There are a large number of benefits and advantages that physical-inventory provides to its users, and the following are the most important benefits:

- Maintain accurate and up-to-date inventory records.

- Provide better forecasts for sales and purchases.

- Ensure that the right quantity of items is always in stock.

- Maintaining and satisfying customers.

- The ability to meet your customers’ requests immediately or tell them when they will be fulfilled.

- Improving the profits of the company or organization in general.

How to conduct a physical inventory?

What to Do Before You Conduct a Physical Count of Your Inventory

- 3 Things to Take Care of First. To prepare for a regular (preferably an annual) physical inventory, many elements need to be put into place.

- Preparation. Preparation is the key to a successful physical inventory. ...

- Cycle Count Program. ...

- Pre-Count Verification/Quarantine. ...

- Work Order (WO) or Job Order (JO) Planning. ...

What purpose does physical inventory serve?

Purpose of a Physical Inventory. A physical inventory is the process of a business physically inspecting and counting every item on the shelves and in the warehouse or storage rooms. Too many times a company can lose track of what inventory it does have, which is a dangerous proposition.

How to perform a physical inventory?

Tips for taking inventory

- Create a map of your store, stockroom or warehouse. ...

- Label boxes and shelves. ...

- Clean up areas where count is taking place. ...

- Use barcode scanners. ...

- Schedule a convenient time for counting. ...

- Weigh stock instead of counting it. ...

- Train and inform staff. ...

- Create a list of included and excluded items. ...

- Leverage inventory management technology. ...

What does physical inventory mean?

Physical inventory is an actual count of the goods in stock. This can involve counting, weighing, and otherwise measuring items, as well as asking third parties for counts of inventory items that have been consigned to them. If a business is maintaining inventory records for each item in stock, then these counts are compared to the recorded balances; the recorded amounts are then changed to match the physical counts.

What are at least 3 reasons to take A physical inventory?

Here are a few more reasons why performing a physical inventory count is so important:Taxes. An annual physical inventory count is usually required for tax purposes. ... Shrinkage control. Physical inventory counts help you identify shrinkage problems. ... Informed decision making. ... Efficiency.

What does physical inventory consist of?

What is Physical Inventory? Physical inventory is an actual count of the goods in stock. This can involve counting, weighing, and otherwise measuring items, as well as asking third parties for counts of inventory items that have been consigned to them.

What does physical inventory count determine?

It is also called Stocktaking of Spot Goods, and is a method to calculate the inventory quantity by counting the quantity of inventory actually existing in a warehouse and multiplying it by unit . Compared with this, the inventory check on the ledger sheet is called Book Inventory.

Why is physical inventory important in SAP?

Production planning and order fulfillment don't work without precise inventory data. Additionally, SAP physical inventory processes make end-of-year counts easier, enabling businesses to create an accurate balance sheet for financial purposes and tax reporting.

How do you conduct A physical inventory?

How to Take Physical Inventory in 12 StepsSave the date. ... Assign your counters. ... Inform all storage locations. ... Review your stock. ... Lay out the land. ... Create your categories. ... Initiate a pre-count. ... A few reminders.More items...•

How do you organize your physical inventory?

HOW TO ORGANIZE WAREHOUSE INVENTORYUse information labels and use photos of products.Store products sold together near each other.Keep best selling products close to the front.Make clear aisles throughout the warehouse.Stack inventory higher to make use of vertical space.Use mobile shelving units for seasonal products.More items...•

When should be A physical inventory be taken?

When Is a Physical Inventory Usually Taken? A physical inventory count is usually taken both when goods are not being sold or received and at the end of the company's fiscal year. You can, of course, take it more often to ensure greater accuracy.

What is the purpose of observing the physical counting of inventories?

Observation of physical inventory is a mandatory procedure during an annual audit because it is the most absolute, sometimes the only, way to prove existence of the asset. It is also a tell tale sign if management refuses to allow the auditors to perform an inventory count.

Is A physical inventory count still necessary?

Taking Year-End Physical Inventory Can Help Ensure Accuracy Even if you use inventory management software or other systems to track inventory throughout the year, only an actual count can reveal what you have on hand and make sure it matches what's in your system.

What is so important about inventory?

Inventory management helps companies identify which and how much stock to order at what time. It tracks inventory from purchase to the sale of goods. The practice identifies and responds to trends to ensure there's always enough stock to fulfill customer orders and proper warning of a shortage.

What are the major importance of inventories?

A good inventory management strategy helps save time and money. Inventory management can have real-time and monetary benefits. By keeping track of which products you have on-hand or ordered, you save yourself the effort of having to do an inventory recount to ensure your records are accurate.

Why is it important to have a inventory?

Regardless of the size of your company, having a proper inventory management system is very important for any business. It can help you keep track of all your supplies and determine the exact prices. It can also help you manage sudden changes in demand without sacrificing customer experience or product quality.

What are the 3 components of inventory?

There are three general categories of inventory, including raw materials (any supplies that are used to produce finished goods), work-in-progress (WIP), and finished goods or those that are ready for sale.

What items are included in inventory?

inventory, in business, any item of property held in stock by a firm, including finished goods ready for sale, goods in the process of production, raw materials, and goods that will be consumed in the process of producing goods to be sold.

What are included in inventory list?

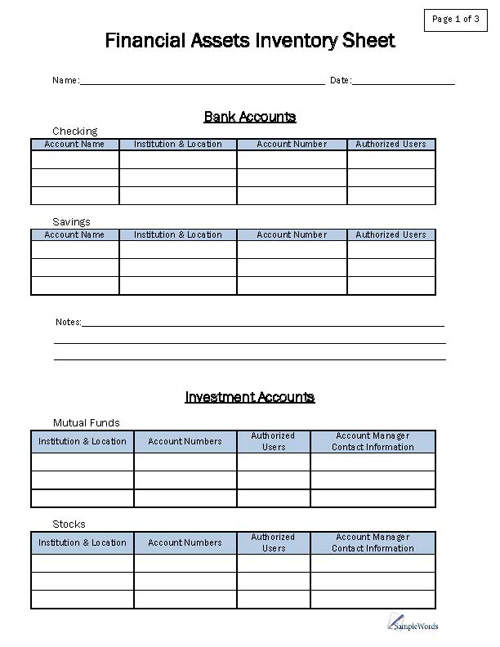

An inventory list is a comprehensive, itemized list that details every product your company has in stock, including raw materials, work-in-progress items, and finished goods. In general, an inventory list should include the product's name, SKU number, description, pricing, and quantity.

When is physical inventory usually taken?

You can choose to record when stock is sold or received in real-time using automation (a perpetual inventory method), or update records over a spe...

How do you keep track of physical inventory?

The traditional method is to record physical inventory counts by conducting frequent inventory audits, but today, online retailers are embracing di...

What is the purpose of counting physical inventory?

Consistently counting physical inventory ensures that what was accounted for in your warehouse(s) matches inventory records. By conducting frequent...

What is a physical inventory count?

A physical inventory count is the process of manually counting the stock you carry in store—from the sales floor to the backstore—comparing the inventory levels you count to the inventory levels recorded in your POS system, and reconciling any discrepancies. Typically, inventory counts will take into account the amount of stock you have for each variant of the product as well.

What is the difference between physical and perpetual inventory?

Physical inventory is a stock-taking method where retail employees manually count in-store inventory and adjust inventory levels recorded in the POS system if they find any discrepancies.

Why do you do inventory checks on Shopify?

Doing a physical inventory check also helps improve inventory forecasting and purchasing. With Shopify POS, for instance, merchants can view demand forecasting reports that recommend which products to restock based on its profitability and restock rate. This enables you to restock items based not only on their popularity, but their profitability as well.

How accurate is inventory count?

The way you measure your inventory levels’ accuracy is through shrinkage rate , which is the percentage of inventory missing from your POS records.

What is perpetual inventory?

Perpetual inventory, on the other hand, happens when stock levels are updated after your point of sale system processes a transaction and the inventory levels for the items sold adjust automatically. If you have five quantities of inventory and one gets sold at your checkout desk, for example, your POS system will automatically update the recorded inventory levels of that SKU to four.

Why is physical inventory count important?

Physical inventory count is a necessary step in inventory management because it reconciles the actual stocks in storage with the inventory count on the system. If there’s a discrepancy, it means that there’s an issue. It could either be a loss of inventory or a failure to send out stocks to retail outlets.

Why is forecasting important?

Forecasting is an important part of inventory management . It happens when you predict how much demand there will be for a product, how quickly it will sell out, and when that SKU needs to be replenished.

When should you count physical inventory?

To decide how often you should count physical inventory, you first need to decide between a perpetual and periodic process.

Why is it important to conduct inventory counts?

Conducting physical inventory counts can help you identify inventory discrepancies sooner than later. Timely inventory reconciliation is key to ensuring that all ecommerce inventory is accounted for.

How can technology help in the supply chain?

Technology and automation can help to enhance visibility by tracking data and collecting information as goods move through the supply chain. By integrating an inventory management software or partnering with a tech-enabled 3PL like ShipBob, businesses can easily track how much inventory is available at all times, where items are located, and see how each SKU is performing over time.

Why do you need a 3PL?

If you or your team don’t have the bandwidth to manage and track inventory on a consistent basis, you might want to consider partnering with a 3PL to help you optimize the inventory management process while saving your team time.

How to improve inventory accuracy?

To improve inventory accuracy, it’s wise to implement an inventory scanner system.

What is cycle counting?

Cycle counting is a type of manual method in which inventory is split into more manageable sub-segments (such as location) and physically counted on a recurring basis.

What is electronic counting?

Electronic counting is done with the use of an inventory tracking system or any other type of technology that is designed to enhance visibility by tracking data and collecting information as goods move through the supply chain.

What is physical inventory?

Physical inventory is the in-person count of retail goods and products that a company owns. Most often, an employee of a retail store will count the inventory being sold on the floor and the products currently held in the location's storeroom to generate the physical inventory count results. These counts normally occur during the end of every reporting period and a company can use their information in several ways, including:

Why is it important to restock inventory?

Before conducting the count, it's important to restock as much inventory on the floor as possible to help create an easier counting experience. Moving and sorting inventory from the backroom to the selling floor can help employees organize the products so they can find them more easily while counting. It can also help to diminish the amount of inventory that employees need to count in the back and help make room for incoming products.

How does cycle counting work?

Cycle counting is taking inventory counts at different points throughout the day or week. This can help stores save time and resources by allowing them to complete the full count in manageable sections. It also allows stores to stay open, so they don't have to shut down operations like they might for a full inventory count. However, depending on the cycle counting method, it's possible some stores might not compile a full list of inventory frequently enough to be beneficial for a company's financial reports.

What is a full inventory count?

For full inventory counts, stores make use of current employees, or hire a temporary staff, to fully count the store's inventory. Managers can provide individuals with helpful counting documents and instructions to record the number of goods and products with accuracy.

Why is inventory count important?

Counting the inventory of a retail store is important because it can provide helpful information to managers and the store's parent company so they can make influential business decisions, such as what goods or products to reorder and if a store needs training or development to improve their sales and revenue numbers. Using important counting techniques and understanding helpful terms, such as physical inventory counting, can help retail stores manage their products more efficiently and report accurate numbers to company executives.

How does inventory software help?

These modern solutions often offer dedicated inventory counting features. For example, it allows you to use barcode scanners with your device’s camera or SKU lookups to speed up inventory counts and minimize human error. Additionally, inventory software provides data such as when a product was manufactured, how long it has been on the shelf, and its physical location in the warehouse. From there, the reporting and analytics feature can suggest what you should do to improve your business.

What is the difference between periodic physical inventory and cycle count?

In the cycle count process, you count a small set of inventory at a specific location on a specific date, instead of counting the entire inventory like in the periodic physical count process.

How often should you do inventory checks?

Retailers need to do a physical inventory count once a year for tax purposes or just before a specific sales season. However, pushing all your inventory control procedures into a single event requires much time and resources. On the other hand, regular inventory checks can keep your stock information updated and reduce inventory carrying costs. Therefore, the benefits you get far outweigh the efforts involved. The article will explain the concept and how you can improve your physical inventory counting procedures.

What are the different types of inventory counts?

There are 4 most common types of physical inventory counts: inventory sampling, continuous inventory, cycle counting, and periodic physical inventory ( or physical inventory for short). You can choose one technique depending on your retail inventory and counter resources. To make it easier for you to decide, below is a comparison table that summarizes the pros and cons of these inventory counting methods.

How to minimize downtime in a retail store?

As a retail store owner, you’ll want to minimize store downtime during the physical inventory counting process. So try to schedule it after business hours. But if it’s not possible and you need to close the store for a few hours, be sure to notify your customers. For example, place a sign outside your store and at the checkout counter detailing the date and time you’ll be closing and why. Also, make sure your employees can participate at the scheduled time.

Why is cycle count important?

So, if you’re looking for a more cost-effective solution, the cycle count is more beneficial because it causes less disruption, is less complicated, and takes less time. In addition, it allows you to evaluate each product segment. However, if you’re a small retailer with little inventory, you can choose a physical inventory count and start the new year with precise data.

How far away should you count inventory?

To practice safety measures, you need to keep a safe physical distance of at least 6 feet by designating different areas between groups when taking a physical count of inventory. Or you can schedule counting in shifts, so your employees don’t have to go to the store all at once.

What is physical inventory?

Physical inventory is a process of determining that the inventory quantities are exact, or if there are differences in quantity mentioned physically present and that mentioned in the SAP system. Basically, after you are finished with physical inventory, your system and physical stock levels must be the same. It is mandatory for legal reasons, and ...

How often is cycle counting used?

So a fast moving and high value material can be counted four times a year while slow moving and low value material can be counted once a year. The indicator for this is set in material master in the Plant/Storage Location 1 View, in the field

What is CC phys. inv. ind?

Ind. Inventory sampling Only a number of randomly selected materials are counted on the balance sheet key date, and if those materials show small enough differences, the other materials can also be considered to have a correct stock levels. Not really used that often, as it is essentially an approximation, but in some cases it can be used if material and warehouse structure imply that.

How often is physical inventory used in SAP?

In most cases, it is done once a year, and this kind of inventory is called annual physical inventory. That means that material stock is counted once a year.

What is cycle counting?

This type of inventory is mainly utilized in warehouse management based warehouses, but it can be done in inventory management too. Cycle counting This type of inventory allows us to set a period for regular intervals for physical inventory on the material level.

What is 31.12 in inventory?

Enter posting date. Goods posting will be done according to this date. Some companies use 31.12. In the annual physical inventory as the last day of fiscal year.

What does it mean when stock levels are not correct?

Not having the correct stock levels in the system means quite the opposite. Management has the wrong picture on the financial aspect of the stock in possession. ATP uses the wrong data (sales might not be able to sell something physically on stock but not existing in the system, or system might allow selling something that isn't physically present in the warehouse). MRP is inaccurate (production planning and other material planning processes might be in a big problem as they are required to calculate the needs for production/procurement based on stock levels and several other information).