SCADA Modbus OPC Server (Telemetry / OPC DA)

- Designed specifically for remote telemetry type applications.

- Noisy networks are no problem thanks to the robust communication algorithms included.

- Perfect for low bandwidth networks such as radio or satellite.

- Supports Enron, Daniel and most other variations of Modbus.

- Modbus TCP, RTU and ASCII communication modes built in.

What is an OPC Server?

The OPC server converts the hardware communicated data from PLC into OPC protocol. So that other software like SCADA can access the data. The OPC server is a program that often connects with hardware like HMI to get the data and convert it into OPC protocol.

What is OPC protocol in industrial automation?

It is a type of protocol used in Industrial Automation. The OPC is always used in the Client/Server pair. The OPC server converts the hardware communicated data from PLC into OPC protocol. So that other software like SCADA can access the data.

How to implement OPC in a single system?

Usually, the OPC is implemented in a Single Server – Client in a single system format. But there are some famous alternate methods, OPC aggregation – In this method, the OPC Client is connected to several OPC servers to acquire data

What is open platform Communications OPC?

Open Platform Communications. Open Platform Communications (OPC) is a series of standards and specifications for industrial telecommunication. An industrial automation task force developed the original standard in 1996 under the name OLE for Process Control (Object Linking and Embedding for process control).

What is an OPC server?

OPC is a client/server technology. One application acts as the server providing data, and the other acts as a client using data. OPC is a widely accepted industrial communication standard that enables the exchange of data between multi-vendor devices and control applications without any proprietary restrictions.

Is SCADA OPC client?

OPC client Typical examples are MMI and SCADA/HMI systems.

What is OPC server in DCS?

OPC stands for Open Platform Communications or some say OLE (Object Linking and Embedding) for Process Control. It is a type of protocol used in Industrial Automation. The OPC is always used in the Client/Server pair. The OPC server converts the hardware communicated data from PLC into OPC protocol.

Why do we need OPC server?

An OPC server reduces the load on data source devices as it enables communication with several applications, while having only one connection with the data source. This reduces multi-access from the data source, and hence reduces the load on the data source.

What is OPC server Siemens?

dataFEED OPC Server Siemens is a dataFEED OPC Suite component and bundles the functionalities for fast and convenient access to process and diagnostic data in Siemens SIMATIC S7 and Siemens-compatible controllers.

Is PLC a OPC server or client?

OPC is implemented in server/client pairs. The OPC server is a software program that converts the hardware communication protocol used by a PLC into the OPC protocol. The OPC client software is any program that needs to connect to the hardware, such as an HMI .

What is OPC stand for?

Open Platform CommunicationsToday the acronym OPC stands for Open Platform Communications. These are just some of the reasons why so many members and other technology organizations (collaborations) are turning to OPC UA for their interoperability platform.

How do I connect to OPC server?

1.3. Connect to an OPC serverRight click on the OPC DataHub system-tray icon and choose Properties.In the Properties window, select OPC .Check the Act as an OPC Client box. ... Type in or select the necessary information as appropriate. ... Click the Apply button in the Properties Window.

What is the difference between OPC and PLC?

While ordinary portland cement (OPC) may contain up to 5% limestone, PLC contains between 5% and 15% limestone.

What is the difference between OPC server and client?

Client/Server describes the relationship between two computer applications in which one application, the OPC client, makes a service request from another application, the OPC Server, which fulfills the request.

Why do SCADA vendors include OPC in their systems?

The main purpose of the OPC is to enable the safe communication in industrial processes, such as in electric power generation and distribution, industrial hydraulics and pneumatics, petrochemical refining, assembly lines for motor vehicles, etc.

What is OPC UA server and client?

OPC Unified Architecture is the next generation OPC standard that provides secure and reliable access to real-time and historical data as well as events. OPC UA replaces the classic OPC COM architecture which is tightly connected to the Microsoft Windows platform and security model.

What is OPC Datahub?

Engineers working on a high-security project in Denmark used the OPC DataHub, from Cogent Real-Time Systems, for OPC client connections between equipment at the secure facility and a remote monitoring station.

What is the efficiency rating of a CP10?

Using the latest power supply technology, this 240W DIN-Rail single-phase power supply series boasts an unmatched efficiency rating of 95.2%

Can a SCADA system connect to an OPC server?

At the monitoring facility, Barsballe discovered another potential setback. His SCADA systems were not able to connect remotely to an OPC server. They required a local OPC connection, so Barsballe decided to use the tunneling capabilities of the OPC DataHub. He installed two more OPC DataHubs, one on each SCADA system machine, and configured connections across the network to the first OPC DataHub. His SCADA systems each connected to its local OPC DataHub, and the data link was complete. Technicians could now view data from the high-security facility from the safe distance of the monitoring location.

Is OPC networking slow?

However, it soon became apparent that there would be some problems with networking. OPC networking depends on distributed component object model (DCOM), which at the best of times can be difficult to configure and slow to reconnect after a network break.

Who is Rockwell Automation collaborating with?

With skilled labor shortages on the horizon for many manufacturers, Rockwell Automation and Cisco are collaborating with the University of Wisconsin to nurture a more automation-savvy workforce.

Does Barsballe have an OPC server?

After that, they will also attach an OPC server for several meter-reading input devices. All of this data will then be sent across to the SCADA systems, and made available to the service people who need access to it.

What is OPC in automation?

What is OPC? OPC is the interoperability standard for the secure and reliable exchange of data in the industrial automation space and in other industries. It is platform independent and ensures the seamless flow of information among devices from multiple vendors.

What is OPC in computer?

As such, the acronym OPC was borne from OLE (object linking and embedding) for Process Control. These specifications, which are now known as OPC Classic, have enjoyed widespread adoption across multiple industries, including manufacturing, building automation, oil and gas, renewable energy and utilities, among others.

What does OPC stand for?

Today the acronym OPC stands for Open Platform Communications.

Who is responsible for the development and maintenance of the OPC standard?

The OPC Foundation is responsible for the development and maintenance of this standard. The OPC standard is a series of specifications developed by industry vendors, end-users and software developers.

When was the PLC standard first released?

When the standard was first released in 1996, its purpose was to abstract PLC specific protocols (such as Modbus, Profibus, etc.) into a standardized interface allowing HMI/SCADA systems to interface with a “middle-man” who would convert generic-OPC read/write requests into device-specific requests and vice-versa.

What is an OPC server?

An OPC server can communicate data continuously among PLCs on the shop floor, RTUs in the field, HMI stations, and software applications on desktop PCs. Even when the hardware and software are from different vendors, OPC compliance makes continuous real-time communication possible.

What is OPC in automation?

OPC is open connectivity in industrial automation and the enterprise systems that support the industry. Interoperability is assured through the creation and maintenance of non-proprietary open standards specifications.

What is the purpose of OPC?

A major goal of the OPC Foundation and the Data Access specification was to eliminate the need of client application vendors to develop their own proprietary set of communications drivers. For many vendors, the effort required to develop numerous communications drivers outweighed the development effort involved in the client application itself. With the adoption of OPC technology, a vendor could now focus their efforts almost exclusively on the development of the client application. The Data Access specification defines how both the client and the server application interface must be constructed. If the specification is followed properly, a client vendor knows that any OPC server that exists for an industrial device can provide the connectivity needed for data access. Issues like time to market or reliability no longer restrict OPC applications.

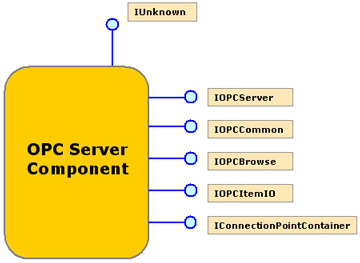

How does an OPC client work?

An OPC client application communicates to an OPC server through the specified OPC custom and automation interfaces. OPC servers must implement the custom interface, and optionally may implement the automation interface.

Why is OPC important?

OPC has given the end user the additional benefit of being able to select best-of-breed software to solve application problems. Historically, if the application software did not have the desired communication driver or if the available driver didn't perform adequately, the only solution was to try to persuade the application vendor to either develop the desired driver or repair an existing driver. The time required to complete either of these solutions was not typically short. With OPC, the end user is no longer tied to the resource limitations of the client application vendor. The user can now choose from a variety of OPC server vendors to address a new driver requirement or remedy a performance issue. Equally, the client application vendor can now focus on the continued improvement of their core product without the disruptive effort required to address communication issues and needs.

What is OPC interoperability?

OPC Interoperability: Open Connectivity Through Open Standards. OPC is a client /server technology. One application acts as the server providing data, and the other acts as a client using data. OPC is a widely accepted industrial communication standard that enables the exchange of data between multi-vendor devices and control applications without ...

What is an inproc handler?

An inproc (OPC handler) may be used to marshal the interface and provide the additional item level functionality of the OPC automation interface.

Case Study

In a recent data integration project, Siemens engineers in Copenhagen, Denmark were able to connect equipment and instrumentation running in a high-security facility to a remote monitoring location, using the OPC DataHub.

Siemens - Denmark

In a recent data integration project, Siemens engineers in Copenhagen, Denmark were able to connect equipment and instrumentation running in a high-security facility to a remote monitoring location, using the OPC DataHub.

What is an OPC server?

This method remains the same regardless of the type and source of data. An OPC Server for one hardware device provides the same methods for an OPC Client to access its data as any and every other OPC Server for that same and any other hardware device. The aim was to reduce the amount of duplicated effort required from hardware manufacturers and their software partners, and from the SCADA (Supervisory Control And Data Acquisition) and other HMI (Human-Machine Interface) producers in order to interface the two. Once a hardware manufacturer had developed their OPC Server for the new hardware device, their work was done with regards to allowing any 'top end' to access their device, and once the SCADA producer had developed their OPC Client, their work was done with regards to allowing access to any hardware, existing or yet to be created, with an OPC compliant server.

What is OPC data access?

IDL and methods for use in process control and manufacturing automation applications to facilitate interoperability. The most common OPC specification is OPC Data Access, which is used for reading and writing real-time data. When vendors refer to OPC generically, they typically mean OPC Data Access (OPC DA). OPC DA itself has gone through three major revisions since its inception. Versions are backwards compatible, in that a version 3 OPC Server can still be accessed by a version 1 OPC Client, since the specifications add functionality, but still require the older version to be implemented as well. However, a Client could be written that does not support the older functions since everything can be done using the newer ones, thus a DA-3-compatible Client will not necessarily work with a DA 1.0 Server.

What is OPC HDA?

In addition OPC DA specification, the OPC Foundation also maintains the OPC Historical Data Access (HDA) specification. In contrast to the real time data that is accessible with OPC DA, OPC HDA allows access and retrieval of archived data.

What is OPC in telecommunications?

Open Platform Communications ( OPC) is a series of standards and specifications for industrial telecommunication. An industrial automation task force developed the original standard in 1996 under the name OLE for Process Control ( Object Linking and Embedding for process control ). OPC specifies the communication of real-time plant data between ...

What is UA in OPC?

The OPC Unified Architecture (UA) has been specified and is being tested and implemented through its Early Adopters program. It can be implemented with Java, Microsoft .NET, or C, eliminating the need to use a Microsoft-Windows -based platform of earlier OPC versions. UA combines the functionality of the existing OPC interfaces with new technologies such as XML and Web Services to deliver higher level MES and ERP support.

What is OPC in plant control?

OPC specifies the communication of real-time plant data between control devices from different manufacturers. After the initial release in 1996, the OPC Foundation was created to maintain the standard. As OPC has been adopted beyond the field of process control, the OPC Foundation changed the name to Open Platform Communications in 2011.

When did OPC Foundation and MTConnect Institute start cooperating?

On September 16, 2010, The OPC Foundation and the MTConnect Institute announced a cooperation to ensure interoperability and consistency between the two standards.