What are the different uses of polystyrene?

few of the places that you’ve probably seen polystyrene:

- Plastic cutlery

- Shipping and packing materials

- Insulation in buildings

- Food packaging

- Libraries

What products are made from polystyrene?

Polystyrene

- Uses & Benefits. Refrigerators, air conditioners, ovens, microwaves, vacuum cleaners, blenders – these and other appliances often are made with polystyrene (solid and foam) because it is inert (doesn’t react ...

- Safety Information. In the United States, the U.S. ...

- Polystyrene Safety in Food Packaging. ...

- Answering Questions

What is polystyrene used for?

Usually in the form of foam or plastic, polystyrene is a non-toxic and odorless material and is one of the predominant plastics used in the food packaging industry as well as the automation industry. Its solidity and clarity make it useful for everything from automobile parts and electronics to toys and plastic utensils.

What are the properties of polystyrene?

Properties of Polystyrene

- Polystyrene exists in an amorphous state because of the presence of bulky phenyl groups, packing of polystyrene chains is not efficient.

- Polystyrene is non-polar in nature.

- The polystyrene melting point is 240 degrees Celsius.

- Polystyrene density is 1.05 g/cm3

- The polystyrene boiling point is 430 degrees Celsius.

What is an example of polystyrene?

Polystyrene (solid and foam) is widely used to protect consumer products. CD and DVD cases, foam packaging peanuts for shipping, food packaging, meat/poultry trays and egg cartons typically are made with polystyrene to protect against damage or spoilage.

Is plastic the same as polystyrene?

Polystyrene (PS) plastic is a naturally transparent thermoplastic that is available as both a typical solid plastic as well in the form of a rigid foam material. PS plastic is commonly used in a variety of consumer product applications and is also particularly useful for commercial packaging.

What is polystyrene used for?

It is widely employed in the food-service industry as rigid trays and containers, disposable eating utensils, and foamed cups, plates, and bowls. Polystyrene is also copolymerized, or blended with other polymers, lending hardness and rigidity to a number of important plastic and rubber products.

Is polystyrene plastic toxic?

Why ban polystyrene foam? Studies show that styrene, a likely carcinogen, can leach from polystyrene foam cups and containers when heated. Never put hot food/drink into polystyrene foam containers, and never microwave these (or any plastic) products!

Is polystyrene toxic to humans?

Although the migration of styrene monomers in foods and food contact materials (FCMs)86 is a concern, polystyrene products are useful for food packaging87,88 and are thought to be harmless. We confirmed that PS particles were not toxic to human cells at an experimental dosage of approximately 500 µg/mL.

Is polystyrene plastic BPA free?

Styrene , a chemical believed to cause cancer, can leach out of polystyrene containers, though the amount of styrene in packaged foods is very low. This is a catch-all category for plastic that doesn't fall into the other categories. It contains BPA and is generally not considered safe.

What are the disadvantages of polystyrene?

Disadvantages of Polystyrene include: Brittle, poor chemical resistance especially to organics. Susceptible to UV degradation. Flammable.

Is polystyrene eco friendly?

Despite what you may have heard, expanded polystyrene (EPS) is environmentally friendly. Made from 98% air, no toxic substances are used in the manufacture of EPS and it is 100% recyclable.

Can polystyrene be recycled?

Yes, polystyrene is recyclable! While polystyrene recycling is not as popular as recycling glass, paper, disposed batteries or aluminium cans, there are recycling initiatives that recognise its importance. Here are some ways to recycle polystyrene. Polystyrene materials can be reprocessed and moulded into new products.

Why is polystyrene banned?

The chemical can easily contaminate food and drinks, and may affect our hormones and contribute to health problems. The manufacturing of the product can also release harmful chemicals that pollute the air and water, and cause ozone layer depletion.

Why should polystyrene be banned?

Expanded Polystyrene (EPS) or Styrofoam, is a petroleum-based non-biodegradable foam, which the EPA and International Agency for Research on Cancer consider styrene a “possible human carcinogen” and “that such materials can have serious impacts upon human health, wildlife, and aquatic environment, and the economy.”

How long does styrene stay in your system?

After an 8-hour exposure of workers to styrene at concentrations of 26–130 mg/m3 (6.1–30.5 ppm), both metabolites have a half-life of about 2.5 hour for the first phase and 30 hours for the second (35). These compounds are used in assessing occupational exposure to styrene.

What are the 2 types of plastic?

Thermoplastic and thermosetting As mentioned above, polymers that are classified as plastics can be divided into two major categories: thermoplastics and thermosets. Thermoplastics such as polyethylene and polystyrene are capable of being molded and remolded repeatedly.

Is poly a plastic?

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging (plastic bags, plastic films, geomembranes and containers including bottles, etc.).

What are the two kinds of plastic?

Depending on physical properties, plastics are divided into two types: Thermoplastic and thermosetting. Thermoplastic: Plastics that can be deformed easily upon heating and can be bent easily. Linear polymers and a combination of linear and cross-linked polymers come under thermoplastics.

What are the 2 categories of plastic?

So even though the number of plastics is unclear, plastics makers tend to group plastics into two general classes: thermoplastics and thermosets.

What do public health organizations say about polystyrene foodservice packaging?

Public health officials encourage the use of sanitary, single-use foodservice packaging (such as polystyrene) in appropriate settings. Single-use f...

What do regulatory agencies say about the safety of polystyrene foodservice packaging?

In the United States, FDA strictly regulates all food packaging materials, including polystyrene. FDA has for decades stated that polystyrene is sa...

What do scientific experts say about the safety of polystyrene foodservice packaging?

From 1999 to 2002, a 12-member international expert panel selected by the Harvard Center for Risk Analysis conducted a comprehensive review of pote...

Is it common for substances from packaging to “migrate” into food?

All packaging – glass, aluminum, paper and plastics (such as polystyrene) – contains substances that can “migrate” in very tiny amounts to foods or...

Where does styrene come from?

Styrene occurs naturally in many foods and beverages. Its chemical structure is similar to cinnamic aldehyde, the chemical component that creates c...

How can people come into contact with styrene?

People can come into contact with styrene from the small amounts that may be present in air (primarily from automobile exhaust and cigarette smoke)...

What is Styrofoam made of?

Many people incorrectly use the name STYROFOAM® to refer to polystyrene in food service; STYROFOAM® is a registered trademark of The Dow Chemical C...

What are styrene uses?

For more than 70 years, styrene has been used as a chemical building block to make the materials used in a wide variety of finished consumer produc...

What is the difference between styrene and polystyrene?

The difference is chemistry. Styrene is a liquid that can be chemically linked to create polystyrene, a solid plastic that displays different prope...

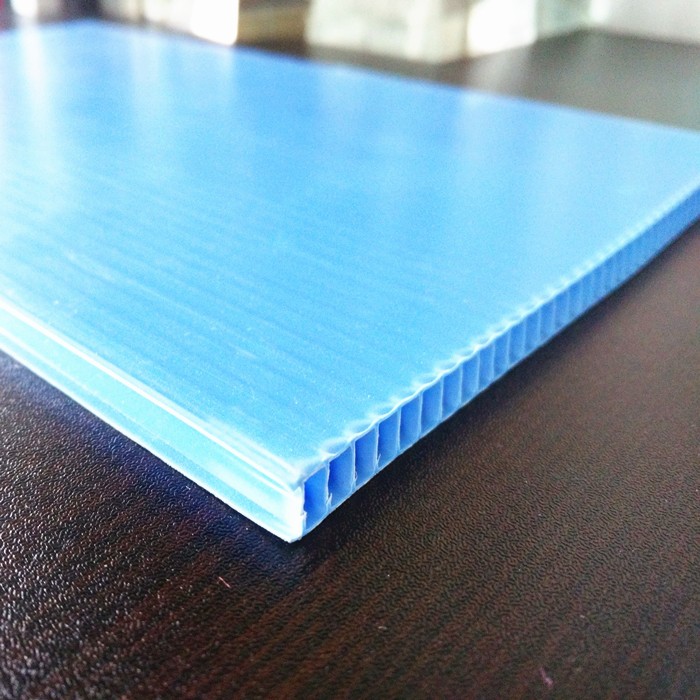

What is extruded polystyrene foam?

Extruded polystyrene (XPS) foam is a rigid insulation that has also formed with polystyrene polymer, but manufactured using an extrusion process. T...

What is polystyrene used for?

polystyrene is extensively used in packaging applications like meat and sea-food packaging, egg cartons, vegetable packaging, etc.

What are the advantages of polystyrene?

Ideal for Hydro Cooling Light-weight Water-Resistant Fabulous shock absrobtion abilities Great dimensional stability Good insulation properties

How can people come into contact with styrene?

People can come in contact with styrene though air(though ciggerate smoke and sutombile exhaust). FDA has approved styrene as a food additive – it...

What is polystyrene made of?

What is Polystyrene? Polystyrene is a naturally transparent and synthetic thermoplastic extracted from a styrene monomer. It is typically available in two forms – Solid Plastic and rigid foam material.

How many grades of polystyrene are there?

There are three main grades of polystyrene used worldwide.

How is PS Made?

Like other thermoplastics, PS is made by filtration of hydrogen fuels into lighter groups called “fractions”. Some of those fractions are blended with certain catalysts to though polystyrene; the process is called polymerization. PS foams are made by “Blowing agents” that enlarge or lengthen and shape the foam so that it can trap air.

What is a GPPS?

GPPS: General-purpose polystyrene is a crystal clear polymer, and it is rigid and rather brittle in its nature and an in-expensive thermoplastic extracted from styrene monomer. GPPS is solid form plastic that is usually manufactured in the form of 2-5 mm pellets.

How much is polystyrene worth in 2023?

PS plastic and foam will have a market value of over USD 33 Billion by the end of 2023.

What is EPS in packaging?

EPS: Expanded Polystyrene is comprised of beads commanded by pentane ( the blowing agent). EPS is widely utilized in packaging applications and boasts good processability, high impact resistance, and thermal insulation.

What are the disadvantages of polystyrene?

Disadvantages of Polystyrene – 1 High Flammability. Should be handled carefully 2 Recycling is possible but is very expensive 3 Harmful to environment 4 EPS, due to its low density, fill a large amount of space in the landfills.

What is polystyrene polymer?

Polystyrene is an addition polymer that results when styrene monomers interconnect ( polymerization ). In the polymerization, the carbon-carbon π bond of the vinyl group is broken and a new carbon-carbon σ bond is formed, attaching to the carbon of another styrene monomer to the chain.

When was polystyrene discovered?

Polystyrene was discovered in 1839 by Eduard Simon, an apothecary from Berlin. From storax, the resin of the Oriental sweetgum tree Liquidambar orientalis, he distilled an oily substance, a monomer that he named styrol.

How is styrene butadiene rubber made?

Styrene-butadiene rubber (SBR) is produced like PS-I by graft copolymerization, but with a lower styrene content. Styrene-butadiene rubber thus consists of a rubber matrix with a polystyrene phase dispersed therein. Unlike PS-I and SBC, it is not a thermoplastic, but an elastomer. Within the rubber phase, the polystyrene phase is assembled into domains. This causes physical cross-linking on a microscopic level. When the material is heated above the glass transition point, the domains disintegrate, the cross-linking is temporarily suspended and the material can be processed like a thermoplastic.

Why is polystyrene not recycled?

Most polystyrene products are currently not recycled due to the lack of incentive to invest in the compactors and logistical systems required . Due to the low density of polystyrene foam, it is not economical to collect. However, if the waste material goes through an initial compaction process, the material changes density from typically 30 kg/m 3 to 330 kg/m 3 and becomes a recyclable commodity of high value for producers of recycled plastic pellets. Expanded polystyrene scrap can be easily added to products such as EPS insulation sheets and other EPS materials for construction applications; many manufacturers cannot obtain sufficient scrap because of collection issues. When it is not used to make more EPS, foam scrap can be turned into products such as clothes hangers, park benches, flower pots, toys, rulers, stapler bodies, seedling containers, picture frames, and architectural molding from recycled PS. As of 2016, around 100 tonnes of EPS are recycled every month in the UK.

How long does it take for polystyrene to biodegrade?

Waste polystyrene takes hundreds of years to biodegrade and is resistant to photo-oxidation.

Which is stronger, acrylonitrile or polystyrene?

Acrylonitrile butadiene styrene (ABS) is a material that is stronger than pure polystyrene.

What is the name of the substance that is heated with styrol?

This eventually led to the substance receiving its present name, polystyrene.

What are the Characteristics of Polystyrene?

Depending on the type of PS it could be classified as a “thermoplastic” or a “thermoset” material. The name has to do with the way the plastic responds to heat. Thermoplastic materials become fully liquid at their melting point (210-249 degrees Celsius in the case of Polystyrene), but they begin to flow at their glass transition point (100 degress Celsius for PS). A major useful attribute about thermoplastics is that they can be heated to their melting point, cooled, and reheated again without significant degradation. Instead of burning, thermoplastics liquefy, which allows them to be easily injection molded and then subsequently recycled. Thermoset plastics, by contrast, will not reliquify once they are “set” in solid form.

Why is Polystyrene used so often?

At Creative Mechanisms, we have used Polystyrene in a number of applications across a range of industries. For many years Polystyrene, or as it is often referred to as just Styrene, was used as the go-to prototyping material - basically for the same reasons we now use ABS. It's inexpensive, readily available, white in color, and it glues, sands, cuts, and paints well. The “S” in ABS is Styrene. A lot of older engineers and designers who have been in the industry for a while will ask for a Styrene model when they’re looking for a quick-down-and-dirty prototype. We still have a lot of sheets of Styrene in the shop at Creative Mechanisms. We will use them to make quick test models, paint samples, vacuum formed or thermoformed prototypes, or large models that can be created with flat sheets.

What Are The Different Types of Polystyrene?

Three major types of polystyrene include polystyrene foam, regular polystyrene plastic, and polystyrene film. Amongst the different types of foam are expanded polystyrene (EPS) and extruded polystyrene (XPS). EPS includes the most well-known and common types of polystyrene to include styrofoam and packing peanuts. XPS is a higher density foam typically used in applications like architectural building models. Some types of polystyrene plastic are copolymers. Oftentimes homopolymer PS is fairly brittle and can be made more impact resistant if combined with other materials (known in this form as the copolymer High Impact Polystyrene, or HIPS). Polystyrene film can also be vacuum formed and used in packaging applications. Films can be stretched into oriented polystyrene (OPS) that is cheaper to produce (albeit more brittle) than alternatives like PP.

What is PS plastic?

What is PS, and What is it Used For? Polystyrene (PS) plastic is a naturally transparent thermoplastic that is available as both a typical solid plastic as well in the form of a rigid foam material. PS plastic is commonly used in a variety of consumer product applications and is also particularly useful for commercial packaging.

Why is polystyrene so controversial?

The material is somewhat controversial amongst environmental groups because it is slow to biodegrade and is increasingly present as outdoor litter (particularly in the form of foam floating in waterways and the ocean). The solid plastic form of polystyrene is commonly used in medical device applications like test tubes or petri dishes, ...

What is foam used for?

The foam form of polystyrene is used most often as a packing material. You have probably unpacked a custom styrofoam housing if you’ve ever bought a new television, or a significant piece of new equipment like a Miter saw.

What temperature does thermoplastic melt?

Thermoplastic materials become fully liquid at their melting point (210-249 degrees Celsius in the case of Polystyrene), but they begin to flow at their glass transition point (100 degress Celsius for PS). A major useful attribute about thermoplastics is that they can be heated to their melting point, cooled, and reheated again without significant ...

Overview

Forms produced

Polystyrene is commonly injection molded, vacuum formed, or extruded, while expanded polystyrene is either extruded or molded in a special process. Polystyrene copolymers are also produced; these contain one or more other monomers in addition to styrene. In recent years the expanded polystyrene composites with cellulose and starch have also been produced. Polystyrene i…

History

Polystyrene was discovered in 1839 by Eduard Simon, an apothecary from Berlin. From storax, the resin of the Oriental sweetgum tree Liquidambar orientalis, he distilled an oily substance, a monomer that he named styrol. Several days later, Simon found that the styrol had thickened into a jelly he dubbed styrol oxide ("Styroloxyd") because he presumed an oxidation. By 1845 Jamaican-born chemist John Buddle Blyth and German chemist August Wilhelm von Hofmann sh…

Structure

In chemical terms, polystyrene is a long chain hydrocarbon wherein alternating carbon centers are attached to phenyl groups (a derivative of benzene). Polystyrene's chemical formula is (C 8H 8) n; it contains the chemical elements carbon and hydrogen.

The material's properties are determined by short-range van der Waals attractio…

Degradation

Polystyrene is relatively chemically inert. While it is waterproof and resistant to breakdown by many acids and bases, it is easily attacked by many organic solvents (e.g. it dissolves quickly when exposed to acetone), chlorinated solvents, and aromatic hydrocarbon solvents. Because of its resilience and inertness, it is used for fabricating many objects of commerce. Like other organic compounds, polystyrene burns to give carbon dioxide and water vapor, in addition to othe…

Co-polymers

Ordinary (homopolymeric) polystyrene has an excellent property profile about transparency, surface quality and stiffness. Its range of applications is further extended by copolymerization and other modifications (blends e.g. with PC and syndiotactic polystyrene). Several copolymers are used based on styrene: The crispiness of homopolymeric polystyrene is overcome by elastomer-modified styrene-butadiene copolymers. Copolymers of styrene and acrylonitrile (SAN) are mor…

Environmental issues

Polystyrene foams are produced using blowing agents that form bubbles and expand the foam. In expanded polystyrene, these are usually hydrocarbons such as pentane, which may pose a flammability hazard in manufacturing or storage of newly manufactured material, but have relatively mild environmental impact. Extruded polystyrene is usually made with hydrofluorocarbons (HFC-134a), whi…

Safety

The American Chemistry Council, formerly known as the Chemical Manufacturers' Association, writes:

Based on scientific tests over five decades, government safety agencies have determined that polystyrene is safe for use in foodservice products. For example, polystyrene meets the stringent standards of the U.S. Food and Drug Administration and the European Commission/European Fo…