What are the principles of dry heat sterilization?

Principle of Dry heat sterilization using HOT AIR OVEN. Sterilizing by dry heat is accomplished by conduction. The heat is absorbed by the outside surface of the item, then passes towards the centre of the item, layer by layer. The entire item will eventually reach the temperature required for sterilization to take place.

What is the most effective methods of sterilization?

- Plasma Gas Sterilizers.

- Autoclaves.

- Vaporized Hydrogen Peroxide Sterilizers.

What are the different methods of sterilization?

- i. Physical Control with Heat: The Citadel is novel by A.J. ...

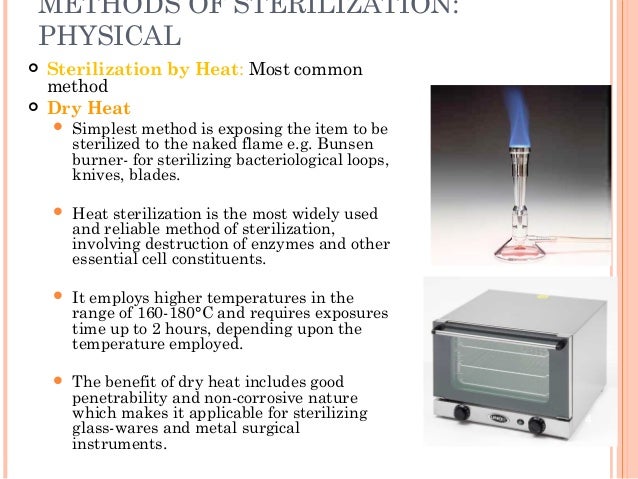

- ii. Direct Flame: Perhaps the most rapid sterilization method is the direct flame method used in the process of incineration.

- iii. Hot-Air Sterilizer: The hot-air-sterilizer utilizes radiating dry heat for sterilization. ...

- iv. ...

- v. ...

- vi. ...

- vii. ...

- i. ...

- ii. ...

- iii. ...

Is autoclave example of dry heat Sterlization?

This type of sterilizer is particularly useful when sanitizing metal instruments because it does not rust the equipment nor dull metal edges. Steam sterilizers, or autoclaves, like dry heat sterilizers use very high temperatures to destroy harmful microorganisms, but they also use pressure over a specific amount of time to disinfect.

What is the simplest method of sterilization?

Filtration is the quickest way to sterilize solutions without heating. This method involves filtering with a pore size that is too small for microbes to pass through. Generally filters with a pore diameter of 0.2 um are used for the removal of bacteria.

What is dry heat method of sterilization?

Dry heat sterilization is accomplished by the conduction of heat. Heat is absorbed by the outside surface of the device and is transferred through the entire device till the target temperature is attained. Dry heat kills microorganism by oxidizing molecules.

What is an example of dry heat sterilization?

The essential cell constituents are destroyed and the organism dies. The temperature is maintained for almost an hour to kill the most difficult of the resistant spores. Things such as glassware, metal instruments, paper wrapped things and syringes are effectively sterilized through dry heat.

What are the two types of dry heat sterilization?

There are two types of dry-heat sterilizers: the static-air type and the forced-air type. The static-air type is referred to as the oven-type sterilizer as heating coils in the bottom of the unit cause the hot air to rise inside the chamber via gravity convection.

Which material are used for dry heat sterilization?

Materials that can be sterilized using dry heatMaterialMaximum TemperatureHigh-density polyethyleneUp to 120°CMetalUp to 190°CaMuslinUp to 160°CNylon (polyamide, heat-stabilized grades)Up to 266°F27 more rows

What are the 3 types of sterilization?

With that said, there are three main types of sterilization methods common within the scientific community today. They are steam, dry heat, and ethylene oxide (EtO) sterilization.

Which of the following is an example of dry heat?

Examples of dry-heat methods include: Roasting and Baking. Grilling and Broiling. Sautéeing and Pan-Frying.

Is autoclave dry heat sterilization?

There are a number of differences between dry heat sterilization and steam sterilization, the most obvious difference being that autoclaves use steam, vacuum, and pressure to clean tools and cages, while dry heat sterilization simply uses hot air.

What is the most efficient type of dry heat sterilizer?

The best device to perform the process of sterilization is Hot Air Oven. These are the dry heat ovens that are used to perform the process of sterilization to distract the microbes using dry heat.

What are the most common forms of heat sterilization?

Of all the methods available for sterilization, moist heat in the form of saturated steam under pressure is the most widely used and the most dependable. Steam sterilization is nontoxic, inexpensive 826, rapidly microbicidal, sporicidal, and rapidly heats and penetrates fabrics (Table 6) 827.

What are the examples of dry heat cooking?

Grilling, broiling, baking, roasting, sautéing or stir-frying, and searing are the different ways to cook using dry heat:Grilling. Grilling uses heat from underneath to cook the food. ... Broiling. ... Baking. ... Roasting. ... Sautéing. ... Searing. ... You may also be interested in:

Why autoclaving is the best method of sterilization?

Autoclaving is the most effective method of sterilizing the lab equipment specially for liquid handling products to kill harmful bacteria, viruses, fungi, and spores. The autoclaving process takes advantage of the phenomenon that the boiling point of water (or steam) increases when it is under high pressure.

Which of the following method is used for sterilization?

Solution : Boiling, exposure to sunlight and chlorination are considered to be the methods of sterlization as they can kill bacteria and germs.

What are the two main types of sterilization?

The Sterilization is conveyed out by the methods according to requirement. The methods are: 1. Moist Heat Sterilization 2. Dry Heat Sterilization 3.

What temperature is required for dry heat sterilization?

Ovens, conductors, and vacuums can be used to achieve dry heat sterilization. Depending on the type of sterilization equipment being used, temperatures up to 180 degrees Fahrenheit must be reached for a predetermined amount of time.

What is dry air sterilization?

Dry heat sterilization is one of the most practical and preferable forms of sterilization, using blown hot air to eliminate or deactivate all forms of life inside the chamber of an industrial oven.

Which of the dry heat or moist heat sterilization methods is the most effective Why?

Compared with dry heat sterilization, steam sterilization is the more efficient method because the moisture in steam is a good conductor of heat and is superior at penetrating the load. With less energy needed, steam sterilization offers increased productivity with lower energy expenditure, resulting in cost savings.

What are the 5 methods of sterilization?

In this post, we'll discuss the five methods of lab sterilization that will keep you and your materials safe.Wet Heat (Autoclaving) Autoclaving is the most popular method of lab sterilization. ... Dry Heat (Baking or Flaming) ... Filtration. ... Chemicals/Solvents. ... Radiation.

How long does dry heat sterilization take?

The proper time and temperature for dry heat sterilization is 160 °C (320 °F) for 2 hours or 170 °C (340 °F) for 1 hour, and in the case of High Velocity Hot Air sterilisers, 190°C (375°F) for 6 to 12 minutes. Items should be dry before sterilization since water will interfere with the process.

What is sterilization and its types?

Sterilization can be achieved through various means, including heat, chemicals, irradiation, high pressure, and filtration. Sterilization is distinct from disinfection, sanitization, and pasteurization, in that those methods reduce rather than eliminate all forms of life and biological agents present.

What is drying in sterilization?

In a gravity-displacement sterilizer, drying takes place by evaporation resulting from the heat in the chamber walls and is thus much less efficient. At the end of the sterilization cycle, if a package is noted to have moisture on the outside of the pack, the package should be completely re-processed.

What is dry heat in microbiology?

Dry heat destroys microorganisms by causing coagulation of proteins. The dry heat sterilization process is accomplished by conduction; that is where heat is absorbed by the exterior surface of an item and then passed inward to the next layer.

Where is dry heat is used?

Dry heat is primarily used to sterilize instruments and heat-resistible glass and instrument parts. The heat transfer by dry heat is less effective than by airless, saturated steam, because steam is able to transport the heat quicker than by condensation just air.

What are the examples of dry heat cooking?

Grilling, broiling, baking, roasting, sautéing or stir-frying, and searing are the different ways to cook using dry heat:Grilling. Grilling uses heat from underneath to cook the food. ... Broiling. ... Baking. ... Roasting. ... Sautéing. ... Searing. ... You may also be interested in:

How long does it take to dry sterilize?

30 minutes. Dry heat sterilization is used on items that cannot get wet and for glassware, oils, powders, metal instruments, and items wrapped in paper. There are several different types of dry heat sterilization such as:

How long does it take to sterilize a hot air oven?

The hot air oven is the most commonly used form of dry heat sterilization. It is a large container that holds several objects. Once the oven is filled, it is closed and secured for the allotted time it will take to sterilize. For example, the oven is set at 160 degrees Celsius so it will not be opened until 60 minutes have passed. A hot air oven does not harm any of the objects that are being sterilized and it is non-toxic to the environment. However, it's time consuming and requires extremely high temperatures.

How does Kathy test a hot air oven?

She completes the tests herself. Kathy begins by making sure all of the parts of the instrument are accounted for and in place. She then checks that everything is in working order. She sets up data loggers in the oven and turns it on to test the temperature in various areas of the oven. It all looks good. The final test is the biological indicator, which was successful. She documents the validation tests and sends them to the appropriate companies. The operating room is successfully using sterile equipment from the hot air oven dry heat sterilization instruments.

Why does a static air oven take so long to heat?

The oven has coils on the bottom to heat the oven. It takes a long time for the temperature to be reached because the hot air has to rise through convection. This also means that the temperature may not be uniform throughout the oven.

What is a hot air oven?

A hot air oven in which there is static air (heating coils on the bottom) or forced air hot air oven (motorized blower) that are used differently. Incineration, which burns medical waste that's disposable. Flaming, which involves exposing objects to direct fire or flame.

Does the hospital use forced air ovens?

Kathy finds out that the hospital uses forced air hot air ovens. The machines appear to be in good condition and are working correctly. She is ready to see if they are successful at completing the sterilization process.

Types of Dry Heat Sterilization

There are several different types of dry heat sterilization, listed here.

Advantages of Dry Heat Sterilization

Almost all laboratories are equipped with dry heat sterilization equipment. This is because of the advantages that can be found with this method. Hydrophobic items like fats and oils simply cannot be sterilized in an autoclave, because the molecules repel water.

Disadvantages Compared to Other Processes

Steam heat sterilization is a more common method of heat sterilization. Steam sterilization, sometimes called wet sterilization, occurs inside of an autoclave. Autoclaves have significantly higher rates of sterilization success because the high specific heat of water ensures that heat is transferred quickly and effectively.

Instruments Used for Dry Heat Sterilization

The instruments used for dry heat sterilization will change based upon the goal of the sterilization. Incinerators, which are created to burn almost any material to ash, are used when items need to be both sterilized and disposed of. Bunsen burners and other types of open flame are frequently used in the flaming technique for sterilization.

Common Applications of Dry Heat Sterilization

The most common application of dry heat sterilization is to sterilize materials that can't be used in an autoclave. These include:

How is dry heat sterilization performed?

As mentioned above, sterilization by dry heat is performed in cabinet ovens or conveyor tunnels. In these systems, temperature, time, and blower speed are controlled during sterilization. In cabinet ovens, HEPA filtered air flows across the load, moved by a blower. Though HEPA filters remove most particulates, there is always a risk that particulate matter generated from the heat source could collect on the sterilized load. In order to prevent particulates from entering the cabinet and consistent temperature during sterilization, the door cabinet dryer door must be appropriately sealed before sterilization. Note that the size of the cabinet oven chamber is limited. Limited chamber size, along with manual loading and unloading, reduces the processing rate for dry heat sterilization. Dry heat sterilization processing rates are much higher for tunnel sterilizers. Tunnel sterilizers are dry heat conveyor systems. In the conveyor system, items are sterilized and depyrogenated as they move from heating zones through cooling zones. The heat source for a dry heat sterilization tunnel is either convection or radiant heat. Cooling zones contain vertical laminar airflow units under HEPA filtration. Tunnel sterilizers contain a stainless-steel conveyor belt. The conveyor belt often moves nonsterile containers through the dry heat sterilization cycle and onto a collection table for immediate sterile product filling. Tunnel dry heat sterilizers are primarily used to sterilize glass containers and are part of a sterile fill system. Tunnel sterilizers, like cabinet ovens, may generate particles from the heating source. Where tunnel sterilizers provide advantages in dry heat sterilization loading and unloading speeds, tunnel sterilizers are more challenging to validate than cabinet ovens, as it is tricky to control uniform heating throughout the entire conveyor system.

What is sterilization by dry heat?

Heat-based sterilization methods kill microorganisms by denaturing proteins within the cells.

What is sterilization?

Sterilization is any process that removes, kills, or deactivates all forms of life. Sterilization is related to the term sterile, which means a complete absence of viable microorganisms or microbes that have the potential to reproduce. Thus, sterile products that undergo sterilization are often chemically or heat sterilized after being placed in their final packaging. The chemical or heat sterilization kills any microorganisms inside the products (obtained during manufacturing and packaging). This chemical or heat sterilization process after final product packaging is known as terminal sterilization.

What items can be sterilized by dry heat?

Items typically sterilized by dry heat are glassware, metal parts, oils, and some dry powders.

How does dry heat sterilization affect the temperature?

For example, heat penetration through steel is faster than penetration through glass. Additionally, shiny surface reflectance and variances in air density have significant effects on the rate of dry heat sterilization. Fans or blowers aid heat circulation by minimizing air density issues and keeping air from stratifying. During sterilization by dry heat, materials expand during heating and contract during cooling. Thus, all openings must be securely covered to protect microorganisms from being drawn into materials during contraction.

What is the temperature range for dry heat sterilization?

Additionally, the dry heat sterilization process is difficult to control within precise temperature limits, which is why the USP states that an acceptable operating temperature range for the empty chamber is ± 15◦C.

Why is dry heat used in sterilization?

Dry heat penetrates to interior surfaces of items via conduction. Air is a poor heat conductor , which is one reason why dry heat sterilization is so slow. Heat transfer through the air is much slower than heat penetration through steam heat because of the long exposure times required to kill spores. The long exposure time needed to kill spores is the other reason dry heat sterilization cycles are lengthy. The high temperatures necessary for dry heat sterilization often cause material degradation, which is why dry heat is used as a sterilization method for only a few applications.

What is dry heat sterilization quizlet?

Dry heat. The sterilization method used mainly for sterilizing powders, oils, and petroleum-based items. It is not widely used otherwise because of it’s high temperatures and long exposure times, which can damage devices and packaging materials.

Which is an example of a dry heat cooking method?

Examples of dry-heat methods include: Roasting and Baking. Grilling and Broiling. Sautéeing and Pan-Frying.

What is method of sterilization?

Sterilization can be achieved by a combination of heat, chemicals, irradiation, high pressure and filtration like steam under pressure, dry heat, ultraviolet radiation, gas vapor sterilants, chlorine dioxide gas etc.

What is a dry heat oven?

Dry heat ovens are used to sterilize items that might be damaged by moist heat or that are impenetrable to moist heat (e.g., powders, petroleum products, sharp instruments).

Is an autoclave dry heat?

They kill all forms of microbial life, such as bacteria, viruses, and even spores. Typically, autoclaves run at a temperature of 270 degrees Fahrenheit for thirty (30) minutes. US FDA registered dry heat sterilizers sterilize by using high levels of dry heat.

What is dry method?

Dry heat cooking refers to any cooking technique where the heat is transferred to the food item without using extra moisture. This method typically involves high temperatures—300 F or hotter. Note that the browning of food, as when bread is toasted, can only be achieved through dry heat cooking.

How is dry heat different?

Dry heat allows the body to cool more quickly, so you are less likely to get heat stress in an arid environment. Dry air allows more efficient evaporation than humid air, which is why you usually feel cooler in dry air — it has less moisture!

Types of Industrial Sterilization Methods

Industrialization sterilization works well in many industries because of the sensitive nature of production in those markets and the need for safety and controls in the production, testing, and distribution stages of products. Sterilization kills living organisms from specific environments and product surfaces.

Types of Heat Sterilization Methods

Two basic approaches to heat sterilization exist. One approach is moist heat sterilization, where heat is applied to boiling or steaming, such as pasteurization or autoclaving (by steam). Temperature and duration are two critical factors with this sterilization approach. Generally speaking, the longer the exposure to heat, the better.

Steam Versus Dry Heat Sterilization

Choosing the right sterilization method for your application is critical. But with so many methods to choose from, it can be confusing. Steam and dry heat sterilization are the most common methods of industrial sterilization. Both methods are widely used in the medical, research, laboratory, biotechnology, and pharmaceutical industries

Heat

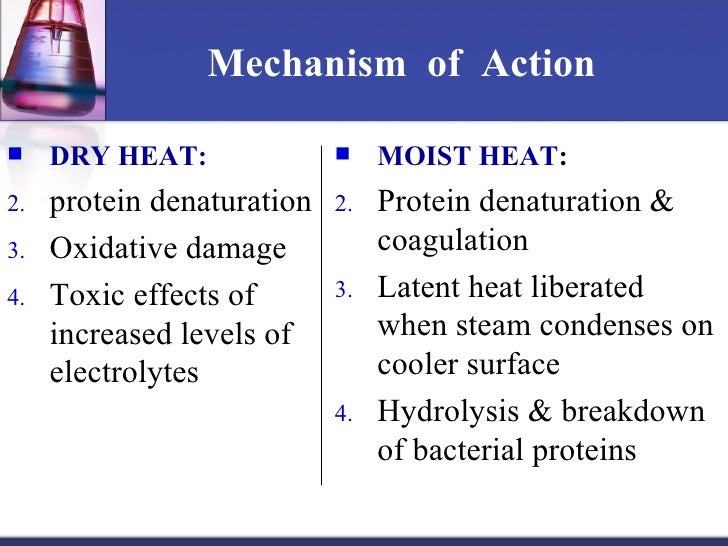

The use and effectiveness of this method will depend on two factors, time and temperature. Within heat, we divide into two types: moist heat and dry heat. Submit an article for publication

Moist heat

Moist heat causes denaturation and coagulation of proteins and fluidization of lipids. Through the chemical action of evaporating water, it favors protein binding. The methods of moist heat are Autoclaving and finalization.

Dry heat

Dry heat is a thermal method of sterilization, and its effect is similar to that of baking. With this method, microorganisms are burned slowly. This method is used for the sterilization of glassware, metal needles, and surgical instruments.

Filtration

Filtering membranes of a determined size are used. This will depend on the use to which the sample is going to be subjected. The filters used do not retain viruses or microplasmas. Filtration is used for oily or thermolabile emulsions.

Packaging

The main purpose of packaging is to protect the sterility of the products. The material to be sterilized is divided into: