What is make-to-order supply chain?

Make-To-Order in Supply Chain Make-To-Order or Made-To-Order (MTO) is a production method used by several businesses . In this methodology, the manufacturing process starts only after a confirmed order from a customer is received. This leads to increased time in delivery but allows for greater customisation.

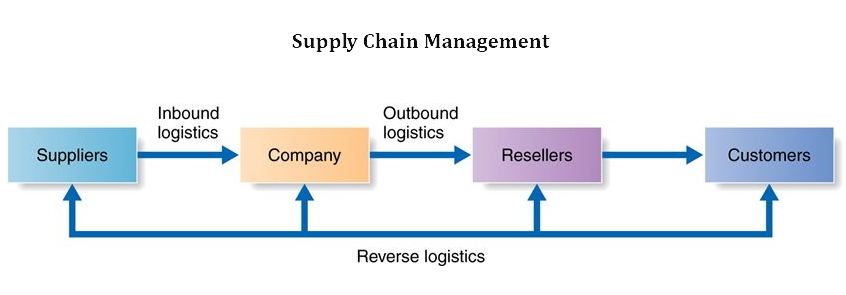

What is the role of a supply chain?

The major role of the supply chain management is to assure that the demand of customers is met with the supply of the products. Supply chain role has to assure that the companies never produce extra or insufficient products. Here we have everything you should know about the supply chain roles and responsibilities.

What does a supply chain end with?

Supply chains consist of several supply chain steps. In many supply chains, the first step is that companies unearth raw materials. These materials are then moved and/or transformed by: In the final step, the end customer gets a delivery of a product or service.

What are the benefits of supply chain?

What Are the Benefits of Supply Chain Sustainability?

- Reduced environmental impact. ...

- Greater business efficiency that can reduce operating costs. ...

- Better continuity of supply. ...

- Improved organizational reputation. ...

- Opportunities to expand corporate partnerships. ...

- Helps you to win business. ...

- Facilitates innovation. ...

- Improved talent attraction and retention, and increased employee satisfaction. ...

How is postponement important in supply chain?

Postponement lessens the forecasting horizon and thereby solves the uncertainty of end product demand (Whang and Lee, 1998). Also better inventory performance can be achieved by redesigning a product or its supply chain.

What is the postponement strategy?

A postponement strategy is a strategy that businesses implement in their supply chain or distribution networks to delay the customization of products. Implementing a postponement strategy allows businesses to decrease costs.

What is postponement example?

Postponement is a concept in supply chain management where the manufacturer produces a generic product, which can be modified at the later stages before the final transport to the customer. Take for example an umbrella manufacturer who does not know what the demand will be for different colored umbrellas.

What companies use postponement strategy?

Well-known businesses such as Dell use postponement to keep remarkably low inventories while maintaining short lead times. Toyota also employs postponement strategies to make vehicles to specific customer requirements, without excess inventory or long lead times.

What are the benefits of postponement strategy?

Reduction in inventory - one of the key benefits that you can realise through postponement manufacturing is a reduction in finished goods stock. Finished units would be configured, tested, packaged and shipped out only when firm demand has been confirmed - i.e. an order has been placed.

What is the concept of postponement quizlet?

The concept of postponement: seeks to reduce the risk of anticipation. What is the primary reason that the time to market has decreased? information technology.

What is the primary meaning of postponement?

Postponement adds flexibility and agility to manufacturing and distribution processes. What is the primary meaning of postponement? Speed up. Stay the same. Regulation.

What is postponement in warehousing?

Assembly Postponement This means delay in the assembly of the final product until the customer order is received.

How postponement can help pharma manufacturers increase supply chain performance

Postponement is a supply chain strategy for rapid response to changing market conditions. Lead times are reduced, working capital is cut and waste is minimized.

A solution for pharma

Postponement models improve on-time, in-full (OTIF) performance metrics, reduce lead times and decrease stock inventory. They are particularly suitable for high-value, low-volume medicines with short shelf lives, such as cell and gene therapies and rare disease medicines.

Understand rationale and complexity

The rationale for postponement needs to be clear from the outset. Analysis should show how issues would be resolved through its application.

Design for responsiveness and resilience

To design a postponement supply chain network, organizations should be guided by important factors, such as OTIF, lead time, working capital, CAPEX or OPEX. Scenarios can be developed and assessed to determine locations of hubs and bright stocks (unlabeled finished products) locations.

Determine financial returns and execute

Companies can benefit by evaluating two to three network options in terms of OPEX and CAPEX, as well as key criteria such as speed to market, scalability and ease of implementation.

What is a postponement strategy?

The postponement strategy leverages the above characteristics of demand forecasting. It dictates that the firms should postpone the creation or delivery of the final product as long as possible. For retailers, this takes the shape of postponing the delivery of the final product to its destination, while for assemble-to-order manufacturers this means postponing the final assembly of the product. For manufacturing scenarios like build-to-stock, the postponement strategy may drive pushing the packaging or final assembly of the products, allowing the manufacturer to personalize, configure finished products to customer orders, and change the final product mix to suit any changes in demand. The postponement strategy effectively reduces inventory obsolescence and takes out the risk and uncertainty costs associated with having undesirable products, but it requires an integrated and agile supply chain to ensure that the latest demand forecasts can be frequently created and propagated through the supply chain to produce or allocate the right products for their customers.

Can medical supplies be postponed?

Therefore, medical supplies manufacturer cannot select postponement as their supply chain strategy any more than a grocer can postpone delivering their cereal.

Is postponement a supply chain strategy?

While postponement is conventionally thought of as a supply chain strategies, a little thinking will dispel this notion. Postponement is not an absolute choice, it is an imperative forced by the type of industry, assortment, and demand patterns. For example, a postponement strategy for delivering supplies to a trauma center or cereal ...

Does Dell have postponement?

For example, Dell has mastered the art of postponement for their custom-designed machines for individual consumers. When Dell started, this was not necessarily the case in the industry, however, Dell invented a new business model and leveraged postponement as a business model – not as a supply chain strategy – though, ...

Is postponement a choice?

The situations in which postponement may be an explicit choice to be made for a supply chain are limited, but may become real options for specific categories of products or sales channels of a company. For example, Dell has mastered the art of postponement for their custom-designed machines for individual consumers.

How does postponement affect the supply chain?

The biological products life cycle of product is the concern in respect to inventory risks and this is in contrast with electronics industries where short product life cycles in the market are a key driver of postponement. Postponement reduces the uncertainty and risks coupled with product variety. In additional, it saves costs and adds values to the supply chain by eliminating obsolete inventory and making the product to customer’s specification more easily. The accelerating need for simultaneous product differentiation, rapid delivery, regional product variation and competitive cost levels are also the factors that led to the usage of postponement strategy.

What is a postponement?

Postponement is a mass customization technique that is applicable for certain products that can have their variety postponed until just before shipping. Here’s a list of methods for achieving mass customization: Create products and services that are customizable by customers (involving design function)

Why is postponement important?

Postponement is first implemented in manufacturing processes to reduce cost of inventory and improve service level within the company while the product variety increases. The concept of postponement is to delay the change in form, identity and place to the latest possible point until customer commitments have been obtained.

What are the different types of postponements?

Five types of postponements are there: labeling postponement, packaging postponement, assembly postponement, manufacturing postponement and time postponement. Labelling and packaging postponement is related to the level of postponement in deferred packaging, both impacting the place and form of the finished product.

What is Dell supply chain?

Dell’s supply chain is a model of excellence, one to be emulated. Dell Computers created a unique model within the computer industry by pioneering the build to order computer. Dell uses an assortment of techniques; postponement, modularity, vendor managed inventory, supply chain partnerships, and demand management that support build ...

Does Amazon use dropship?

In practice, Amazon.com usually chooses to work closely with its vendors and the United States Postal Service to ensure that it can use such a postponement strategy (drop-ship) to handle the volume and delivery timing of a popular product.

What is postponement supply chain?

A postponement supply chain strategy is nothing more than an order fulfillment strategy, one that reduces risk by making sure the company only manufactures, ships and invoices a customer what they want, when they want it. Ultimately, it’s a strategy that allows a company to deliver a customised product offering at the last possible moment.

What is postponement strategy?

At its core, it is a method of pushing products to customers and then relying upon those customers to determine when the supply chain should pull the remaining requirements to finish their purchase order. This is the essence of a push-pull strategy: it works because it pushes ...

How does a time postponement benefit a SME?

The benefit for any SME is that it is able to run a strategy that meets the unique demands of its customer base, while also reducing the time it takes to deliver those products. Ultimately, the strategy adopts a time postponement approach, one where the customer gets a tailor-made finished good at the time of their choosing. The company reduces its time to market, while the customer gets a tailor-made solution.

How does postponement work?

The postponement strategy only works if the gross profit margins on the final sale are high enough to compensate for the costs of financing and holding the semi-finished goods. In essence, it costs money to manufacture, assemble and hold semi-finished goods. The longer it’s held in stasis, the higher the costs.

Why is it important for a SME to have multiple vendors?

This often requires having multiple agreements with multiple vendors in order to compensate for any delays in incoming shipments.

What is a strong supply contract?

Strong Supply Contracts. A company must have strong supply contracts, ones that clearly define the costs of retaining inventory for both parties. Vendors will be required to hold inventory until demand is confirmed. This means they must incur their own costs to retain that inventory within their warehouse.

How to maximize seasonal business?

Maximize seasonal business by anticipating high and low demand periods, thereby reducing how long the company holds semi-finished goods.

What is a postponement strategy?

What is Postponement? Postponement is a business strategy that aims to maximize the possible benefit and minimize risk by delaying current investment into a product or service until the last possible moment.

What are the types of postponements?

The five types of postponement are labelling, packaging, assembly, manufacturing and time postponements. Postponement is a very important concept used in Supply Chain Management wherein the manufacturer on produces a generic product, to be modified at later stages before transporting it to the customer. For example, an umbrella manufacturer may ...

Is postponement strategy universally applicable?

However, postponement strategy is not universally applicable. It is not practical to use this strategy in a medical trauma centre or in a grocery store as the demand may be urgent and stocking the final product seems to be the most logical alternative in these cases.