What are the signs of bad connecting rod?

Top Symptoms of a Bent Rod

- Low Compression. If the connecting rod is slightly bent, you may be able to drive on it without too much of an issue.

- Engine Knocking Sounds (Rod Knock) When your engine is turned on and running, you may hear a knocking sound coming from it. ...

- Low Oil or Oil Pressure. ...

- Visibly Bent or Damaged Rod. ...

- Seized Engine. ...

Which way to install connecting rod?

- Important: Ensure that the arrow on top of the piston faces towards the front of the engine.

- Orient the connecting rod in the piston.

- Examine the lower end of the connecting rod.

- Locate the bump on the connecting rod lower end.

- This bump is at the top of the large end where it forms the connecting rod beam.

How to replace a connecting rod?

Using torque wrench measure break-away torque of one nut on one bolt of this rod; remove nut. (measure the torque on three bolts and create an average for reference.) Remove the old rod bolt just measured. Lubricate and then install a new rod bolt into rod and run nut down finger tight.

Why do rod bearings go bad?

What causes rod bearings to go bad? Crankshaft bearings can wear out due to: exposure to dirt or debris in the oil, which will scratch the bearings (in turn scratching the engine parts they contact) drying out due to oil leakage, blockage or otherwise poor circulation (also sometimes caused by incorrectly sized or fitted bearings) Click to see ...

What happens when connecting rod bearing failure?

A damaged or worn-out connecting rod bearing may result in excessive rod knock, which is a rapping noise produced by the engine. This means that the clearance between the connecting rod and crankshaft has changed, hence the knocking sound.

What is the purpose of a rod bearing?

A rod bearing is a bearing that provides a low-friction pivot point between the connecting rod and the crankshaft and the connecting rod and piston. The big end of the connecting rod is connected to the crankpin journal.

How much does it cost to replace connecting rod bearings?

The Average Cost for Replacing a Rod Bearing is $10 to $5,000, Depending on Whether You Have it Done by a Mechanic or DIY. The listed average cost is based on the national average for all vehicles and does not factor in any fees or taxes or your particular make and model.

How long does it take to replace a rod bearing?

i can confirm, someone who has done it before, can most likely get it done in about 8 hours.

What causes connecting rod failure?

Connecting rods undergo cyclical tensile and compressive loading during the combustion cycle, suggesting fatigue could be the cause of a failure. At the point of failure, the brake and throttle were being applied, increasing the magnitude of these forces.

How can you tell if a rod bearing is bad?

2:306:34How to EASILY Diagnose Engine Connecting Rod Knock ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipIf there's any slump and then also you can hit it with a rubber mallet and you'll be able to hearMoreIf there's any slump and then also you can hit it with a rubber mallet and you'll be able to hear the piston going down and hitting the rod.

How does a rod bearing get damaged?

The main culprits behind a broken engine bearing are: insufficient lubrication, dirt or debris, misassembly, bearing crush, overloading, hot rodding, or forcing excessive loads.

What does engine bearing noise sound like?

Crankshaft bearing noise is also caused by low oil pressure, which damages the bearing surfaces and could eventually damage the crankshaft itself. This type of noise is usually described as a rumbling or thumping sound deep in the engine when accelerating.

How do you fix a rod bearing knock?

How Do You Fix Rod Knock? The only solution is an engine rebuild where you pull the rods and replace the bearings. It's likely that the flailing rod damaged the crank journal surface, so you'll definitely need the crank polished and most like turned.

Where are the rod bearings?

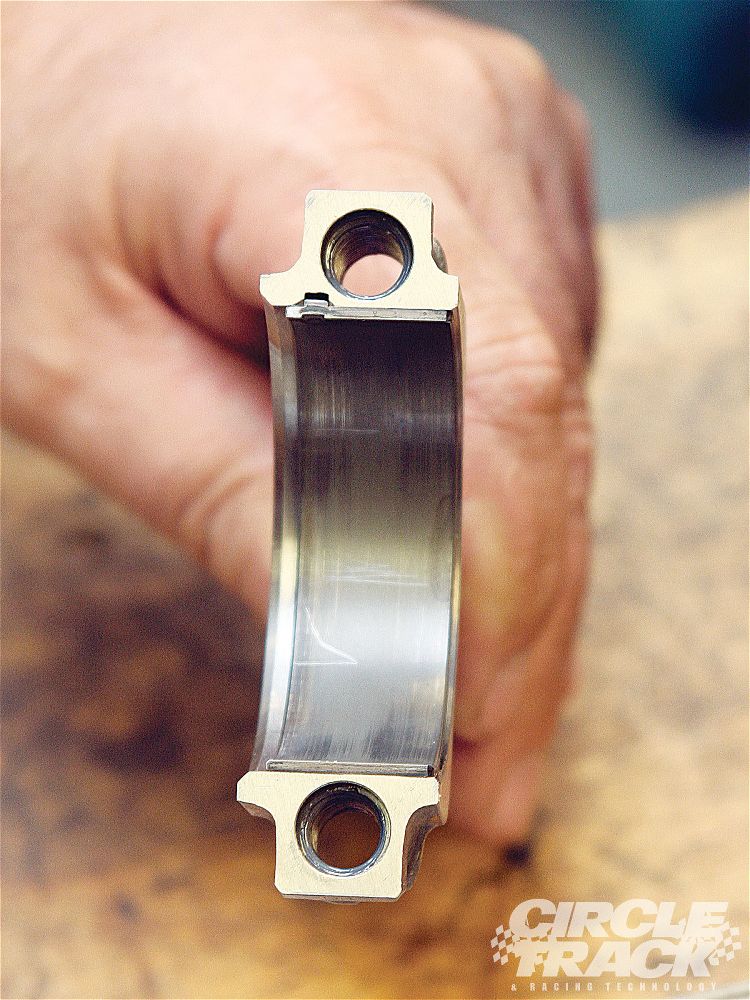

Connecting rod bearings are located in the large end of the connecting rod, by which, it is attached to the crankshaft.

How do you install a connecting rod bearing?

3:528:58HOW TO: Install CONNECTING ROD bearings - YouTubeYouTubeStart of suggested clipEnd of suggested clipFirst put together the connecting rod cap and the connecting rod. You want to make sure the tangsMoreFirst put together the connecting rod cap and the connecting rod. You want to make sure the tangs are both on the same. Side.

What causes a spun connecting rod bearing?

A spun bearing is usually the end result of a chain of unfortunate events. These include high operating loads, excessive heat and a loss of lubrication. Spun bearings are often blamed on a loss of oil pressure, but there can be numerous contributing factors that eventually cause the bearing to seize and spin.

What's the difference between main bearings and rod bearings?

4:245:43Difference Between Main and Rod Bearings - YouTubeYouTubeStart of suggested clipEnd of suggested clipNumber of bearings since each piston has one rod bearing the total number of bearings in an engineMoreNumber of bearings since each piston has one rod bearing the total number of bearings in an engine depends on the number of cylinders. In case of main bearings. Most small engines have two bearings.

What causes bearing failure?

The majority of bearing failures occur because of improper lubrication. Lubrication failure can occur if the wrong lubricant is used, if not enough lubricant is applied, or if the bearing has been exposed to excessive temperatures that have caused the lubricant to degrade. Corrosion & Contamination.

Why do BMW rod bearings fail?

Lack of proper clearance limits oil lubrication between the crank journal and the rod bearings. This causes premature wearing of the rod bearings. This rubbing also creates debris which can damage other engine parts. Because of this, we see BMW engines wearing through their bearings early.

What causes a rod bearing to spin?

A spun bearing is usually the end result of a chain of unfortunate events. These include high operating loads, excessive heat and a loss of lubrication. Spun bearings are often blamed on a loss of oil pressure, but there can be numerous contributing factors that eventually cause the bearing to seize and spin.

What is the function of connecting rod?

The main function of the connecting rod is to get forward and backward motion by the engine piston and transfer this motion to the crankshaft.

What causes connecting rod failure?

The main reasons for the connecting rod failure are given below: Overheating of the engineHydrolock problems. This problem occurs while you drive t...

What are the components of Connecting rod?

The connecting rod has the following components: Bearing capPistonWrist pinShankNut and BoltSmall EndBearing insertsLarge EndBushing

What are the types of connecting rod?

The connecting rods have the following types: Powered metal conrodsPlain type rodForged rodsFork and blade rodCast rodsBillet conrodsMaster and sla...

What is the bearing insert on a crankshaft?

These are made in two parts that fit together on the crankshaft. This is the position where the connecting rod travels along the reverse direction. 5.

What is the purpose of connecting rods?

The purpose of the connecting rod is to convert the linear motion of the piston into the rotary motion of the crankshaft. The connecting rod consists of an I-beam cross-section and is made of forged steel. Aluminum alloy is also used for connecting rods. They are precisely matched in sets of similar weight in order to maintain engine balance.

How are connecting rods made?

Some of the connecting rods are manufacture by forging. These types of connecting rod made by forcing a grain of material to the shape of the end. Depending on the required properties the material may be steel alloy or aluminum. Commonly used steel alloys are chrome and nickel alloy.

Why are connecting rods preferred?

These types of connecting rod are preferred and designed by manufacturers because they can capable of handling the load of a stock engine.

What is a bronze bush?

A phosphor bronze bush is fitted with the solid eye is attached to the small end of the connecting rod. The Big end is attached to the crankpin. The end is divided into two parts and is supported over the crank bearing shell.

Why do engines have longer connecting rods?

The benefit of this, It reduces the alternating mass for safety and reduces component wear. That’s it, thanks for reading.

What is the purpose of aluminum alloy connecting rods?

Aluminum alloy is also used for connecting rods. They are precisely matched in sets of similar weight in order to maintain engine balance. The lighter the connecting rod and piston, the greater the resulting in power and the lesser the vibration because the reciprocating weight is less.

What is an engine rod bearing?

An engine rod bearing is a split-sleeve type of bearing (meaning it has two separate semicircular halves or shelves) that keeps the crankshaft and connecting rod in place as they rotate. The bearing’s top half has a pinhole that keeps the crankshaft lubricated, allowing it to spin freely inside the bearing without generating excessive heat. Each piston and connecting rod assembly inside your engine has a rod bearing.

What is aftermarket rod bearing?

Aftermarket rod bearings are made from the same high-quality materials as original equipment manufacturer (OEM) bearings but without the hefty price tag. These are made by more than one manufacturer, which makes them easier to source than their OEM counterparts.

What causes a rod bearing to fail?

Lack of lubrication is the number one cause of rod bearing failure. The root cause of the issue could be anything from a low oil level to a faulty oil pump. Clogged oiling passages can also lead to isolated bearing failures.

Why do bearings corrode?

Pitting in the bearing surface may occur due to the accumulation of harmful acids in the crankcase. Although corroded bearings are more common in diesel engines due to the presence of high sulfur fuel, this can also happen to gas cars if the motor oil is not changed periodically.

What are bearings made of?

Both rod and main bearings are usually made from nonferrous metals (a metal that doesn’t contain iron). Examples of bearing materials include aluminum and bronze .

Why does my engine make a knocking noise?

A damaged or worn-out connecting rod bearing may result in excessive rod knock, which is a rapping noise produced by the engine. This means that the clearance between the connecting rod and crankshaft has changed, hence the knocking sound.

How much does a rod bearing cost?

Rod bearings can cost anywhere between $25 and $80 plus labor costs, depending on your vehicle’s year, make, and model. Other factors that may affect the price include the brand, quantity, and size.

What is a Connecting rod?

The connecting rod is a component of the reciprocating engine that connects the crankshaft to the piston. The connecting rod, together with the crankpins, transforms the reciprocating motion of the piston into the rotatory motion of the crankshaft.

What is the purpose of connecting rods?

It connects the crankshaft to the piston. It transmits the rotation of the crankshaft towards the piston of the engine . With the help of the ‘CR,’ the rotational motion (RM) of the crankshaft shifted into the reciprocating motion of the piston. Connecting rod essentials to convey the tensile force and the compressive force from the piston also rotates at both ends.

Which alloy has the greatest tensile strength?

As “Aluminum alloy 7068 T6511″ possesses greater tensile yield strength and ultimate tensile strength than other aluminum alloys (7075 T6, 6061 T6, and 6082), which are also given in table1, table2 table3 and table4.

How does the connecting rod handle forces?

discussed that the Connecting rod handles many different types of forces: the occasionally thrusts power from the inactivity force and the piston nail purposed by the reciprocating inactivity force and the connecting rod of the piston types. When improvement is applied, the weight of the model decreased, and the safety factor decreased by 5.4 %. And also give the low deformation of the model. By the conclusion, the displacement and the safety factor of the model improved by 1.7 % and 5.4 %, and the most considerable stress decreased by 4.9%.

What is the purpose of aluminum alloy in a bike?

In the bike, the aluminum alloy is pre-eminent suited for the high speed of the engine. The connecting rod of the aluminum alloys absorbs the high strength impact and also contained less weight.

What is the best material for a high speed bike?

Basically, it manufactures by the use of carbon steel. But these days, aluminum alloy is an excellent alternative material to fabricate the connecting rod. But the aluminum alloys have a smaller weight and suck up immense influence strength. So, it is very suitable for the high-speed bike engine.

What is the primary objective of CR?

The primary objective of ‘CR’ is to provide power and deliver the power from piston to crankshaft. All of the necessary experiments of the connecting road were all about within the range of two materials used, i.e., “Aluminum” and “Steel.” ‘CR’ made up of these two materials are used in various engines.

What is an I beam rod?

I-Beam rods are the most common style of connecting rods and are used for most stock applications as well as performance builds. These rods have a large flat area that is perpendicular (90 degrees) to the side beams. The side beams of the rod are parallel to the holes in the ends for the piston pin and crank journal, and provide a good combination of light weight, and tensile and compressive strength. I-Beam rods can handle high rpm tension forces well, but the rod may bend and fail if the compressive forces are too high. To handle big horsepower loads, the I-Beam can be made thicker, wider or be machined in special ways to improve strength.

What is a powder rod?

Powder metal rods are used by many OEs today because they can be manufactured less expensively than steel rods and they are stronger. PM rods start off as a powdered mix of metal that is pressed into a mold and heated to high temperature, which melts the metal into a solid mass (i.e., sintering). The finished rod is much closer to a finished product and therefore requires very little machining to finish the rod. PM rods have cracked caps, which leaves a unique mating surface and it saves time and additional machining. There are also aftermarket PM rods available for certain applications. PM rods can be a good upgrade over stock cast rods and can handle higher loads, but for big horsepower builds or high rpm applications, high grade steel, aluminum or other exotic materials are usually a better choice.

What is a billet rod?

Billet. Billet rods are generally the highest strength connecting rod and mostly used for high end racing builds. These are machined out of one piece of steel or aluminum and come in a variety of styles and material. They are typically CNC machined and stronger, lighter, and more durable than other types of rods.

How long do rod bearings last?

One bearing expert explained at Engine Builder’s Bearing Summit held in March that they have seen rod bearings survive in extreme loads such as top fuel drag racing engines where loads can reach 63,000 psi for up to four seconds. He said that bearing longevity is directly related to the amount of load on the bearing. In NASCAR, Formula One and IndyCar loads may exceed 14,000 psi but the average life of those bearings increases to 500 miles or more from a quarter mile. In heavy-duty diesel applications, bearing loads are not as high, around 6,500 psi, but the average lifespan increases substantially to 500,000 miles for these applications.

Why are performance rods beefed up?

Because of this, performance rods are beefed up for compression strength and stiffness for the higher loads, and the higher tensile strength of the upgraded rods help keep them from snapping apart at high rpms.

Why use a lighter connecting rod?

Because of this, performance rods are beefed up for compression strength and stiffness for the higher loads, and the higher tensile strength of the upgraded rods help keep them from snapping apart at high rpms. In sprint or drag racing applications a lighter connecting rod is usually preferred for quicker acceleration.

Why use cast rods?

Cast rods are often the choice for OEMs because they are inexpensive to manufacture and can handle the loads of a stock engine fairly well. One way for you to distinguish these rods is they have a noticeable seam at the parting line down the middle of the rod where it was poured into a mold.

What is the transfer of pull and push in an engine?

The pull and push in the piston receive the piston pin, then the connecting rod acts as the transfer of the pull and pushes from the piston pin to the crank pin. That is, in any internal combustion engine with the help of it, the reciprocating motion is converted to rotary motion. In the design requirements of the rod, ...

What happens to the piston if the length is more?

In the same way, if the length is more then the ratio of l / k will be more. Due to this, the angularity of the rod will decrease, so due to this, the side thrust on the piston will also decrease which causes less wear is obtained in the cylinder.

What happens when the length of a piston is low?

If the length is low then the l/r ratio will also be low, Due to this, the rod will increase in angularity due to which the side thrust on the piston will increase which causes increasing linear wear.

What is a connecting rod?

Connecting rod Definition: The connecting rod is defined as it is a mechanical component that helps to connect the piston and crankshaft of the engine. In other words, you can say it acts as an intermediate member between the piston and the cylinder.

Where is splash lubrication done?

Splash lubrication is done in the bearings in the big end of the crankshaft. And pressure lubrication is done in the small end bearing. In splash lubrication, a sprout is placed at an angle, so that whenever the rod is down, the sprout is inserted into the lubricating oil.

Which side of the piston is a small end?

The rod which is facing the piston side is termed as a small end. And which is on the crank side is termed as a bigger end.

Why are bearings connected to the cap?

In the design requirements of the rod, the bearings are connected with the cap so that we have accurate and smooth rotation. Same as bush near the smaller end to fit to get accurate and smooth motion.

Did You Know?

Engine bearings are made of layers of different metals, with some layers even thinner than one-thousandth of an inch.

Why are main bearings inserted between the crankshaft and the saddles of the engine block?

To prevent this, main bearings are inserted between the crankshaft and the saddles of the engine block, so that the shaft (moving part) can rotate freely inside the block (stationary part).

Why are connecting rods bearings inserted?

However, the connecting rod is under tremendous strain, because it is connected to two parts which move in different directions. Therefore, rod bearings are inserted where the rod comes into contact with the crankshaft. These rod bearings help the connecting rods rotate the crankshaft without breaking under pressure.

What material is used in a split sleeve bearing?

Material Used. Being of the same split-sleeve type, both, rod and main bearings are made of similar materials. While most of the material used is steel, to impart strength, other materials like a copper-lead-tin alloy (known as ‘babbitt’), nickel, white metal, or aluminum are added to ensure that the bearing is also soft enough not to damage ...

What is journal oil?

Oil Supply. A ‘journal’ is the surface of a connecting rod or crankshaft which is in contact with the bearing. Since there needs to be an oil layer for lubrication between the inner surface of the bearing and the shaft, oil is supplied by an oil pump to the engine block. From here, it flows into the upper half of each main bearing.

What type of bearings are used in IC engines?

However, most bearings used in IC engines are of the split-sleeve type, because the small contact area in ball bearings cannot handle the heavy stresses produced in such cases. The three main types of engine bearings are connecting rod (or rod), crankshaft (or main), and camshaft bearings.

What is the difference between rod bearings and main bearings?

The primary differences that come up in a rod bearings vs. main bearings comparison is their location and function . WheelZine gives you the complete comparison between these types of engine bearings, to help understand their purpose better.