What is subtractive prototyping and manufacturing?

Jun 06, 2020 · Subtractive rapid prototyping provides the ability to prototype in end-use materials. Since milling or machining removes material from a larger piece of material, the finished part has a solid composition rather than a layered composition as seen in additive rapid prototyping with 3D printers.

What is rapid prototyping?

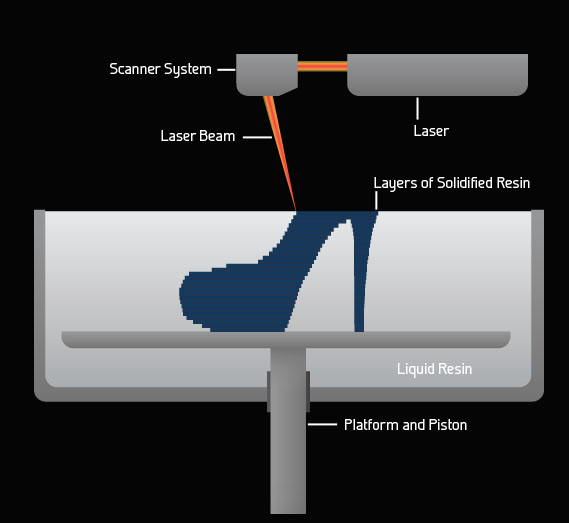

Nov 08, 2021 · Rapid prototyping is the fast fabrication of a physical part, model or assembly using 3D computer aided design (CAD). The creation of the part, model or assembly is usually completed using additive manufacturing, or more commonly known as 3D printing. Subtractive prototyping typically works with resins or metal materials, including ABS, Acetal Coplymer, …

Is additive rapid prototyping right for You?

Introduction to Subtractive Rapid Prototyping White Paper (Sample) Two major shifts are changing the world of manufacturing that will evolve the way companies rapidly design, develop and manufacture products. The first shift is on the economic front. The continual rising costs of outsourcing product development and manufacturing are prompting companies to re-establish …

Does subtractive manufacturing have a place in additive manufacturing?

Mar 28, 2022 · Subtractive rapid prototyping provides the ability to prototype in end-use materials. Since milling or machining removes material from a larger piece of material, the finished part has a solid composition rather than a layered composition as seen in additive rapid prototyping with 3D printers. Contents hide

What is subtractive method for prototype development?

Subtractive manufacturing is a process by which 3D objects are constructed by successively cutting material away from a solid block of material. Subtractive manufacturing can be done by manually cutting the material but is most typically done with a CNC Machine.Jan 4, 2016

What is the subtractive process?

Subtractive processes involve removing material from a solid block of starting material. Machining, milling, and boring are all subtractive processes that create or modify shapes.

What is additive and subtractive modeling?

Additive manufacturing processes build objects by adding material layer by layer, while subtractive manufacturing removes material to create parts.

What is an example of subtractive manufacturing?

Subtractive manufacturing or subtractive fabrication involves cutting away from a solid block of material. It could be a block of, for example, metal, plastic, or wood. A milling machine cutting/hollowing out a piece of metal or plastic is an example of subtractive manufacturing.

What is subtractive and additive manufacturing process?

Additive manufacturing processes build objects by adding material layer by layer, while subtractive manufacturing removes material to create parts.

What are the advantages of subtractive manufacturing?

Thus, the advantages of subtractive prototyping include a wide selection of end-use materials, good dimensional control and surface finish, and a high degree of repeatability suitable for end-use manufacture.Oct 3, 2011

What is subtractive Modelling?

Subtractive Methods. An object can be viewed as the remainder of a solid block that has had the geometry of one or more forms sequentially removed. In the creation of real world objects, this method is represented by milling, drilling, turning, grinding, and other manufacturing processes.

What is the difference between subtractive manufacturing and additive manufacturing?

Additive manufacturing refers to the process that creates an object by adding multiple layers. On the other hand, subtractive manufacturing removes or cuts away material to create parts.Apr 28, 2021

Is 3D printing additive or subtractive?

Additive manufacturingAdditive manufacturing is a process that adds successive layers of material to create an object, often referred to as 3D printing. Subtractive manufacturing, as the name suggests, is the opposite.Jul 29, 2018

What is rapid prototyping technology?

Rapid prototyping is the fast fabrication of a physical part, model or assembly using 3D computer aided design (CAD). The creation of the part, model or assembly is usually completed using additive manufacturing, or more commonly known as 3D printing.

When did subtractive manufacturing start?

1940sSubtractive manufacturing hit the world's stage in the 1940s, and is primarily used for machining projects that require high complexity, reliable repetition, and optimal precision. It was initially known as numerical control machining.Oct 15, 2018

What are the disadvantages of subtractive manufacturing?

Disadvantages of subtractive manufacturingCannot alter volumetric density of building material.Material wastage takes place.Process planning is mandatory (it is laborious task that needs a lot of data).Limited capability in feature form (enclosed features cannot be generated).

What is subtractive manufacturing?

Subtractive manufacturing gives you the opportunity to design, prototype, and manufacture in end-use materials. It is an appropriate choice for parts used for small and large volume production runs, to obtain specific finishes, or to obtain specific mechanical properties. Should you wish to handle your subtractive manufacturing needs in-house, ...

What is Rapid Injection Molding?

Sometimes viewed as a subset of subtractive prototyping, Rapid Injection Molding (RIM) is done by injecting thermoplastic resins into a mold, just as is done in production injection molding . What makes the process “rapid” is the technology used to produce the mold, which is often made from aluminum instead of the traditional steel used in production molds.

What is a benchtop device?

It mills a variety of nonproprietary materials and popular engineered plastics such as ABS, Delrin®, and nylon. The benchtop device produces functional prototypes for structural, thermal, and electrical testing. It also produces non-ferrous metal rapid injection molds.

What is rapid prototyping?

Rather, a rapid prototype represents a tangible, hold-in-your-hands, physical creation. There are different types of rapid prototyping, with the current trends following additive manufacturing and 3D printing. However, subtractive rapid prototyping still continues to be a major driver and is often better suited for certain types ...

What is high speed CNC?

High-speed CNC prototyping is critical to product development at Lockheed Martin, the global corporate giant committed to advanced technologies in pursuit of aerospace, defense, and security initiatives, which asserts: “We are pushing the limits of additive technology and bringing design engineers to the factory floor to produce parts, layer by layer, that previously could not be built.”

What is Brightwake?

Certainly not a household name, nevertheless Brightwake is a research and design firm that is saving lives by saving blood. Or, more accurately, recycling blood that would otherwise be lost.

Can you 3D print aluminum?

Currently, engineers cannot 3D print metals like aluminum.

What are some examples of CNC machines?

Examples of retrofitted machines include lathes and milling machines. In both cases, the machine’s built-in mechanisms are replaced with high accuracy components and new mounts for the actuators.

What is CNC milling machine?

CNC Milling Machine. Once only available in an enormous in size, milling machines built specifically for CNC purposes today are smaller in footprint and can include auto-feed mechanism, built-in tool changers, and electrical sensors to ensure careful monitoring for safe cutting.

Can you get tunnel vision and lose sight of a project?

Unfortunately, it’s easy to get tunnel vision and lose sight of the entire project when focused on a single prototype. The pitfall here is the potential for product developers to miss a solution that could prove better in the long run by focusing too intently on the prototype at hand (literally).

Why is rapid prototyping important?

Rapid Prototyping helps designers present new concepts to board members, clients or investors so that they can understand and approve a development or product. This visualisation can also allows designers to gain ready feedback from customers and clients based on an actual physical product rather than a concept.

What is additive manufacturing?

While additive manufacturing is the most common rapid prototyping process, other more conventional processes can also be used to create prototypes. These processes include: Subtractive - whereby a block of material is carved to produce the desired shape using milling, grinding or turning.

Why is RP important?

RP is a very cost effective way to prototype products as it is an automated process, requiring less staff to operate. This process is also extremely precise, being able to use computer aided design (CAD) to help reduce the amount of material wastage and does not require special tools for prototyping each new product.

How does binder jetting work?

Binder Jetting uses a powder bed onto which nozzles spray micro-fine droplets of a liquid to bond the powder particles together to form a layer of the part. Each layer may then compacted by a roller before the next layer of powder is laid down and the process begins again.

What is TWI welding?

TWI is an Industrial Membership based organisation. TWI's experts can provide your company with an extension to your own resources as well as engineering consultancy services.

What is SLS used for?

Used for both metal and plastic prototyping, SLS uses a powder bed to build a prototype one layer at a time using a laser to heat and sinter the powdered material. However, the strength of the parts is not as good as with SLA, while the surface of the finished product is usually rough and may require secondary work to finish it.

What is a 3D printer?

This inexpensive, easy-to-use process can be found in most non-industrial desktop 3D printers . It uses a spool of thermoplastic filament which is melted inside a printing nozzle barrel before the resulting liquid plastic is laid down layer-by-layer according to a computer deposition program. While the early results generally had poor resolution and were weak, this process is improving rapidly and is fast and cheap, making it ideal for product development.