What is snarling in textile manufacturing?

Snarling is a persistent problem in textile manufacturing processes such as warping, winding, knitting and weft insertion. In such processes, the tendency of yarn to snarl is considered to be a negative feature leading to the yarn breakage, reduced fabric quality and low production efficiency.

What is the tendency of yarn to snarl?

In such processes, the tendency of yarn to snarl is considered to be a negative feature leading to the yarn breakage, reduced fabric quality and low production efficiency. On the other hand, the tendency of a yarn to snarl is employed to advantage in fancy yarn manufacture.

What is yarn in textile?

22 Types Of Yarns In Textile – Explained!!! - Textile Property 22 Types of Yarns In Textile – Explained!!! Yarn is a collective term of linear assembles of fibers or filaments that are twisted together to impart strength or they can laid together to form a continuous strand that is suitable to manufacture fabric.

What is spiral fancy yarn?

The spiral fancy yarn is a plied yarn with smooth spiraling of one component around the others. Delivering one or more of its components at a greater speed can produce fancy yarn with spirals, so the shorter length of the component forms the core, while the greater length of the components creates the spirals.

How is snarl yarn made?

During yarn formation by spinning, fibres are bent into approximately helical shapes and tension is created Twisted yarns tend to untwist because of this tension. When twisted yarn tension is slackened, the yarns usually get coupled as loops and twisted in the reverse direction forming snarls.

What are the different yarn twists?

There are two types of twist applied in yarn. One is S twist and another one is Z twist. What is S Twist in Textile? The fibers from a helical angle at the yarn surface when yarn is twisted in anticlockwise direction.

What is a gimp yarn?

Gimp is a narrow ornamental trim used in sewing or embroidery. It is made of silk, wool, polyester, or cotton and is often stiffened with metallic wire or coarse cord running through it. Gimp is used as trimming for dresses, curtains, furniture, etc.

What are slub yarns?

Definition of slub yarn : a yarn with thick and thin sections alternating regularly or irregularly — compare slub.

What are the three types of textured yarns?

These are produced by additional heat treatment through a second heating zone to the stretch yarn during false-twist or Edge crimping methods....Types of Textured YarnsStretch yarns.Modified yarns.Bulk yarn.

What are the two types of yarn?

Yarns can be described as single, or one-ply; ply, plied, or folded; or as cord, including cable and hawser types.

Why do they call it gimp?

Gimp was first used in the 1920's, possibly as a combination of limp and gammy, an old slang word for "bad."

Why was it called gimp?

GIMP is a popular image editing tool, but its name isn't as universally loved. The software's title, which is an acronym of GNU image manipulation program, is a word that can also be used as an ableist slur, and has sexual connotations. To fix this, a new fork of the GIMP editor, called Glimpse, has been created.

What are gimps used for?

GIMP is an acronym for GNU Image Manipulation Program. It is a freely distributed program for such tasks as photo retouching, image composition and image authoring.

Is slub yarn a fancy yarn?

One of the most popular and well-known fancy yarns is slub yarn which has been used in various types of apparel such as suits and shirts. Corkscrew, spiral, chenille, gimp, loop, snarl and boucle have all found acceptance in apparels and for the production of furnishings and upholstery.

What is flock yarn?

Flock is a lightweight yarn made from American wool and milled in Vermont. It is made of a single strand of yarn giving it a rustic, handspun feel. That said, the wool used in Flock is soft!

What does Slubb mean?

: a soft thick uneven section in a yarn or thread.

Is S or Z twist better for crochet?

Lefties have an easier time crocheting with S twisted yarn as both crocheting and yarn spun direction are the same. That means lefties have a harder time crocheting with Z twisted yarn.

What is the difference between S twist and Z twist yarn?

S-twist yarn is a yarn spun counter-clockwise and is normally used to create right-handed twill, while Z-twist yarn is used for left-handed twill. By opposing the direction of the yarn and the direction of the twill, the finished material is softer than fabric created with a corresponding yarn and twill weave.

How do I know what twist my yarn is?

The number of twists per inch can, in plied yarns, be determined by counting the number of bumps in one inch, and dividing that number by the number of singles (the strands plied together to make the yarn).

Which yarns have Z twist?

Creped yarns Yarns with a 'cabled' or 'crepe' construction also usually have a final Z-twist. In these yarns, singles are Z-twisted, then plied together with an S-twist, then those 2 ply yarns are plied together again with a final Z twist.

How are spiral yarns made?

Spiral yarns can be produced with one component yarn being fed faster than the other, requiring special overfeeding devices, which are described later in this chapter; they may also be made by simply plying yarns with differing linear densities but with the same feeding speed. In this case, no special feeding devices are required. Although the two component yarns have the same length during feeding, once plied, the two yarns will have different lengths depending on the ply twist direction. If the ply twist is in the same direction of the thick yarn twist, the thick yarn will contract, leading to a final yarn in which the thin yarn spirals around the thick yarn; if the ply twist is in the opposite direction of the thick yarn twist, the thick yarn will lengthen, leading to a final yarn in which the thick yarn spirals around the thin yarn.

What is fancy yarn?

In fancy yarns, however, the variations are introduced by design to enhance the aesthetic appearance. These yarns provide the fabric designer greater scope in achieving a more attractive and exclusive product, but also pose greater challenges as they usually suffer from poorer performance and higher costs. Fancy yarns structures are manifested in terms of irregularities of curvatures of the central yarn axis and changes in the diameters of cross-sections in the yarns. The fancy yarn gives a fancy touch to the fabrics to a broad range of end uses. Significant demand for the fancy yams is the ladies and children outerwear.

Why is fancy yarn so slow?

The production speeds for fancy yarns are generally slower than for plain commodity yarns because of the inherent unevenness of fancy yarn. In addition, most fancy yarns require multiple components and several twisting stages, so the cost of fancy yarn production is typically several times that of commodity yarns.

How to change the loop size of a spinning machine?

Although the loop size is obviously dependent on the effect overfeed ratio, it can also be controlled by the spacing of the two core yarns, the twist level used during the first twisting stage, and the yarn tension. Controlling the twist level is the easiest way to alter the loop size, as it does not require the change of any of the spinning machine parts. The reverse binding process also affords the opportunity to readjust the final yarn twist so that the yarn is not overly hard.

How to introduce unevenness in spinning?

Unevenness can be introduced by varying the drafting roller speed in traditional ring spinning. It can also be introduced by deliberately creating local mechanical faults in machine components in a spinning system , such as the opening roller of a rotor spinning system. It is also possible to exploit the fact that fibers of dramatically different lengths tend to cluster during roller drafting, so mixing these fibers together before drafting and during drafting, the shorter fibers tend to cluster together to form slubs.

Can you overfeed a spiral yarn?

Although it is common to overfeed the effect in the first twisting stage, this is not essential. When the effect yarn is much thicker than the core yarn, which is often the case to emphasize the wavy effect, it is possible to produce a spiral effect without the specialist overfeeding device. Reverse binding this spiral yarn can also produce a gimp yarn with more subtle wary projections.

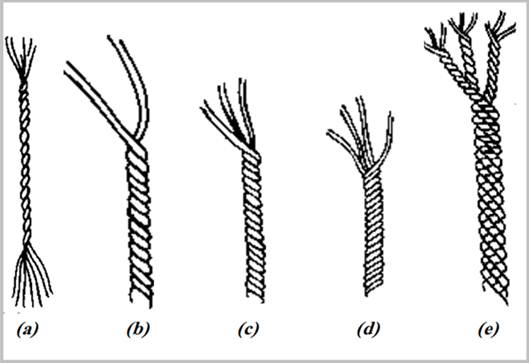

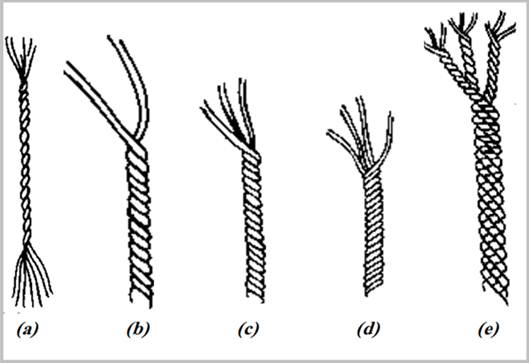

What is a snarl yarn?

A snarl yarn is one that displays ‘snarls’ or ‘twists’ projecting from the core. It is produced by a similar method to the loop yarn but uses a lively, high twist yarn and a somewhat greater degree of overfeeding as the effect yarn.

What is loop yarn?

A loop yarn has a core with an effect yarn wrapped around it and overfed to produce a nearly circular projection on its surface . Figure 5 shows the structure of a loop yarn, in this case somewhat simplified by showing the core as two straight bars. In reality, the core, which for a loop yarn always consists of two yarns twisted together, which, can entrap the effect yarn.

What are the components of a yarn?

The three components of the yarn are the core, the effect, and the tie, or binder. The effect yarn has the loops wrapped around a core, or base yarn, and then the third ply, or binder, is wrapped over the effect ply to hold the loops in place. The individual plies could be filament or spun yarns.

What is diamond yarn?

Clearly, a true diamond yarn would show some compression effect upon the thick yarn from the thin ones, an effect which in the interests of clarity is not provided in Figure. This is a yarn that can be very useful to designers looking to create subtle effects of color and texture, particularly in relatively simple fabric structures.

How many yarns are in a loop?

In reality, the core, which for a loop yarn always consists of two yarns twisted together, which, can entrap the effect yarn. As a general rule, four yarns are involved in the construction, of which two forms the core or ground yarns. The effect yarn or yarns are formed with an overfed of about 200% or more.

What is a corkscrew yarn?

A spiral or corkscrew yarn is a plied yarn that displays a characteristic smooth spiraling of one component around the other. The figure below shows the basic structure, which can be produced relatively simply on a doubling frame or under the ring spinning system.

How is diamond yarn made?

A diamond yarn is produced by folding a coarse single yarn or roving with a fine yarn or filament having contrasting color using S-twist, and cabling it with a similar fine yarn using Z twist. Multi-fold or ‘cabled’ yarns may be made by extending and varying this technique, to bring about a wide range of effects.

What is snarling in knitting?

Snarling is a persistent problem in textile manufacturing processes such as warping, winding, knitting and weft insertion. In such processes, the tendency of yarn to snarl is considered to be a negative feature leading to the yarn breakage, reduced fabric quality and low production efficiency. On the other hand, the tendency of a yarn to snarl is employed to advantage in fancy yarn manufacture. This series of papers is devoted to the study of snarling both as an undesirable and a desirable feature of yarns. This paper deals with the critical parameters that cause snarling. An experimental study of yarn behaviour during twisting and snarling has been carried out. Theoretical snarling criteria are considered and applied to the prediction of the critical parameters of snarling. A good comparison between the theoretical behaviour of yarns and the experimental results is achieved when the non-linear behaviour of yarns during twisting is taken into account. Recommendations for avoiding snarling during yarn production and handling are given.

How does twisting yarn affect the liveliness of yarn?

When twisted yarn tension is slackened, the yarns usually get coupled as loops and twisted in the reverse direction forming snarls. This situation is called the twist liveliness of the yarn. Yarn twist liveliness properties should be taken into account during the manufacturing process, and necessary precautions should be taken in order to avoid or minimise problems likely to occur during the subsequent processes. Today setting yarn twists on vacuum steaming machines is the most widely used method of decreasing twist liveliness values of yarns in this study, the effects of vacuum steaming processes and other parameters on the twist liveliness of 100% cotton, 100% viscose and 100% polyester yarns were investigated For this purpose, yarns with different twisting coefficients and numbers were twisted and subjected to vacuum steaming at different temperatures and for different durations according to their raw material properties. Twist liveliness values of these yarns were measured before and after vacuum steaming and the results obtained were assessed by means of SPSS statistics software. Variation analyses and SNK (Student Newman Keuls Tests) tests were carried out at a 5% (0.05) level of significance. As a result of this study, it can be concluded that the vacuum steaming temperature, raw material, the amount of twist, and yarn number have a significant effect on twist liveliness values of yarns.

How is a spiral yarn made?

Spiral or Corkscrew : It is made by twisting together two ply yarns that differ in size, type or twist. These two parts may be delivered to the twister at different rates of speed.

What is novelty yarn?

Novelty yarn and and types of novelty yarn is one kind of fancy yarn. We produce it in textile yarn manufacturing. The use of it is for decorative purpose. Now we use novelty yarns in the art of fashion and designing textiles.

What is chenille in weaving?

These create special effects chenille means caterpillar in French. The yarn has a cut pile effect wh bound to the core on the loom warps are arranged in groups (2-6) which are interlaced in a cross weaving manner. Weft need to insert in a normal manner. Need to cut these into wrap way threads.

What is a cloud yarn?

Cloud: A two coloured yarn, in which both yarns take in turn to obscure or cloud the other, giving the appearance of an intermittent color change. Spiral or Corkscrew : It is made by twisting together two ply yarns that differ in size, type or twist.

How many ply yarns are there?

The characterization of these yarn process by projecting from the body of the yarn at fairly regular intervals. There are 3 ply yarns. The effect yarns forms irregular way surface and binder ties it to the base. It has twisted core yarn.

What is fancy yarn?

Yarn refers to a structure composed of continuous length of interlocked fibers. They are suitable for use in the production of textiles, sewing, crocheting, knitting, weaving, embroidery and rope making. However, fancy yarn deviates from the normal yarns. These deviations occur mainly due to introduction of deliberate decorative discontinuities in the form of color, structure or both. The size and value of the market for fancy yarn is negligible. However, fancy yarns appear mainly in high value items, so their small volumes cannot be ignored. The fancy yarn gives a fancy touch to the fabrics to a broad range of end uses. Significant demand for the fancy yams is the ladies and children outerwear.

Who edited technical textile yarns?

Technical Textile Yarns: Industrial and Medical Applications Edited by R. Alagirusamy and A. Das

Who studied fundamental parameters of some fancy yarns?

Testore and Minero, Study on fundamental parameters of some Fancy yarns, Journal of Textile Institute-1988.

Is there a substitute for handling yarns?

In developing an understanding of yarn structures and types, there is no substitute for handling yarns and analyzing their structure and form. It is a valuable exercise to create a private collection of interesting yarns, and their use in fabrics.

Classification of Textile Yarn construction

Yarn construction, yarn ply, and yarn count associate with each other to form the functional characteristics of the yarn.

Staple Yarns

The industrial textiles mills receive boxes of cut staple artificial fibres for getting carded and processed into yarns. It’s crucial to provide substantial blending before carding the fibres and sustained doubling of the silver when two or more staple fibres are mixed. It will ensure close and efficient blending before spinning and roving.

Innovative yarns for industrial textiles and their uses

These yarns are fed at a faster pace compared to the core yarn during the spinning process. That’s how they are manufactured for industrial textiles .

Innovative yarns: Growth and demand

Entrepreneurs can make a great profit from this excellent, unexplored opportunity. For instance, Reliance Industries has introduced its polyester fibre brand named Recron. The brand is launched in vast ranges depending on the applications like Recron LP or low-pill tow and fibre, Recron easy stretch, and more.

Innovative Yarns: Conclusion

When it comes to conventional yarns for industrial textiles, several countries like India hold a strong position in the global market. However, with time, it has become essential to understand the need for high-performance, innovative yarns for special and technical textiles.