What are probes and how do they work?

Probes are a key part of any ultrasonic nondestructive testing (NDT) inspection procedure. They generate the high-frequency sound waves that are used to map surfaces.

How does an ultrasonic probe work?

An ultrasonic probe or a transducer is a device that converts the pulse of electric energy generated from the equipment to mechanical energy i.e., high-frequency sound waves that travel through the tested material. These sound waves after bouncing back from the test subject are captured and converted by the probes into an electrical energy pulse.

What is ultrasonic testing?

Ultrasonic testing (UT) comprises a range of non-destructive testing (NDT) techniques that send ultrasonic waves through an object or material. These high frequency sound waves are transmitted into materials to characterise the material or for flaw detecting.

Can the frequency of the probe be used in ultrasonic testing?

In Ultrasonic testing, the UT Operator may have to make a decision about the frequency of the probe to be used. As we all know that wavelength and frequency are inversely proportional for fixed velocity (same material), changing the frequency of the probe will affect the probability of detecting a discontinuity.

What is normal probe in ultrasonic testing?

NORMAL PROBE-STRAIGHT BEAM SINGLE ELEMENT Single piezoelectric crystals are used for transmitting and receiving the ultrasound. This probe is used for inspection of flaw or Back wall parallel to scanning surface and Preferred for the examination of thick material.

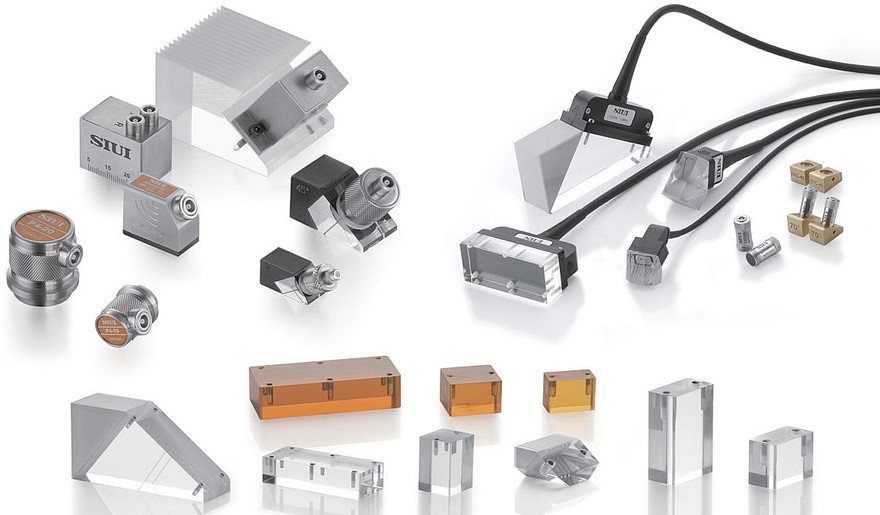

What are different types of probes used in ultrasonic testing?

Ultrasonic probesAngle Beam Probes (single element)Angle Beam Probe (single element)Straight Beam Probes (double element)Straight Beam Probes with replaceable membrane (dual element)Straight Beam Probe with ceramic face (single element)Straight Beam Probes (single element)More items...

What are 3 types of probes?

There are three basic types of probe used in emergency and critical care point-of-care ultrasound: linear, curvilinear, and phased array. Linear (also sometimes called vascular) probes are generally high frequency, better for imaging superficial structures and vessels, and are also often called a vascular probe.

How do you select a probe in ultrasonic testing?

Based on groove angle:Probe Angle (Ø) = 90 – α/2.Or, HSD = T X Tan ØOr, HBP = T / Cos ØNOTE: 1. Scanning area should be 1-1/2 Skip Distance i.e. 3T X Tan ØProbe Travel Speed shall not be more than 150 mm/S.

What are the four types of probes?

The probes can be divided into 4 basic categories: the lin- ear probe, the loop probe, the side-by-side probe and the concentric probe ( fig. 3 ) [10] .

What is probe explain its different types?

A probe is a nucleic acid which has been labeled i.e., chemically modified in some way which allows it and hence anything it hybridizes to, to be detected. There are three major types of probe: Oligonucleotide probes, DNA probes and.

What is probe in testing?

A test probe is a physical device used to connect electronic test equipment to a device under test (DUT). Test probes range from very simple, robust devices to complex probes that are sophisticated, expensive, and fragile. Specific types include test prods, oscilloscope probes and current probes.

What is a probe used for?

1) In telecommunications generally, a probe is an action taken or an object used for the purpose of learning something about the state of the network. For example, an empty message can be sent simply to see whether the destination actually exists. Ping is a common utility for sending such a probe.

How does a probe work?

A probe is a single-stranded sequence of DNA or RNA used to search for its complementary sequence in a sample genome. The probe is placed into contact with the sample under conditions that allow the probe sequence to hybridize with its complementary sequence.

What is skip distance in ultrasonic testing?

The “skip distance” is the surface distance from the probe "index point" where the sound beam returns to the surface. This distance must be calculated to determine the probe distance to the weld to provide full inspection coverage for the component thickness.

How many angle probes are in ultrasonic test?

To do this both compression and shear wave probes may be used, shear wave probes projecting the beam into the test piece at an angle, as shown in Fig. 1. Probes with angles of 30o, 45o, 60o and 70o are commercially available.

What is near zone in ultrasonic testing?

Therefore, the near-field length of a beam of ultrasound is related to the diameter (area) of the piezoelectric plate and the speed and frequency of the ultrasound propagation in the medium. At a certain frequency and speed, the larger the diameter, the longer the near-field length. Ultrasonic sound field.

What are the different types of probes in counseling?

When seeking more detail, there are a number of types probes you can use, depending on what they are saying and what you want to discover.Clarification. ... Purpose. ... Relevance. ... Completeness and accuracy. ... Repetition. ... Examples. ... Extension. ... Evaluation.More items...

What are the different types of ultrasound transducers?

Below we list the three most common ultrasound transducer types – linear, convex (standard or micro-convex), and phased array.

What are the different types of probes that can be used in interviews?

Russell Bernard (2000) specified seven seven different kinds of probes that can be used in, what he called, qualitative interviews.Silence. ... Echo. ... Uh-huh. ... Tell-me-more. ... Long question. ... Leading.More items...•

What are curvilinear probes used for?

A curvilinear probe uses lower frequency ultrasound allowing a deep penetration and a wide depth of field, which is excellent for viewing intra-abdominal structures.

Why is ultrasonic testing important?

Ultrasonic testing is important for most industries that require a full volumetric examination of its components. But while standard ultrasonic testing has some limitations, phased array ultrasonic testing (PAUT) gives this form full expression.

What is an NDT probe?

Probes are a key part of any ultrasonic nondestructive testing (NDT) inspection procedure. They generate the high-frequency sound waves that are used to map surfaces. With this map, technicians can inspect for corrosion and identify flaws. That’s why selecting the correct probe is crucial.

Why is it important to select the correct probe?

That’s why selecting the correct probe is crucial. Without the correct probe, flaws smaller than those detected by a standard ultrasonic probe will likely go unnoticed. Not only that, but cracks that branch off or have unusual orientations can be missed or improperly sized.

What is a 1D linear probe?

Standard 1D-linear array probes cover the requirements for most typical weld and component integrity inspection configurations. A low-profile phased array probe is ideal for detecting small flaws in thin-wall pipes. These can include corrosion, cracks, and other minute flaws.

What is Zetec design?

Zetec’s designers are industry-leading experts in ultrasonic and eddy current technologies, and we can help you navigate any of our NDT testing solutions or devices.

What is the purpose of 2D matrix probes?

2D-matrix array probes have a beam-skewing capability that allows them to better detect misoriented flaws. They do so by using compression waves, which, when compared to shear waves, are less affected by propagation through anisotropic materials.

Can a 1D linear probe operate in small areas?

These can include corrosion, cracks, and other minute flaws. Low profile 1D-linear array probes should be able to operate in small areas due to their small profile. In fact, some low-profile probes can operate with only 11mm in clearance. This gives them a smaller footprint than most standard linear probes.

How does ultrasonic testing work?

What is Ultrasonic Testing and How Does it Work? Ultrasonic testing (UT) comprises a range of non-destructive testing (NDT) techniques that send ultrasonic waves through an object or material. These high frequency sound waves are transmitted into materials to characterise the material or for flaw detecting.

How to perform ultrasonic testing?

Ultrasonic testing can be performed using two basic methods – pulse-echo and through-transmission. With pulse echo testing, the same transducer emits and receives the sound wave energy. This method uses echo signals at an interface, such as the back of the object or an imperfection, to reflect the waves back to the probe.

What Materials Can Be Tested?

UT is ideally used for inspection of dense, crystalline structures such as metals. Ceramics, plastics, composites and concrete can also be successfully inspected but with reduced resolution, since the attenuation in these materials is higher.

What are the advantages of ultrasonic testing?

The advantages of ultrasonic testing include: 1 High penetration power, allowing for flaw detection deep within a part 2 High sensitivity, allowing for the detection of very small flaws 3 Can be used to test when only one side of an object is accessible 4 Greater accuracy, when compared to other non-destructive testing methods, for determining depth of internal flaws and the thickness of parts with parallel surfaces 5 Able to estimate size, shape, orientation and nature of defects 6 Able to estimate alloy structures of components with differing acoustic properties 7 Non-hazardous to nearby personnel, equipment or materials 8 Highly automated and portable operations possible 9 Immediate results can be obtained, allowing for immediate decisions to be made

What is immersion ultrasonic?

Immersion ultrasonic testing is a laboratory-based or factory-based non-destructive test that is best suited to curved components, complex geometries and for ultrasonic technique development. In this method, the component or material is submerged in a water, which acts as a couplant in place of the gels used for contact ultrasound.

What is greater accuracy in non destructive testing?

Greater accuracy, when compared to other non-destructive testing methods, for determining depth of internal flaws and the thickness of parts with parallel surfaces

What is ultrasonic inspection?

Periodic ultrasonic inspections can also be used to check for corrosion or for growth of known flaws, and thus potentially prevent to a failure of a part, component or entire asset. It is used in a wide range of industries including aerospace, automotive, construction, medical, metallurgy, and manufacturing.

What is Ultrasonic Testing?

As I discussed earlier, To evaluate or examine an object through the high-frequency waves, Known as Ultrasonic Testing.

Principle of Ultrasonic Testing–

As you know, UT uses high-frequency sound waves to conduct or evaluate the test piece.

How Ultrasonic Testing Works?–

A transducer converts electrical waves into high-frequency sound waves, which propagated inside the test object.

Methods of Ultrasonic Testing–

This method is most commonly utilized in the ultrasonic testing of materials. The transmitter and receiver probes are on the same side of the specimen and the presence of a defect is indicated by the reception of an echo before that of the back wall echo.

What is the Ultrasonic Wave?–

Sound waves are vibrations of particles of gases, solids, or liquids. The audible sound range of frequencies is usually taken from 20Hz to 20KHz. Sound waves with frequencies higher than 20KHz are known as Ultrasonic Waves.

Why Ultrasonic Testing is used?

Ultrasonic testing is the most convenient and easy to navigate testing in the methods of Non-destructive testing.

What Materials can be tested from Ultrasonic Testing?–

There are several materials, which can be tested by UT. The category of materials is given below-

How does a probe work?

As shown in below figure (left) : A probe sends a sound wave into a test material. There are two indications, one from the initial pulse of the probe, and the second due to the back wall echo.

What are the advantages of ultrasonic testing?

Advantages of Ultrasonic Testing 1 High penetrating power, which allows the detection of flaws deep in the part. 2 High sensitivity, permitting the detection of extremely small flaws. 3 In many cases only one surface needs to be accessible. 4 Greater accuracy than other nondestructive methods in determining the depth of internal flaws and the thickness of parts with parallel surfaces. 5 Some capability of estimating the size, orientation, shape and nature of defects. 6 Some capability of estimating the structure of alloys of components with different acoustic properties 7 Non hazardous to operations or to nearby personnel and has no effect on equipment and materials in the vicinity. 8 Capable of portable or highly automated operation. 9 Results are immediate. Hence on the spot decisions can be made.

How is an ultrasonic transducer separated from an object?

The transducer is typically separated from the test object by a couplant (such as oil) or by water, as in immersion testing. However, when ultrasonic testing is conducted with an Electromagnetic Acoustic Transducer (EMAT) the use of couplant is not required.

What is reflection ultrasound?

In reflection (or pulse-echo) mode, the transducer performs both the sending and the receiving of the pulsed waves as the “sound” is reflected back to the device. Reflected ultrasound comes from an interface, such as the back wall of the object or from an imperfection within the object.

What is ultrasonic thickness measurement?

A common example is ultrasonic thickness measurement, which tests the thickness of the test object, for example, to monitor pipework corrosion. Ultrasonic testing is often performed on steel and other metals and alloys, though it can also be used on concrete, wood and composites, albeit with less resolution.

What frequency is UT?

In most common UT applications, very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 MHz, and occasionally up to 50 MHz, are transmitted into materials to detect internal flaws or to characterize materials.

How Does It Work?

Pulse-Echo and through-transmission

- Ultrasonic testing can be performed using two basic methods – pulse-echo and through-transmission. With pulse echo testing, the same transducer emits and receives the sound wave energy. This method uses echo signals at an interface, such as the back of the object or an imperfection, to reflect the waves back to the probe. Results are shown as a lin...

Contact and Immersion Testing

- Ultrasonic testing can also be split into two main types: contact or immersion testing. Contact ultrasonic testingis typically used for on-site inspections accessibility or portability. Contact ultrasonic inspection can be performed where only one side of a test specimen as reachable, or where the parts to be tested are large, irregular in shape or difficult to transport. Immersion ultra…

Why Is It used?

- As a non-destructive testing method, ultrasonic testing is ideal for detecting flaws and defects without damaging the object or material being tested. Periodic ultrasonic inspections can also be used to check for corrosion or for growth of known flaws, and thus potentially prevent to a failure of a part, component or entire asset. It is used in a wide range of industries including aerospace…

What Materials Can Be Tested?

- Ultrasonic testing is used in a wide range of industries due to its suitability for many different materials. UT is ideally used for inspection of dense, crystalline structures such as metals. Ceramics, plastics, composites and concrete can also be successfully inspected but with reduced resolution, since the attenuation in these materials is higher. Ultrasonic technology has been su…

Advantages

- The advantages of ultrasonic testing include: 1. High penetration power, allowing for flaw detection deep within a part 2. High sensitivity, allowing for the detection of very small flaws 3. Can be used to test when only one side of an object is accessible 4. Greater accuracy, when compared to other non-destructive testing methods, for determining depth of internal flaws and …

Limitations

- There are, however, a few limitations to ultrasonic testing, as follows: 1. Requires experienced technicians for inspection and for data interpretation 2. False positive results, also known as spurious signals, may result from tolerable anomalies as well as the component geometry itself 3. Objects that are rough, irregularly shaped, very small or thin, or not homogeneous are difficult to …

Applications

- Ultrasonic testing has a variety of applications across industry, including testing the integrity of a material or component. This can include testing of welds to determine if there are any discontinuities present. This testing can be performed on both ferrous and non-ferrous materials as well as for thicker sections and those that are reachable from one side only. UT is also capab…

Twi Services and Courses

- TWI provides a number of ultrasonic testing services to our Industrial Members as well as a range of non-destructive testing training coursesfor those wishing to learn about the techniques involved. We can provide a full range of testing services and expertise, including in methods such as phased array ultrasonic testing (PAUT), laser ultrasonic testing and manual ultrasonic testing.