What is solid wood Kerfing? Kerf refers to the width of cut a sawblade makes when it’s cut through wood. When you’re cutting a board you have to allow for the width of the sawblade and its teeth when you’re cutting.

What woods are good for kerf bending?

What happens when plywood is kerfed?

Why does a kerf break?

What happens if you cut a kerfs in the same direction as a grain?

How deep should a kerf be for masonite?

What holds plywood together?

What is Lauan plywood?

See 2 more

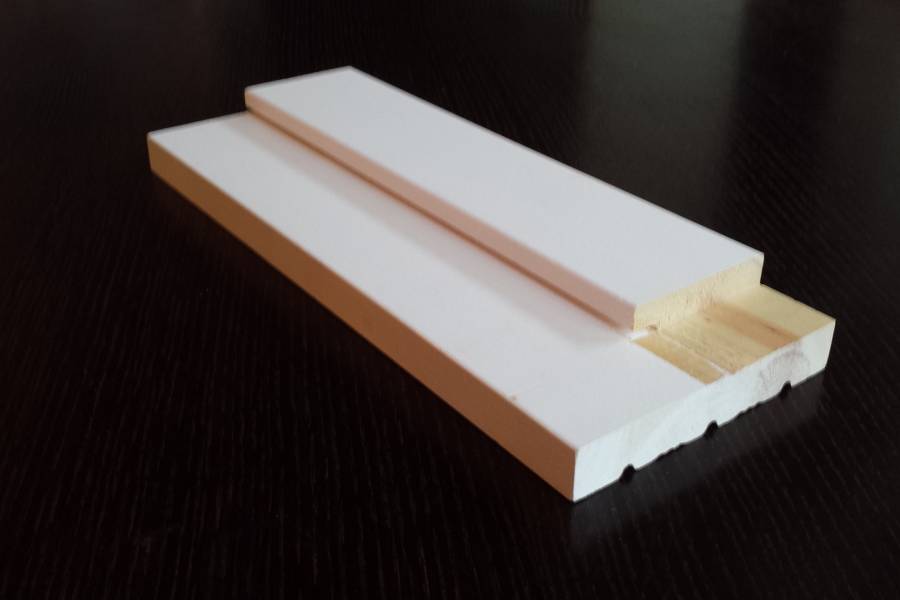

What is wood Kerfing?

Noun. kerfing (plural kerfings) (music, chiefly lutherie) A thin strip of wood kerfed to allow easy bending and then glued inside the body of a string instrument along the rim between its two abutting sides to reinforce the joint.

What is Kerfing in construction?

A kerfed door jamb is one where a kerf (slot) is cut into the door jamb for the purpose of allowing a drywall corner bead to be wrapped directly into the jamb. With this wrapping, the drywall connects directly to the door frame and gap between the door frame and drywall goes away.

What is Kerfing aid?

Kerfing is tapered strips of wood that are glued around the inside seams of a guitar. Their primary function is to add strength and stability where the sides meet the top and back of the instrument.

How do you kerf bend solid wood?

0:0410:01How to Quickly Kerf Bend Plywood and Solid Wood - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou can use any blade it doesn't have to be a flat bottom blade I just have my combination bladeMoreYou can use any blade it doesn't have to be a flat bottom blade I just have my combination blade here in the table saw. And we're gonna use my crosscut sled is a website called block layer com.

Why is it called a kerf?

The width of a saw cut is called kerf. That's an Anglo-Saxon word related to our word carve. The kerf of a lumber saw -- the width of its cut -- might be 3/8 of an inch. Make 50 lengthwise cuts in a 4-foot diameter log, and you waste a lot of wood.

Can you kerf solid wood?

This wood bending technique works with both plywood and solid wood. In this tutorial video we go over how many kerfs to cut, spacing and depth without getting into unnecessary math.

Can you bend wood with vinegar?

Yes, Vinegar help to soften the wood. Vinegar soaks into the wood fibers and makes them saturated. This makes the wood flexible. You can easily bend wood using vinegar.

What is a Kerfing knife?

The Kerf Knife is a carving and decorating tool for fruits and vegetables. Similar to a canal knife, it cuts ribbons, dents and notches but with variable cutting depth. The blade is sharpened and made of stainless steel.

How does Kerfing aid the bending of timber?

If timber is soaked in water or exposed to steam, it can become more flexible. Slots can be cut along the inside face of the timber to be bent allowing for the inside face to cope with the compressive force - this is called kerfing .

How deep is a kerf cut?

For plywood, the general rule is to cut deep enough so you just barely score the second ply (the layer under the face veneer), see photo (C). And for Masonite, the kerf depth should be about one-half (or a little more) of the thickness of the material, see photo (D).

What is the easiest wood to bend?

Certain species of wood bend much easier than others as well. Essentially, the more open the grain, the easier it steams which makes sense as the steam can penetrate the open pores more easily. Of common woods, white oak is best, followed by red oak and beech.

How do you calculate kerf?

Measuring the kerf is fairly straightforward. You simple make a part with a known dimension (such as a one-inch square) and then carefully measure the actual width. If your one-inch square is actually 0.96 inches, then your kerf is 0.04 inches.

How do you make Kerfing?

1:333:47Luthier Tips du Jour - Kerfing jig - YouTubeYouTubeStart of suggested clipEnd of suggested clipWith a small nail is used to attach to the material you want to make kerfing on him the notches willMoreWith a small nail is used to attach to the material you want to make kerfing on him the notches will serve to advance the piece after each cut this assembly is then placed into the jig.

How deep is a kerf cut?

For plywood, the general rule is to cut deep enough so you just barely score the second ply (the layer under the face veneer), see photo (C). And for Masonite, the kerf depth should be about one-half (or a little more) of the thickness of the material, see photo (D).

How do you fill kerf cuts?

You fill kerf cuts by using epoxy/resin or glue. The best are those who have stuck well to wood, and you can use many specialty products. Depending on the project, you either need to screw or nail the wood into place first and then fill it, but you also use clamps.

How do you kerf a stud?

1:071:57Framing Tip - How to Straighten Studs - YouTubeYouTubeStart of suggested clipEnd of suggested clipCut across maybe twice. Essentially all we're doing is we're creating a little space where. We canMoreCut across maybe twice. Essentially all we're doing is we're creating a little space where. We can go back and push this stud into straightness. And then you'll take a block.

What is solid wood?

Other types of wood, such as plywood, medium-density fiberboard or veneers, are manufactured from wood composites. Solid wood is wood that has been cut from a tree.

What are the characteristics of solid wood?

Each type of solid wood has its own characteristics, including its grain pattern, color and texture.

Can you use fillers on solid wood?

No fillers or adhesives are used. Solid wood is often used for furniture, construction, cabinetry and flooring. It does not warp as easily as many engineered woods, but it is more susceptible to stains.

What is kerf bending?

Of these, kerf bending ranks as the simplest method, used primarily on parts whose edges do not show. Kerf spacing determines the minimum bending radius for a piece of stock. (When the kerfs close on the inside, the piece won’t bend anymore.)

How to bend wood to form curved parts?

T here are three basic ways to bend wood to form curved parts: steaming solid stock to make it temporarily pliable; glue-laminating thin strips of wood around a form; or cutting closely spaced kerfs into the back face of solid stock, leaving a thin web of wood on the outside face holding together a series of narrow ribs on the inside, as shown on Drawing 1, below. Of these, kerf bending ranks as the simplest method, used primarily on parts whose edges do not show.

Can you sand flats into a smooth curve?

To avoid this, space the kerfs closer together than required by the “closed kerf” limit. The closer spacing , while not completely eliminating the flats , reduces them so they are easily sanded into a smooth curve.

What is kerfing used for?

Kerfing allows for bending all sorts of thicknesses of stock, and is especially useful for bending plywood. Note here how I kerfed just the areas that were going to be curved, leaving the flat areas to be attached conventionally.

What is kerf bending?

This allows you to work gaps out as you go. Kerf bending is the process of cutting a number of slots into a piece of material that allow it to bend. Essentially, by kerfing the part, you are making it thinner, so it can be flexed to follow a curve.

How to make a good glue joint?

A good rule of thumb is that if the part can be formed by hand, then a good glue joint should hold it perfectly well. Glue up the mating surfaces and clamp the parts together. To avoid gaps, start clamping from the center and work outward, or from one end to the other. This allows you to work gaps out as you go.

How to bend wood to hold shape?

The most basic method is to simply manually bend the wood and attach it to a solid piece to hold the shape. Banding the edge of a curved piece of ply is an excellent example. If the curve is not too tight, and the stick relatively thin, this is easy.

Can veneer be flexed?

Veneer can follow a very tight curve, while a 3/4 inch thick piece of oak cannot be flexed much at all. Typically, the part is held to the curve with glue only since piercing the wood with a nail or screw would tend to break it under the bending stress.

Can a circular saw be used for kerfing?

While this method is not very strong, it does allow for easy forming of wide or tall parts. Nearly any saw can be used for kerfing. Here I used the table saw, but for very long parts, a radial arm saw is ideal. A circular saw or even a handsaw can do the job too.

Can wood be curved?

Nature hates straight lines, and as woodworkers we spend a huge amount of time and effort in making things straight. But curves can and should be a large part of your woodworking. There are several methods for forming wood into curves, and the next few blog posts will explore these techniques. We will be looking at simple force bending, kerf bending, lamination and steam bending.

What is kerfed lining on guitar?

This style of kerfed lining is glued in place with the un-kerfed side out toward the inside of the guitar body. First and foremost it’s just a whole lot easier to glue and clamp in place than the triangular style of kerfed linings, which in and of itself is a great benefit especially for a new builder just starting out. Having the kerfed side glued to the guitar side has other benefits too, it helps to add stiffness and strength to the body shape and also stiffens the perimeter of the guitar in the critical point where the top or back plates meet the sides. I feel this takes some of the structural load off of the top and back plates as well since the stiffer rims can hold its shape more independently.

What is a triangular kerfed lining?

The triangular kerfed lining is probably the most traditional for steel string guitars and might still be the most commonly used, though I don’t know for sure. The interesting feature to note is that the un-kurfed portion gets glued to the guitar side.

What is a solid guitar lining?

Lastly, the solid linings are made from one or more strips of wood bent to the actual shape of the guitar body. They can be a single piece or several thinner pieces that are laminated together for even more strength.

Can you cut a kerf?

There are no Kerf cuts (with some exceptions that you can see in my Luthier’s EDGE step by step tutorial on how to make these solid linings coming in part 2 of this series) with this style since the shape is pre-bent into the wood with steam and heat.

What woods are good for kerf bending?

As you might expect, the solid woodsthat bend the best using steam or thin laminations are also the best choice for kerf bending. Woodssuch as oak. walnut, mahogany, and ash are flexible and bend well. Whatever type of wood is used, choose pieces for bending with grain that runs in a fairly straight line, see photo (A).

What happens when plywood is kerfed?

After plywood is kerfed, the web that remains consists of the thicker second ply and the thin face veneer. If plywood is kerfed across the face grain, the grain of the second ply runs with the kerf. Usually, cutting with the grain weakens wood.

Why does a kerf break?

If you cut the kerfs with the grain, the piece may break along the grain lines as it's bent. PLYWOOD. Hardwoodplywood with softer inner cores bends easier than softwood (fir) plywood. There are two reasons for this. First, the face veneer on softwood plywood is thicker than that used on hardwood plywood.

What happens if you cut a kerfs in the same direction as a grain?

IF KERFS ARE CUT THE SAME DIRECTION AS GRAIN IN SECOND PLY, SECOND PLY WILL FLEX EASILY

How deep should a kerf be for masonite?

And for Masonite, the kerf depth should be about one-half (or a little more) of the thickness of the material, see photo (D).

What holds plywood together?

But with plywood, the face veneer holds it together (and allows it to flex). COMPOSITES. Composites such as particleboard and hard-board (Masonite is one common brand name) have an advantage over both solid wood and plywood — there's no grain direction to worry about, see photo.

What is Lauan plywood?

Second, many hardwood plywoods use lauan for some inner plies, see photo. Lauan (also called Phillipine Mahogany) is more flexible than the fir plies used in most softwood plywoods and bends easier.