What is the maximum span for engineered floor joists?

| Yellow Pine Douglas Fir | Western red cedar Eastern white pine | |

| Joist Size | 16″ o.c. | 24″ o.c. |

| 2×8 | 12′ 8″ | 8′ 6″ |

| 2×10 | 16′ 0″ | 10′ 5″ |

| 2×12 | 18′ 6″ | 13′ 0″ |

How far can you span a 2x10 floor joist?

With 16” spacing, a floor joist can span up to 14’ as long as it is not cantilevered and terminates with support on either end. If the joists are 24” apart, then one 2×10 joist can span up to 11’ 5”. These lengths are for SYP lumber. If you have Spruce-pine-fir lumber, then your span changes to 13’ 7” for 16” joist spacing.

What size are floor joists in residential construction?

Understanding Floor Joist Spans

- Wood Species. Different wood species have different strength characteristics, with some having much higher bending strength than others.

- Lumber Grade. The fewer defects contained in a piece of lumber, the stronger it will be. ...

- Lumber Size. ...

- Load. ...

- Joist Span Tables. ...

What size joist per span?

The joist span tables start with 2×6 lumber and it goes all the way up to 2×12. For example, a 2×6 Southern Pine joist can span 12’. A 2×12 joist of the same species and quality can span nearly 25’. The spans listed in the span tables of the IRC indicate max span, so many contractors will often overbuild a floor for the sake of stability.

How far apart should floor joists be?

With some structures, floor joists are required to be 12 or 24 inches apart on center. To find the actual distance between the inside edges of each adjacent floor joist, subtract 1-¾ inches from either 12 or 24 inches.

How far can an engineered floor joist span without support?

With these factors, the lightest joist will have a maximum span of 17 feet, 8 inches. This is the most common as the typical span is 15 feet. The heaviest joist, along with the above factors, will span a maximum of 23 feet, 8 inches.

How far can engineered floor trusses span?

A floor truss can be designed to span 30 or more feet with ease. The truss manufacturer can build them so strong that there's no bounce to the floor at all. This comes in handy if you desire a tile floor.

What is the largest span all wood I joists are available for?

IRC covers the maximum span length of wood joists, from 2×6 to 2×12 or greater. IRC also specifies floor joist sizing and spans depending on the joist spacing, commonly 16 inches on center but can vary from 12 to 24 inches apart.

Can an I joist span 20?

What size i joist to span 20′:- as per general thumb rules and guideline, a 2-5/16″×11-7/8″ size of i joists made of engineered wood can allows spans up to 20 feet for a live load of 40 pounds per square foot and dead load of 10 pounds per square foot when spaced 16 inches apart.

How far can an engineered beam span?

Although, you may be wondering how far an LVL beam can span. Due to its strength, the LVL beam can span up to 60 feet and is much stronger than conventional lumber. Generally, you can find laminated beams in 4-foot increments starting at 24 feet and going up to 44 feet long, with special orders up to 60 feet.

Are engineered joists stronger?

Engineered floor joists are joists that use engineered wood in conjunction with standard lumber to comprise a more lightweight yet stronger joist than just using traditional lumber. It is important to note that engineered joists come in several types, from the popular I-beam type to truss-style joists.

How big of a beam do I need to span 20 feet?

What size beam to span 20 ft:- as per general thumb rule and guidelines, a 4 nailed 2×16 or 4-2×16 or 8×16 size of wood beam can allow to span 20 ft. Thus, for a 20 foot span, you will need atleast 4-2×16 or 8×16 size of wood beam.

How far can I-joist span without support?

Span is determined by species, grade, dimensions, spacing, use, and load. A rule of thumb is 1.5 times a joist's depth but in feet when spaced at 16” centers. In general, a 2×8 will span 1.5 x 8, so 12-feet. Based on all factors though, a 2×8 joist span is 7'-1” to 16'-6”, and a rafter 6'-7” and 23'-9”.

What size lumber can span 24 feet?

What size beam to span 24 ft:- as per general thumb rule and guidelines, a 4 nailed 2×18 or 4-2×18 or 8×18 size of wood beam can allow to span 24 feet. Thus, for a 24 foot span, you will need atleast 4-2×18 or 8×18 size of wood beam.

What size beam do I need for a 22 foot span?

What size beam to span 22 ft:- as per general thumb rule and guidelines, a 3 nailed 2×18 or 3-2×18 or 6×18 size of wood beam can allow to span 22 feet. Thus, for a 22 foot span, you will need atleast 3-2×18 or 6×18 size of wood beam.

What size lumber can span 28 feet?

What size lvl beam for a 28 foot span:- as per general thumb rule, for a 28 foot span, size of LVL beam or GLULAM should be 15-16 inches deep and 4 inches wide, thus you need something like a 15-16″ GLULAM or LVL to span upto 28 feet used for residential building or projects.

How big of a beam do I need to span 16 feet?

For a 16 foot span, you will need atleast 3-2×14 or 6×14 size of wood beam. Thus, a 3 nailed 2×14 or 3-2×14 or 6×14 wood beam can allow to span 16 feet. For a 16-foot spans, the wood beam has to be at least 14 inches in depth and 6″ in width (3-2×14) used for residential building, wood frame structure or projects.

Are Floor Joists Hangers Necessary?

Floor joists need to be securely fastened to the wood beams in order to prevent them from swaying or twisting. Whether or not joist hangers are nec...

How to Replace a Rotted Floor Joist in a Crawl Space?

If you have a rotted floor joist in your crawl space, it's important to replace it as soon as possible. If damage to the floor joist is limited, in...

How to Sister a Floor Joist?

A sister joist is used to repair a bad floor joist. However, it can also bridge the span distance between two beams. When repairing a bad floor joi...

Do You Need a Permit to Sister Floor Joists?

In most cases, you don't need a permit to sister floor joists. However, it's always best to check with your local building department to be sure. T...

Which Way do Floor Joists Run?

Floor joists usually run perpendicularly between two load-bearing beams. In some cases, it may be necessary or desirable to run the joists at an an...

How Much Weight Can Floor Joists Support?

As discussed earlier in this post, a floor joist can generally hold between 30 and 40 pounds per square foot (PSF). Floor joists are designed to su...

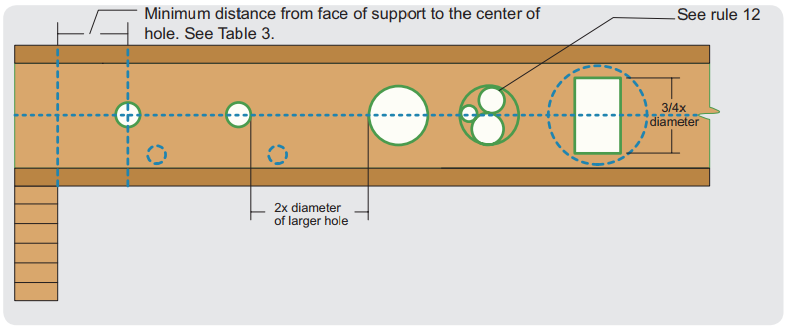

Can You Notch a Floor Joist?

Floor joists can be notched to fit around obstructions, such as plumbing pipes or ductwork. However, there are IRC guidelines directing how where a...

Are Floor Joists Treated?

In most cases, floor joists are made from untreated lumber. However, there are a few exceptions. If your home is in a moist or humid environment, y...

What are the two types of joists used in floor systems?

Two types of engineered joists are most frequently used in floor systems today: Wood I-Joists with dimension lumber top and bottom chords and OSB web. Open web trusses with wood webbing held together with metal plates. I-joists have major advantages in high-volume construction with standard layouts. This is because they are less expensive.

How long can a TRIFORCE joist span?

Joists are available in several depths and lengths and superior strength allows them to span up to 30 feet ( TRIFORCE span tables ). TRIFORCE ® joists can fill the bill for any type of wood frame construction.

Why are engineered wood floors better than traditional wood floors?

Nowadays however, engineered wood floor systems are undergoing rapid market growth due to their many advantages over traditional wood. Engineered wood is more sustainable, using less trees and costs less to use per square foot. It weighs less and is easier to handle, saving time and money on construction sites. It is also stronger and more rigid in its support. Also, depending on the product you are using, you can easily adjust it on site, whether because of a deviation from the original plan or an adjustment to a non-conformity.

Why are I-joists better than open web trusses?

I-joists have major advantages in high-volume construction with standard layouts. This is because they are less expensive. Also, you can adjust their length is onsite, without an engineer’s approval. However, they can’t attain the spans of open web trusses.

Is wood more expensive than concrete?

August 14, 2019. In North America residential construction, wood has long been a material of choice: abundant, readily available, flexible, and easily repairable, it is less expensive than steel and concrete, and is naturally an overwhelmingly popular material.

Is conventional wood used in new buildings?

Now, in new residential buildings, more often than not, a combination of both is being used. When it comes to floor systems, conventional wood has enjoyed a long tradition of use, created by a universal familiarity with the product as well as the amount of experienced, highly qualified workers using it.