What is a Reed Mark in fabric?

Reed mark: In woven fabric, a crack between the groups of warp ends either continuous or at intervals. It’s maybe caused by the wrong drawing-in of the warp or damage to the reed wires. 19. Slub: If the yarn contains an unexpected slub in it then that slub will appear in the fabric as a fault.

What is the importance of Reed of loom?

Reed of loom is a very important part. It is directly associated with fabric quality and loom efficiency. Improper reed specifications directly affect the warp breakages. High warp breakage rate due to improper reed specifications reflects in the form of poor fabric quality.

How many ends and picks are in a square of fabric?

On that fabric sample, a 1” X 1” square is made. The vertical laid yarns are ends (warp) and horizontal yarns are picks (wefts). Here you can counts ends and picks without any pick glass as the sample fabric is loosely woven. In one inch length there is 9 ends and 8 picks.

What is meant by the term “Reed width”?

Reed width: this parameter is decided after calculating the reed space to be used during weaving of a particular fabric. we have to weave 120” fabric width. Now we calculate the required reed space for 120” wide fabric. Suppose reed space comes 124”.

How do you calculate reed and pick fabric?

Weaving CalculationsReed Count. It is calculated in stock port system.No. ... Reed Width. Reed Width = Cloth Width *(100+ weft crimp %age)/100.Crimp Percentage. Crimp %age = {(Warp length – Cloth length)/Cloth Length}* 100. ... Cloth Cover Factor. ... Maximum EPI for particular count. ... Warp Density.

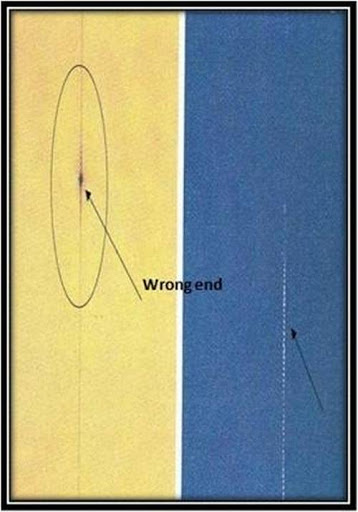

What is reed mark in fabric?

Definition of reed mark : a warp mark in cloth caused by defective reeds or a faulty setting of the loom or yarns.

How do you check reed picks?

0:252:50How to use a Pick Glass for textiles - YouTubeYouTubeStart of suggested clipEnd of suggested clipThis is one inch by one inch. So it's already telling you the area that you need to count. So you'reMoreThis is one inch by one inch. So it's already telling you the area that you need to count. So you're first gonna count along the top of the swatch. Here and then you're going to count along this side.

What is reed yarn?

This is the highest quality linen yarn which produces a supple and soft fabric with tons of "swish" and drape. Reed is a smooth 100% linen chainette that flows easily across the needles for graceful garments and accessories.

What is reed plan in weaving?

– Reed Plan. • The weave or design is the pattern (or order) in which the interlacing between the warp and weft threads takes place. • The drawing-in draft (DID) shows the arrangement of the warp threads on the different heald frames.

What is ends and picks in fabric?

A single thread of the weft crossing the warp is called a pick. Terms vary (for instance, in North America, the weft is sometimes referred to as the fill or the filling yarn). Each individual warp thread in a fabric is called a warp end or end.

What is Reed Space?

Reed Space is a retail store that was founded by Jeff Ng, in 2003. Originally offering just shirts, the retail store now sells streetwear, lifestyle items and features an art gallery.

Why reed mark occurs in a woven fabric?

Reed mark: In woven fabric, a crack between the groups of warp ends either continuous or at intervals. It's maybe caused by the wrong drawing-in of the warp or damage to the reed wires.

What is read and pick in textile?

Pick Glass is used to determine the reed and pick in woven fabric. Reed is actually number of ends or number of warp threads per inch and by picks we mean the number of picks or number of weft threads per inch.

What is Heald count?

The number of heald eyes per inch across the healds in a set expresses the count of the heald. Ex: 60s count for a plain set means 60 heald eyes on 4 shafts per inch i.e. 15 eyes per inch per shaft. For a 6 shaft set, it becomes 60 heald eyes on 6 shafts per inch i.e. 10 eyes per inch per shaft.

What is a loom reed called?

In multi-shaft weaving the reed also serves as the beater to pack the weft yarn against the warp yarn. In rigid heddle weaving, the reed is also called the rigid heddle, or heddle; it also serves as the beater, and when raised and lowered creates the sheds to allow for weaving.

What is the function of Profile reed?

Its function is to push weft yarn into shedding and arrange warp yarn and weft yarn according to certain regularity and density in order to make the fabric reach the required weft density and width.

What is loose reed motion?

Loose Reed Warp Protector Motion: The principle of the mechanism is that the reed is forced out of its support whenever the shuttle is trapped in the shed and this backward inside movement of the reed will cause a knock off device to act and stop the loom. The reed A is held at the top of the slotted reed cap B.

What is weft count?

Here, count refers to the yarn count (warp yarn count and weft yarn count) and by construction primarily it means the number of warp yarns and weft yarns used in one inch of fabric. The yarn count (number) is defined as the thickness and fineness of the yarns.

How do I calculate yarn count?

The direct system is calculated with the formula N = (W/l) / (L/w). The indirect system uses the formula: N = (L/w) / (W/l). In these formulas, N is the yarn count, W is the weight of a sample of yarn, l is the unit of length, L is the length of the sample, and w is the unit of weight.

How is weft calculated?

If it's plain weave, twill, or lace weaves, this is usually the same number as warp threads per inch. Then you multiply that number (picks per inch) times the number of inches you'll be weaving the piece times the width of the weaving plus about 10% (for example, by 11 inches for something 10 inches wide).

What is GSM formula?

Now, by applying all the data in the required formula, we can easily find out the above-woven fabric GSM. GSM (Gram per square meter), = (3.12 + 1.5) × 23.5.

What is EPI and PPI in textile?

Fabric, material typically produced by weaving, knitting or knotting textile fibers, yarns or threads, is measured in units such as the momme, thread count (a measure of the coarseness or fineness of fabric), ends per inch (e.p.i) and picks per inch (p.p.i).

How do you count ends and picks?

The vertical laid yarns are ends (warp) and horizontal yarns are picks (wefts). Here you can counts ends and picks without any pick glass as the sample fabric is loosely woven. In one inch length there is 9 ends and 8 picks. So EPI and PPI of this sample is 9 and 8 respectively.

What is a pick count?

PICK COUNT. The number of weft yarns per inch in a woven fabric.

What is the cause for thick place in weft direction?

Thick places- thick places are bars across the fabric with greater weft density than on the rest of the fabric. Thick places caused by disarrangement of take-up motion, Improper loom stoppage and improper warp let-off motion. Thin places- a thin place is a defect of fabric.

Reed & Pick is a vertical manufacturer of household textiles, based in India with 35 years of experience in manufacturing and exporting home textiles from India

We are a fully integrated unit with manufacturing facility to produce Bathmats, Rugs, Cushions and Outdoor Home Textiles. We have our own Dyeing, Weaving, Cutting, Stitching, Coating and Finishing facility, helping us maintain an over 95% on-time delivery.

Why Choose Us

We are a family owned company with a full commitment towards every part of our business.

Our Products

Our range of Cushions and Poufs is built on our traditional weaving strength. These products are crafted keeping in mind the current trend of design and colors and can be used as a decorative or as a functional part of any room.

Manufacturing

Complete monitoring of the material supply network to ensure uninterrupted fabric supply...

Reed & Pick is a vertical manufacturer of household textiles, based in India with 35 years of experience in manufacturing and exporting home textiles from India

We are a fully integrated unit with manufacturing facility to produce Bathmats, Rugs, Cushions and Outdoor Home Textiles. We have our own Dyeing, Weaving, Cutting, Stitching, Coating and Finishing facility, helping us maintain an over 95% on-time delivery.

Our Team

Established the company in 1972 at the age of 20. He has been instrumental in guiding us to setup new manufacturing facilities and improve our sourcing capabilities for raw material and fabrics.

History

Reed & Pick, is a vertical manufacturer of household textiles based in India with 35 years of experience in manufacturing and exporting home textiles from India.

Wednesday, May 8, 2019

Reed of the loom is a very important part. It is directly associated with fabric quality and looms efficiency. Improper reed specifications directly affect the warp breakages. High warp breakage rate due to improper reed specifications reflects in the form of poor fabric quality.

REED'S SPECIFICATIONS, CALCULATION OF DENT WIRE THICKNESS

Reed of the loom is a very important part. It is directly associated with fabric quality and looms efficiency. Improper reed specifications directly affect the warp breakages. High warp breakage rate due to improper reed specifications reflects in the form of poor fabric quality.

What happens if a reed is too hairy?

If the warp is too hairy then the reed will create a ball in warp yarn in between the reed and heald shaft. If the ball is small enough to pass through the dent of reed then those will form the ball in fabric.

What is a fabric imperfection?

A fabric imperfection in which one or several yarns are sufficiently damaged to create an opening.

What is woven fabric?

In the textile industry, woven fabric is produced by interlacing warp and weft yarn. Faulty woven fabrics hamper the total quality of woven garments such as shirts, pants, trousers, jackets, etc. As a textile engineer, you should know about the major woven fabric faults produced during woven fabric manufacturing.

What is a thick place in fabric?

If the thick or thin place is more than one inch (2.54cm) wide then it is considered a major defect in fabric grading. A thick and thin place. A segment of yarn at least ¼ inch (0.6cm) long that is noticeably thicker than adjacent portions of yarn is called the thick place.

When is fault produced in woven fabrics?

This type of fault is produced in woven fabrics when the tension of warp yarn is slow.

What does EPI stand for in fabric?

You can do that just by sitting on your chair. For a newbie, EPI stands for Ends per inch and PPI stands for Picks per inch. Where Ends is known as Warps and Pick are known as weft yarn.

Can you send a fabric sample to an outside lab?

In case, the factory has its in-house testing lab then it is ok. You would get the information about fabric sample EPI and PPI on the same day. But when you need to send a sample to an outside lab, it would cost you money and has to wait for at least one day.