How do you remove PSA sandpaper?

Another alternate way to remove PSA sandpaper is to heat up the back of your metal mounting plate with either a heat gun or hair dryer. Works really slick. Another alternate idea is to heat the metal mounting plate with a heat gun or hair dryer. Works pretty slick.

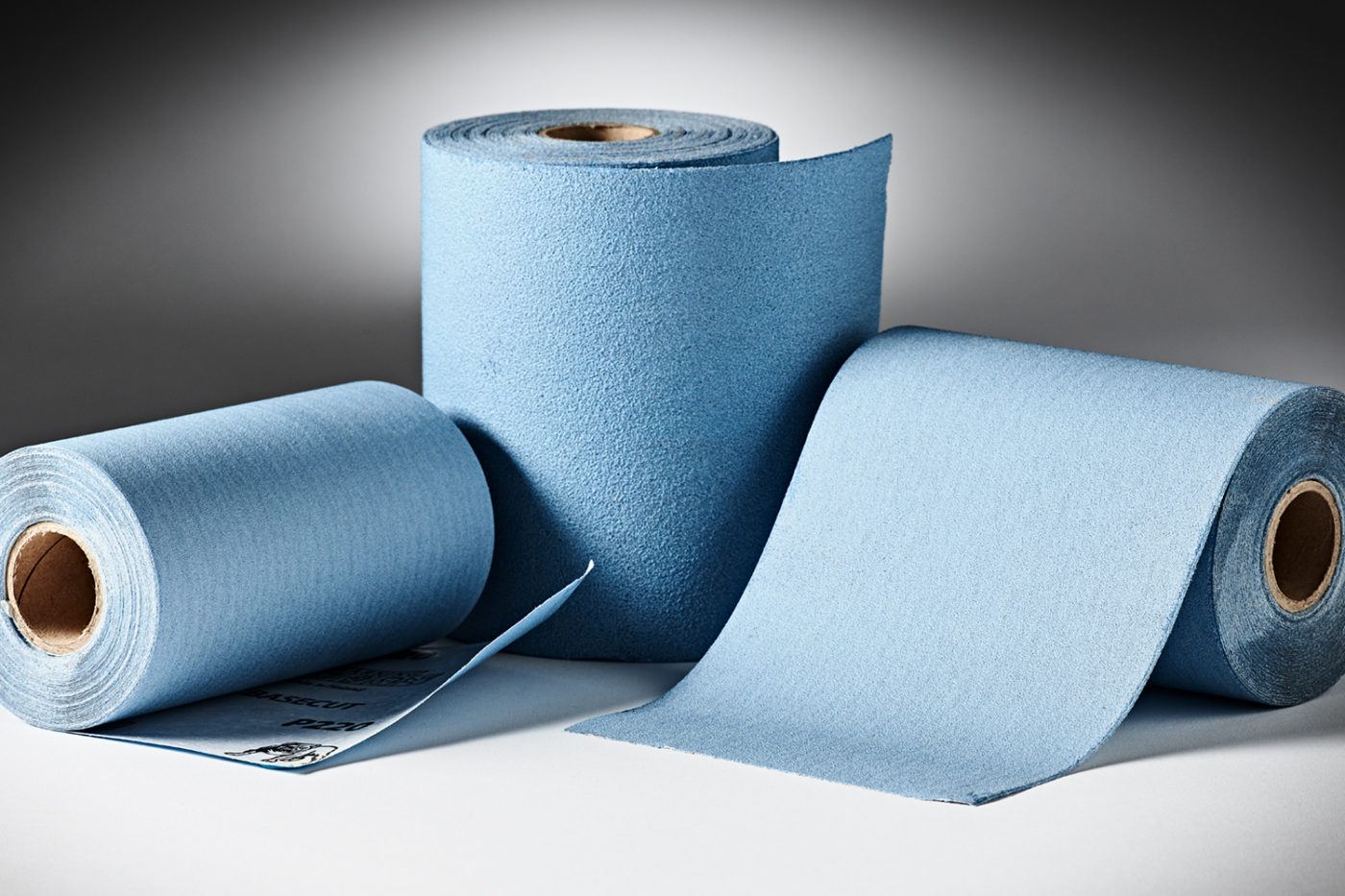

How do you use PSA sandpaper?

0:329:17Peel and Stick Abrasive Rolls - Tips & Tricks - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd basically just peel and stick it right on to your sander. No more messing around with thoseMoreAnd basically just peel and stick it right on to your sander. No more messing around with those those clumsy clamps that hold the sandpaper in place.

What is PSA abrasives?

These are abrasive sanding discs that are meant to be conveniently attached to your sanding machine by way of a Pressure Sensitive Adhesive, aka PSA. The self-adhesive backing easily attaches to various power tools such as orbital sanders, rotary sanders, disc sanders and belt disc sanders.

What is PSA pad?

PSA backing pads, thicker foam vinyl face backing pads. Backing pads with holes and channel have a circular channel or recess, that allows you to apply a disc to the pad without aligning holes.

Which is better hook and loop or PSA?

PSA has a sticky back and is good to be used on large jobs that are likely to wear out the sandpaper. Hook-and-loop paper uses a fuzzy backing that sticks to the bottom of a sander. It can be pulled off and reused before the abrasive on the paper wears out.

Can you attach regular sandpaper to an orbital sander?

What kind of sandpaper do you use on an orbital sander? Well, you can use regular sandpaper on one, with no need to use a finishing sandpaper. It is the motion, the circular (orbital) motion, that provides the smooth finish. So, even regular sandpaper will give you the finish you want for your project.

What are adhesive sanding discs?

These red abrasive discs are intended for shaping filler, paint removal from damaged areas, and scratch refinement of bare metal. Each disc has a diameter of eight inches, a medium coarseness of 80 grit, and a non-vacuum hole design. The pressure sensitive adhesive enables easy disc attachment and removal.

How do you get glue off a disc sander?

A: A number of solvents and chemical automotive cleaners will cut through any remaining adhesive residue, Hal, but we prefer using a citrus-based cleaner. Use a rag and the cleaner to remove the old adhesive, then wipe the platen down with a window/glass cleaner, such as Windex, and let it dry.

How do you use a stick on sanding discs?

0:082:55Convert Disc Sander To Use Hook-And-Loop (Velcro) Sanding ...YouTubeStart of suggested clipEnd of suggested clipOn i'm sure you know how they work peel off the back and press the sanding disc onto the platen.MoreOn i'm sure you know how they work peel off the back and press the sanding disc onto the platen. Then apply pressure to get the adhesive to stick hence the name pressure sensitive adhesive.

What does hook and loop sandpaper mean?

Hook-and-loop sandpaper has a backing made of a material similar to Velcro. It has hooks and loops that are used to attach the sandpaper to a machine such as a random orbital sander or disc sander. This makes it very simple to change the sandpaper.

How does hook and loop sandpaper work?

It works in the same way. Tiny hooks wrap around tiny loops and form a tight connection, and in this case, hold the sandpaper tightly to the surface of your power tool. Hook and loop sandpaper has a backing made of a similar material. When the two are pressed together, the hooks catch the loops and bind together.

How do you use a stick on sanding discs?

0:082:55Convert Disc Sander To Use Hook-And-Loop (Velcro) Sanding ...YouTubeStart of suggested clipEnd of suggested clipOn i'm sure you know how they work peel off the back and press the sanding disc onto the platen.MoreOn i'm sure you know how they work peel off the back and press the sanding disc onto the platen. Then apply pressure to get the adhesive to stick hence the name pressure sensitive adhesive.

How do you get glue off a disc sander?

A: A number of solvents and chemical automotive cleaners will cut through any remaining adhesive residue, Hal, but we prefer using a citrus-based cleaner. Use a rag and the cleaner to remove the old adhesive, then wipe the platen down with a window/glass cleaner, such as Windex, and let it dry.

What are adhesive sanding discs?

These red abrasive discs are intended for shaping filler, paint removal from damaged areas, and scratch refinement of bare metal. Each disc has a diameter of eight inches, a medium coarseness of 80 grit, and a non-vacuum hole design. The pressure sensitive adhesive enables easy disc attachment and removal.

What is PSA Sanding Pad?

Pressure Sensitive tape (also known as PSA, self-adhesive, self-stick adhesive) is a significant adhesive tapes category . It may be a relatively thin, flexible material with a single or double-sided coating. PSA will adhere to a spread of substrates when applied to most clean and dry surfaces with pressure. Pressure Sensitive adhesives don't require solvent, water, or heat to activate the adhesive. The bond is directly influenced by the quantity of stress employed to use the glue to the surface.

What is a PSA Pad?

Pressure-sensitive adhesives (PSA) pads are utilized in many applications. PSA's use will grow as an option to fasten and join due to advances in Tape for Graphics Adhesive technology, easy use, and low cost compared to traditional fastening systems. The subsequent is supposed to offer you the fundamentals of adhesives and things to think about when determining your application's most straightforward bond.

How to Use a PSA Pad?

Pressure-sensitive adhesive sand paper offers fast, convenient mounting of sanding discs, rolls, or sheets. Available during a sort of backings, these discs make mounting on a disc sander, orbital sander, rotary sander, and other equipment quick and straightforward. Choose between many grits and abrasive coatings like alumina, carbide, diamond, and more. Believe Grainger as your source for PSA discs for your grinding, dry sanding, and finishing jobs.

Why do PSA pads have a bond?

The bond forms because the adhesive is soft enough to flow, or wet, the adhesive. The bond has strength because the adhesive is tough enough to resist flow when stress is applied to the bond. Once the adhesive and therefore the adherend are in proximity, there also are molecular interactions like van der Waals forces involved within the bond, which contribute significantly to the last word bond strength. PSAs exhibit viscoelastic (viscous and elastic) properties, both of which are used for proper bonding.

What is self wound tape?

Self Wound: The self-wound is a coated carrier on one side with PSA and on the opposite with a release coating. There's no release liner with these sorts of products. Carton sealing, Duct, and Masking are all samples of self-wound tapes.

What is pressure sensitive adhesive?

In contrast with structural adhesives, whose strength is evaluated as lap shear strength, pressure-sensitive adhesives are characterized by their sheer and peel resistance also as their initial tack . These properties are dependent, among other things, on the formulation, coating thickness, rub-down, and temperature.

What is single coated adhesive?

Single Coated: It is the first step in which an adhesive is coated on one side of a cloth (Facestock). A silicone coated release liner protects the adhesive.