What is difference between resawn and rough sawn lumber?

What is difference between resawn and rough sawn lumber? Rough sawn lumber is lumber which is cut, but not finished. It is left literally rough and needs to be dried, planed, and otherwise finished. It is less costly and some people prefer working with it because it gives them greater control over the finished product.

What does a rough cut lumber look like?

Rough sawn lumber is slightly larger than finished lumber. This is because of the shrinkage associated with planing and drying; it is cut rough and large to leave room to plane the lumber to smooth it and to allow it to shrink as it dries.

How to buy rough cut lumber?

Buy smart to get the best deals and the best wood. 1. Start out thick. Rough lumber thicknesses are measured in 1/4-in. increments. The thinnest rough-cut boards, labeled 4/4, and called four quarter, are 1-in. thick. It’s tough to get surfaced stock thicker than 13/16-in. from 1-in. rough stock.

Where to buy rough wood?

The Urban Lumber Company is a Kansas City based hardwood lumber retailer. We sell premium air and kiln dried rough lumber harvested from local neighborhoods.

What is rough wood used for?

Rough sawn timber is usually used for pieces such as internal frames where it will be concealed by a neat outer layer. It is also used for beams beneath flooring or in attics where it will not be visible. In fact, for any job where the strength of the wood is the most important factor, not its appearance, it is ideal.

Is Rough lumber cheaper?

Rough cut lumber is known to be cheaper than treated lumber. However, it is quite a bit more to haul and deliver because it is heavier than treated lumber. But if you are picking the lumber up yourself, it will almost always be cheaper.

How is rough lumber sold?

Rough lumber is sold based on its cost per bd. ft. Some species are more pricey than others, and thicker boards cost more per bd. ft.

What is the difference between rough cut lumber and dimensional lumber?

Dimensional lumber is the exact opposite of rough cut lumber. Dimensional lumber is the type of wood you would normally find in a home improvement store. This type of lumber has been thoroughly milled and represents its final thickness. It's also very smooth and boasts properly rounded edges.

Can I build a house with rough cut lumber?

Rough sawn lumber is a great addition to just about any home. If you've decided that your next home project is going to be built around the use of rough sawn, and it's your first time doing so, then you may have a lot of questions.

What is the difference between nominal and rough lumber?

Nominal sizes harken back to the original rough green lumber sizes, the actual sizes are the size of the board after the rough green lumber has been dried and surfaced smooth on all four sides. The nominal size is the accepted standard terminology used for buying, selling, and specifying softwood lumber.

Is it better to buy rough lumber?

Save Money on Rough-Sawn Buying rough-sawn lumber and planing your own wood definitely saves money; how much money depends on the species and on the size of the project. The larger the project, the more you save.

Is Rough Cut lumber stronger?

You may have heard the term rough sawn (or rough cut) lumber before. What it essentially means is that this lumber type is untreated and cut into planks. It is generally stronger than other types of lumber, but also carries extra moisture because it hasn't been kiln-dried.

What is the price of rough cut lumber?

Rough White Pine Lumber PricingDimensions<100 (bdft)100-500 (bdft)1 X 10 X 16$2.18$1.981 X 12 X 8$2.12$1.901 X 12 X 10$2.12$1.901 X 12 X 12$2.12$1.9021 more rows

Can rough sawn timber be used outside?

Like untreated studwork, this works well in stud wall partitioning and general construction. But you can use it outdoors as well as inside your home. It's also pressure-treated to protect against fungal and insect attack.

Can you sand rough sawn timber?

The proper way to sand wood is to start sanding with a sanding grit coarse enough to remove the debris and expose the wood grain. Then, sand with a slightly higher grit to remove the scratches caused by the coarse grit. Repeat this process until you reach 220 grit.

How do you treat rough cut lumber for outdoor use?

You simply soak the lumber in the borate solution. Most people just build a trough using 6-mil plastic sheeting. The different borate chemicals come with instructions telling you how to mix the powder with water and how long to soak the lumber.

Is it better to buy rough lumber?

Save Money on Rough-Sawn Buying rough-sawn lumber and planing your own wood definitely saves money; how much money depends on the species and on the size of the project. The larger the project, the more you save.

What is the cheapest cut of lumber?

Wood quality The very cheapest boards, furring strips, are usually very rough, with rounded edges and lots of imperfections. More expensive wood planks will have much straighter edges, less warping, and a smoother finish.

What is the price of rough cut lumber?

Rough White Pine Lumber PricingDimensions<100 (bdft)100-500 (bdft)1 X 10 X 16$2.18$1.981 X 12 X 8$2.12$1.901 X 12 X 10$2.12$1.901 X 12 X 12$2.12$1.9021 more rows

What is the cheapest way to get lumber?

Unless you're in a huge time crunch, you're much better off going to a big box store or a lumber yard. When it comes to cheap lumber, The Home Depot generally has a slight edge over Lowe's.

What is rough cut lumber?

As the name suggests, rough-cut lumber is the lumber yielded from a log after the first cut only. After a couple preparation steps, the log is cut into dozens of boards of different sizes. After this, no further processing is done. There is such a market for lumber that is minimally processed because the necessary tools to further prepare a board for a project are residentially sized and largely available to anyone.

Why do people buy rough cut lumber?

Many people prefer to buy rough cut lumber because they are essentially paying for a planking step that is done by a large sawmill, and most woodworkers do not own such equipment . Ultimately, it is the affordability of the lumber that brings this market together. In fact, rough-sawn lumber can be more than three times less expensive than an equivalent size of dimensional lumber. That alone could justify the planer and jointer you’d need to process your rough cut lumber.

What is dimensional lumber?

Dimensional lumber is widely used in appearance projects such as decking, flooring, furniture, and shelving. Dimensional lumber boasts a cleaner finish and guaranteed performance due to the grading system. Aside from appearance projects, dimensional wood is also heavily used in wall framing in houses as well. Builders can rely on the accuracy of dimensional lumber to ensure the wall framing is measured out perfectly and everything goes together smoothly. Since dimensional lumber is already cut to standard size, larger projects may save money and time by not worrying about getting every board planed down to the exact size.

What is flat sawn lumber?

Lastly, you’ll want to keep an eye out for flat sawn vs. quarter sawn lumber. Most boards will be flat sawn, that is, all cuts were parallel on the log. This method yields boards with varying grain patterns, with less texture on boards cut from the outer edges. Occasionally, you will find quarter sawn boards. To make these boards, a log is first quartered, then boards cut from the outside edge inward. This creates an incredibly stable board as each board has a quality grain structure.

Can you use rough sawn lumber?

There are many applications for rough sawn lumber. Many structural projects that won’t be exposed can use this kind of wood since you will be more worried about the strength properties over the appearance. Unless you are working on a project that would benefit from a textured, rustic appearance, it is best to use rough-cut lumber for structural builds and framework.

What is rough sawn lumber?

Depending on a variety of factors including lumber type, lumberyards will cut timber to various sizes and leave them out in the air to dry. Once it dries, the lumber will not all be the same uniformed size, even if they are close. This is called rough-sawn lumber. It might still contain up to 20 percent water. If this is the case, the boards will still be close to the dimensions that it had when it was cut.

Why do woodworkers buy rough sawn lumber?

Since the lumber is usually available from local producers, some woodworkers also like to purchase rough-sawn lumber because it helps support local businesses and companies . Lumber from large chains may have been transported from across the country or even from another country. Transportation costs also add to the environmental impact of mass-produced lumber.

Why do woodworkers prefer rough sawn wood?

* The surfaces can have a more rustic appearance, since they aren’t milled like what you see in the lumber store.

What are the disadvantages of rough sawn wood?

The main disadvantage of rough-sawn wood stock is that it takes more effort to work with it. Woodworkers are normally the ones that will employ and purchase this type of material. You have to mill it including planning and possibly running it on a jointer, depending on if you purchase the wood true on one side.

Why is air dried lumber called full dimension lumber?

This is because air drying leaves quite a bit more water in the wood than modern, commercial drying processes, such as in a kiln or dryer. The water expands the wood.

Where do woodworkers buy lumber?

These days, woodworkers and carpenters tend to purchase lumber from retail sources . These retail wood sources include home improvement stores and even big box stores. This mass-produced wood comes in bundles and gets dried in commercial kilns before it gets packaged up and sold at retail outlets.

Can you buy lumber before it is dry?

Another problem is purchasing it before it is completely dry. The lumber mill should tell you if it needs to sit up, stacked with sticks between them so that they can dry for a longer period. If this is the case, you aren’t able to work with the material right away, but have to wait for the moisture to air out.

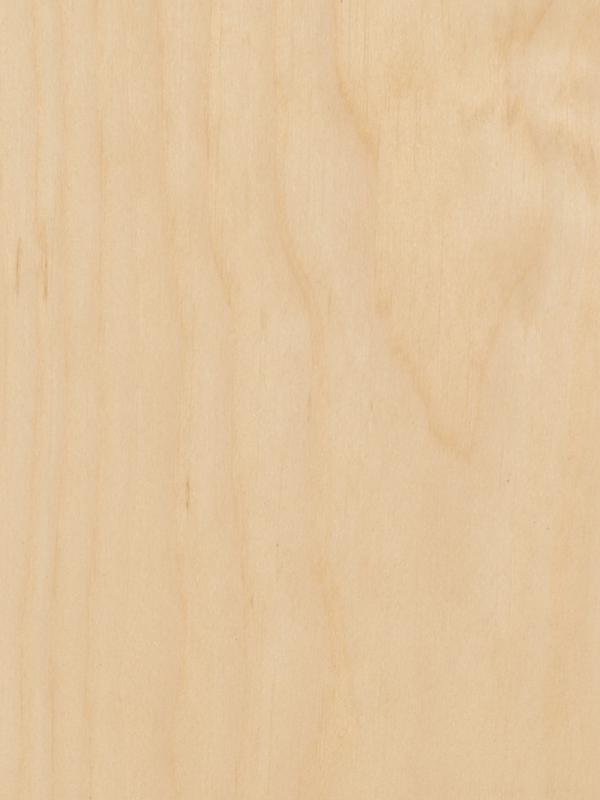

What is rough cut lumber?

Rough cut lumber is a variety of lumber that’s name perfectly describes what it is: rough, unfinished lumber. Rough cut lumber is usually not milled nor does it represent its final thickness or correct dimension. Typically, rough cut lumber is coarse to the touch and shows the saw marks.

How is lumber processed?

Lumber is Processed in Different Ways. From providing the framework of a home to a variety of furniture needs, lumber has a vast number of uses. Additionally, depending on the purpose it will serve, lumber will be processed in different ways before it is sold. Before shaped, whittled, or sanded, lumber will be cut to a certain dimension ...

What is the purpose of a planer for wood?

Once this is completed, the wood lumber will be sent through a planer to ensure that the dimensions are correct, the surface is smooth, and the edges are properly rounded. However, this is a process that differs depending on the cut of wood and the purpose it will serve; especially in the case of rough cut lumber.

Can carpenters use rough cut lumber?

Although rough cut lumber is oftentimes jagged and irregular, some woodworkers and carpenters actually prefer to use it in the assorted projects. For example, carpenters and woodworkers can use this type of wood to create special furniture pieces.

Do you sand lumber before shaped?

Before shaped, whittled, or sanded, lumber will be cut to a certain dimension and placed through the drying stage–sometimes the boards will slightly shrink during this process since it’s being stripped of all water that it has retained over time; this is sometimes done through the use of a kiln.

Is rough cut lumber environmentally friendly?

House framework. In addition to these applications, rough cut lumber is actually more environmentally savvy since it reduces transportation and processing costs. Those who purchase rough cut lumber are helping to support lumber yards and businesses, as well.

What is rough sawn?

What is the meaning of rough sawn? This is the most basic form of wood preparation after felling. The timber has been cut to size with a circular saw and received no further treatment. This will leave the sides and edges of the timber with a rough, unfinished surface where the saw cut through the wood. Due to the simplicity of preparation, rough ...

What is hardwood group?

Hardwoods Group are specialist suppliers of wholesale timber. We can supply rough sawn timber to all specifications and specialise in oak machining and moulding. Whatever style or finish you have in mind, we can meet your needs. Contact us today to discuss your requirements, we will be happy to help.

What is PAR wood?

As noted above, PAR is used for feature pieces where all four sides of the timber will on display . For example, outdoor structures such as gazebos or summerhouses where the entire frame is visible. It is also the only safe choice for pieces that bare skin will be in contact with regularly. For balustrades or fence tops, a rough finish can easily cause splinters to hands run along their surface. PAR timber is also used in furniture construction for this reason. For internal features, PAR just looks prettier than rough sawn timber. While many people prefer the look of bare wood such as oak, planed timber is also far easier to apply finishes to. Applying wax, stains or varnish to rough sawn timber would be difficult and pointless. This gives the user a much wider choice of finishes and planed timber is much easier to dust and clean. A major boon to DIYers is the ability to start working with PAR timber as soon as it is delivered. It needs no preparation and is safer to handle.

What does PAR stand for in woodworking?

PAR is a trade acronym that stands for Planed All Round. After sawing, the timber is passed through the planer to smooth all four surfaces. This gives a level, uniform surface to all edges and sides. For features where all four sides of the timber will be visible, this gives a neater, safer finish.

What is PBS flooring?

PBS (Planed Both Sides) is planed on both of the wider surfaces, as the name implies. This can be useful for flooring when building verandas or internal balconies. As the floorboards are visible from above and below, this give a neat, smooth finish without the expense of PAR timber. 4.

Can you wax rough sawn wood?

Applying wax, stains or varnish to rough sawn timber would be difficult and pointless. This gives the user a much wider choice of finishes and planed timber is much easier to dust and clean. A major boon to DIYers is the ability to start working with PAR timber as soon as it is delivered.

Is PAR timber the most expensive?

Both are planed, but to different degrees depending on the use they will eventually be put to. The extra work involved in producing PAR timber makes it the most expensive of all.

How thick is rough sawn lumber?

Hardwood lumberyards sell rough-sawn lumber in various thicknesses. Most yards label thicknesses in 1/4-in. fractions: 4/4 = 1 in., 5/4 = 1-1/4 in., 6/4 = 1-1/2 in., etc. Buy boards at least 1/4 in. thicker than your final dimension in order to account for the material that will be removed by the jointer and planer. Thicker boards cost more per board foot, so you won’t save any money by buying a 2-in. board and resawing it into two 1-in. boards.

What is lower grade lumber called?

Lumber with more knots costs less, which makes sense. If your project contains a bunch of smaller pieces, you can save money by cutting out and around those defects. This lower-grade lumber is often called No. 1 Common (1C). Sometimes you can find a gem or two that may look good enough as is, or have long enough clear cuts between the knots for the boards you need. Plus: Understanding Plywood Grades

What is 1C lumber?

If your project contains a bunch of smaller pieces, you can save money by cutting out and around those defects. This lower-grade lumber is often called No. 1 Common (1C). Sometimes you can find a gem or two that may look good enough as is, or have long enough clear cuts between the knots for the boards you need.

How many cubic inches is a board foot?

What's a Board Foot? Lumberyards sell rough-sawn wood by the board foot, not linear foot. A board foot (bd. ft.) is 144 cubic inches of wood. Bring a tape measure because the length and thickness of the boards might be labeled, but the width will not.

What is a sticker on wood?

Stickers are the spacers used to separate boards while they’re drying. Occasionally stickers can create shadow-like stains. These stains appear to be just on the surface, but it’s common that they go deeper than 1/8 in. into the wood, so they may still be visible after planing. Plus: How to Stain Wood Evenly Without Getting Blotches and Dark Spots

Is rough sawn wood flat or rough?

Most rough-sawn wood these days has been plain (or flat) sawn. But you may come across a couple of species that have been quarter-sawn. Quarter-sawn wood is more stable and much less likely to warp, but it also costs a lot more. Plus: How to Use a Bench-Top Planer

Can you use twisted boards in milling?

The shorter the boards you need, the bigger the bend you can work with. However, avoid twisted boards. The internal forces that are causing the twist may never go away no matter how much material you remove. Our expert’s motto: “Once twisted, always twisted.” Plus: Choosing 4x4 Wood

What is Rough-Sawn Lumber?

When a tree is processed at a lumber mill, the first stage of cutting the lumber up into dimensional lumber is known as the “rough sawn” stage.

What to look for when buying rough sawn lumber?

You’ll need to invest in a good jointer and benchtop planer, or a set of hand planes that include a No.7 jointer plane.

What happens when you cut lumber?

If it is cut from green lumber, it will warp, cup, and twist during the drying process. Sometimes, the edges of rough-sawn lumber crack while drying. The wood is rough to the touch, and you’ll see tool marks from the bandsaw. Rough sawn lumber requires a lot of work, either with a hand plane or a jointer and thickness planer.

What does it mean to get processed S4S lumber?

Do you want to save time? Getting processed S4S lumber means you have boards that are ready to cut and be transformed into furniture. However, if the S4S lumber has not thoroughly dried, you’ll still find cups and twists. Removing these will result in an even thinner board.

What happens if you process rough sawn lumber by yourself?

If you process rough-sawn lumber by yourself, you will lose less and end up with larger boards.

What is S2S lumber?

At this stage, it is called S2S lumber – which stands for “surfaced two sides.” (Some people refer to is as “smooth four sides” instead, although I believe the former is the correct one.) These two sides are enough for a woodworker to work with.

What to know when buying S4S lumber?

If you decide to buy S4S lumber, take note of the differences between nominal and actual dimensions. Make sure to buy wood where the actual dimension is larger than what you require since you might need to joint and plane it anyways.

How many BF is a piece of hardwood?

Also, if you sell a dry, planed piece of hardwood lumber that is 1.00 x 11.51 x 10.5', this is actually considered as 5/4, so it is 12 BF (the first piece) and 13 BF the second piece, etc.

How much wood is 6BF?

It is 6BF. Now look at a piece that is 1.24 inches thick x 6.49 inches wide and 12.99 feet long. It is also 6BF. The first one is 793 cubic inches, or 132 cubic inches per BF. The second one is 1254 cubic inches or 209 cubic inches per board foot. Of course, you could add a little wane or a beaver tail to the end of the first piece and get even less than 132 cubic inches of wood per BF!

How much BF is a 2x4x8?

For example, a 2x4x8' is really 1.5" x 3.5" x 8.00'. So, 5.33 BF (softwoods use 2 decimals, hardwoods do not) is actually 504 cubic inches, or 95 cubic inches per BF.

How thick is a board foot?

The definition of board foot is quite tricky, as with hardwoods, the thickness is 1-1/8 inch (often) and not 1-inch (or 4/4). Actually, 4/4 goes from 1.00 to 1.24 inches thick. Also, because hardwoods only use BF to the closest foot, 1 BF is the size of a piece of hardwood lumber ranging from 6" to 18" wide and 12" ...

Why is current terminology skewed?

Current terminology is all skewed way out of line. The reason for it being that way is because it has been that way, but that doesn't make it right.

Is shaving lumber profitable?

Now it is a profit item. Those shavings are worth more than the cost to make them, or as in a lot of new mills, lumber is sawn very close to finish size--1 3/4 for a 2X and then dressed down to finish size.

Is lumber sold by board foot?

Lumber is indeed sold by the board foot. Hardwoods are sold by the "whole number" or integer board foot and not fractions. It does not have to do with scale, it has to do with the measure, which for hardwoods does not have fractions.