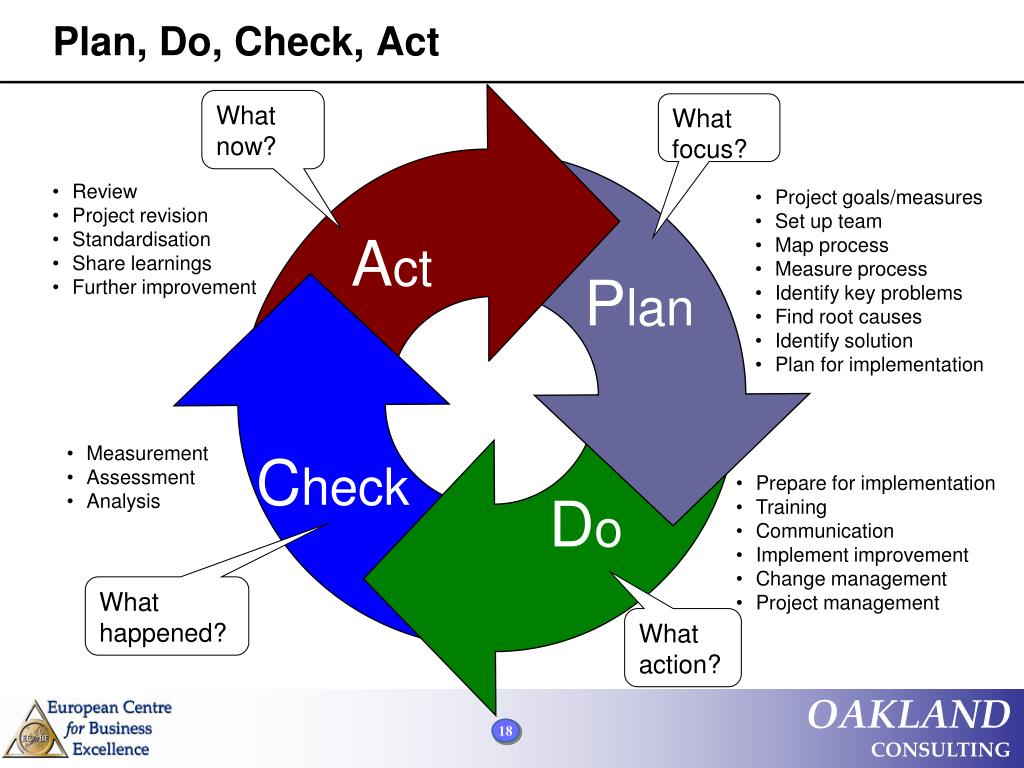

The Plan-do-check-act Procedure

- Plan: Recognize an opportunity and plan a change.

- Do: Test the change. Carry out a small-scale study.

- Check: Review the test, analyze the results, and identify what you’ve learned.

- Act: Take action based on what you learned in the study step. If the change did not work, go through the cycle again with a different plan. ...

What is the Plan do Check Act model?

Plan-do-check-act is a four-step model that carries out the change in a process, product, or service. This cycle has no end, and it can be repeated over again for continuous improvement; therefore, this cycle is called a loop. Moreover, this model is considered as a project planning tool.

What is Plan-Do-Check-Act (PDCA)?

Remember, plan-do-check-act (PDCA) is a loop and not a process. It means your upgraded process or a product becomes a new baseline. This cycle doesn't stop here; you have to continuously look for ways to make it better for your customers. When to Use the PDCA Cycle? Plan-do-check-act is a tool that can be used for various purposes, such as:

What is the Plan-Do-Check-Act cycle?

The Plan-do-check-act cycle (Figure 1) is a four-step model for carrying out change. Just as a circle has no end, the PDCA cycle should be repeated again and again for continuous improvement . The PDCA cycle is considered a project planning tool .

What is the PDCA check phase?

The check phase is one of the most important stages of the PDCA cycle. Here, detailed audits of the plan’s execution and results are conducted to determine if the initial plan was successful. The checking phase also helps team members identify problematic elements of the current process, enabling them to take the necessary corrective actions.

What is the Plan Do Check Act cycle?

What is the act step in teaching?

How does the A+ approach work?

What is the act step in A+?

What is planning data collection and analysis?

What happens if assessments show students are not learning as expected?

See 3 more

About this website

When should you use the Plan Do Check and Act process?

When should you use the PDCA process?Exploring and testing multiple solutions in a small, controlled trial.Avoiding waste by catching and adapting ineffective solutions before rolling them out on a large scale.Implementing change and continuous improvement.Implementing Total Quality Management or Six Sigma initiatives.More items...

What is the plan phase of PDCA?

The PDCA cycle consists of four components: Plan – Identify the problem, collect relevant data, and understand the problem's root cause, develop hypotheses about what the issues may be, and decide which one to test.

What is Plan-Do-Check-Act example?

The Plan-Do-Check-Act model includes solutions testing, analyzing results, and improving the process. For example, imagine that you have plenty of customer complaints about the slow response rate of your support team. Then you will probably need to improve the way your team works to keep customers satisfied.

What are the 5 stages of PDCA process?

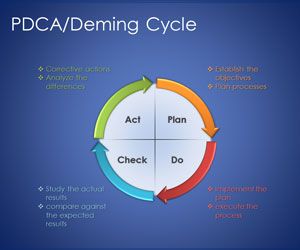

PDCA or the Deming cycle is a management methodology that aims to continually improve processes. This cycle is based on four stages: plan, do, check, and act. To adapt to market changes, improve efficiency, boost productivity, and meet the needs of your customers, having a method is required.

What is PDSA cycle explain?

PDSA, or Plan-Do-Study-Act, is an iterative, four-stage problem-solving model used for improving a process or carrying out change. When using the PDSA cycle, it's important to include internal and external customers; they can provide feedback about what works and what doesn't.

Why is PDSA cycle important?

The purpose of PDSA cycles is to learn as quickly as possible whether and how an intervention works in a particular setting and to make adjustments accordingly to increase chances of delivering and sustaining the desired improvement, or to stop the intervention and try something else.

How do you use the PDSA cycle?

Steps in the PDSA CycleStep 1: Plan. Plan the test or observation, including a plan for collecting data. ... Step 2: Do. Try out the test on a small scale. ... Step 3: Study. Set aside time to analyze the data and study the results. ... Step 4: Act. Refine the change, based on what was learned from the test.

What are the benefits of PDCA cycle?

Change Management: PDCA cycle helps in managing change effectively. It provides continuous improvement because it works in a cyclical way. Each part of the project will go through the same phase multiple times, ensuring that errors can be corrected and adapted to the needs and the actual situation of the corporation.

What companies use the PDCA cycle?

As a process checks through the PDCA stages, one is able to successfully observe the small loopholes and benefits of the process. The study of these processes will bring out the best in an organization. PDCA has time and again proved its efficiency in companies like Nestle, Lockheed Martin and Toyota.

What are the 4 steps of the quality assurance cycle?

This cycle for quality assurance consists of four steps: Plan, Do, Check, and Act. because it analyzes existing conditions and methods used to provide the product or service customers.

What are the 4 stages of improvement?

Phase 1 “Plan”: Plan for change and identify improvement opportunities. Phase 2 “Do”: Implement changes identified. Phase 3 “Study”: Check to determine if the change had the desired outcome. Phase 4 “Act”: If successful, implement it across the organization and process.

What is PDCA in agile?

PDCA (plan–do–check–act) is an iterative four-step quality improvement and management agile process typically used for the better of the business strategy. PDCA is a successive cycle which starts off small to test potential effects on processes, but then gradually leads to larger and more targeted change.

In which stage of PDCA outcome of the solution is evaluated?

Do Phase stage of PDCA, outcome of the solution is evaluated. The Do phase involves testing potential solutions on a small scale, and the results are then examined and verified.

What is the full form of PDCA?

PDCA is an acronym that stands for, 'Plan, Do, Check, Act.

What is Deming cycle explain briefly?

The Deming cycle is a continuous quality improvement model which consists of a logical sequence of four key stages: Plan, Do, Study, and Act.

Which of the following is part of Deming's PDCA cycle?

Which of the following is part of Deming's PDCA cycle? The PDCA cycle is a plan-do-check-act cycle using observed data for continuous improvement of operations. Which of the following is an example of an informational resource control?

What Is PDCA? Understanding the Plan-Do-Check-Act Method - HubSpot

The Plan-Do-Check-Act cycle helps your business plan and innovate — learn how to implement the process at your own business.

Where Does Plan-Do-Check-Act Cycle Come From?

The American statistician and physicist Walter Shewhart is considered the father of PDCA. He was passionate about statistical analysis and quality improvement, and he built the foundation of PDCA recorded in numerous publications.

What happens after you agree on a plan?

After you have agreed on the plan, it is time to take action. At this stage, you will apply everything that has been considered during the previous stage.

What is PDCA cycle?

PDCA cycle is an iterative process for continually improving products, people, and services. It became an integral part of what is known today as Lean management. The Plan-Do-Check-Act model includes solutions testing, analyzing results, and improving the process. For example, imagine that you have plenty of customer complaints about ...

What is the most important step in the PDCA cycle?

If you want to clarify your plan, avoid recurring mistakes, and apply continuous improvement successfully, you need to pay enough attention to the CHECK phase . Here, you need to audit your plan’s execution and see if your initial plan actually worked.

What is PDCA in business?

PDCA (Plan-Do-Check-Act) is a method for improving processes and products continuously. Find out more about the PDCA process and its practical application. What is Lean Management?

How many stages are there in the PDCA process?

Let’s take a closer look at the four stages of the PDCA process.

Who developed the PDCA cycle?

First, proposed by Walter Shewhart and later developed by William Deming, the PDCA cycle became a widespread framework for constant improvements in manufacturing, management, and other areas.

What is the plan do check act?

Plan-do-check-act is a four-step model that carries out the change in a process, product, or service. This cycle has no end, and it can be repeated over again for continuous improvement; therefore, this cycle is called a loop.

What is PDCA in planning?

Before you only build, applied, and assessed your plan. In this stage, you implement your solution. Remember, plan-do-check-act (PDCA) is a loop and not a process. It means your upgraded process or a product becomes a new baseline.

When to Use the PDCA Cycle?

Plan-do-check-act is a tool that can be used for various purposes, such as:

Is PDCA a one time event?

PDCA is not a one-time event. It requires commitment from team members because it is an on-going and continuous process. In the absence of committed leadership, your model won't work effectively for an extended period.

Is PDCA a project planning tool?

Moreover, this model is considered as a project planning tool. The PDCA cycle has several pros and cons that need to be considered before applying to different small-scale projects. There are several templates available, but we have mentioned some free templates that you can use to create your model in no time.

What are the steps of the PDCA process?

The four steps of the PDCA process are in the name: planning, doing, checking, and actioning. Notably, this process is a cycle, so as soon as you reach the end, you can start over from the beginning again.

What is the first step in process improvement?

The first step to any process improvement or project planning is to figure out what you need to do. Like any project plan, this includes a variety of information, including:

What is PDCA cycle?

The PDCA cycle is a framework for how to approach and resolve project management and process improvement problems. As a result, it can be implemented for a wide variety of projects. Teams that use the PDCA cycle effectively embrace the element of continuous improvement—rather than using the cycle for an end-to-end process, the PDCA cycle is a way to ensure continuous improvement and implement the iterative process .

What is PDCA in business?

The PDCA (Plan-Do-Check-Act) cycle is an interactive problem-solving strategy to improve processes and implement change. The PDCA cycle is a method for continuous improvement. Rather than representing a one-and-done process, the Plan-Do-Check-Act cycle is an ongoing feedback loop for iterations and process improvements. By following the PDCA cycle, teams develop hypotheses, test those ideas, and improve upon them in a continuous improvement cycle.

What is the purpose of the Plan Do Check Act cycle?from investopedia.com

The Plan-Do-Check-Act (PDCA) Cycle is a four-step problem-solving iterative technique used to improve business processes. Originally developed by American physicist Walter A. Shewhart during the 1920s, the cycle draws its inspiration from the continuous evaluation of management practices and management’s willingness to adopt ...

Where Does Plan-Do-Check-Act Cycle Come From?from kanbanize.com

The American statistician and physicist Walter Shewhart is considered the father of PDCA. He was passionate about statistical analysis and quality improvement, and he built the foundation of PDCA recorded in numerous publications.

What Is the PDCA Cycle?from investopedia.com

The Plan-Do-Check-Act (PDCA) Cycle is a four-step problem-solving iterative technique used to improve business processes. Originally developed by American physicist Walter A. Shewhart during the 1920s, the cycle draws its inspiration from the continuous evaluation of management practices and management’s willingness to adopt and disregard unsupported ideas.

What is PDCA in business?from kanbanize.com

PDCA (Plan-Do-Check-Act) is a method for improving processes and products continuously. Find out more about the PDCA process and its practical application. What is Lean Management?

What is the final step in the PDCA cycle?from investopedia.com

The final step is to take corrective action once past mistakes have been identified and resolved. The PDCA Cycle is repeated and can be redefined perhaps to better results under new guidelines.

How many stages are there in the PDCA process?from kanbanize.com

Let’s take a closer look at the four stages of the PDCA process.

How does the A+ approach work?from asq.org

The A+ Approach begins with a "plan" step, which the school district calls "analyze." In this step, students’ needs are analyzed by examining a range of data available in Pearl River’s electronic data "warehouse." The data reviewed includes everything from grades to performance on standardized tests. Data can be analyzed for individual students or stratified by grade, gender, or any other subgroup. Because PDCA does not specify how to analyze data, a separate data analysis process (Figure 3) is used here as well as in other processes throughout the organization.

What is the check phase in PDCA?

Here, detailed audits of the plan’s execution and results are conducted to determine if the initial plan was successful. The checking phase also helps team members identify problematic elements of the current process, enabling them to take the necessary corrective actions.

What should an action plan be rolled out on?

Ideally, action plans should be rolled out on an incremental scale, preferably in a controlled environment.

What is PDCA cycle?

The PDCA cycle is a simple yet effective framework for identifying and rectifying issues at any level of an organization. It provides an iterative approach to help project teams determine and analyze solutions and improve them through a waste-reducing cycle.

What happens if a pilot project does not produce the desired results?

If the pilot project does not produce the desired results, then the team reverts back to step one to reassess the plan. If the results were as expected, the team can progress to step four.

Who created the PDCA cycle?

Developed in 1950, the PDCA cycle was created by an American engineer, statistician, and management consultant, Dr. W. Edwards Deming. Deming is widely considered to be the father of modern quality control.

Does PDCA require time commitment?

Organizations should, however, bear in mind that the PDCA cycle does require a time commitment from team members, making it unsuitable for solving urgent issues.

Overview: What is the plan-do-check-act (PDCA) model?

Plan-do-check-act, or PDCA, is a method organizations use to continually improve their internal processes, increasing the quality of their products and the overall efficiency of their business. PDCA is also called the Deming wheel, Deming cycle, or Shewhart cycle, after some of its earliest proponents.

Benefits and disadvantages of using the plan-do-check-act (PDCA) models

PDCA doesn’t have universal acclaim, at least not in modern times. The business world still debates its efficacy and applicability in today’s environment.

How to use the plan-do-check-act (PDCA) model

The PDCA is a four-step process. Here’s what each step means and how to enact it.

Use software to implement PDCA concepts

Project management software has incorporated many best practices such as PDCA to make it easier to improve the way your business runs. The Ascent has reviewed the top software options, so check out a few to see if any fit your business. Then give a few a trial run, and settle on one you like the most.

About the Author

DP Taylor is a business software expert writing for The Ascent and The Motley Fool.

What is the relation between process groups and PDCA?

What is the relation between the process groups and PDCA? The process groups are a form of PDCA, since we are dealing with project management processes, which are like any other business process. For any project, we have to plan, do, check, and act. There are some differences.

What is P-D-C-A?

The P-D-C-A is an iterative four-step management method, which one use continuous improvement. In simple terms, this approach advises us to

Is PDCA a factor in process groups?

Not true. PDCA was never a factor in the development of the process groups.

What is the check phase of PDCA?

The Check phase of PDCA is where you analyze the results of your changes to see if the level of error was reduced.

What does "act" mean in science?

Act – either implement the successful hypothesis or repeat the process to find a more suitable solution

What is PDCA?

PDCA (Plan-Do-Check-Act) is a four-step cycle for continuous improvement. The way it does this is through identifying errors, creating hypotheses to deal with them, testing the method, and acting on the results.

What is PDCA in manufacturing?

PDCA focuses on errors/defects within a process or product and testing hypotheses to fix them

What stage does PDCA start?

Every PDCA starts with the Plan stage.

What is the key to a PDCA test?

The key with any testing cycle (PDCA included) is to have a solid process backing it up. You need to be able to follow the instructions of the test to the letter to avoid corrupting the results. Your team should have something to check their new method when implementing your hypothesis.

Why is it important to test your changes?

It’s also worth testing your changes on a small-scale first. This way you can limit the number of elements that could affect your outcome, more accurately predict the effects, and limit any potential damage as a result.

What is the Plan Do Check Act cycle?

The Plan-do-check-act cycle (Figure 1) is a four-step model for carrying out change. Just as a circle has no end, the PDCA cycle should be repeated again and again for continuous improvement. The PDCA cycle is considered a project planning tool.

What is the act step in teaching?

The "act" step is where instruction is provided, following the curriculum and teaching goals. Within set parameters, teachers vary the delivery of instruction based on each student’s learning rates and styles.

How does the A+ approach work?

The A+ Approach begins with a "plan" step, which the school district calls "analyze." In this step, students’ needs are analyzed by examining a range of data available in Pearl River’s electronic data "warehouse." The data reviewed includes everything from grades to performance on standardized tests. Data can be analyzed for individual students or stratified by grade, gender, or any other subgroup. Because PDCA does not specify how to analyze data, a separate data analysis process (Figure 3) is used here as well as in other processes throughout the organization.

What is the act step in A+?

In this example, the "act" step is "standardization." When goals are met, the curriculum design and teaching methods are considered standardized. Teachers share best practices in formal and informal settings. Results from this cycle become input for the "analyze" phase of the next A+ Approach cycle.

What is planning data collection and analysis?

Planning data collection and analysis in order to verify and prioritize problems or root causes

What happens if assessments show students are not learning as expected?

Throughout the school year, if assessments show students are not learning as expected, mid-course corrections are made (such as re-instruction, changing teaching methods, and more direct teacher mentoring). Assessment data become input for the next step in the cycle.