A Guide to Shot Blasting / Shot Peening

- Shot peening/shot blasting is a surface conditioning process which increases/improves a surface finish with benefits such as fatigue resistance.

- The process works by inducing residual stresses on the work piece surface to increase fatigue resistance.

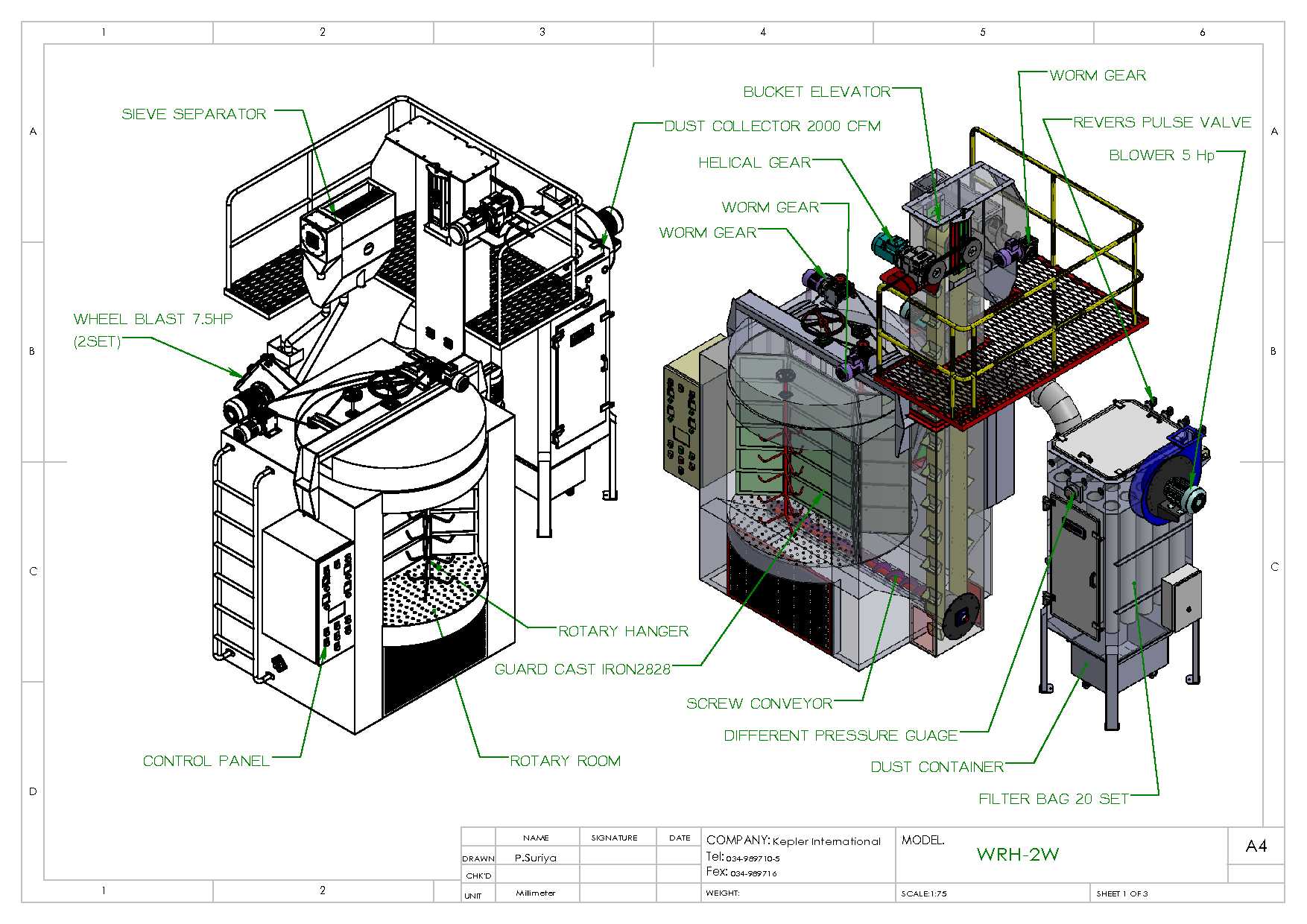

- Shot blasting uses a peening chamber with the work item placed on a rotating turntable and bombarded with small balls at extremely high velocity.

What are the advantages of shot blasting?

The Advantage of Shot Blasting:

- No chemicals used at all

- No acids

- The only cleanup is physical pellets

- The process only uses abrasion to clean the metal surface

- Shot blasting Minimizes Operation cost, Maintenance cost

- Shot blasting eliminates the usage of non-eco friendly and harsh chemicals

How does shot blasting work?

How Does Shot Blasting Work? Shot blasting works by propelling round materials known as shot media against a surface which in turn removes the contaminants of the surface and also can improve its finish. What type of shot media is used is a very important decision for the shot blasting process. The size and hardness of the shot material will ...

How shot blasting works?

- The process involves the utilization of solely abrasion to scrub the surface of the metal merchandise

- No chemicals are used throughout the complete method.

- Acids too don’t seem to be used at any time within the entire method.

- The only needed pack up is of the physical pellets.

Is shot peening and shot blasting process same?

This process is very different from Shot Blasting. Shot Blasting is used to either prepare or clean material, while shot peening is a procedure that is precisely controlled by a careful selection of media, along with the required concentration. It is a stressful process carried out on the surface of metals.

What material is used for shot blasting?

Types of metal abrasives used in shot blasting include steel grit, copper shots, and aluminum pellets. Other methods of shot blasting use silica sand, glass beads, synthetic materials like sodium bicarbonate (baking soda), and even agricultural materials like crushed kernels.

What is shot blasting finish?

Shot blasting is a specialized surface finishing process where small metal (or mineral) pellets, called blast media, are thrown onto the surface of a work piece at incredibly high speeds, ranging from 200-800 feet per second.

What is the process of sandblasting?

Sandblasting is process of smoothing and cleaning a hard surface by forcing solid particles across that surface at high speeds using compressed air. There are two kinds of sandblasters: “Suction” / “Siphon”" & “Pressure” Blast Systems. There are two basic kinds of sand blasters: Blast Cabinets & Portable Blasters.

What is shot blasting machine used for?

Shot blasting machines concentrate these beads in one area at extremely high speeds to clear materials such as rust, paints or other coatings. Typically, this blasting method is used for metals and concrete, and it's preferred for its surface preparation ability and environmental friendliness.

How many types of blasting are there?

There are various types of abrasive blasting including, silicon dioxide, soda, steel, bristle, glass bead and much more. All these different abrasive blasting methods usually use a specific type of grit to achieve the desired results, hence the need to determine the correct technique to use.

What is the difference between sandblasting and shot blasting?

One of the primary differences between shot-blasting and sandblasting is the medium used. Shot-blasting uses abrasive “shot” made of metal such as aluminum oxide or carbon grit almost exclusively. Sandblasting can use metallic shot, but more often it uses gentler abrasives such as organic media or glass.

Why shot blasting is done before painting?

The Benefits Of Blast Cleaning Blast cleaning helps in surface preparation by removing contaminants before coating, painting or lining. Surface cleaning removes rust and other contaminants which could cause problems with paint adhesion, or in the most extreme cases, compromise the integrity of the surface metal itself.

Can you use sand in a shot blasting?

No, abrasives which contain more than 1% free silica are forbidden. In the past, blast cleaning operations were done with silica sand. The term sandblasting originates from those days.

Will sandblasting remove paint?

Sandblasting is the best way to remove paint from all surfaces. It is less laborious than other methods, yet allows you to achieve the results within a short time. The method is perfect when dealing with objects with nooks and crannies.

Is shot blasting easy?

Please note: While many tools exist that make the process easier, shot blasting is a delicate and potentially dangerous process. If undertaking the work, always ensure that physical safety is given a high degree of prominence as individual pieces of shot can be highly dangerous.

What is shot blasting concrete?

Shot blasting concrete is a resurfacing process that uses metal beads “shot” out of a machine to “blast” away tough debris and contaminants. It's a comparable method to sand blasting, but it provides a much more powerful clean due to the size and speed of the metal pellets.

What is SA 2.5 blasting?

SHOT BLASTING SERVICES TO SA 2.5 Shot blasting is ideal for removing paint, deburring, eradicating sand from castings, and provides an excellent key for painting. Shot blasting also removes any scale left behind after heat treatment.

What is shot blasting concrete?

Shot blasting concrete is a resurfacing process that uses metal beads “shot” out of a machine to “blast” away tough debris and contaminants. It's a comparable method to sand blasting, but it provides a much more powerful clean due to the size and speed of the metal pellets.

What is shot blasting in casting?

Shot blasting is a finishing process used to clean castings and prepare them for further treatment. It is widely used in many industrial areas, such as the automotive, aviation, rail and shipbuilding sectors. At Haworth Castings, we use this technique in all our sand casting work.

What is shot blast steel?

What Is Shot Blasting? Shot blasting is the process of abrading the surface of a metal workpiece to remove rust, dirt and other solidified contaminants by hurling a high speed stream of tiny pieces of stainless steel that resemble buckshot. It is capable of deburring, shaping and texturing a surface.

Is shot blasting easy?

Please note: While many tools exist that make the process easier, shot blasting is a delicate and potentially dangerous process. If undertaking the work, always ensure that physical safety is given a high degree of prominence as individual pieces of shot can be highly dangerous.

How the Shot Blasting Process Works

There are two ways to apply abrasive cleaning media to a surface. One is with compressed air, the other involves a centrifugal turbine.

Why is Surface Preparation Important?

When it comes to treating steel or other metal substrates, surface preparation is a crucial starting point.

Shot Blasting Applications

Shot blasting is not simply a crude method of cleaning surfaces and removing stubborn debris.

What is Shot Peening?

Shot peening uses the same basic process as shot blasting, but with a different purpose.

When Should You Use Shot Blasting?

Using shot blasting will depend on the type of project you are working on, and what your desired end-result is.

Find Out More

Is shot blasting right for your project? We specialise in a whole range of pre-treatments.

What is Shot Blasting?

Shot blasting is a mechanical cleaning process that uses spheres of material to remove oxides and other debris from the surface of another material . Although less commonly mentioned than sandblasting, shot blasting belongs in the same family of abrasive blasting processes in which sandblasting is categorized. The main difference between shot blasting and sandblasting is that shot blasting uses spherical shot as an abrasive media and a centrifugal wheel for propulsion, while sandblasting uses grains of sand and almost exclusively uses compressed air for propulsion.

How Does Shot Blasting Work?

Shot blasting works by propelling round materials known as shot media against a surface which in turn removes the contaminants of the surface and also can improve its finish. What type of shot media is used is a very important decision for the shot blasting process. The size and hardness of the shot material will dictate how much surface removal of the material being cleaned will occur. The type of material being cleaned will also play a role in the effectiveness of the shot blasting process. Typically, the shot material and size will be selected depending on the composition of the material whose surface is being shot blasted.

What is a shot blast recovery system?

The shot blast recovery system will collect the material shot that has already been propelled and impacted against the material being cleaned and return it to the propelling device to be used again. Shot blast recovery is typically performed through the use of a vacuum.

What is the difference between sandblasting and shot blasting?

The main difference between shot blasting and sandblasting is that shot blasting uses spherical shot as an abrasive media and a centrifugal wheel for propulsion, while sandblasting uses grains of sand and almost exclusively uses compressed air for propulsion.

How to propel a shot blaster?

The most common way to propel the shot blasting media is through the use of a centrifugal wheel. To propel the shot blasting media, it is unloaded into a centrifugal wheel. Once the shot blast material has been accelerated by the wheel to the desired velocity, it is expelled from the wheel and into the shot blasting gun.

How to clean oxidized metal?

While methods range from simply wiping a metal down with a rag to immersing materials in a bath of complex chemical combinations, one of the most effective and popular ways to clean dirty or oxidized material is by shot blasting it.

What materials are used in shot blasting?

There are also many types of materials that can be used as shot blast material. These include, but are not limited to: 1 Steel 2 Aluminium 3 Zinc 4 Copper

What is a shot blast machine?

Shot blasting machine is a mechanical method of propelling abrasive using a centrifugal wheel to remove surface and other impurities from the surface of steel applications. General, blasting prior to finishing serves three primary purposes:-

How many types of shot blasting are there?

Ans. There are two types of shot blasting:-

Why choose quality spare center sand blasting machine?

Because they offer genuine, economical and quality spares for all type of Sand blasting machine as company name start with quality their product also shows it.

What is sandblasting?

Ans. Sandblasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface and shape a surface or to remove the surface contaminants. Sand used to be the most commonly used material, but since the lung disease silicosis is caused by extended inhalation of the dust created by sand, other materials are now used in its place.

What is an air blaster?

Ans. Air blasting is also called as air cannon, used to clean, peen or polish metal. It is a de-clogging device composed of two main elements:

How does a sandblaster work?

The sandblaster works to clean and abrade a surface, typically metal, of any rust, paint or other unwanted surface materials. In this technology, the hose connects to the air tank, and the hopper is filled with an abrasive to ensure best results without any obstacles.

Why blast zinc?

Since the outer layer of pure zinc requires very little impact or scouring to get required surface roughness, the blasting process should lightly roughen the surface without removing a major amount of the galvanized coating. The purpose of this procedure is to remove the oxide film from the zinc surface. Light sweep blasting can provide maximum topcoat adhesion over galvanizing.

What is the Difference Between Shot Blasting and Shot Peening?

What is the difference between shot blasting machine and shot peening machine?

How much is a shot blaster?

Refer to this guideline chart of the wheelabrator buying a shot blasting machine. Check it and compare it with your sourcing budget, but please bear in mind that the cost of the shot blasting machine is just for your information, the different purpose and workload needs the shot blasting machine’s shot wheels, motor, quantity, brand, automated level all different, so the final cost please contact us for confirm;

What is shot blasting?

Shot blasting is also the name of a mechanical surface treatment process , similar to sand blasting.

What is the name of the equipment used to clean parts in a shot blasting process?

In shot blasting cleaning of parts, the facilities that can make the parts change the cleaned surface continuously in the jet stream to meet the requirements of uniform shot blasting are called shot blasting equipment, or shot blasting machinery .

What is sand blasting used for?

It is often used to remove rust on the surface of parts; to modify the surface of parts (the small wet sand blasting machine sold in the market is for this purpose, the sand is usually corundum, and the medium is water);

Why is a shot blasted to the casting with sand?

The shot is blasted to the casting with sand to remove the shot falling sand of molding sand and core;

How to clean cast parts?

In fact, the cleaning of casting parts is not only by shot blasting , but also by removing the riser of the casting parts and rolling them in the roller. The parts collide with each other in the roller to remove most of the sand on the surface before shot blasting or shot peening.

Why are leaf springs shot blasted?

The spring, leaf spring and gear under variable stress are shot blasted to eliminate stress and improve surface fatigue strength;

Where is the air pressure sandblasting machine used?

Manual air pressure sandblasting machine is widely used in China. It also uses various medium and small parts with complex shapes.