Reservoir Stimulation sets forth a rationalization of stimulation using reservoir engineering concepts, and addresses topics such as formation characterization, hydraulic fracturing and matrix acidizing. Formation damage, which refers to a loss in reservoir productivity, is also examined comprehensively.

Full Answer

What is reservoir simulation?

Reservoir simulation is based on well known reservoir engineering equations and techniques - the same equations and techniques the reservoir engineer has been using for years. In general, simulation refers to the representation of some process by either a theoretical or a physical model.

What is stimulated reservoir volume and why is it important?

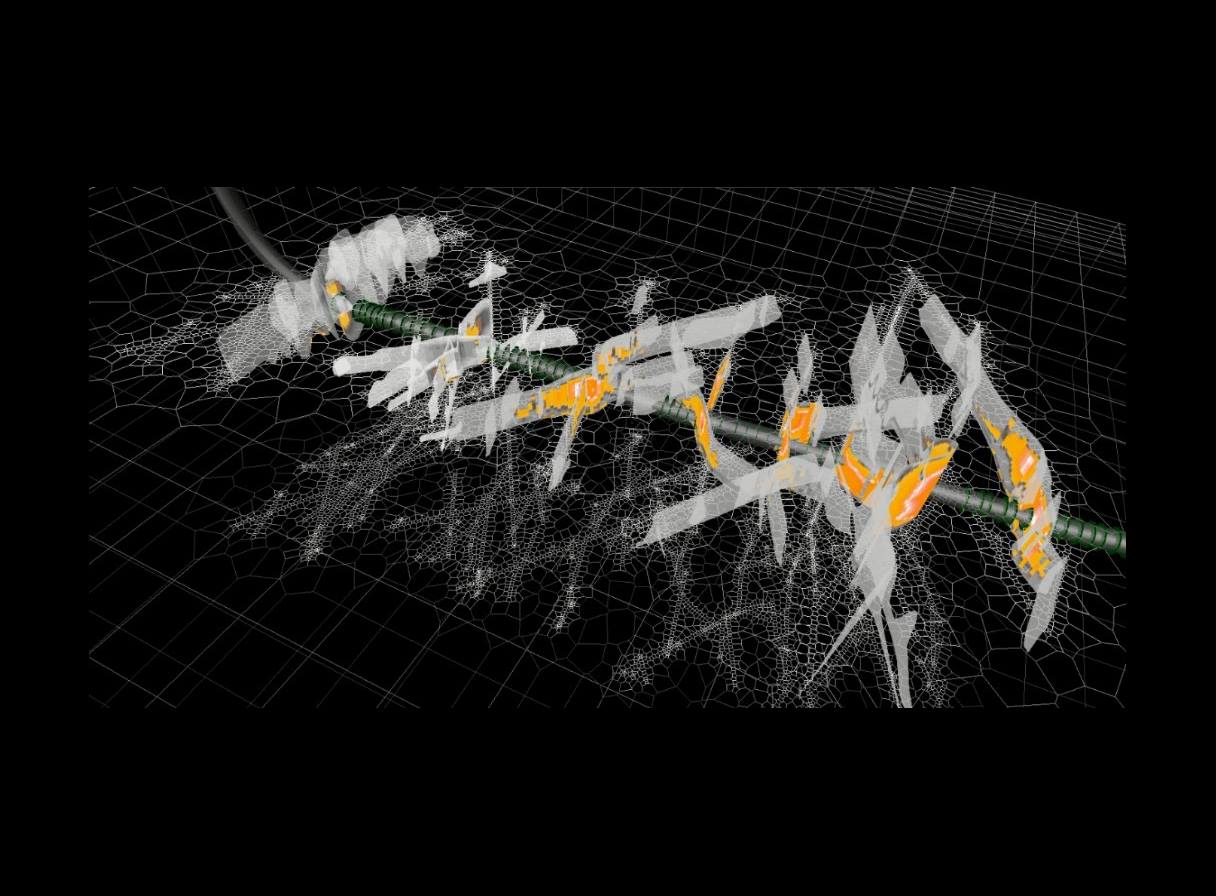

In shale reservoirs, where complex network structures in multiple planes are created, the concepts of single-fracture half-length and conductivity are insufficient to describe stimulation performance. This is the reason for the concept of using stimulated reservoir volume (SRV) as a correlation parameter for well performance.

What is unconventional reservoir stimulation?

Unconventional reservoir stimulation involves multiple fractures possibly propagating in both tensile and shear mode or propagation. Johannes Fink, in Petroleum Engineer's Guide to Oil Field Chemicals and Fluids (Third Edition), 2021 Acidization is an oil reservoir stimulation technique for increasing well productivity.

How do oil and gas companies simulate reservoirs?

In the reservoir simulations usually, the oil and gas companies depend on simulation and modeling software to produce the best representation of reservoirs of oil and gas, all the usage of equipment as well as resistivity and environmental effects.

What is the purpose of reservoir simulation?

The purpose of reservoir simulation is to predict field performance and ultimate recovery for various field development scenarios to evaluate the effects on recovery of different operational conditions and compare economics of different recovery methods. The Simulation method is a spatial, 3D approach.

What is reservoir simulation in petroleum engineering?

Reservoir simulation is an area of reservoir engineering where computer models are used to predict flow of fluids through porous media. In EnKF method, static parameters like porosity, permeability and dynamic variables are updated to match with real-time production data.

What is stimulation in oil and gas?

Well stimulation is a well intervention performed on an oil or gas well to increase production by improving the flow of hydrocarbons from the drainage area into the well bore. Stimulation is the opening of new channels in the rock for oil and gas to flow through easily.

What is numerical reservoir simulation?

Numerical reservoir simulation can be defined as the the process of constructing and running a model that mimic the appearance and flow dynamics of an actual reservoir system, including the subsurface porous and permeable reservoir and its other physical components to produce (wellbore) and process the reservoir fluids ...

What are the three components of reservoir simulation study?

Traditional finite difference simulators dominate both theoretical and practical work in reservoir simulation. Conventional FD simulation is underpinned by three physical concepts: conservation of mass, isothermal fluid phase behavior, and the Darcy approximation of fluid flow through porous media.

What are simulations?

A simulation is a model that mimics the operation of an existing or proposed system, providing evidence for decision-making by being able to test different scenarios or process changes. This can be coupled with virtual reality technologies for a more immersive experience.

What is stimulation method?

Stimulation techniques (SB) include manipulation, acupuncture, acupressure, physiotherapy, transcutaneous electrical nerve stimulation, reflexotherapy, laser treatment and epidural stimulation technique. The purpose of this paper is to investigate the scientific evidence for these techniques.

What is stimulation operation?

1 Introduction. Well stimulation drilling process is used to extract natural gas, crude oil, and geothermal energy from geological formations under the Earth. A rush of oil and natural gas from the drilled well was generated due to the modern use of a hydraulic fracturing process.

How do you stimulate an oil well?

Well stimulation is generally accomplished through three primary methods: explosives, acid injection, and hydraulic fracturing. Hydraulic fracturing is currently the most popular as it has proven to be more effective, efficient, and safer than older methods. However, all three methods are often used.

What does a reservoir engineer do?

Reservoir engineers estimate how much oil or gas can be recovered from underground deposits, known as reservoirs. They study reservoirs characteristics and determine which methods will get the most oil or gas out of the reservoirs.

What is history matching in reservoir simulation?

History matching is an important phase in reservoir modeling and simulation process, where one aims to find a reservoir description that minimizes difference between the observed performance and the simulator output during historic production period.

What is discretization in reservoir simulation?

2.4 Reservoir discretization. Reservoir discretization means that the reservoir is described by a set of gridblocks (or gridpoints) whose properties, dimensions, boundaries, and locations in the reservoir are well defined.

What is oil simulation?

Simulation modeling for oil and gas processes enables the discovery of bottlenecks, the evaluation of external factors, and the development of new organizational policies to deliver immediate savings and ongoing increased revenues. Refinery simulation empowers analysis and decision making.

What does a reservoir engineer do?

Reservoir engineers estimate how much oil or gas can be recovered from underground deposits, known as reservoirs. They study reservoirs characteristics and determine which methods will get the most oil or gas out of the reservoirs.

What is history matching in reservoir simulation?

History matching is an important phase in reservoir modeling and simulation process, where one aims to find a reservoir description that minimizes difference between the observed performance and the simulator output during historic production period.

What is reservoir simulation?

In general, simulation refers to the representation of some process by either a theoretical or a physical model.

Why is reservoir modeling important?

As time goes on, simulators will be used more and more, so a basic understanding of reservoir modeling is essential. The engineer, especially, must become competent in setting up simulation problems, in deciding on appropriate input data, and in evaluating the results.

Why is a reservoir zero dimensional?

It is zero dimensional because rock, fluid properties, and pressure values do not vary from point to point. Instead, they are calculated as average values for the whole reservoir. This tank model is the basic building block of reservoir simulators. Now let us consider a reservoir represented by a sandbar.

Is a reservoir homogeneous or homogeneous?

If a reservoir is fairly homogeneous, average values of the reservoir properties, such as porosity, are adequate to describe it. The average pressure, time, and production behavior of such a reservoir under a production behavior of such a reservoir under a solution gas drive, for example, are normally calculated by the familiar methods of Tamer, ...

What is reservoir simulation?

Reservoir simulation is a useful technology for solving complex reservoir engineering problems with efficiency. The numerical models are considered the best tool for CBM reservoir development. Numerical models can accurately and simultaneously account for gas desorption, relative permeability, permeability, and porosity change caused by the coal compressibility, permeability changes due to matrix shrinkage, well-to-well interference, and operating procedures. Reservoir simulators can be used to perform a variety of analyses. The primary uses of simulators include predicting production performance of the CBM reservoirs under various reservoir management strategies, estimating the ultimate gas recovery, and designing the most effective well completions. As result, simulation has become an indispensable tool for reservoir management because of the need for support decisions and economic justification with accurate technical data. Detailed information for perform a CBM simulation study and guidelines for history matching and production forecasting are documented by Paul [4].

Why is simulation important in reservoir management?

As result, simulation has become an indispensable tool for reservoir management because of the need for support decisions and economic justification with accurate technical data.

How to simulate geomechanical effects in reservoir simulation?

A popular approach to simulate geomechanical effects in reservoir simulation is to relate permeability to pore pressure. As a simplified approach, the average effective stress can be correlated with fluid pressure (Settari et al., 2005 ), which makes it easy and convenient to implement in traditional reservoir simulators. A widely used correlation that relates matrix or fracture permeability with pore pressure is ( Yilmaz et al., 1991; Clarkson et al., 2013)

What is pressure in flow modeling?

Pressure is usually the first variable to be matched in the history matching process. As a first approximation, uncorrected historical pressures can be compared directly with model pressures. Corrections to model calculated pressures should be applied when fine tuning the history match. Pressure corrections are discussed in the more modern flow modeling texts, such as Mattax and Dalton [1990] and Fanchi [2001a ]. The corrections are generally based on Peaceman's pioneering efforts to correctly relate model pressures and field pressures [ Peaceman, 1978 ].

How to determine production rate?

The historical performance of the specified rate is verified by comparing observed cumulative production of the phase or phases that correspond to the specified rate. For example, if we specify oil rate, we adjust model input data to match water and gas rates. To verify that the specified oil rates are correct, we compare model calculated cumulative oil recovery with historical cumulative oil recovery. If the history of reservoir performance is extensive, it is usually advisable to rely more on the validity of the most recent field data when performing a history match.

What are the conservation laws of reservoir simulation?

The basic conservation laws of reservoir simulation are the conservation of mass, energy, and momentum. Mass balance in a representative elementary volume or gridblock is achieved by equating the accumulation of mass in the gridblock with the difference between the mass leaving the gridblock and the mass entering the gridblock. A material balance is performed for each gridblock. The ability of the simulator to account for flow between gridblocks is what makes a simulator different from a reservoir engineering material balance program.

What is the flow rate of a back pressure test?

The classical back pressure test method is applied in simulation with a flow rate of 2, 4, 6, and 8 × 10 4 m 3 /d in an increasing sequence, and flow duration for every rate is the same in a simulation but different for a different simulation. Flow durations for different simulations are 24, 72, 240, and 720 h, respectively. Flowing pressures under each rate are measured. One of the pressure histories with a uniform flow duration of 24 h is shown in Fig. 3.66.

How does a reservoir simulator work?

A compositional reservoir simulator calculates the PVT properties of oil and gas phases once they have been fitted to an equation of state (EOS), as a mixture of components. The simulator then uses the fitted EOS equation to dynamically track the movement of both phases and components in field. This is accomplished at increased cost in setup time, compute time, and computer memory.

What is reservoir model?

For example, a reservoir model may be a stratified heterogeneous reservoir. In the design scheme, the reservoir with the same model of it can be represented as a reservoir of a circular shape, a rectilinear reservoir, etc.

What is a MRST?

MRST – The MATLAB Reservoir Simulation Toolbox (MRST) is developed by SINTEF Applied Mathematics as a MATLAB® toolbox. The toolbox consists of two main parts: a core offering basic functionality and single and two-phase solvers, and a set of add-on modules offering more advanced models, viewers and solvers. MRST is mainly intended as a toolbox for rapid prototyping and demonstration of new simulation methods and modeling concepts on unstructured grids. Despite this, many of the tools are quite efficient and can be applied to surprisingly large and complex models.

What is the Boast simulator?

BOAST – Black Oil Applied Simulation Tool (Boast) simulator is a free software package for reservoir simulation available from the U.S. Department of Energy. Boast is an IMPES numerical simulator (finite-difference implicit pressure-explicit saturation) which finds the pressure distribution for a given time step first then calculates the saturation distribution for the same time step isothermal. The last release was in 1986 but it remains as a good simulator for educational purposes.

What happens to the gas in a reservoir depletion study?

As a result of declining pressure as in a reservoir depletion study, gas will be liberated from the oil. If pressures increase as a result of water or gas injection, the gas is re-dissolved into the oil phase.

What is a natural fracture simulation?

Natural fracture simulation (known as dual-porosity and dual-permeability) is an advanced feature which model hydrocarbons in tight matrix blocks. Flow occurs from the tight matrix blocks to the more permeable fracture networks that surround the blocks, and to the wells.

What is a system of interrelated quantitative ideas about the development of a field?

A system of interrelated quantitative ideas about the development of a field is a model of its development , which consists of a reservoir model and a model of a field development process.

What is reservoir simulator?

Any reservoir simulator consists of n + m equations for each of N active gridblocks comprising the reservoir. These equations represent conservation of mass of each of n components in each gridblock over a timestep Δt from tn to tn+1. The first n (primary) equations simply express conservation of mass for each of n components such as oil, gas, methane, CO 2, and water.

How does lower run turnaround time affect reservoir studies?

This topic relates to the observation that lower run turnaround time can increase benefits from a reservoir study allotted a budgeted time period. As a corollary, time spent in repeated runs fighting model instabilities or time-stepping is counterproductive. While many factors affect this run time, it always equals the product (CPU time/step) × (number of timesteps). The first factor is "large" and the second "small" for the Implicit formulation, and conversely for the IMPES formulation. IMPES is a conditionally stable formulation requiring that Δ t < Δ t * to prevent oscillations and error growth, where Δ t * is maximum stable timestep. The conditional stability stems from the explicit treatment of nonpressure variables in the interblock flow terms. Mathematicians performed stability analyses for constant-coefficient difference equations bearing some resemblance to IMPES. Authors in our industry extended and applied their results to derive expressions for Δ t *, in particular,

How to improve the stability of the IMPES formulation for the two phase water/oil case?

The stability of the IMPES formulation for the two-phase water/oil case was improved by following the IMPES pressure equation solution with solution of a water saturation equation using implicit saturations (mobilities). This concept was extended to the three-phase case and called the sequential formulation. For each Newton iteration, this method requires solution of the IMPES pressure Eq. 7, followed by solution for two saturations from a similar equation where the Aij elements of A are 2 × 2 matrices.

What is the purpose of simulation?

The purpose of simulation is estimation of field performance (e.g., oil recovery) under one or more producing schemes. Whereas the field can be produced only once, at considerable expense, a model can be produced or run many times at low expense over a short period of time.

What is the definition of simulation in petroleum?

Simulation of petroleum reservoir performance refers to the construction and operation of a model whose behavior assumes the appearance of actual reservoir behavior. A model itself is either physical (for example, a laboratory sandpack) or mathematical. A mathematical model is a set of equations that, subject to certain assumptions, describes the physical processes active in the reservoir. Although the model itself obviously lacks the reality of the reservoir, the behavior of a valid model simulates—assumes the appearance of—the actual reservoir.

What is implicit formulation?

The implicit formulation expresses interblock flow terms using implicit (new time level) values of all variables in all gridblocks. As a consequence, all nonzero Aij elements of the A matrix of Eq. 3 are full n × n matrices. The resulting multiplies in the linear solver are then either matrix-matrix or matrix-vector multiplies, requiring work (number of scalar multiplies) of order n 3 or n2, respectively.

What is Well Stimulation?

Well stimulation (or simply stimulation) is a treatment process to enhance or repair the productivity of a well. It basically creates or improves the flow of the mineral underneath the ground. The minerals flow from the reservoir in the formation to the wellbore, from where they are pumping out of the ground and will go transportation.

Types of Oil Well Stimulation

Well stimulation falls under two categories: hydraulic and matrix. Essentially, there are three types or methods of well stimulation.

Why is Well Stimulation Important?

As discussed above, stimulation may not only be necessary for new wells but also existing ones. A reservoir that requires stimulation is classified as unconventional because it doesn’t have a consistent or speedy natural flow.

Conclusion

Well stimulation or reservoir stimulation is crucial for initiating and restoring the productivity of an oil or gas well. Hydraulic fracturing is the most common method today, especially with the advent of shale oil.

What is reservoir stimulation?

Reservoir stimulation is an approach performed to repair formation damage or improve reservoir productivity. Terms like hydraulic fracturing or matrix acidizing are ways of improving reservoir productivity at well or field level.

What do reservoir engineers understand?

Reservoir engineers understand drive mechanisms, well placement, and spacing. IMHO reservoir engineers should “own” the reserve determination and economic evaluation processes, but that’s not always the case.

What is the difference between simulation and stimulation?

In summary, simulations gives structural images and flow pattern of the reservoir, while stimulation improves and enhance the productivity of the well.

What is EOR in well placement?

EOR even includes well placements desiging for an efficient flood pattern , pressure maintanance, some times even altering the crude properties.

MEERA

It is the best reservoir simulation software developed by Target Solutions. It’s basically an accustomed three-phase numerical reservoir simulator with 3D functioning and following features:

ECLIPSE

It is a reservoir simulator originally developed by Exploration Consultants Limited and currently owned, developed, marketed and maintained by SIS (formerly known as GeoQuest), a division of Schlumberger having different features:

Reservoir Grail

This efficient and reliable software or simulator is developed by Grail Quest having different features;

Voxler

Voxler is used extensively by geologists, environmental scientists, project stakeholders, GIS analysts, educators, and many others across the globe. Having different characteristics;

Surfer

It is used globally by many geologists, geophysicists, hydrologists, archaeologists, oceanographers, biologists, consultants, engineers, and many others with different functionalities;

Overview

Reservoir simulation is an area of reservoir engineering in which computer models are used to predict the flow of fluids (typically, oil, water, and gas) through porous media.

Under the model in the broad scientific sense of the word, they understand a real or mentally created structure that reproduces or reflects the object being s…

Fundamentals

Traditional finite difference simulators dominate both theoretical and practical work in reservoir simulation. Conventional FD simulation is underpinned by three physical concepts: conservation of mass, isothermal fluid phase behavior, and the Darcy approximation of fluid flow through porous media. Thermal simulators (most commonly used for heavy crude oil applications) add conservat…

Other engineering approaches

Without FD models, recovery estimates and oil rates can also be calculated using numerous analytical techniques which include material balance equations (including Havlena–Odeh and Tarner method), fractional flow curve methods (such as the Buckley–Leverett one-dimensional displacement method, the Deitz method for inclined structures, or coning models), and sweep efficiency estimation techniques for water floods and decline curve analysis. These methods wer…

Software

Many programs are available for reservoir simulation. The most well known (in alphabetical order) are:

Open source:

• BOAST – Black Oil Applied Simulation Tool (Boast) simulator is a free software package for reservoir simulation available from the U.S. Department of Energy. Boast is an IMPES numerica…

Application

Reservoir simulation is ultimately used for forecasting future oil production, decision making, and reservoir management. The state of the art framework for reservoir management is closed-loop field development (CLFD) optimization which utilizes reservoir simulation (together with geostatistics, data assimilation, and selection of representative models) for optimal reservoir operations.

See also

• Black-oil equations

• Reservoir modeling

• Geologic modeling

• Petroleum engineering

• Computer simulation

External links

• * Software for reservoir simulation