1 The difference between a supply-push and a demand-pull sales model- 1 a supply push model-A push model is a model of manufacturing, model when companies are manufacture products and forecasted the demand or then push these products into the market.This model is the based on Materials Requirement Planning (MRP

Material requirements planning

Material requirements planning (MRP) is a production planning, scheduling, and inventory control system used to manage manufacturing processes. Most MRP systems are software-based, while it is possible to conduct MRP by hand as well.

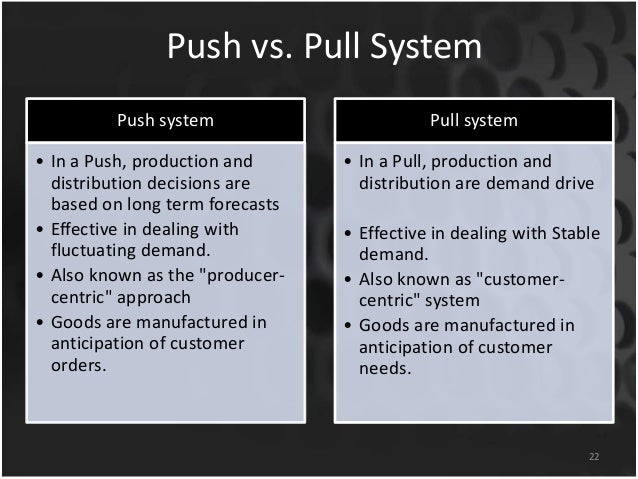

What is the difference between a supply-push and a demand-pull sales model?

What is the difference between a supply-push and a demand-pull sales model? Why do most manufacturer-direct firms have difficulty switching from the former to the latter? supply push: - products are made prior to orders received based on estimated demand demand pull: - products are not built until an order is received

Do you need a push or pull Supply Chain Strategy?

The primary requirements of supply chains either involve adaptability with immediate consumer demand or coping up with future projections. Therefore, businesses have to work on meeting customer demand or the long-term customer forecasts in determining whether they need a push or a pull strategy. What is Push Supply Chain Strategy?

What is product demand in a pull supply chain?

Product demand is the sole determining factor for production and distribution levels in a pull strategy for the supply chain management. The pull supply chain strategy also points out towards possibilities of creating risks in scenarios where supply could not address demands.

What is pull model in Supply Chain Strategy?

The process of manufacturing and supply of goods is based on actual customer demand derived from consumption on granular levels. Basically, the pull supply chain strategy focuses on acquiring inventory only when it is needed. The pull model in supply chain strategy primarily focuses on inventory management with reduction of stock on hand.

What is the main difference between push and pull systems?

The main difference between push and pull systems is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. it dictates when and how much to produce.

What is a push or pull model?

What is push and pull distribution strategy? Push and pull distribution strategy is all about directing your promotional route to market. Either by the product being pushed towards customers or your customers pulling the product through the retail chain towards them.

What is the difference between the push sales strategy and the pull sales strategy?

In simple terms push marketing involves pushing your brand in front of audiences (usually with paid advertising or promotions). Pull marketing on the other hand means implementing a strategy that naturally draws consumer interest in your brand or products (usually with relevant and interesting content).

What is the difference between push and pull view of supply chain briefly explain with examples?

The original meaning of push and pull, as used in operations management, logistics and supply chain management. In the pull system production orders begin upon inventory reaching a certain level, while on the push system production begins based on demand (forecasted or actual demand).

What are examples of push and pull?

Push and pull are the forces that are used to put an object into motion. Both the forces can be differentiated on the basis of the direction of motion of the object....ExamplesThumb Pins. ... Opening and Closing a Door. ... Pushing a Car. ... Pulling a Cart. ... Inserting and Removing a Plug. ... Water Dispensers. ... Pulling Curtains and Blinds.More items...

What is the pull model?

Pull Manufacturing Models They prefer pull-based manufacturing approach, in which the production is based on actual demand. Unlike push model, a pull model leads to more streamlined supply chain by avoiding overproduction, excess inventory carrying cost and save storage space.

What is the pros and cons of push and pull strategy?

Push and Pull Marketing — The Benefits and Drawbacks for Your BusinessPush MarketingPull MarketingAdvantagesWider audience reach Good to raise awareness of your productFewer markdown (cost-effective) Ability to recognise customer's profileDisadvantagesCostly Spam issuesFewer audience reach

What is push and pull strategy in supply chain?

A pull strategy is when customer demand drives the entire production process. On the other hand, a push strategy is when production is based on long term customer forecasts.

How does a push strategy differ from a pull strategy quizlet?

A push strategy is aimed at intermediaries, whereas a pull strategy is aimed at consumers.

What is the difference between push and pull marketing strategy?

On the one hand, push advertising aims to push products towards specific customers, while pull advertising focuses on the right people at the right time. Push marketing, specifically, is a strategy managers use to promote their products to consumers.

What are the advantages and disadvantages of push and pull supply chains?

The pull system has limited inventory; it's customer-centric; it can improve the cash flow, and its make to order. Whereas the Push system has a high list, it's producer centric, it can make to stock, and the demands are based on forecasting.

What is an example of a push strategy?

Examples. A push strategy tries to sell directly to the consumer, bypassing other distribution channels. An example of this would be selling insurance or holidays directly. With this type of strategy, consumer promotions and advertising are the most likely promotional tools.

What is the difference between push and pull marketing?

On the one hand, push advertising aims to push products towards specific customers, while pull advertising focuses on the right people at the right time. Push marketing, specifically, is a strategy managers use to promote their products to consumers.

Is a push or pull system better?

Pull is Preferred in a Lean Process Changes to customer demand can be made more quickly. Customer relationships are typically stronger and “stickier.” Push is based on “just in case” thinking. Pull is based on “just in time.” Large organizations will often combine pull methods with some level of push.

What is supply chain?

A supply chain is a network between a business, its suppliers and the business' customers. In the construct of managing that network, we engage a combination of human capital, logistics processes, materials and information flow systems.

How to reduce supply chain costs?

What's best for you? 1 Reduced warehousing and logistics costs. 2 Only mobilizing what the customer demands at the rate at which they demand it, allows for reduction in the amount of labour that may be needed. 3 The closer your supply chain moves to real-time customer demand fulfillment, the greater the reduction in the risks of overproduction and its attendant costs as well as incorrect allocation of inventory. 4 Operating a pull system of supply chain management allows leadership to respond to changes in customer tastes and expectations quickly and easily.

What is push pull system?

On the other hand, pull systems are perfect for smaller entities with limited budgets that are still establishing themselves. Most businesses, however, use a hybrid approach called a push-pull system that features key elements from both strategies. Let’s dig in to understand the best choice for your business.

What is push pull inventory management?

Push-pull systems (or lean inventory management) aim to strike a balance between having enough product on hand to meet demand while also minimizing storage and production costs.

Why is it important to have a lean ordering plan?

Having a lean and dynamic ordering plan helps you minimize the risk of unsold, wasted product. It also reduces the amount of inventory you have to store, which helps you save on warehousing costs.

How does push inventory work?

Basically, your business predicts how many units of a product you’ll need for the next month, quarter, or year. You then order all the units you’ll need at once. Optimistically, you’ll always be well-stocked without needing to constantly reorder.

What if the plant scored a massive surge in orders?

But what if the plant scored a massive surge in orders? Instead of popping champagne, they’d be scrambling to secure more than a measly 20 windshields per week . If this frantic blitz fails, the plant must cancel orders and disappoint customers since the factory is unable to secure the necessary materials.

What happens if you don't replenish stock?

If you don’t replenish your stock fast enough, you could easily run out of product, losing sales and ruining the customer experience as a result. On the upside, though, a pull system can lower your overall expenses by eliminating waste and leaving you with more cash on hand to invest in other aspects of your business.

Is a push inventory system good for small businesses?

In our opinion, a pure push inventory system is probably best for larger small businesses that have a good handle on how inventory turns within their business.

What differentiates the service sector from the retail sector?

Factors that differentiate the service sector from the retail sector: - retail sector involves physical goods being transferred from manufacturer to the consumer . - service sector performs services such as finance, real estate, business services, insurance, travel, etc.

Do manufacturers want interference?

manufacturers do not want any kind of interference from its channel partners (retialers, dealers, distriubuters) by selling directly to customers by using internet or good marketing schemes

What is pull in supply chain?

Basically, the pull supply chain strategy focuses on acquiring inventory only when it is needed. The pull model in supply chain strategy primarily focuses on inventory management with reduction of stock on hand. At the same time, it also implies the need for comparatively faster responses to fluctuations in product demands.

What is Push Supply Chain Strategy?

The push strategy in the supply chain is ideal for a scenario in which the estimated demand defines the inputs of the process. Basically, it is reasonable to consider push supply chain strategy as an approach based on forecasts. Organizations using the push strategy depend on forecasts for determining the amount of stock they have to order.

What are some examples of pull strategy?

The examples of pull strategy from push and pull strategy examples could showcase how it presents a better advantage in situations driven by consumer demand. For example, a high-end custom jeweler would receive an order from a client, carry out consultation with them and discuss the particular requirements of customers for the product before ordering gemstones and precious metals for manufacturing the product. This is a clear example of the pull supply chain strategy as the jeweler did not have any inventory before receiving the order. The jeweler waited until receiving the order and then procured the materials needed for production.

Why do businesses pull supply chain?

Businesses could opt for a pull supply chain strategy for avoiding the costs of procuring inventory that they will not be able to sell.

Why is supply chain strategy important?

Markets are evolving consistently at a radical speed, and your supply chain strategy helps identify changing demands and adapt accordingly. The characteristic traits and benefits of a supply chain strategy clearly showcase the importance of reflecting on the debate of push vs pull strategy in supply chain.

Why is it important to select supply chain strategies?

As the world recovers from large-scale disruptions in supply chains globally, it is important to select supply chain strategies. So, choose a specific supply chain strategy to cater to the needs of your customers and get ready to take your business ahead!

What is supply chain management?

Supply chain management is undoubtedly one of the significant and core operations in the portfolio of a business. You can come across various components in your supply chain management approach with a profound impact on business and bottom lines. Therefore, many business owners look forward to opportunities in selecting the ideal alternative among push and pull strategy in supply chain .