What are phenolic boards and their use or mostly used for )?

These include laminates, wood panels, etc. This special coating gives phenolic panels special protection against moisture. That is why phenolic boards are often used to manufacture furniture and other wood objects to be used in particularly damp environments such as bathrooms, toilets and changing rooms.

What is a phenolic plywood?

PHENOLIC PLYWOOD Surface with an overlay is smooth, glossy and hard. It resists abrasion, it is weather and moisture proof and resists commonly used chemicals, dilute acids and alkalis. The surface is easy to clean with water or steam.

Can I use phenolic board for flooring?

Phenolic Board as Floor Covering This 34″ thick phenolic overlaid birch board is also used in the transportation industry for truck and bus flooring. It is intended for use as flooring in work platforms, scaffolding, warehouses, and other wet environments.

Is phenolic waterproof?

Phenolic Formaldehyde resin are one kind of thermosetting resin with heat resistant, waterproof and the most used for exterior application or superior water resitance (e.g. external wall house, roof), with low formaldehyde excess.

Which is better phenolic or plywood?

Phenolic surfaces Amongst the various types of plywood available, phenolic provides the toughest and most stable surface. The phenolic surface resists cracking and splitting from fasteners extremely well.

How do you cut phenolic plywood?

Saws with carbide tips should be made of high-speed cutting steel. A chop saw equipped with a diamond or ceramic abrasive can also perform wet-cutting. Cut the phenolic board slowly to avoid melting the wax. Look for waste shavings that resemble the appearance of wood shavings when chopped with a table saw.

Is phenolic ply waterproof?

The plywood sheets are manufactured to a high standard, making them resistant to corrosion and moisture. The coating of the wood is phenolic resin and it is this coating that makes it waterproof.

Do termites eat phenolic board?

Further, the numerous grades of phenolic board with beneficial properties such waterproof, fire resistant, termite and weed resistant is also accelerating the growth of the phenolic board market during the forecast period.

How strong is phenolic?

PhenolicASTM or UL testPropertyHeat resistantMECHANICALD651Tensile strength (psi)5,000- 6,000D790Flexural modulus (105 psi)14D790Flexural strength (psi)10,00016 more rows

Is phenolic board strong?

Phenolic panels are among the most innovative new architectural products available today. They combine cellulose and resin to make a strong, durable, and lightweight building material that sees usage in many parts of a building.

What is the meaning of phenolic?

noun. Definition of phenolic (Entry 2 of 2) 1 : a usually thermosetting resin or plastic made by condensation of a phenol with an aldehyde and used especially for molding and insulating and in coatings and adhesives.

What is marine plywood called?

Marine-grade plywood, often simply called marine plywood, is not what it's often claimed to be. That is, it's not waterproof. It is a good-quality, hardwood plywood made with waterproof glue, but since it's not treated with chemicals, it is not rot-resistant.

What type of material is phenolic?

Phenolics are the result of polymerization between layers of paper, canvas, linen, or glass cloth impregnated with synthetic thermosetting resins. This laminated material is a popular alternative to acrylic because of its high resistance to flexing.

What is the meaning of phenolic?

noun. Definition of phenolic (Entry 2 of 2) 1 : a usually thermosetting resin or plastic made by condensation of a phenol with an aldehyde and used especially for molding and insulating and in coatings and adhesives.

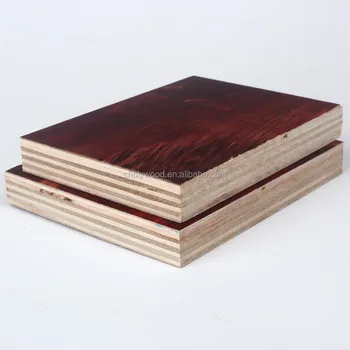

How is phenolic plywood made?

Phenolic Plywood is made of high-grade birch that is soaked in phenolic resin creating an extremely hard-waring, water-resistant ply. Our phenolic faced plywood is made up of 15 layers, so it is very tough and resists splitting and cracking and stands up well to being worked on.

What is phenolic board made of?

Phenolic boards are made up of wooden sheets that are glued together using Phenol-Formaldehyde, hence the name. A protective film is placed at the top and bottom faces.

Why use plywood for exterior wall?

Plywood exterior wall sheathing is often used in areas that see extreme weather, particularly wind, as it has great flexibility, which is why it is also used in many homes for the purposes of earthquake resistance. Do keep in mind that exterior grade plywood needs to be used for this application.

How is plywood made?

Just in case you don’t know, plywood is a special type of engineered wood that is made by taking solid wood and turning it into thin strips. Those long and thin strips of wood are then glued together in a cross-grain fashion. A mixture of adhesives, temperature, and pressure is used to press those wood strips together into boards.

Why is plywood not used as a main floor?

That said, plywood is not often used as the main floor because it just doesn’t look nice enough. Moreover, there are much more durable materials that can be used for the main floor, ones that are much more resistant to wear and tear.

What is the best material for backing shingles?

Plywood is a material that is often used in the roofing industry. It is very thin and lightweight and therefore makes for a great backing for shingles. Plywood is very durable, it can handle a lot of weight and if you get the right type, it can be very moisture resistant too.

Which is better, plywood or solid wood?

Sure, solid wood may be more durable and look a bit better, but it’s also way more expensive and harder to work with. If you need a cheap, fast, and simple shed that will keep the things on the inside dry, then plywood is a great way to go. 6. Skateboard Ramps.

What material is used to make a skateboard ramp?

Skateboard Ramps. This is something you might not have thought of, but the one and only material that is used to make that curved skateboard ramp is plywood. When it comes down to it, plywood is very easy to bend due to its flexibility, but because of its cross-grain pattern, it retains a whole lot of strength.

What is 2x6 plywood?

Many homes in North America are built using 2×4 or 2×6 foot panel frames, skinned in exterior grade plywood sheeting. It is used to fasten the studs together, which helps add strength to the frame of the home. These plywood panels help prevent vertical and horizontal shifting, thus keeping the structure both square and intact.