What is the purpose of the safety relief valve?

What are the main functions of pressure regulating or pressure relief valve

- These valves are capable to protect the system from pressure damage

- Sequence motion

- Limit pressure in selected sections of the circuit

- Removes excess fluid safely

- Prevent the loss of material

- Protect equipment piping and people

What is a PSV pressure?

Pressure support ventilation (PSV) is a mode of positive pressure mechanical ventilation in which the patient triggers every breath. PSV is deliverable with invasive (through an endotracheal tube) or non-invasive (via full face or nasal mask) mechanical ventilation.

What are safety and relief valves?

Relief valves are designed to help your facility avoid system failures, and protect equipment from overpressurized conditions. The term safety valve, on the other hand, refers to pressure valves that are designed to protect people, property, and processes. In other words, the term safety valve refers to a failsafe, last resort valve that will ...

What is an air compressor safety valve?

Safety valve is one of the most important components on your air compressor as it is your best defense against a runaway system, if the pressure switch fails, the safety valve will safeguard against system failure; Check that the safety valve functions properly before each use of the air compressor

What is difference between PSV and pressure relief valve?

A Pressure Safety Relief valve is designed to open suddenly. When the set pressure of the PSV is reached, the valve opens almost fully. PSVs require that the outlet of the valve be larger than the inlet, based on an understanding of engineering flow calculations of compressible gas/fluids.

What is PSV process?

Pressure Safety Valves (PSV) or Pressure Relief Valves are important instruments in the process / manufacturing industry to protect enclosed equipment or vessels from over-pressure scenarios.

What does PSV valve look like?

0:076:49Pressure Safety Valve - YouTubeYouTubeStart of suggested clipEnd of suggested clipThese are generally considered your last line of defense in an overpressure. Situation on thisMoreThese are generally considered your last line of defense in an overpressure. Situation on this sample PSV you can see that the inlet. And the outlet are threaded.

What is purpose of PSV?

A Pressure Safety Valve (PSV) is a type of valve used to quickly release gasses from equipment in order to avoid overpressurization and potential process safety incidents. PSVs are activated automatically when pressure exceeds prescribed pressure limits in order to return equipment pressure to a safe operating level.

How does PSV valve work?

Unlike the direct-operated, a pilot-operated PSV relies on the pilot to signal the main valve to open and close. In normal conditions, the pressure is picked up at the main valve inlet and is sent to a dome above the main valve. This inlet pressure applies enough force to the dome to keep the main valve seat closed.

How many types of PSV are there?

There are two basic types of pilot operated safety valve, namely, the diaphragm and piston type. The diaphragm type is typically only available for low pressure applications and it produces a proportional type action, characteristic of relief valves used in liquid systems.

What is PSV material?

Pressure Safety and Relief Valve (PSV / PRV)Common Materials of ConstructionMaterial SpecificationsStandard Carbon SteelASTM A105 A216 WCB WCCLow temperature Carbon SteelASTM LF2 A352 LCC LCB2 more rows

How many types of pressure safety valves are there?

There are two main types of safety valves. Spring loaded safety valves and pilot operated safety valves. Overpressure is the pressure increase above the set pressure necessary for the safety valve to achieve full lift and capacity.

What are the types of PSV?

The most commonly used PSV types are; Conventional, Balanced-Bellows and Pilot-Operated.

What is PSV testing?

A pressure safety valve (PSV) protects pressure vessels and piping systems from excessive internal pressure.

What is PSV license?

What is a PSV licence? A PSV licence — a type of vocational driving licence — allows the holder to drive any type of vehicle used to transport paying passengers.

What is the difference between PSV and TSV?

Typicaly a thermal relief valve (TSV as you call it) is a low flow relief valve used on equipment protect against over pressurization due to thermal expansion. A pressure relief valve (PSV as you call it) is used for relieving larger volumes due to process of external hazards.

What is the purpose of a pressure safety valve?

The primary purpose of a pressure safety valve is the protection of life, property and environment during an over-pressure event in a pressurized vessel or equipment . An over-pressure event refers to any condition which would cause pressure in a vessel or system to increase beyond the specified design pressure or maximum allowable working pressure. A pressure safety valve is designed to open and relieve excess pressure from vessels or equipment and to re-close and prevent the further release of fluid after normal conditions have been restored.

What is the force of the safety valve?

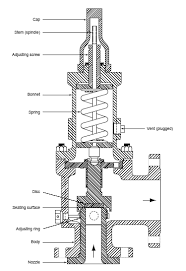

In an upset situation a safety valve will open at a predetermined set pressure. The spring force Fs is acting in closing direction and Fp, the force created by the pressure at the inlet of the safety valve, is acting in opening direction. At set pressure the forces Fs and Fp are balanced. There is no resulting force to keep the disc down on the seat. The safety valve will visibly or audibly start to leak (initial audible discharge).

What happens when the pilot valve is set?

At set pressure, the pilot valve actuates. The medium is no longer routed to the dome. This prevents a further rise in dome pressure. Also, the dome is vented. As a result, the closing force ceases as a precondition for the system over-pressure to push the main valve open. Depending on the design of the pilot valve, this opening is either rapid and complete (Pop Action) or gradual and partial following system pressure (Modulate Action).

How does a pilot operated safety valve work?

Pilot Operated Safety Valve is controlled by process medium. To achieve this, the system pressure is applied to the pilot valve (= control component for the main valve) via the pressure pickup. The pilot valve then uses the dome above the main valve piston to control the opening and closing of the main valve. Figure 4 shows all the steps in working of Pilot Operated Pressure Safety Valves.

How does a safety valve work?

In most applications a properly sized safety valve will decrease the pressure in the vessel when discharging. The pressure in the vessel will decrease at any subsequent point, but not later than the end of the upset situation. A decreasing pressure in the vessel will lower the force Fp. At set pressure however the flow is still acting on the enlarged disc area, which will keep the valve open. A further reduction in pressure is required until the spring force Fs is again greater than Fp and the safety valve begins to close. At the so called reseating pressure the disc will touch the nozzle again and the safety valve closes.

How does a spring loaded pressure safety valve work?

In a Spring loaded Pressure Safety Valve the closing force or spring force is applied by a helical spring which is compressed by an adjusting screw. The spring force is transferred via the spindle onto the disc. The disc seals against the nozzle as long as the spring force is larger than the force created by the pressure at the inlet of the valve. Figure 2 shows all the steps in working of Spring Loaded Pressure Safety Valves.

What happens to the pressure inside a valve when the pressure increases?

As the pressure inside the system increases, the force Fp increase above the set pressure and the additional spring force required to further compress the spring is overcome. The valve will open rapidly with a “pop”, in most cases to its full lift.

What is a PSV valve?

A pressure safety valve (PSV) protects the concerned equipment or vessel in case of pressure build up, by opening up and releasing the fluid service to lower the internal pressure.

When should a PSV valve open?

The valve should open up at set pressure of the PSV.

How are safety valves designed?

Safety valves are designed by analyzing the concerned equipment, related fluid service, then simulating the overpressure scenario to finally perform pressure safety valve sizing calculations.

What is bench testing for PSVs?

Bench testing for PSVs requires removing the relieving devices from their installation and then carrying out a full functional test to check how the valve behaves in case of over pressure scenario.

Why is it important to test a PSV?

PSV Testing. But, before the plant is operational and one can rely on the PSV to protect the equipment from overpressure, it is important that the PSV has been tested. There are two ways for testing a PSV.

Is in situ PSV testing more cost effective?

If the valve is already operational, in situ psv testing would prove more cost effective as it can allow the plant operations to go on while testing is being done. But on the other hand, per valve PSV testing costs are much higher.

What is a safety valve?

The word safety valve, however, describes pressure valves that can safeguard people, property, and procedures. Quite simply, the word safety valve describes a failsafe, last measure valve which will release pressure to avoid a catastrophe, usually when other relief valves have unsuccessful to adequately control pressure inside a system.

Why are safety valves and relief valves the same?

Both of them are pressure relief valves, and they're made to let off pressure in almost any situation in which a system becomes overpressurized. That stated, relief valves and safety valves do function slightly differently:

What is relief valve?

Generally, the word relief valve describes a valve inside a pressurized system which is used to manage pressure for that optimal functionality from the system. Relief valves are made to strengthen your facility avoid system failures, and safeguard equipment from overpressurized conditions.

Why do safety valves open?

Unlike relief valves, safety valves open immediately and completely to prevent a tragedy, instead of to manage pressure of the system.

Do pressure relief valves work?

As we know , there are numerous pressure relief valves available. In the market, we have a tendency to use terms like safety valve and relief valve interchangeably. And typically, this will make sense. Most pressure relief valves are made to perform the same factor - release pressure inside a system.

What is a safety valve?

Safety valves are seen as a last resort safety measure. They are found in power plants, petrochemical systems, boilers, and many more. Safety valves are fail-safe devices that automatically stop the increase of overpressure beyond a determined limit. If the setpoint is reached the safety valve will fully open until it is below the setpoint again.

What is the difference between a relief valve and a safety valve?

The purpose of a relief valve is to keep the pressure in a system within set limits to prevent overpressure. Relief valves are designed to prevent damage due to overpressure conditions. Safety valves have a fail-safe purpose.

What is the setpoint of a safety valve?

The setpoint is usually set below overpressure conditions and above the working pressure level. Safety valves already open a small amount before the setpoint is reached and pop open at the setpoint, or at a specified value after the setpoint. Relief valves only start opening at the setpoint.

Why do safety valves pop open?

Safety valves will pop open immediately when the setpoint is reached. It is designed to relieve the system of dangerous overpressure as fast as possible. Relief valves are commonly used for fluids like oil or water. Safety valves are commonly used for compressible gasses like air or steam.

Why are relief valves important?

They are critical in a pressure system to ensure that system failures are avoided. To prevent system failure the pressure must be kept below a predetermined design limit. Each relief valve has a set point at which it starts to open and starts to prevent overpressure.

What is relief valve?

A relief valve, also known as a pressure relief valve, is a device that lowers the pressure to prevent damage to the system. Their function is to protect pressure sensitive equipment from damage caused by overpressure. They are critical in a pressure system to ensure that system failures are avoided. To prevent system failure the pressure must be ...

Where are safety valves found?

They are found in power plants, petrochemical systems, boilers, and many more. Safety valves are fail-safe devices that automatically stop the increase of overpressure beyond a determined limit. If the setpoint is reached the safety valve will fully open until it is below the setpoint again.

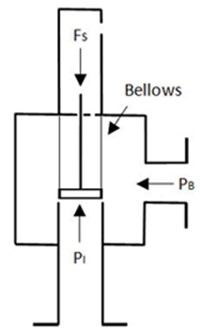

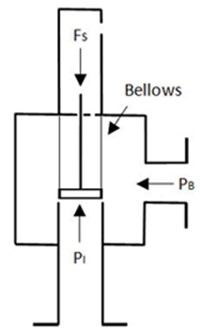

What is a piston type safety valve?

Piston type balanced safety valve. Although there are several variations of the piston valve, they generally consist of a piston type disc whose movement is constrained by a vented guide. The area of the top face of the piston, AP, and the nozzle seat area, AN, are designed to be equal.

What is a conventional safety valve?

The common characteristic shared between the definitions of conventional safety valves in the different standards, is that their operational characteristics are affected by any backpressure in the discharge system.

What is the ASME/ANSI standard for valves?

The ASME/ANSI standard makes the further classification that conventional valves have a spring housing that is vented to the discharge side of the valve. If the spring housing is vented to the atmosphere, any superimposed backpressure will still affect the operational characteristics. Thiscan be seen from Figure 9.2.1, which shows schematic diagrams of valves whose spring housings are vented to the discharge side of the valve and to the atmosphere.

What is an ASME valve?

ASME I valve - A safety relief valve conforming to the requirements of Section I of the ASME pressure vessel code for boiler applications which will open within 3% overpressure and close within 4%. It will usually feature two blowdown rings, and is identified by a National Board ‘V’ stamp.

Why is a bellows valve important?

It is important, therefore, that there is some mechanism for detecting any uncharacteristic fluid flow through the bellows vents. In addition, some bellows balanced safety valves include an auxiliary piston that is used to overcome the effects of backpressure in the case of bellows failure. This type of safety valve is usually only used on critical applications in the oil and petrochemical industries.

What is a bellows safety valve?

Bellows safety valve - A direct loaded safety valve wherein sliding and (partially or fully) rotating elements and springs are protected against the effects of the fluids by a bellows. The bellows may be of such a design that it compensates for influences of backpressure.

How far does a low lift valve lift?

In low lift valves, the disc only lifts a distance of 1/24th of the bore diameter. The discharge area is determined entirely by the position of the disc, and since the disc only lifts a small amount, the capacities tend to be much lower than those of full or high lift valves.