A shuttle valve has several applications including:

- The use of more switches on one machine: by using the shuttle valve, more than one switch can be operated on a single machine for safety, and each switch can ...

- Winch brake circuit: a shuttle valve provides brake control in pneumatic winch applications. ...

- Air pilot control: converting from air to oil results in locking of the cylinder. ...

How does a shuttle valve work?

The Chemistry of Regeneration

- A strong salt-water (brine) solution is created with the salt added to the softener.

- The brine solution flows through the resin tank, rinsing the beads and exchanging new sodium for the hard water minerals that have collected. ...

- The brine solution and hard water minerals are flushed from the tank into a nearby drain.

What shuttle should have been?

What Shuttle Should Have Been: The October 1977 Flight Manifest An internal NASA document from 1977 outlined the first 23 space shuttle missions, but not a single one came off as planned. Space historian and Beyond Apollo blogger David S. F. Portree examines a spaceflight program that never was.

What is a pneumatic shuttle valve?

Shuttle valve (OR)

- Design: OR gate (shuttle valve)

- Pressure range: 100 – 1000 kPa (1 – 10 bar)

- Nominal flow rate 1, 1/3...2: 500 l/min

What valves to use?

What is a Plug Valve and When is it Used?

- Lubricated Plug Valve. As the name suggests, a lubricated valve uses a lubricant usually made up of a base oil and viscosity improver (like amorphous or fumed silica) that ...

- Non-Lubricated Plug Valve. This plug valve utilizes a tapered or cone-shape that acts as a wedge and presses a polymeric sleeve against the body cavity.

- Eccentric Plug Valve. ...

What is the purpose of the shuttle valve in the landing gear system?

The shuttle valve is actuated by high or low pressure depending on what you select, gear up or down. It routes the hydraulic fluid to the bottom of the cylinders to raise the landing gear with high pressure, or to the top of the cylinder to lower them with low pressure and to allow the fluid to return to the reservoir.

What is shuttle valve in aviation?

Shuttle Valves are two position devices that connect two separate pressure sources with a common outlet to provide system redundancy. When one valve outlet is connected to the outlet, the opposite inlet is shut off.

What is logic valve is known as shuttle valve?

The shuttle valve is a pneumatic OR valve and is also called as a double check valve. The valve consists of a valve body and a synthetic ball or cuboid valving element moving inside the bore in the valve housing and it is shown in the below figure.

What does the shuttle valve do within the closed loop circuit?

In a closed loop hydrostatic transmission circuit, a low side hot oil shuttle valve is used to discharge supercharge oil from the low side of the loop for cooling.

Where are shuttle valves used?

0:022:45Shuttle Valve - YouTubeYouTubeStart of suggested clipEnd of suggested clipShuttle valve this valve designed to take two control signals and onto a common end of a pilot valveMoreShuttle valve this valve designed to take two control signals and onto a common end of a pilot valve. You've got two signals. We have to have a device that will separate these two signals. And the

What are the differences between check valve and shuttle valve?

While opposed check valves allow flow from one of two ports to a third, they block flow from the outlet to both inlets. Non-biased shuttle valves have two inlet ports and a single outlet port with flow direction controlled by fluid pressure.

What is the difference between shuttle valve and dual pressure valve?

There are basically two types of double check valves; shuttle valves and Disc valve both carry the same functioning but the only difference is that the shuttle type has a movable shuttle to seal off the lower pressure source, whereas the disc type has a movable disc.

What is the purpose of a shuttle valve draw its graphic symbol?

Hydraulic shuttle valve symbol They are used to always feed the highest pressure to the top connection. The symbol clearly shows that if two different pressures are fed onto the bottom lines then the ball will move either way to allow the maximum pressure onto the top connection.

What is the function of Twin pressure valve?

Aventics Twin Pressure Valves are used for the main or pilot flow limitation of one or two actuator ports from 80 to 800 litres per minute. When two pressure valves are aligned symmetrically to each other, they are able to limit flow in one direction and allow free return flow in the opposite direction.

What two systems does a shuttle valve tie into?

Pneumatic shuttle valves are a type of valve component used in a range of industrial hydraulic and pneumatics systems.

What is a hot oil shuttle valve?

The hot oil shuttle valve W33H-1X06 is a direct operated flush valve. As soon as the switching pressure of 10 bar is reached, the flush valve allows the medium to flow from port 1 or 2 to the tank in port 3. The hot oil shuttle is highly suitable for cooling in closed circuits.

What is the difference between shuttle valve and dual pressure valve?

There are basically two types of double check valves; shuttle valves and Disc valve both carry the same functioning but the only difference is that the shuttle type has a movable shuttle to seal off the lower pressure source, whereas the disc type has a movable disc.

What is a load shuttle valve?

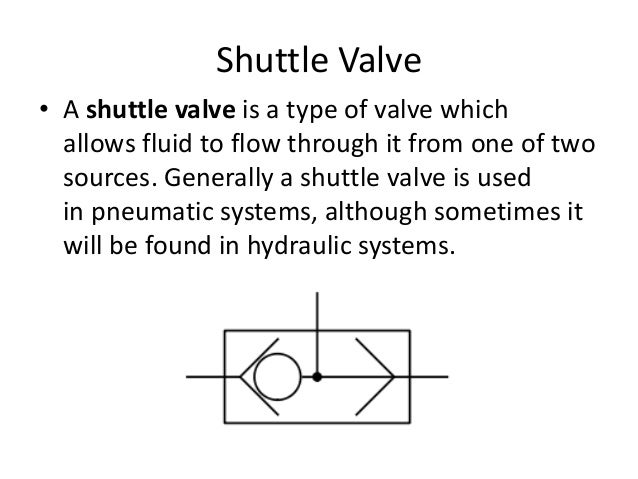

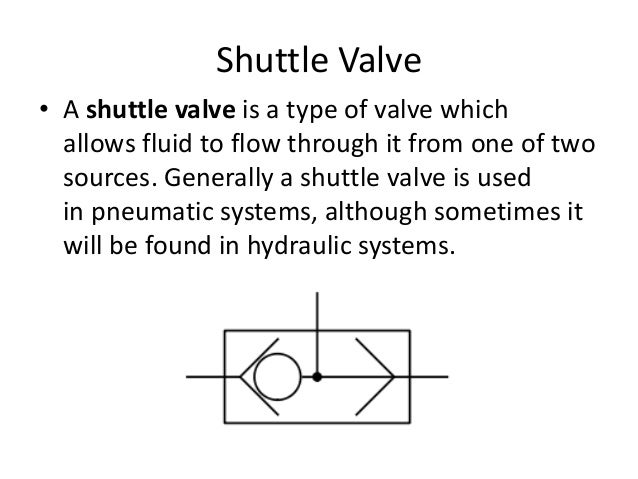

A shuttle valve is a type of valve which allows fluid to flow through it from one of two sources. Generally a shuttle valve is used in pneumatic systems, although sometimes it will be found in hydraulic systems.

What is the purpose of a shuttle valve draw its graphic symbol?

Hydraulic shuttle valve symbol They are used to always feed the highest pressure to the top connection. The symbol clearly shows that if two different pressures are fed onto the bottom lines then the ball will move either way to allow the maximum pressure onto the top connection.

What is an unloading valve?

Unloading valves are pressure-control devices that are used to dump excess fluid to tank at little or no pressure. A common application is in hi-lo pump circuits where two pumps move an actuator at high speed and low pressure, the circuit then shifts to a single pump providing high pressure to perform work.

What is shuttle valve?

A shuttle valve is also a kind of double check valve. It allows pressure in a line to be accessed from alternative sources. It is basically a pneumatic device and also found in hydraulic circuits. There is a sliding part that resides in the enclosure is called the shuttle. Its purpose is to seal off either one or other inlet ports.

How many ports are in a shuttle valve?

The figure below shows the cutaway view of a typical shuttle valve. The housing contains three ports.

What is the shuttle in a pneumatic outlet?

Pneumatic or hydraulic supply from the alternate inlet source then has a free flow to the outlet port but is prevented from entering the normal inlet system by shuttle, which block s off the normal inlet system port.

What are the disadvantages of a shuttle?

Disadvantages. If there is small leakage and it is some distance away, there may not be enough differential pressure to move the shuttle. If the shuttle does not have a good seal (to block), leakage takes place.

What are the most common types of directional control valves?

The most common type of valving elements is the ball, sleeve, puppet, rotary spool, and sliding spool.

What is shuttle valve?

Shuttle and fast exhaust valves. A shuttle valve, also known as a double-check valve, allows pressure in a line to be obtained from alternative sources. It is primarily a pneumatic device and is rarely found in hydraulic circuits.

How does fluid move through a shuttle valve?

With the shuttle valves in the neutral position, fluid moves through the intake passages on the right hand end of the shuttle valve pistons, to the two annular grooves on the periphery of the worm head. Fluid then passes from the worm head annular grooves to the left hand side of the power piston via the horizontal long passage and sector chamber, and to the right hand piston face directly by way of the short passage. From the worm head grooves fluid will also flow into the shuttle valve return grooves, over each return groove land which is aligned with the exit groove, to the middle waisted region of the shuttle valve and into the torsion bar and input shaft chamber. Finally fluid moves out from the return pipe back to the pump reservoir.

How does fluid flow in a power cylinder?

At the same time as the fluid expands the right hand side of the power cylinder, the left hand side of the power cylinder will contract so that fluid will be displaced through the long horizontal passage to the worm head right hand annular groove. Fluid then flows back to the reservoir via the upper shuttle valve return groove and land, through to the torsion bar and input shaft chamber and finally back to the reservoir.

How does the shuttle work in an alternate system?

In this position, the shuttle is seated against the alternate system inlet port and held there by system pressure and the shuttle valve spring. The shuttle remains in this position until the alternate system is activated. This action directs fluid under pressure from the alternate source to the shuttle valve and forces the shuttle from the alternate inlet port seat to the normal inlet port seat. Fluid from the alternate system then has a free flow path to the outlet port and prevents inlet flow from the primary or normal system.

How fast can you weld a shuttle valve?

Trials with laser and electron beam welding showed at welding speeds between 2 and 4 m/min. the part distortion was very low and near to the tolerance required for the shuttle valve operation. On early production valves the weld between the stainless steel and the mild steel produced an underbead which penetrated into the valve cylinder bore. This together with bore eccentricity was quickly removed by a reaming operation. Owing to the low distortion achieved, it became apparent that if the cylinder parts were accurately, concentrically preassembled with the aid of a small spigot, and the weld penetration controlled to stop just at the cylinder bore, the material removal during the reaming operation could be substantially reduced. Having proved this point, it was a short step to manufacture valve assemblies, as shown in Fig. 3.16, whereby the pre-assembled shuttle valve and cylinder assembly is also finally sealed by two laser welds, employing spigotted joints, which also permit a design which eliminates screwed in end caps.

Why is the shuttle valve loose?

The shuttle valve is a loose fit in its cylinder to permit a slow leakage of air from one spring to the other should one spring be inflated more rapidly than the other , due possibly to uneven loading of the vehicle .

What is a directional control valve?

The most common form of directional control valve is the shuttle or spool valve. Shuttle valves have a spool moving horizontally within the valve body. Raised areas, termed lands, block or open ports to give the required valve operation. Figure 6.18 illustrates these features with a 3/2 valve. In the first position, the shuttle is located so that its lands block off the 3 port and leave open, and connected, the 1 and 2 ports. In the second position, the shuttle is located so that it blocks of the 1 port and leaves open, and connected, the 2 and 3 ports. The shuttle can be made to move between these two positions by manual, mechanical, electrical or pressure signals applied to the two ends of the shuttle.

What is shuttle valve?

WikiProject Engineering may be able to help recruit an expert. A shuttle valve is a type of valve which allows fluid to flow through it from one of two sources. Generally a shuttle valve is used in pneumatic systems, although sometimes it will be found in hydraulic systems.

How does a shuttle valve work?

The basic structure of a shuttle valve is like a tube with three openings; one on each end, and one in the middle. A ball or other blocking valve element moves freely within the tube. When pressure from a fluid is exerted through an opening on one end it pushes the ball towards the opposite end. This prevents the fluid from traveling through that opening, but allows it to flow through the middle opening. In this way two different sources can provide pressure without the threat of back flow from one source to the other.

What happens when the control valve is centered?

When the control valve is centered, the brake cylinder is vented through the shuttle valve, and the brake shoes are allowed to close. Air pilot control: converting from air to oil results in locking of the cylinder. Shifting the four-way valve to either extreme position applies the air pilot through the shuttle valve, ...

What is shuttle valve?

A shuttle valve is like a combination of two or more one-way check valves in general speaking, the shuttle valve is widely used in hydraulic systems, especially more in hydraulic circuit of mobile machinery. The shuttle valve is most used as a part of hydraulic actuator, or some equipment accessories. – finotek.com. out from the outlet ports.

How many inlet ports are there in a shuttle valve?

Usually there are one or at least two inlet ports of shuttle valve, the hydraulic fluid will be able to choose automatically to exert from one inlet port with a comparison of higher pressure and. out from the outlet ports.

Is a shuttle valve a pressure transmitting signal?

Theoretically speaking, it is just a pressure transmitting signal, no flow, but in actual application, there are a few of flow rate though it, thus, it will affects the pressure drop should be considered, especially when more than one series connections.

Why use a shuttle valve?

By using a shuttle valve in a machine we can operate more than one switch and each switch can be placed at any suitable location. This would increase the safety and reliability of the machine. So because of this shuttle valves are used in many industrial types of machinery.

How does a shuttle valve work?

The shuttle valve is also called a double check valve, a shuttle valve has two inlets and one outlet. If any of the inlets is unloaded the flow will be shut off in that direction and it will be open from the loaded one to the outlet . A shuttle valve may be installed, for example when a power unit or control unit is to be actuated from two points, which may be remote from one another. A shuttle valve is a pressure operated valve, these valves can separate the normal hydraulic system from the emergency pneumatic system. The air pressure in the lines will be removed through the vent port of the control valve if the control handle is returned to the normal position. The working of the shuttle valve is related to the OR logic function. If we supply fluid under pressure to any of the two inlet ports, then there will be a supply from the outlet port

What is a twin valve?

A twin valve has a spool inside the valve body and when the fluid is supplied from one inlet port then the spool will close the outlet. The outlet port will only open if the fluid is supplied from both the inlet port.

What is twin pressure valve?

What is a twin pressure valve. The twin pressure valve has two inlet ports, these valves operation is related to AND logic function. The flow from the outlet is only possible if the fluid under pressure is supplied to both the inlet ports. A twin valve has a spool inside the valve body and when the fluid is supplied from one inlet port then ...

What is sequence valve?

Sequence valves are pressure control valves, sequence valve is normally a closed valve with the pilot line to sense the inlet pressure. These valves are used in the hydraulic system, sequence valves which are used in hydraulic systems can do many operations. The function of the sequence valve is to direct the flow in a predetermined sequence.

What is the function of a sequence valve?

The function of the sequence valve is to direct the flow in a predetermined sequence. How does a shuttle valve work? What does a shuttle valve do. The shuttle valve is a pneumatic OR valve and is also called as a double check valve. The valve consists of a valve body and a synthetic ball or cuboid valving element moving inside the bore in ...

What is the purpose of a pressure sensor?

Its purpose is to pick a pressure signal from the cylinder port with the higher pressure, according to whether the cylinder is extending or retracting, and still to vent the sensing line in the valve neutral.

What is shuttle valve?

A shuttle valve is a type of valve which allows fluid to flow through it from one of two sources. Generally a shuttle valve is used in pneumatic systems

How do valves close?

The valves open and close by means of a camshaft, which rotates in timing with the engine. The cam lobes either push directly on a lever called a rocker arm, or a cylinder called a cam lifter, or on a pushrod that in turn pushes against the rocker arm. Let’s take an overhead camshaft engine as an example — the camshaft is mounted in bearings in the cylinder head:

What is the purpose of the intake and exhaust valves?

In a gasoline engine, the intake valves admit air with fuel into the engine during an intake stroke of the piston, both valves seal the cylinder to allow the piston to compress the air/fuel mixture to ~ 9.0 - 11.0 psi (+/-), the spark plug ignites the fuel/air mix and the expanding gas pushes the piston down, applying torque to the crankshaft through the connecting rods. When the piston comes back up from a power stroke, the exhaust valve is open to allow the lower-pressure burned exhaust gas to exit the cylinder.

Why does the exhaust valve expand?

The exhaust valve sees a very high temperatures as it allows high temperature exhaust gases to exit the cylinder during the exhaust stroke. Consequently the exhaust valve expands/grows more than the intake valve that allows cooler air and fuel (a refrigerant) into the cylinder on the intake stroke. Since the exhaust valve grows more it requires more clearance/valve lash to keep in contact with the seat in the cylinder head and remain cool. Some exhaust valves have sodium in their stems to transfer the heat better.

Why do we need a low pressure exhaust valve?

At the exhaust outlet, we want to have a low pressure, in order to exhaust as much spent gas as possible. If the exhaust valve were very large, it would indeed present a large section for a lot of gas to exit through it, but it will also generate a higher pressure in the exhaust outlet pipe, which in turn will mean lower flow speed of the gas, which is not what the designers want.

Which valve is larger, intake or exhaust?

pressure, high density gases. The intake val ve is slightly larger than the exhaust valve to handle the same gas mass.

Where are the inlet and exhaust valves located?

The inlet & exhaust valves are located in the cylinder head of the engine. The point at which the valve seals against the head is called the valve seat. For closing, each val

Principle

Construction

- The figure below shows the cutaway view of a typical shuttle valve. The housing contains three ports. 1. The Normal inlet 2. Alternate or emergency inlet 3. Outlet. A shuttle valve is also a kind of double check valve. It allows pressure in a line to be accessed from alternative sources. It is basically a pneumatic device and also found in hydraulic circuits. There is a sliding part that resi…

Working of Shuttle Valve

- When the shuttle valve is in the normal operation place, the pneumatic or hydraulicsupply has a free flow from the normal inlet port, through the valve. Afterward, flow is passed out through the outlet port to the actuating unit, it may be a pneumatic or hydraulic cylinder. The operation is very simple and consists of a ball inside a shuttle valve, as shown below figure. If the pressure is app…

Advantages

- Shuttle valve serves to isolate the failed supply line, If either of the dual supply ruptures or develop leakage,

Disadvantages

- If there is small leakageand it is some distance away, there may not be enough differential pressure to move the shuttle.

Applications

- Used as a hot standby in sub-sea applications.

- Hydraulic cranes, excavators.

- Serve as a part of the braking system.