What is Quality Function Deployment QFD?

Quality Function Deployment (QFD) Definition: Quality Function Deployment, or QFD, is a model for product development and production popularized in Japan in the 1960s. The model aids in translating customer needs and expectations into technical requirements by listening to the voice of customer. What is Quality Function Deployment?

Why choose QFD for Quality Assurance?

Focusing consistently on customer desires, QFD ensures these are always considered during both the design process and various quality assurance milestones throughout the entire product lifecycle.

How do you use QFD effectively?

Effective use of QFD requires team participation and discipline inherent in the practice of QFD, which has proven to be an excellent team-building experience. The House of Quality is an effective tool used to translate the customer wants and needs into product or service design characteristics utilizing a relationship matrix.

What is QFD in qfd3?

Quality control QFD helps to prioritize the process control methods and parameters and establishes production methods that best support the prioritized process elements of QFD3. When do we use QFD? You may apply QFD into the product development process when you find well-understood clients with quantifiably captured desires.

What is QFD and its benefits?

QFD stands for Quality Function Deployment. It is a functional product management system that has been popular in Japan since the 1960s. It helps in understanding and aiding the voice of customers and giving the technical help that is essential to their needs.

What is the importance of Quality Function Deployment?

Quality Function Deployment benefits companies primarily by ensuring they bring products to market that customers actually want, thanks to listening to customer preferences at the beginning of the design process.

What are the basic principles of QFD?

The three principles of QFD are analysis and integration, diversification and visualization, and generalization and localization. The principle of analysis and integration obviously refers to the process of splitting things up and putting them back together.

What are the 4 phases of QFD?

In the other hand, Pahl, Wallace, & Blessing [5] has also highlighted the importance of the QFD, and for them the four phases are: product planning, product development, process planning and production planning.

What are the advantages and disadvantages of Quality Function Deployment?

QFD focuses solely on what a business needs to do to satisfy its customers. A major disadvantage is that it ignores other factors such as cost, the length of the product life cycle, long-term strategy and growth objectives and available resources.

What is Quality Function Deployment explain with an example?

The organising framework for the QFD process is a planning tool called the "house of quality" (simplified example above). Working as a team, design engineers and marketers first establish critical customer attributes for the product. These attributes become the rows of the central matrix of the house of quality.

What is Quality Function Deployment in software engineering?

Quality Function Deployment (QFD) is process or set of tools used to define the customer requirements for product and convert those requirements into engineering specifications and plans such that the customer requirements for that product are satisfied.

What is importance of Six Sigma in process control?

Six Sigma is a method that provides organizations tools to improve the capability of their business processes. This increase in performance and decrease in process variation helps lead to defect reduction and improvement in profits, employee morale, and quality of products or services.

What is QFD in business?

In QFD, quality is a measure of customer satisfaction with a product or a service. QFD is a structured method that uses the seven management and planning tools to identify and prioritize customers’ expectations quickly and effectively.

What is QFD in product development?

QFD Explained ( Quality Progress) Learn more about quality function deployment, the structured method for translating customer requirements into appropriate technical requirements for each stage of product development and production.

What is the Blitz QFD 3?

Blitz QFD Part 3: The Analytical Hierarchy Process In the final installment of a three-part Blitz QFD series, Dr. Jack ReVelle walks through the analytical hierarchy process, a structured technique for organizing, analyzing, and ultimately deciding on the most important customer needs to focus on.

When was QFD invented?

First developed in Japan in the late 1960s as a form of cause-and-effect analysis, QFD was brought to the United States in the early 1980s. It gained its early popularity as a result of numerous successes in the automotive industry.

Is quality function deployment an essential tool?

Some have only internal customers, some have only external customers, and some have both. When you are working to determine what you need to accomplish to satisfy or even delight your customers, quality function deployment is an essential tool.

When to use QFD?

It is most effective when used throughout the entire product lifecycle, as its main purpose is to ensure a constant focus on the voice of the customer. You can’t “check it off” as completed since it is an ever-present ingredient every step of the way.

When was QFD introduced?

Developed in 1960s Japan, QFD was imported to the United States in the early 1980s and caught on thanks to its popularity and successful track record in the automotive industry. Copying the model from manufacturers such as Toyota and Mitsubishi, the “big three” American car makers used QFD to bring customer centricity to their industry.

What is Quality Function Deployment?

Although it might sound like a modern testing methodology, Quality Function Deployment (QFD) has a 50-year track record of putting customer needs first throughout the entire product development process. Focusing consistently on customer desires, QFD ensures these are always considered during both the design process and various quality assurance milestones throughout the entire product lifecycle.

What are the Advantages and Disadvantages of Quality Function Deployment?

Quality Function Deployment benefits companies primarily by ensuring they bring products to market that customers actually want, thanks to listening to customer preferences at the beginning of the design process. Then, mandating these needs and desires is met throughout every aspect of the design and development process. In short, if something isn’t being built because a customer wants it (or it provides underlying support for a customer need), it doesn’t get built at all, which can prevent technology from driving strategy when it’s not directly beneficial to the customer experience.

How did QFD impact the design process?

Once adopted, QFD shortened design cycles significantly and reduced the total number of employees required in the design process. Shifting the focus from bottom-line cost analysis to customer satisfaction brought innovations and increased sales of domestic vehicles after the surge in popularity of Japanese imports in the 1970s.

Why is customer input important in product development?

Since collecting customer inputs and applying them throughout the product development process is such a cross-functional activity, it can also increase teamwork and ensure the entire organization is aligned around customer satisfaction instead of competing with other internal priorities.

When is QFD appropriate?

QFD is most appropriate when companies are focused on relatively iterative innovation versus something completely new since there is a large base of customer feedback and input to drive the process. When a product is creating a completely new category, it’s more difficult to fully articulate the voice of the customer since they don’t necessarily have a frame of reference, but even in these cases carrying forward what is known about customer needs and preferences can provide value.

What is the purpose of QFD?

The main aim of QFD is to improve a product or service so that it will be better received by the market. The focus here is also on customer satisfaction. Ideally, it’s best to apply QFD during the product planning phase, but you can also make adjustments to the product later on the basis of a QFD analysis.

What is QFD in business?

This technique allows you to systematically work out customer requirements and then present them in a clear way. QFD is mainly used in quality management, but it is also used in product management and product development. Ultimately, this method involves all areas of the company.

What is QFD in manufacturing?

Quality Function Deployment (QFD) is a systematic analysis of customer requirements that is used to improve the quality of your products. QFD originated in Japan in the 1960s and 70s and was primarily developed by Yōji Akao. Mitsubishi and Toyota, as well as many other companies, have used this method to better tailor their products and services to their target market and accelerate growth. As part of this method, customer requirements, product performance, and the products offered by the competition are all taken into consideration.

What are the advantages of QFD?

Another advantage of Quality Function Deployment – when implemented early and effectively – is that it can reduce development costs and times. As this method focuses on customer requirements with a well-thought-out method and is not based on assumptions, you can use it to make specific plans. Not only does QFD support companies by helping them to increase their revenue, but it also helps them to work in a more streamlined manner during production.

What happens at the end of the Quality Function Deployment process?

At the end of the Quality Function Deployment process, a clear catalog of measures will be produced. The knowledge gained must now be communicated and implemented in product development, product management, production, sales, and marketing.

What to ask yourself during product development?

The first thing to ask yourself during the product development phase is who the product is aimed at or who will buy it later. You must also think about the distinction between B2B and B2C – a relatively banal subject. Next, you must consider information such as income, gender, marital status, age, and level of education. Finally, you may have to make some assumptions about details that are more difficult to measure, such as the requirements, standards, and values of potential customers.

Is quality function deployment a fixed model?

Quality Function Deployment is not a rigid, fixed model. It has undergone many further developments since it was first used by Yōji Akao (e.g. such as those implemented by Bob Kind or Emil Jovanov). Even Akao himself believed that it was incredibly important for each person to adapt the concept to their own situation. Something that all variants of the method have in common is that they proceed step by step, starting with a customer survey and finishing with production or the product launch.

Why is QFD important?

QFD is not only a quality tool but also an important planning tool. It allows the consideration of the “voice of the customer” along the service development path to market entry.

What is QFD in service design?

The QFD technique is based on the analysis of the clients’ requirements, which normally are expressed in qualitative terms, such as: “easy to use”, “safe”, “comfortable” or “luxurious”. In order to develop a service, it is necessary to “translate” these fuzzy requirements into quantitative service design requirements;

What is component deployment QFD?

Component Deployment QFD. It helps identify the critical parts and assembly components using the prioritized offering characteristics in QFD 1 and establishes critical target values.

What is QFD matrices?

QFD matrices also called “the house of quality”, are graphical displays of the result of the planning process. QFD matrices vary a great deal and may show such things as competitive targets and process priorities.

What is QFD in engineering?

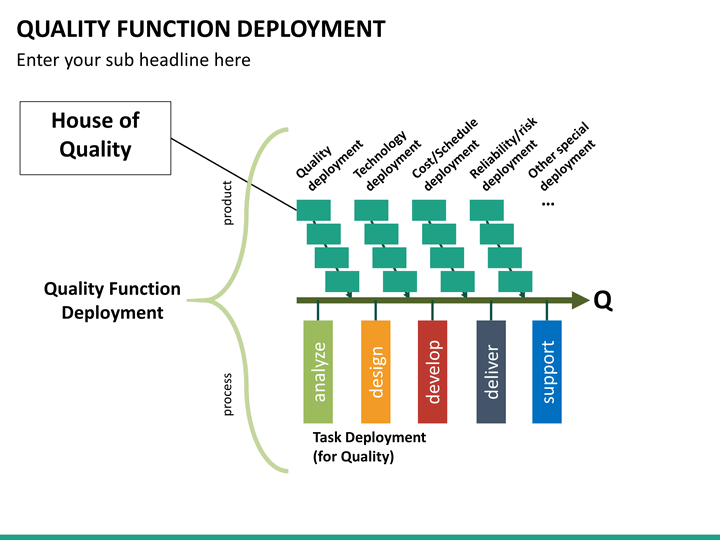

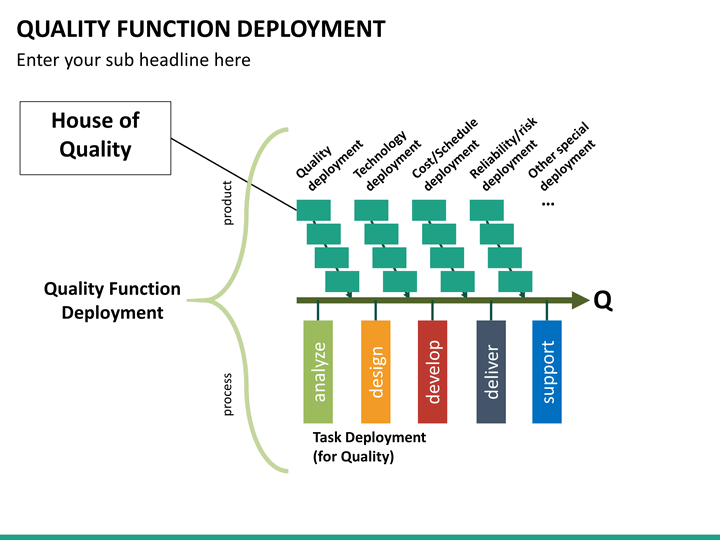

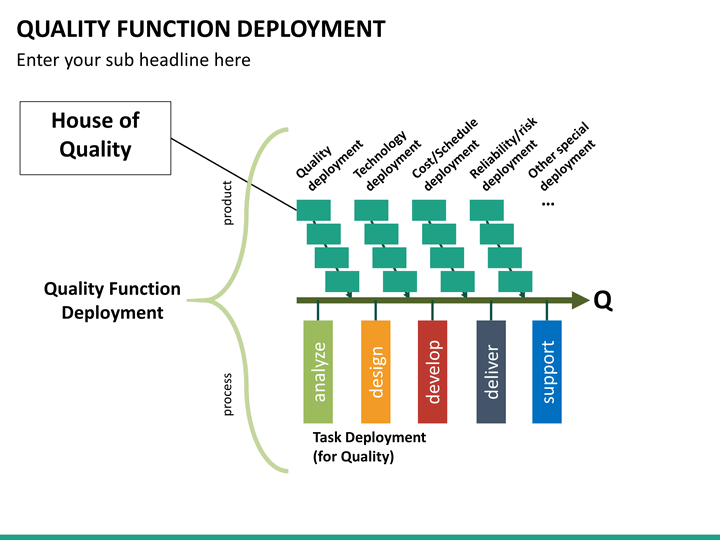

In this approach, design engineers typically start progressive drill-down approach with planning the development and go through four phases to reach a deeper understanding of the required process control and quality. The details are as follows:

What is quality function deployment?

There is no single definition for quality function deployment, but a general basic concept of this method is as follows: “Quality Function Deployment is a system with the purpose of translating and planning the VoC into the quality characteristics of products, processes and services for reaching customer satisfaction”.

When was QFD first used?

History of QFD. The tool was first used to design an oil tanker at the Kobe shipyards of Japan in 1972 by Yoji Akao and Shigeru Mizuno to design customer satisfaction into a service offering before it is produced. Prior to this, quality control methods were primarily aimed at fixing a problem during or after production.

Why is QFD important?

Every business, organization, and industry has customers. Meeting your customers’ needs is critical to success. Implementing QFD can enable you to drive the voice of your customers throughout your organizational processes to increase their satisfaction and delight.

Why is QFD important to understand?

Understanding this linkage and the cascading of the how of one phase feeds into the what of the next phase is the secret of being able to successfully use QFD.

What is QFD in Six Sigma?

A structured methodology and mathematical tool used to identify and quantify customers’ requirements and translate them into key critical parameters. In Six Sigma, Q FD helps you to prioritize actions to improve your process or product to meet customers’ expectations.

What is the power of QFD?

The power of QFD is that it is your customers’ needs driving the technology, and not the technology driving your customers’ needs.

When was QFD invented?

QFD was developed in Japan by Yoji Akao in about 1966 while working for Mitsubishi. Toyota and other auto manufacturers started using the approach later on.

Can you complete a QFD without completing each previous house?

The QFD phases, or Houses, are structured and the elements linked. You can’t complete the QFD without completing each previous House.

Can QFD be used to replace a process?

If you already have a functioning development process, QFD can be used to help support and enhance your current process, not replace it.

What is QFD in business?

QFD is applied in a wide variety of applications viz product design, manufacturing, production, engineering, research and development (R&D), information technology (IT), support, testing, regulatory, and other phases in hardware, software, service, and system organizations. organization functions necessary to assure customer satisfaction, including business planning, packaging and logistics, procurement, marketing, sales & service. QFD is also deployed in quality improvement, quality management, military needs and consumer products. Customer services Applications for Education improvement and services in hotels etc.

What is QFD in engineering?

Quality function deployment ( QFD) is a method developed in Japan beginning in 1966 to help transform the voice of the customer into engineering characteristics for a product. Yoji Akao, the original developer, described QFD as a "method to transform qualitative user demands into quantitative parameters, to deploy the functions forming quality, and to deploy methods for achieving the design quality into subsystems and component parts, and ultimately to specific elements of the manufacturing process." The author combined his work in quality assurance and quality control points with function deployment used in value engineering .

When was the House of Quality made?

The house of quality appeared in 1972 in the design of an oil tanker by Mitsubishi Heavy Industries.

Is fuzzy logic used in QFD?

The concepts of fuzzy logic have been applied to QFD ("Fuzzy QFD" or "FQFD"). A review of 59 papers in 2013 by Abdolshah and Moradi found a number of conclusions: most FQFD "studies were focused on quantitative methods" to construct a house of quality matrix based on customer requirements, where the most-employed techniques were based on multiple-criteria decision analysis methods. They noted that there are factors other than the house of quality relevant to product development, and called metaheuristic methods "a promising approach for solving complicated problems of FQFD."

Why is QFD important?

QFD is useful for companies because it ensures that they bring products to market that customers actually want. It happens thanks to listening to customer preferences at the beginning of the design process and meeting these desires and needs.

When do we use QFD?

You may apply QFD into the product development process when you find well-understood clients with quantifiably captured desires.

What is the History of Quality Function Deployment?

The tool has a 50-year history as the methodology for putting customer needs.

What is QFD in marketing?

To identify the superfluous aspects that can be removed. To prioritize the desires and requirements of your clients. To get a vision about your situation in the market.

What is QFD in engineering?

QFD is an acronym that combines functionality from different disciplines, such as management, marketing, and engineering. Quality Function Deployment is typically used for new product design. It can also focus teams on improving existing products and processes. What are the key advantages of the QFD matrix and what are the components ...

What is the house of quality?

The house of quality is part of the QFD system. As the basic design instrument of quality function deployment, it defines and classifies customers’ desires, identifies their importance, specifies engineering characteristics, and assigns priorities for the system requirements.

What is QFD?

House of Quality is a part of a larger process called QFD, which stands for Q uality, F unction, D eployment. This represents quality -monitoring, a focus on the function of execution of a quality plan, and the application of resources for deployment of that plan.

House of Quality Diagram

Below is an example of a House of Quality Diagram. We will now walk through a summary overview of its various parts. We continue our example of a media-production drone manufacturer.

In Closing

There are various levels of detail into which one can go using the House of Quality diagram. Some might include ratings for each engineering specification that indicate technical difficulty of execution, and so forth. But the example above is widely applicable and fairly detailed.

Quality Function Deployment Definition

History of QFD

Benefits of QFD

- In QFD, quality is a measure of customer satisfaction with a product or a service. QFD is a structured method that uses the seven management and planning tools to identify and prioritize customers expectations quickly and effectively. Beginning with the initial matrix, commonly termed the house of quality, depicted in Figure 1, the QFD methodology ...

QFD House of Quality Matrices

Quality Function Deployment Process