What is the difference between AC gear motor and DC gear motor?

AC gear motors and DC gear motors are 2 types of geared motors divided by working power. The meaning of AC gear motor is that the power source used is AC, such as 110 Volt, 120 Volt, 220 volt, 240 volt. DC gear motor uses DC power as the power supply, such as 12V, 24V, 48V.

What is a gear motor?

A gear motor adds mechanical gears to alter the speed/torque of the motor for an application. Usually such an addition is to reduce speed and increase torque. A DC motor without gears is useful in many applications, for example the simple fan.

What is the difference between DC motor and DC generator?

DC motor converts electrical energy into mechanical energy whereas DC generator converts mechanical energy into an electrical energy. Furthermore, in DC motors, EMF in the armature is less than its terminal voltage (Eb < V E b < V) whereas in DC generators, generated EMF is more than its terminal voltage (Eg > V E g > V ).

What are the different uses of DC motors?

These uses include phone vibrators, power tools, car windows, cranes, conveyors, and many more applications that prioritize both sustained output power and price. While nowhere near as accurate as stepper motors, DC motors are a tried-and-true workhorse of industry with both the power and the endurance to still compete with modern motors.

What is a geared DC motor?

What is universal motor?

What type of motor produces rotary motion?

How can a DC motor be controlled?

What is DC motor?

What is the difference between gear motor and motor?

A gear motor is an all-in-one combination of a motor and gearbox. The addition of a gear head to a motor reduces the speed while increasing the torque output. The most important parameters in regards to gear motors are speed (rpm), torque (lb-in) and efficiency (%).

What is difference between geared and non geared motors?

Efficiency is important for maintaining speed and saving power. The geared motor is more efficient than its gearless counterpart and has a longer travel range on a full charge.

Why are DC motors geared?

Gears Harness the Power of DC Motors To reduce shaft speeds, many DC motors are paired with a gearbox. This helps to reduce the motor's shaft speed, and increase the torque output of the motor. In most cases, torque is increased by the ratio of the gear reduction, minus any losses in the gearbox.

What are the 3 types of DC motors?

Types of DC MotorSeries DC Motor.Shunt/Parallel DC Motor.Compound DC Motors.Permanent Magnet DC Motor.

What's a geared DC motor?

A geared DC Motor has a gear assembly attached to the motor. The speed of motor is counted in terms of rotations of the shaft per minute and is termed as RPM . The gear assembly helps in increasing the torque and reducing the speed.

Why geared motor is used?

A geared motor is a component whose mechanism adjusts the speed of the motor, leading them to operate at a certain speed. geared motor have the ability to deliver high torque at low speeds, as the gearhead functions as a torque multiplier and can allow small motors to generate higher speeds.

What are the 4 types of DC motor?

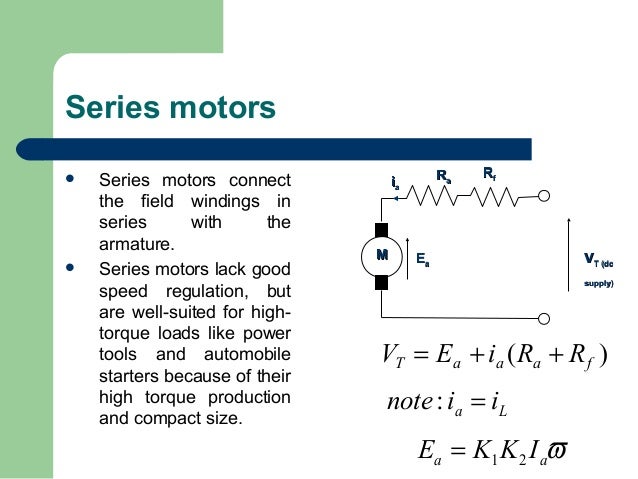

There are 4 main types of DC motors:Permanent Magnet DC Motors. The permanent magnet motor uses a permanent magnet to create field flux. ... Series DC Motors. In a series DC motor, the field is wound with a few turns of a large wire carrying the full armature current. ... Shunt DC Motors.Compound DC Motors.

What are the two main advantages of gear motors?

Top Benefits of Using Geared MotorsSavings On Expenses. Using a gear motor to increase torque and lower speed eliminates the expense of running the system. ... Reduced Speed. ... Environmental Advantage. ... Torque. ... Increased Rigidity.

What type of motor is a gear motor?

electric motorA gearmotor (or geared motor) is a small electric motor (AC induction, permanent magnet DC, or brushless DC) designed with an integral (non-separable) gear reducer (gearhead) attached.

Which type of DC motor is best?

Series wound DC motors are best for applications that require high startup torque, without the need for speed regulation. Like a shunt motor, as a load is applied to a DC series motor, the motor speed decreases, which reduces the back EMF and increases the net voltage.

What are the two classification of a DC motors?

There are 3 main types of DC motor that are available: Series, Shunt and Compound. These terms relate to the type of connection of the field windings with respect to the armature circuit.

What are the 2 types of motor?

We know there are generally two types of motors, AC motor, and DC motor. AC motors are flexible for speed control and demand low power during start. On the other hand, DC motors are widely used due to its initial cost of low power units is less compared to AC and can be easily installed.

Which is best geared or non geared?

Geared cycles help you change the gears as per different terrains, making all your rides more comfortable. These help you accelerate faster as compared to non-geared ones. You can go on long distance, adventurous trails as these bikes cover a larger distance without exhausting you.

Is a geared cycle better than non geared cycle?

Advantages of geared cycles: This makes your ride more comfortable and strenuous. Geared cycles help you accelerate and ride faster (Compared to a similar single speed cycle) You can cover a larger distance using a geared cycle.

What are the two main advantages of gear motors?

Top Benefits of Using Geared MotorsSavings On Expenses. Using a gear motor to increase torque and lower speed eliminates the expense of running the system. ... Reduced Speed. ... Environmental Advantage. ... Torque. ... Increased Rigidity.

Why do electric motors not need gears?

Electric cars don't require multi-speed transmissions because of the so-called “engine” in an electric car, an electric motor. While internal combustion engines require multiple gears with different ratios for power output, electric motors produce a consistent amount of torque at any given RPM within a specific range.

What is the difference between a generator and a motor?

Motor has a DC Current as an input and provides mechanical output. Generator has a mechanical energy as an input and provides DC Current as an output. Commutation. Motor uses commutators for changing the magnetic field polarity. Generator uses the commutators in order to cancel the polarization effect.

What is EMF in motors?

Emf is utilized by coil and useful for rotating the axle. EMF, produced around the coil, is transmitted to the load and used by them. EMF Vs Terminal Voltage. EMF in armature is less than its terminal voltage ( Eb < V E b < V) Produced EMF is more than its terminal voltage ( Eg > V E g > V) Generated EMF/Back EMF. For DC motor, back EMF is:

What is the difference between a stepper motor and a DC motor?

The main difference is that, while stepper motors can push harder from rest, DC motors tend to have more sustained output. Finally, both of these motor types are inexpensive, so the purchase price is of little concern.

What is a rotor assembly?

The rotor assembly contains the armature, or a wire coil insulated by metal laminations, as well as commutator rings and the output shaft . The commutator rings are connected to the terminal ends of the armature coil but do not directly touch the brushes or the output shaft when the motor is off. The brushes will squeeze ...

How does a DC motor work?

As shown above, DC motors are powered by a DC power supply connected to the rotor assembly via carbon brushes. This rotor is inside a stator, or a stationary housing that contains a permanent magnetic field, generated by either a magnetic metal or some type of electromagnet (shown in Figure 1 as the coil labeled “stator field”). The rotor assembly contains the armature, or a wire coil insulated by metal laminations, as well as commutator rings and the output shaft. The commutator rings are connected to the terminal ends of the armature coil but do not directly touch the brushes or the output shaft when the motor is off. The brushes will squeeze the commutator rings together when the motor is started, thus allowing DC power to run through the brushes, through the commutator rings, and into the armature winding. When current passes through the armature, a magnetic field will be produced, which will oppose the stator field. The rotor assembly, therefore, spins because of this opposition and causes the motor to produce useful mechanical energy and torque.

How fast is a stepper motor?

The speed range of stepper motors is typically below 2000 RPM, as their torque decreases as speed increases.

Why does a rotor spin?

The rotor assembly, therefore, spins because of this opposition and causes the motor to produce useful mechanical energy and torque. These motors have been around since the 1830s, and so have been used in a variety of applications.

How long do stepper motors last?

When stepper motors are not run continuously, they can easily reach 10,000 hours of useful life or almost 5 years of use. DC motors can also run this long depending on the type chosen, but require constant maintenance to prevent failure.

Why are stepper motors used in 3D printers?

While they are both cheap and easily controlled, stepper motors give most of their benefit when being used as a precision machine . They are often found used in 3D printers, CNC machines, medical imagery machinery, printers, security cameras, and other precisely controlled applications. In short, they provide control as an advantage over mechanical power generation and should be used if accuracy is a primary concern.

What are the advantages and disadvantages of a DC motor?

The advantages and disadvantages of DC motor, servo motor, and stepper motor include the following. DC motors are fast and continuous rotation motors mainly used for anything that needs to rotate at a high rotation per minute (RPM). For instance; car wheels, fans etc. Servo motors are high torque, fast, accurate rotation in a limited angle.

What is a stepper motor?

Stepper Motors. A stepper motor is fundamental ly a servo motor that uses a different method of motorization. Where a motor includes a continuous rotation DC motor and combined controller circuit, stepper motors utilizes multiple notched electromagnets arranged around a central equipment to describe the position.

What is PWM in servo motors?

PWM (pulse width modulation) is used to control the signal of a servo motor. But, unlike DC motors it’s the period of the positive pulse that controls the position, somewhat than speed, of the servo shaft. The value of the neutral pulse depends on the servo keeps the shaft of the servo motor in the middle position.

How many wires does a servo motor have?

The servo motor position can be controlled more precisely than those of typical DC motors, and generally, they have three wires like power, GND, and control. Power to these motors continually applied, with the servo motor control circuit changing the draw to drive the servo motor. These motors are designed for more exact tasks where ...

What are the pros and cons of DC motors?

Pros and Cons of DC, Servo, and Stepper Motor 1 DC motors are fast and continuous rotation motors mainly used for anything that needs to rotate at a high rotation per minute (RPM). For instance; car wheels, fans etc. 2 Servo motors are high torque, fast, accurate rotation in a limited angle. Generally, a high-performance alternative to stepper motors, but more complicated setup with PWM tuning. Suited for robotic arms/legs or rudder control etc. 3 Stepper motors are slow, easy setup, precise rotation, and control – Advantage over other motors like servo motors in controlling of a position. Where these motors require a feedback mechanism and backing circuitry to drive locating, this motor has positional control through its nature of rotation by fractional additions. Suitable for 3D printers and related devices where the position is essential.

What is DC motor?

DC Motor is a two wire continuous rotation motor and the two wires are power and ground. When the supply is applied, a DC motor will start rotating until that power is detached. Most of the DC motors run at high revolutions per minute (RPM), examples are; fans being used in computers for cooling or car wheels controlled by a radio.

How often does a servo pulse?

The servo control pulse is typically recurrent every 20 ms, fundamentally telling the servo motor where to go, even if that means remaining in the similar position. When a servo is commanded to move, it will move to the position and hold that position, even if the external force pushes against it.

What is a geared DC motor?

Geared DC motors can be defined as an extension of DC motor which already had its Insight details demystified here. A geared DC Motor has a gear assembly attached to the motor. The speed of motor is counted in terms of rotations of the shaft per minute and is termed as RPM .The gear assembly helps in increasing the torque and reducing the speed. Using the correct combination of gears in a gear motor, its speed can be reduced to any desirable figure. This concept where gears reduce the speed of the vehicle but increase its torque is known as gear reduction. This Insight will explore all the minor and major details that make the gear head and hence the working of geared DC motor.

What is universal motor?

The universal motor can operate on direct current but is a lightweight motor used for portable power tools and appliances. Larger DC motors are used in propulsion of electric vehicles, elevator and hoists, or in drives for steel rolling mills. The advent of power electronics has made replacement of DC motors with AC motors possible in many ...

What type of motor produces rotary motion?

Most types produce rotary motion; a linear motor directly produces force and motion in a straight line. DC motors were the first type widely used, since they could be powered from existing direct-current lighting power distribution systems.

How can a DC motor be controlled?

A DC motor’s speed can be controlled over a wide range, using either a variable supply voltage or by changing the strength of current in its field winding. Small DC motors are used in tools, toys, and appliances.

What is DC motor?

DC MOTORS: A DC motor is any of a class of electrical machines that converts direct current electrical power into mechanical power. The most common types rely on the forces produced by magnetic fields.