What is OQ training and why is it important?

What Is OQ training? OQ stands for operator qualification. The Pipeline Operator Qualification (OQ) training is a set of courses developed to help pipeline operators meet the DOT Operator Qualification Rule requirements—the OQ Rule (more about that in a moment). And that includes Subpart N 49, Subpart G 49, CFR Part 192, and CFR Part 195.

What is OQ training for pipeline operators?

OQ stands for operator qualification. The Pipeline Operator Qualification (OQ) training is a set of courses developed to help pipeline operators meet the DOT Operator Qualification Rule requirements—the OQ Rule (more about that in a moment). And that includes Subpart N 49, Subpart G 49, CFR Part 192, and CFR Part 195.

What does OQ stand for?

The Operator Qualification rule was adopted into the Code of Federal Regulations under Subpart N in 49 CFR Part 192 and Subpart G in 49 CFR Part 195 . Under the rule, each pipeline operator is responsible for developing an OQ program, following their written OQ plan, establishing a covered task list applicable...

What are the different types of training under the OQ rule?

Under the OQ rule, operators are free to choose from several different types of training. Computer-based and web-based training represent just two choices available to operators. Training is not required, but must be considered, and should be utilized, where appropriate.

How long is OQ training Good For?

MEA supports these efforts through a one-day initial evaluator classroom training and online refresher training. MEA approved OQ evaluator status must be renewed every three years.

What does OQ certified mean?

PG&E Operator Qualification (OQ) overview Operator Qualification is required for any work on the gas pipeline system or in construction of new gas pipeline facilities that will be connected to the gas pipeline system.

How do I get OQ qualified?

We'll identify your needs and design an Operator Qualification process that fits your company from among the following ITS solutions:Create an OQ Plan. Your OQ Plan outlines the covered tasks you perform and details how you qualify your workforce. ... Choose Your Testing and Training. ... Demonstrate Workforce Performance.

What does OQ stand for in pipeline?

Operator Qualification Overview | PHMSA.

What does OQ stand for?

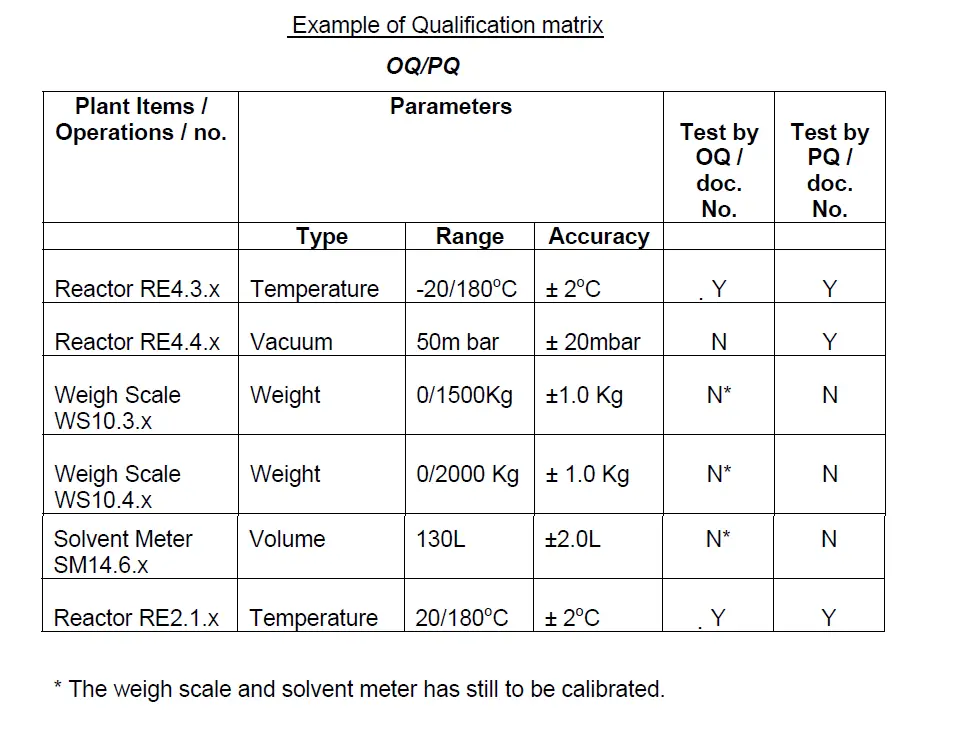

Operational QualificationIQ, OQ, and PQ are sequential activities that manufacturers carry out to validate their manufacturing processes. IQ stands for Installation Qualification, OQ for Operational Qualification, and PQ for Performance Qualification.

What is operational qualification OQ?

Operational Qualification (OQ) OQ's purpose is to determine that equipment performance is consistent with the user requirement specification within the manufacturer-specified operating ranges. In action, this means identifying and inspecting equipment features that can impact final product quality.

Who are qualified operators?

Qualified Operator means an individual responsible for the operation and maintenance of the water and air quality systems and the associated infrastructure of the aquatic facility and who has successfully completed an AHJ-recognized operator training course to operate an aquatic facility offered by an AHJ-recognized ...

What does a pipeline operator do?

A pipeline operator—also known as a pump operator, gauger or gas operator—is a technical professional who controls the flow of gas, oil and other materials through pipelines.

What are some abnormal operating conditions?

Abnormal operating conditions means equipment startup, equipment shut down, Smelter and AQC plant or equipment malfunctions which were not reasonably foreseeable, accidents and emergencies.

What is ASME B31Q?

ASME has been defining piping safety since 1922. ASME B31Q establishes the requirements for developing and implementing an effective Pipeline Personnel Qualification Program.

What causes internal corrosion in pipelines?

Internal corrosion occurs due to environmental conditions on the inside of the pipeline. In most cases, the corrosive materials are contaminants naturally contained within the transported commodity, such as hydrogen sulfide, carbon dioxide, other chemicals, or even water.

What is the maximum operating pressure a pipeline should be allowed to reach?

§ 192.619 Maximum allowable operating pressure: Steel or plastic pipelines. (ii) If the pipe is 123⁄4 inches (324 mm) or less in outside diameter and is not tested to yield under this paragraph, 200 p.s.i. (1379 kPa).

What is Veriforce Qi?

Veriforce is a contractor safety and supplier management services software solution that enables companies to hire and manage safe and certified contractors, and safeguard their supply chain.

What is a covered task?

Covered task means any task that:• Is performed on a pipeline facility;• Is an operations or maintenance task;• Is performed as a requirement of 49 CFR Part 192; and• Could affect the operation or integrity of the pipeline. Sample 1.

What is Operator Qualification?

The Department of Transportation requires that all employees and contractors who work on gas facilities hold their operator qualifications. It is required for workers on all hazardous liquid pipeline job sites, including propane and natural gas. There is no grace period for getting this qualification either. All workers must already have their OQ before working on any covered tasks.

When did the operator qualification requirements start?

The operator qualification requirements were originally put into place by the DOT in 1992. Since then, there have been many changes. To keep up to date on those changes, you’ll want to check out their regulations page on a monthly basis. If you’d like help understanding the rule updates and how each one impacts your business, feel free to get in touch with our team. We are well-versed in all the current rules and are always here to help.

How many protocols are there in OQ?

By addressing all nine protocols, you can keep your jobsite in full compliance of the OQ regulations. Remember to keep new training programs in mind whenever you review how your OQ program is working. You may find that many new programs roll out with regulatory changes, so keep your ear to the ground in figuring out what will best benefit your employees and contractors.

Do you have to have an OQ to operate a pipeline?

One such rule is the need for an operator qualification, or OQ, plan and training. Since it’s designed to improve worker safety and wellbeing, it is non-negotiable and well worth reviewing before you start each job. Here is an overview of everything you need to know.

Should gas facilities have OQ training?

To be safe, all gas facility owners should have every onsite employee and contractor complete OQ training and testing. Since it improves worker safety, prevents costly mistakes, and ensures DOT compliance, it just makes sense to get it done.

What is an OQ plan?

Your OQ Plan outlines the covered tasks you perform and details how you qualify your workforce.

What is an OQ in pipelines?

Federal law requires operators of energy pipelines to have an Operator Qualification (OQ) Plan and Program in place to reduce human error and protect life and property. Discover industry-proven solutions that give pipeline operators the clearest and simplest path to compliance. CONTACT US WITH QUESTIONS.

What is the Train the Trainer program?

Train your instructors and evaluators through our Train-the-Trainer program, which covers training best practices and how to conduct exam testing and performance evaluations following ITS protocols.

Why is operator qualification important?

Operator Qualification is vital for the safety of your employees and communities, and we know the process can get complicated.

Where is Industrial Training Services located?

Industrial Training Services, Inc., a woman-owned small business headquartered in Murray, Kentucky, has provided innovative training products and best-in-class support to the energy industry for over 30 years. ITS is dedicated to maintaining lasting customer relationships by providing groundbreaking and industry-proven compliance tools, training, and products to streamline complex operations and help meet safety, regulatory, and qualification standards.

Is Industrial Training Services an accredited provider?

Industrial Training Services has been approved as an Accredited Provider by the International Association for Continuing Education and Training (IACET). In obtaining this accreditation, ITS has demonstrated that it complies with the ANSI/IACET Standards which are widely recognized as standards of good practice internationally. As a result of their Accredited Provider membership status, ITS is authorized to offer IACET CEUs for its programs that qualify under the ANSI/IACET Standards.

What is training in OQ?

Training is a means to the end result, qualification. Under the OQ rule, operators are free to choose from several different types of training. Computer-based and web-based training represent just two choices available to operators.

Why is it important to provide training prior to reevaluation?

The most important of these is ensuring that the reason for failure is recognized and addressed prior to reevaluation. If fundamental knowledge, skill or ability gaps are disclosed by the failure, additional training should be provided prior to reevaluation.

How long can a non qualified employee work?

There is no set time limit on how long a non-qualified employee may work under the supervision of a qualified worker. The Rule stipulates that non-qualified individuals (new employees, or employees that are no longer qualified) can perform covered tasks only if they are directed and observed by another qualified individual. The operators' written program shall include provisions that demonstrate the operator has control mechanisms or processes in place regarding the utilization of non-qualified personnel to perform covered tasks. The control mechanisms may include:

When can an operator not permit a candidate who fails the reevaluation process to perform the covered task?

An operator must not permit a candidate who fails the reevaluation process to perform the covered task until that person has passed the evaluation or is directly observed by a person who is qualified to perform the covered task.

What does "operation" mean in a system?

However the common dictionary definitions of "operation" (starting, stopping and/or monitoring and controlling devices or systems ) and "maintenance" (the act of maintaining; the work of keeping something in proper condition; upkeep) can be referred to for further guidance.

When is full compliance required?

Operators should have documentation supporting attainment of full compliance by that date. Full compliance by an operator includes its commitment to the requirement that covered tasks may be performed only by qualified individuals or non-qualified individuals who are under the direction and observation of qualified individuals. An operator should be able to demonstrate through documentation that it has fulfilled this requirement.

Do operators have to monitor the performance of individuals qualified to perform covered tasks?

While operators are not required to continuously monitor the performance of individuals qualified to perform covered tasks, the rule does require operators to: (a) evaluate an individual if the operator has reason to believe that the individual's performance of a covered task contributed to an incident (as defined in Part 191) or accident (as defined in Part 195); and (b) evaluate an individual if the operator has reason to believe that the individual is no longer qualified to perform a covered task. The operator should document in its OQ Program how it intends to satisfy these requirements.

Why are pipeline operators required to have individuals who perform covered tasks trained and qualified?

To assure safety in the transport of hazardous gases and liquids in the nation’s pipelines , pipeline operators are required to have individuals who perform covered tasks trained and qualified.

How to become qualified for EnergyU?

Generally, to gain an INITIAL qualification for a specific covered task, an individual must complete the EnergyU online training (TNG), and then pass the knowledge test (KNT) and performance evaluation (PEF) for the task.

What is OQ training?

Training is a means to the end result, qualification. Under the OQ rule, operators are free to choose from several different types of training. Computer-based and web-based training represent just two choices available to operators. Training is not required, but must be considered, and should be utilized, where appropriate. Any computer-based or web-based training must be tailored to: (1) determine if the individual is able to perform the covered task (s); and (2) recognize and react to any AOC which may be reasonably anticipated to occur during the performance of that covered task. If computer-based or web-based training accomplishes these objectives and is accepted by the Operator and regulator (s), then it has a role in complying with the OQ Rule. Training programs will be reviewed by regulators for adequacy during inspections (also see FAQ 1.11).

What is the OQ rule?

The OQ rule requires that an operator must have provisions to “evaluate an individual if the operator has reason to believe that the individual's performance of a covered task contributed to an incident (or accident)”. Therefore, an operator must have a process for investigating incidents (or accidents) that identifies factors contributing to the incident in sufficient detail to determine whether or not performance of a covered task may have contributed to that incident or accident. If the answer is in the affirmative, the process must be able to identify the individual (s) that performed that task and provide for the appropriate corrective action (reevaluation) to be taken. If WPHR is to be used as one possible reevaluation method, consideration must be given to the individual (s) contributing to an incident through the performance of a covered task in subsequent reevaluations of that individual.

Why should operators have some means in place?

Operators should have some means in place to make sure that field supervisors can verify that individuals are currently qualified for the tasks that they are performing. Some means is needed to allow a supervisor or foreman to determine the covered tasks for which persons under his/her supervision are qualified. FAQ #3.1 discusses some of these methods.

What is the purpose of the Operator Qualification Rule?

A major purpose of the operator qualification rule is to eliminate job performance errors that might affect the integrity of pipeline systems. Such errors can be inadvertent (e.g., forgetting a step in implementation of a procedure) or systemic (e.g., practices that are inconsistent with written procedures, such as purposely ignoring SCADA system alarms because they are known to be inaccurate). Elimination of systemic errors is as important as eliminating inadvertent ones. Therefore, operators should incorporate into their qualification program provisions for ensuring that practices in the field are the same as those documented in the operator’s O&M Plan, which provide the basis on which persons are qualified. Such provisions might include field audits of on-the-job performance by separate audit units within the company.

What is the final rule of OQ?

The OQ Final Rule preamble (64 FR 46853; August 27, 1999) states that the operator must establish the parameters for a Work Performance History Review. Such a review should include, as a minimum:

How long do you have to keep a record of a prior training?

According to §192.807 (b)/§195.507 (b), records of prior qualification and records of individuals no longer performing covered tasks must be retained for a period of five years. If qualification was completed during the interval from 12/26/99 to 10/28/02 (as it has been in most cases) then the applicable qualification records must be available for a period of at least five years from the date of the first qualification. If the operator believes that records documenting training of individuals are necessary to support qualification, then these records must also be maintained.

How long can a non qualified employee work?

There is no set time limit on how long a non-qualified employee may work under the supervision of a qualified worker. The Rule stipulates that non-qualified individuals (new employees, or employees that are no longer qualified) can perform covered tasks only if they are directed and observed by another qualified individual. The operators’ written program shall include provisions that demonstrate the operator has control mechanisms or processes in place regarding the utilization of non-qualified personnel to perform covered tasks. The control mechanisms may include: