives paint well and is used as underlayment, wall panels, backer boards, in furniture and cabinetmaking and as sacrificial work surfaces. Artists often use hardboard as a canvas.

Is Masonite board waterproof?

Masonite composite hardboard has a natural moisture resistance. When you install Masonite, the area of the hardboard penetrated by a fastener can absorb moisture.

Is Masonite the same as MDF?

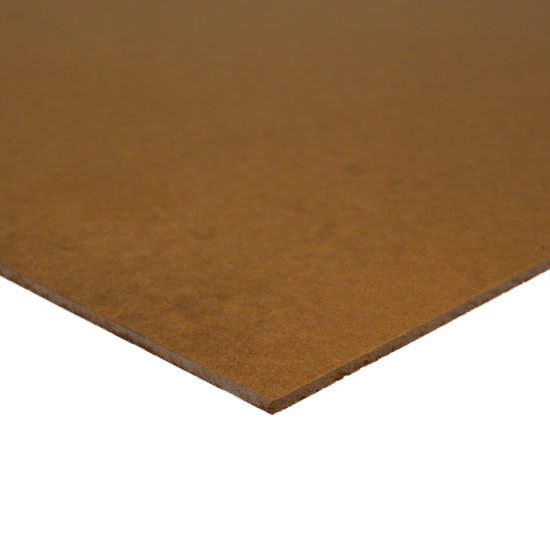

Masonite Is Thinner Masonite may be denser than MDF, but it is also a bit thinner. It takes a much thicker sheet of MDF to achieve the same strength when compared to Masonite.

What happens to Masonite when it gets wet?

Swelling, buckling, and rotting are all really common issues with masonite siding. This is caused when moisture begins to infiltrate the siding. The wood chips and resin are not stable when they become wet. Instead, the wood swells, causing the boards to warp and buckle.

Does Masonite have asbestos?

It is usually the 'sharp/solid' sounding products that require further investigation, especially if it has signs of raised nail heads, cover straps, etc. Masonite, Cement Sheet and AC Sheet can all fall into this category.

Is Masonite toxic?

classified as hazardous according to the criteria of the National Occupational Health and Safety Commission [NOHSC:1008(2004) and www.ascc.gov.au/applications/hsis. Risk Phrases R36/37/38 Irritating to eyes, respiratory system and skin (dust). R42/43 May cause sensitization by inhalation and skin contact.

What are the disadvantages of hardboard?

Hardboard, also known as high-density fiberboard (HDF), is a relatively cheap composite wood building material....High-Density Fiberboard Advantages And Disadvantages.AdvantagesDisadvantagesMoisture resistantNo natural wood grain aestheticRelatively low cost compared to plywoodNot as strong as plywood1 more row

Is hardboard stronger than plywood?

Strength Although you might think otherwise due to the names of these two types of engineered wood, the simple reality is that plywood is actually much stronger than hardboard. Yes, hardboard is fairly strong, but it's just not as strong as plywood. It cannot handle as much impact or weight as plywood.

Can hardboard get wet?

The hardboard is susceptible to water which can cause expansion and damage. Waterproofing the material prevents the potential damage from water due to rain, soaking or any other potential situation where the board gets wet.

Can you paint on Masonite board?

Masonite board is a type of hardboard that's very popular with painters because of its light weight and smooth surface. It's also versatile, and you can paint directly onto it or use it to mount paintings on paper.

Can you use Masonite for flooring?

Laminate and hardwood floors often use Masonite, a brand of pressed-wood fiberboard, as an underlayment floor covering. Masonite covers a wooden subfloor or concrete slab's imperfections, giving the laminate or hardwood flooring a smooth and flat surface to bond against.

What is Masonite used for in art?

Usually made in thin thicknesses of 1/8th of an inch, it is used for anything from floor underlayment to being used as a painting surface for fine art paintings. It is used as an alternative to canvas because it is rigid, inexpensive and lightweight. Why Masonite?

What is used to hold Masonite together?

[untempered] Standard Masonite Presdwood (Masonite Corporation) used in the building trades is a hard composition board made of wood fibers pressed with heat. No binder is added, the particles being held together by the natural adhesives in the wood.

1. Blistering

Because Masonite is produced out of wood fiber, it can succumb to moisture damage through water retention.

2. Faulty Caulking

The areas between the edges of the Masonite siding and the siding itself need to be sealed before you install them.

4. Deterioration & Discoloration

Any cracks, holes, or chunks of Masonite siding that are missing indicate that there are issues.

What is a hardboard masonite panel?

Hardboard Masonite panels are a specific and surprisingly versatile type of wood-based composite panel. It’s strength and durability make it an excellent product for a wide variety of applications.

What is masonite used for?

Manufacturers use hardboard masonite panels in a huge range of ways. Pallets, crates, and other packaging companies use it as lightweight tops, slip sheets or dunnage. Furniture manufacturers use it for cabinets, drawers, shelves, and backing for mirrors and pictures, among other things.

Is MDF the same as hardboard?

It is often confused with MDF or cement fiberboard, but it is not the same thing. It can be unfinished – standard hardboard, or tempered hardboard, a process that adds a minuscule amount of oil as a finishing agent that makes it stronger and less prone to warping.

Is B grade hardboard more expensive than premium?

And one fact that not many people know is that B Grade hardboard, while much less expensive, can feature only minor defects, making it nearly as usable as premium grades! Hardboard’s unique qualities make it an ideal option as a panel substrate for hundreds of different products.

What is masonite backing?

Masonite was a popular protective backing for wooden console stereo and television cabinets from the 1960s to the 1980s.

When was masonite made?

A product resembling masonite ( hardboard) was first made in England in 1898 by hot-pressing waste paper. Masonite was patented in 1924 in Laurel, Mississippi, by William H. Mason, who was a friend and protégé of Thomas Edison. Mass production started in 1929.

How big is a masonite strip?

Masonite 4-by-8-foot (1.2 by 2.4 m) panels are sometimes sawn into 4-inch (100 mm) by 8-foot strips. These strips are used to form the edge of sidewalks where curved shapes are desired when pouring concrete.

Why do you tape masonite sheets together?

The Masonite sheets are taped together with duct tape to prevent shifting and to keep substances from leaking through. Masonite is used extensively in the construction of sets for theater, film and television. It is especially common in theaters as the stage floor, painted matte black.

How is masonite formed?

Masonite is formed using the Mason method, in which wood chips are disintegrated by saturating them with 100-pound-per-square-inch (690 kPa) steam, then increasing the steam or air pressure to 400 pounds per square inch (2,800 kPa) and suddenly releasing them through an orifice to atmospheric pressure.

What is a quartrboard?

Quartrboard, Masonite Corporation, c. 1930. Masonite is a type of hardboard, a kind of engineered wood, which is made of steam-cooked and pressure-molded wood fibers in a process patented by William H. Mason. It is also called Quartrboard, Isorel, hernit, karlit, torex, treetex, and pressboard.

What is a chess board made of?

A chessboard made of Masonite. Artists have often used it as a support for painting, and in artistic media such as linocut printing. Masonite 's smooth surface makes it a suitable material for table tennis tables and skateboard ramps. Masonite is used by moving companies.

Who invented wet dry hardboard?

Wet-dry hardboard was invented also by Mason, a few years after the wet process. Fiberizingand mat formation is essentially the same as in the wet process. However, water in the wet matis evaporated in a tunnel dryer before the mat is delivered to the hot press. Since no water is

How to fiberize wood?

Fiberizing of the wood is accomplished by a variety of methods but basical-ly they consist of steaming chips to soften them followed by grinding betweenabrading discs to tear the fibers apart.

Is hardboard tempered?

After pressing any type hardboard may be “tempered”. Unfortunately, this term has often beenmisused and abused. Some manufacturers quite properly refer to a product of theirs as “tem-pered” even though it doesn’t conform to Class I of the Commercial Standard (See Table 1).Other manufacturers produce board which meets the physical property specifications of Class Ibut can’t be properly described as “tempered”. Terms such as “treated”, “chest-tempered”, “vat-tempered”, “core-tempered” and “heat-tempered” have contributed to misunderstanding andconfusion, even though used in good faith effort to describe a particular process.In the most commonly accepted “tempering” process, both surfaces of the hardboard are

Is a hardboard a jungle?

despite their complexity, hardboards are really not a jungle of confu-sion. This article has stressed the variables in hardboard process and properties. Thesedifferences are, in reality, benefits to the knowledgeable buyer, for they mean that inthem there is a hardboard just right for most every use.

What is hardboard siding?

Hardboard siding – also knows as pressboard, Masonite or hardboard siding – is a synthetic home siding product composed of a mixture of wood fibers, glues and resins, all bound together using heat and pressure. This inexpensive siding option made it a widely popular choice for homeowners from the 1980s to the mid-1990s.

When did hardboard siding stop being made?

This stipulated that owners of properties constructed using hardboard siding from January 1, 1980 through January 15 , 1998, depending on the manufacturer, could be reimbursed for any damages caused by the product. Following this, nearly all manufacturers stopped producing Masonite siding.

How Do I Tell if I Have Pressboard Siding?

The best way to determine what kind of siding your home has is to go to an unfinished area, such the attic or garage. Then pull back the tar paper from the back of the siding and see if there are any markings – either the manufacturer’s name or AHA (American Hard board Association) code.

What are the problems with pressboard siding?

The Problems with Pressboard Siding. One problem with hardboard is that it tends to absorb water, making it deteriorate and shortening its lifespan. The results, especially with improper installation, can be board swelling, warping, buckling, blistering, rotting and softening, as well as mold development and insect infestation.

What is the best siding to replace?

The best bet is to replace all your siding with a product like James Harding Siding , consistently ranked as one of the best products on the market for its durability, good looks, ability to stand up to all kinds of weather conditions and easy maintenance.

Can you replace Masonite siding?

If there is more extensive damage – with Masonite siding that is rotting or swollen from water retention – then It is important that you get replacement siding. That water is not just harming your siding, but it could be wrecking the structure of your house.

Can you replace hardboard siding with fiber cement?

Since hardboard siding is no longer made, you will have to find other kinds of siding replacement. And while you can get fiber-cement or vinyl replacement siding for the affected area, you would definitely notice a difference in siding thickness and texture.

Overview

Masonite is a type of hardboard, a kind of engineered wood, which is made of steam-cooked and pressure-molded wood fibers in a process patented by William H. Mason. It is also called Quartrboard, Isorel, hernit, karlit, torex, treetex, and pressboard.

History

A product resembling masonite (hardboard) was first made in England in 1898 by hot-pressing waste paper. Masonite was patented in 1924 in Laurel, Mississippi, by William H. Mason, who was a friend and protégé of Thomas Edison. Mass production started in 1929. In the 1930s and 1940s, Masonite was used for applications including doors, roofing, walls, desktops, and canoes. It was sometimes used for house siding.

Production

Masonite is formed using the Mason method, in which wood chips are disintegrated by saturating them with 100-pound-per-square-inch (690 kPa) steam, then increasing the steam or air pressure to 400 pounds per square inch (2,800 kPa) and suddenly releasing them through an orifice to atmospheric pressure. Forming the fibers into boards on a screen, the boards are then pressed and heated to form the finished product with a smooth burnished finish. (Later a dry process wit…

Use

Artists have often used it as a support for painting, and in artistic media such as linocut printing. Masonite's smooth surface makes it a suitable material for table tennis tables and skateboard ramps.

Masonite is used by moving companies. Among other things, they use it to protect the walls of buildings where they work, and lay on floors to enable smo…

Deterioration

Masonite swells and rots over time when exposed to the elements, and may prematurely deteriorate when it is used as exterior siding. In 1996, International Paper (IP) lost a class action suit brought by homeowners whose Masonite siding had deteriorated. The jury found that IP's Masonite siding was defective.

See also

• Engineered wood

• Fiberboard

• Glued laminated timber

• Hardboard

• Haskelite

External links

• Masonite Doors