Full Answer

What is the tolerance for a 23mm H7 hole?

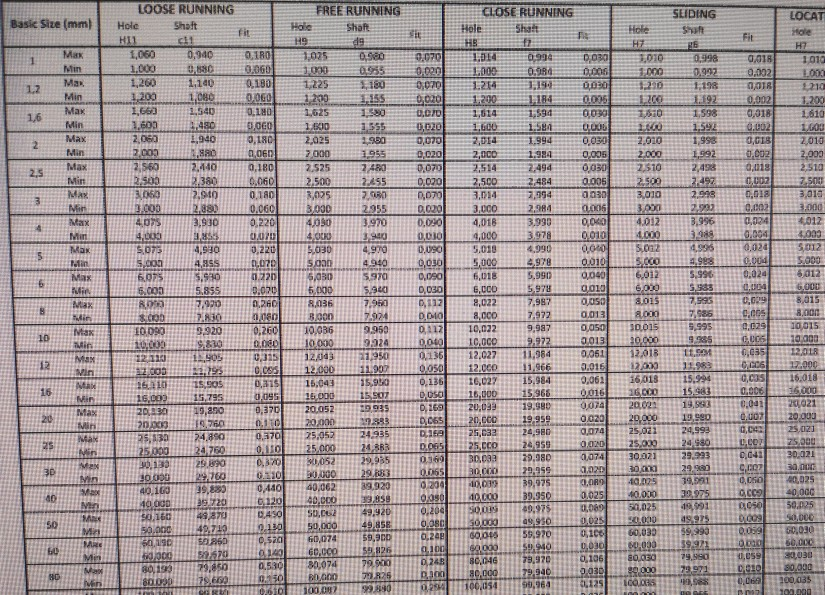

The tolerances work in such a way that for a hole H7 means that the hole should be made slightly larger than the base dimension (in this case for an ISO fit 10+0.015−0, meaning that it may be up to 0.015 mm larger than the base dimension, and 0 mm smaller).

What is the difference between H7 and H11?

The main differences between H7 and H11 bulbs come down to their mounting hardware and the specific use cases which they fulfil. H7 bulbs are single filament bulbs. They have double holders similar to traditional electrical plugs we use for household appliances and are used for low beam applications, whereas H11 bulbs are used for fog lights and have an enclosed connector plug.

What is the value of H7 tolerance?

The letter signifies the start of the tolerance zone. For H7, the starting point is at exactly 25.000 mm. The maximum hole size is then 25.021 mm. For F7, the tolerance range is the same but the starting point is 25.020 mm, taking the last acceptable measurement to 25.041 mm.

How to calculate tolerance values for shaft or a hole?

The three main categories are:

- Clearance fit

- Transition fit

- Interference fit

What is the tolerance for a H7 hole?

+0.000 mm to +0.025 mmH7 (hole) tolerance range = +0.000 mm to +0.025 mm. p6 (shaft) tolerance range = +0.042 mm to +0.026 mm. Potential interference will be between −0.001 mm and −0.042 mm.

What is H7 in hole dimensions?

ISO Hole Tolerances (ISO 286-2) (3mm-400mm):GradeNOMINAL HOLE SIZES (mm)H6+8 0+16 0H7+12 0+25 0H8+18 0+39 0H9+30 0+62 018 more rows

What is the hole tolerance?

A component's maximum and minimum permissible size are known as its limits and their difference is termed the tolerance. These definitions also apply to the holes drilled to accommodate fasteners when joining multiple components to form an assembly.

What is the tolerance for the hole diameter?

Machinist Drill Sizes - ANSI Size Drills, ISO Metric Drill SizesMinimum Recommended Position Tolerances for Location of Hole Features in (mm) Less than 1" (25.4mm) in Diameter *MethodNormal Tolerance inches (mm)Manual location techniques (center punch and drill).080 (2)Drill fixture using bushing.025 (0.635)3 more rows

What is H7 in drawing?

the H7 applied to the holes are the codes for the type of fit required,These can be anything from a loose clearance fit to a very tight interference fit.

What does H7 g6 mean?

In this capital letter H denotes hole and small letter g denotes shaft. This combination H7-g6 denotes the clearance fit. It can be seen in the table below the various types of fit according to the hole shaft system.

Is H7 a clearance fit?

H8/g7, H7/g6, G7/h6 Running fits with very small clearances for accurate guiding of shafts. Without any noticeable clearance after assembly.

What are the 3 types of tolerances?

Three basic tolerances that occur most often on working drawings are: limit dimensions, unilateral, and bilateral tolerances. Three basic tolerances that occur most often on working drawings are: limit dimensions, unilateral, and bilateral tolerances.

How do you find the tolerance of a hole?

7:2010:14How to Calculate Clearance Hole Diameter w/ GD&T Positional ...YouTubeStart of suggested clipEnd of suggested clipPoint three one three three plus the absolute value of this negative two plus two we get point threeMorePoint three one three three plus the absolute value of this negative two plus two we get point three one five three and this is our mathematical.

What is the typical tolerance for a drilled hole?

0.2 mmWhen drilling on a machine tool, the expected position tolerance should be no tighter than an eight thou, or 0.2 mm, diameter.

What is clearance fit?

This is an intuitive concept to grasp- a clearance fit specifies a fit where there will always be a gap in the joint between the mating shaft and hole. Even at the maximum shaft and minimum hole tolerance, the shaft will be able to freely pass through the mating hole. Conversely, an interference fit is a fit where there will always be overlap in the joint between the specified mating shaft/hole, even at the minimum material condition values allowed by the shaft and maximum value allowed by the hole tolerance values (i.e., the largest hole and the smallest shaft). This concept is illustrated in the figure below for both Clearance and Interference fits.

Can a fit be specified from a hole?

The second important concept to note is that fits can be specified using either a hole or a shaft as the primary reference basis. This means that fits can be specified from existing holes or shafts, which is important to know for design purposes, but in most instances, it’s up to the designer to decide how to build the joint from ...

What is the minimum clearance for a H11/C11?

Using a 25 mm diameter, a H11/c11 fit gives a minimum clearance of 0.11 mm and a maximum clearance of 0.37 mm. In this case, the shaft diameter can fall in between 24.76 and 24.89 mm while the minimum hole size is 25 mm and the max 25.13 mm.

Why do engineers follow the hole system?

Engineers tend to follow the hole system because of simplicity. As the hole size stays constant, the shaft’s upper and lower deviation values determine the type of fit. Drilling does not allow for much precision, as the tooling comes in certain measurements.

What is a hole and shaft system?

The system tells which part has a controlled measurement and which part is made based on the other.

What is tolerance class?

The number shows the international tolerance grade (ISO 286). A tolerance class determines a range of values the final measurement can vary from the base measurement.

When the shaft diameter is at its minimum and hole diameter at its maximum, we have a situation of?

When the shaft diameter is at its minimum and hole diameter at its maximum, we have a situation of maximum clearance. When the shaft diameter is at its max and hole diameter at its minimum, we have a situation of minimum clearance.