What are the different mill finishes for stainless steel?

There are three very popular mill finishes: No. 1 stainless steel finish, 2B stainless steel finish, and 2D stainless steel finish. No. 1 mill finishes are achieved by hot rolling the stainless steel to a desired thickness.

What is a No 1 mill finish?

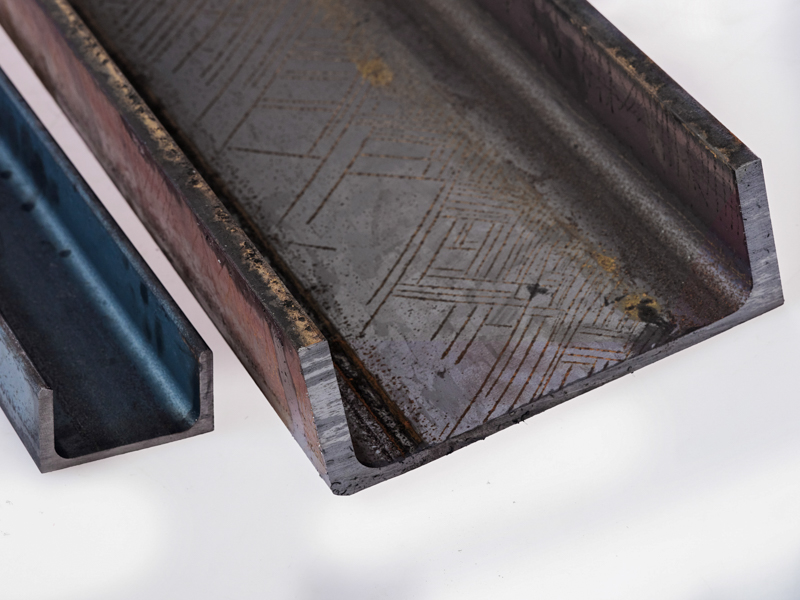

No. 1 mill finishes are achieved by hot rolling the stainless steel to a desired thickness. They tend to look dark and varied, and demonstrate the roughest, least uniform surface character of all of the stainless steel finishes.

What is the difference between Mill and brushed finish?

Mill finishes produce matte finishes that are most suitable for industrial uses and when a smooth surface is not required. Usually, mill finishes are selected for end uses where durability remains the highest priority. Brushed and polished finishes are mechanically achieved. These finishes are considered more abrasive than mill finishes.

Why choose stainless steel finishes for your application?

With a wide variety of Stainless Steel Finishes available to choose from, it becomes easier to find the perfect finish for each application. Whether it be Automotive Exhaust or Automotive Grill, or Entrance of the Airport, there is a stainless steel finish to suit it all.

What is the last step in 2B mill finishing?

The last and final step in the 2B mill finishing method includes, cold rolling the substrate using polished rolls. This process provides a smooth, even, reflective, and grey sheen on the substrate.

What is the process of heat treating stainless steel coils?

During the process, a dull silver-gray finish is applied to stainless steel coils. Then, the thickness is reduced or made even using the cold rolling method. Next, is heat-treating the coils to create a uniform microstructure, and also to enhance the metal’s mechanical properties. After heat-treating the metal, the process known as pickling, or descaling occurs. This process ensures the complete removal of chromium depleted dark surface layer from the metal surface.

Can you use 2B mill finish on stainless steel?

Even though 2B mill finish can provide a comprehensive coating to resist the harshest industrial conditions, the quality of the finish is directly dependent on the quality of the substrate being coated. Some alloy combinations in stainless steel cannot be provided with an exceptional finish using a 2B mill finish. Hence, polishing service providers must carefully examine the stainless steel alloy combination before applying 2B mill finishing technique.

What is applied finish?

Applied finishes may further enhance the surface appearance and environmental performance of your product. This requires physical alteration of the metal, most notably through the use of abrasive material that removes portions from the surface. The higher the abrasive grit used, the finer and more reflective the look.

What is the final step to ensuring your stainless steel is truly complete?

In the end, determining your finish and the specific needs of your application and properly conveying those to your producer could be the final step to ensuring your stainless steel is truly complete.

What grit is used for abrasive finish?

The higher the abrasive grit used, the finer and more reflective the look. For example, one common applied finish is #4, which you will find on your average restaurant or kitchen equipment, food processing or dairy equipment, and elsewhere. This finish uses between 120 and 320 abrasive grit, depending on the application. For comparison, applied finish #3 uses between 100-120. The level of the grit impacts the surface roughness, which is typically measured in terms of micro-inches or micro meters, represented as Ra (roughness average). The higher the grit numbers, the finer the polishing lines and more reflective the finish.

What is pit free finish?

These types of finishes use an intense polishing method to eliminate any unseen pits, scratches or imperfections. Eliminating these imperfections early could also make the finished product is easier to clean, without the need to use harsh chemicals to eliminate that bacteria that develops. Check out more about what it means to create a pit-free finish from Guy Metals, part of the Ryerson Family of Companies.

Do stainless steel products need mill finishes?

While some products may only require standard stainless steel finishes, others may need something extra in order to enhance surface appearances, improve environmental performance or even reduce safety concerns.

Is stainless steel a metal?

All stainless steels are iron-based alloys containing at least 10.5% chromium. A reaction between that chromium and the oxygen in the atmosphere produces a chromium oxide film at the surface. This allows the film to immediately self-repair in the presence of oxygen in the event of any surface damage. The next layer comes at the mill.