The design factor defines how much force a product design should withstand. Whereas the value of the safety factor is derived from actual load requirement and how much actual load a body can withstand. For example, if the design factor value for critical automotive components is two.

How factor of safety is determined in the design?

Safety factors are often calculated using detailed analysis because comprehensive testing is impractical on many projects, such as bridges and buildings, but the structure's ability to carry a load must be determined to a reasonable accuracy.

How to start a factor of safety calculation?

How to Calculate Factor of Safety?

- Firstly determine the factor of safety and design load.

- Then, use the formula Factor of Safety = Maximum Strength/ Design Load and substitute the known paramters in it.

- Simplify the equation and find the safety factor.

How to choose factor of safety?

Factor Of Safety = Yield Stress / Working Stress. If the factor of safety is 1, then it means that the design load is equal to the safety load. So for a better design, the factor of safety should be always greater than 1. If the safety of factor is less than 1, then the product is in the danger zone.

What is a typical factor of safety?

Factor Of Safety = Yield Stress / Working Stress If the factor of safety is 1, then it means that the design load is equal to the safety load. So for a better design, the factor of safety should be always greater than 1.

What is factor of safety?

A safety factor is most commonly expressed as the ratio between a measure of the maximal load not leading to the specified type of failure and a corresponding measure of the maximal load that is expected to be applied.

What is the difference between factor of safety and margin of safety?

An alternate definition of factor of safety is based on the use of stresses. In nuclear safety and in aeronautical engineering, the margin of safety is used in place of the factor of safety. The margin of safety is defined as the factor of safety minus one; that is margin of safety = FS-1.0.

What is the design factor in engineering?

A design factor1 is a margin applied to a load or structural strength to account for uncertainty as to the load, the structural properties, or both.

Why factor of safety is used in design?

The Factor of Safety is essentially used to assure the structural designing does not occur any unexpected failure or presence of deformation or defect. The smaller the Factor of Safety, the higher chances was there for the design to be a failure. Resulting in an uneconomical and nonfunctional design.

What is safe design stress and factors of safety?

A very basic equation to calculate FoS is to divide the ultimate (or maximum) stress by the typical (or working) stress. A FoS of 1 means that a structure or component will fail exactly when it reaches the design load, and cannot support any additional load.

What is factor of safety in engineering?

Factor of safety (FoS) is ability of a system's structural capacity to be viable beyond its expected or actual loads.

What are design factors examples?

Some essential factors of product design:Fitness for Purpose: Every product is designed for a unique purpose. ... Materials and Finish: Before manufacturing a product, the designer must decide the material to be used. ... Maintenance: ... Efficiency: ... Cost Ratio: ... Fashion: ... Safety Measures: ... Aesthetics:

What are the two types of design factor?

Product design consists of two types of designs, engineering design and industrial design.

What is design factor formula?

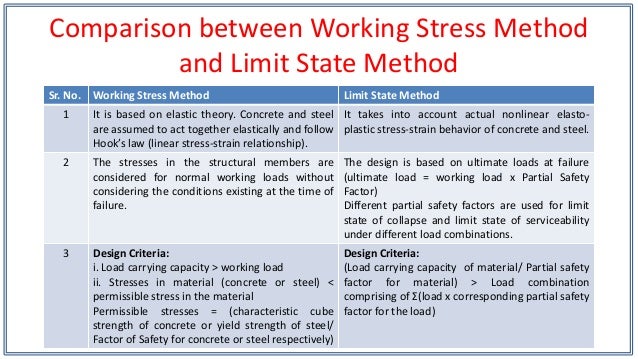

Putting this definition into simpler terms: Design Factor (DF): The inverse of the safety factor. DF is used to reduce the material's breaking stress to provide a safe design stress. In equation form: Design stress = Breaking stress x DF.

What does a safety factor of 1.5 mean?

1.3 – 1.5. For use with reliable materials where loading and environmental conditions are not severe. 1.5 – 2. For use with ordinary materials where loading and environmental conditions are not severe. 2 – 2.5.

What is design factor of pipeline?

The design factor of gas transmission pipelines is a safety factor which controls the operating pipelines at stress levels below a certain range of the specified minimum yield strength (SMYS) of the pipe material.

What is the ratio of factor of safety?

The factor of safety is defined as the ratio of ultimate to working stress (in case of brittle material). The factor of safety may also be defined as the ratio of the resisting force to failure causing force.

What is margin of safety?

Margin of safety is a principle of investing in which an investor only purchases securities when their market price is significantly below their intrinsic value. In other words, when the market price of a security is significantly below your estimation of its intrinsic value, the difference is the margin of safety.

What is the factor of safety ratio?

The factor of safety is defined as the ratio of ultimate to working stress (in case of brittle material). The factor of safety may also be defined as the ratio of the resisting force to failure causing force.

What is factor of safety in materials?

The factor of safety is defined as the ratio of ultimate stress of the component material to the working stress. It denotes the additional strength of the component than the required strength.

What does margin of safety tell us?

The margin of safety tells the company how much they could lose in sales before the company begins to lose money, or, in other words, before the company falls below the break-even point. The higher the margin of safety is, the lower the risk is of not breaking even or incurring a loss.

What is the difference between design factor and safety factor?

The difference between the safety factor and design factor (design safety factor) is as follows: The safety factor is how much the designed part actually will be able to withstand (first "use" from above). The design factor is what the item is required to be able to withstand (second "use").

2 Replies

The difference between the safety factor and design factor (design safety factor) is as follows: The safety factor is how much the designed part actually will be able to withstand (first "use" from above). The design factor is what the item is required to be able to withstand (second "use").

What are the factors that affect safety?

Factors affecting the value of Safety Factor 1 Criticality of the Component or part. 2 Impact of environmental conditions on product life. 3 Impact on user safety due to product failure. 4 Unknown design parameters. 5 Variations in user behavior. 6 Cost Factor. 7 Variation in the manufacturing process.

What are the factors that affect the value of a factor of safety?

The following factors have an impact on the value of the factor-of-safety. Criticality of the Component / part. Impact of environmental conditions on product life. Impact on user safety due to product failure. Unknown design parameters. Variations in user behavior.

What does it mean when the safety margin is zero?

If the value of the safety margin is zero, that means the product is not designed to take any additional load. But if the value of the safety margin is negative. Design modifications are advisable because the product will fail before reaching the design load.

What is the minimum FOS for critical components?

Critical automotive components should have a minimum FOS equal to or more than 2. In other words, the value of the safety factor is always greater than or equal to the design factor.

Why is safety important in product design?

Safety Factor is a very important factor used in product design due to the following reasons. To consider uncertainty in applied forces, design specifications, and material properties. Consider the impact of manufacturing variations. To ensure product function even after wear and tear up to acceptable limits.

What is the safety factor?

In a layman language safety factor is the ratio of actual capacity and the demand value. Safety Factor Formula. The Factor of Safety value depends on the end-use of a product. For example, the value of the factor of safety is kept higher if a design failure has a greater impact on the product performance or safety of humans.

What is design factor?

Design factor value is driven by standards, regulatory bodies, or industry-specific. It defines how much force a product should be able to withstand. Whereas the value of the safety factor is derived from actual load requirement and how much actual load a body can withstand.

What are the factors that should be considered when designing a product?

Good design engineers must consider so many factors when designing a part or component. Design for assembly, cost, logistics, manufacturability, reliability, and other qualities all require forethought and creativity. Perhaps one of the most important qualities to be considered when creating parts or products is safety...and naturally, an entire industry has cropped up around the need to manufacture safe products and structures for consumer use. Most commonly, you’ll hear the terms “Factor of Safety” (FoS) or “Safety Factor (SF), but there are several definitions and calculations that may be referred to. Let’s look at the basics of FoS for design and engineering.

How to calculate FOS?

A very basic equation to calculate FoS is to divide the ultimate (or maximum) stress by the typical (or working) stress. A FoS of 1 means that a structure or component will fail exactly when it reaches the design load, and cannot support any additional load. Structures or components with FoS < 1 are not viable; basically, 1 is the minimum.

What is the most important thing to consider when creating parts or products?

Perhaps one of the most important qualities to be considered when creating parts or products is safety ...and naturally, an entire industry has cropped up around the need to manufacture safe products and structures for consumer use.

Is a higher FoS required by law?

Obviously, if the consequences of failure are significant, such as loss of life, personal harm, or property loss, a higher FoS will be required by design or by law.