What is water-based printing?

Water-based printing is a special ink that gets absorbed by the fabric, rather than sitting on top like plastisol printing. So when the final product is complete, it feels like nothing is there!

How to start water-based printing without drowning?

Here’s how to start water based printing without drowning. A good way to start water-based printing is to print water-based ink only on your light colored garments, using darker ink colors. Stepping into water-based printing this way is fairly easy.

What is a water-based ink?

WATER-BASED INK IS AN INK MADE WITH WATER RATHER THAN PLASTIC OR PVC. WATER-BASED INKS CAN BE SPLIT INTO TWO MAIN INGREDIENTS, WATER AND PIGMENT. It serves as a great alternative to plastisol ink in many circumstances.

What is the difference between Plastisol and water-based printing?

Stepping into water-based printing this way is fairly easy. Since water-based ink is thinner than plastisol, it’s recommended to use a higher screen mesh and print wet on wet instead of flashing in-between. Since the ink is thinner, it penetrates the garment more than plastisol does and doesn’t pick up as much on the back of the screen.

What does water based ink mean?

Water based inks are defined as inks that use water as the main solvent for carrying pigment. They are made up mostly of acrylic resins or hybrid blends of acrylic resin and polyurethanes.

Is water based printing good?

Sharper Details. Due to the fact that water-based inks dye the fabric instead of sitting on top of the fabric, as is the case with plastisol, it can hold much finer details. In addition to finer detail, the edges of prints are much sharper as well.

Is water based ink better?

Water-based inks soak into the fabric as opposed to sitting on top of the fabric, therefore, making the print smoother and breathable. Water-based inks are better when printing on light-colored cotton, if the design has a lot of details, and if the ideal print has muted colors.

What are the 4 types of printing?

The most widely used print processes are surface, flexographic (flexo), gravure and screen. It is important to recognize that each process is capable of yielding attractive, stylized and salable products.

How long does water based ink last?

Most catalyzed water-based ink pot life's are between four and twelve hours. Since water-based inks contain water as an evaporative solvent, care must be taken to prevent the ink from drying in the screen.

Is water based ink permanent?

Water-based ink is non-toxic and not permanent. It washes off the skin and other surfaces easily. That's why Crayola markers are one of the popular art supplies among parents as they're water-soluble.

Which ink is best for t shirt printing?

Plastisol Ink1. Plastisol Ink. A commonly used ink in screen printing, plastisol ink is versatile and durable and thus perfect for custom t-shirt printing. It is a thick ink and easy to mix as well.

What printers use water based ink?

Water-based inks are not used for inkjet printing. They are mainly used in silk screen printing. They have specific uses, just like other types of ink and colors. Lacquer water-based inks are commonly used on dark and light-colored shirts and light-colored plastic surfaces.

What is the best ink to use for screen printing?

Plastisol inkPlastisol ink This is the most widely used ink in the industry. Durable, versatile, opaque, and able to lay down a crisp and detailed print, plastisol is still the go-to ink for screen printers.

What are the 5 major types of prints?

Prints can fall in to one of several broad categories:Intaglio Printmaking. An intaglio print is one where the image is printed from a recessed design incised or etched into the surface of a plate. ... Relief Printmaking. ... Lithography. ... Serigraphy (Screen Printing) ... Monotype.

What are the 3 types of printing?

When it comes to professional printing processes there are three main types: Offset litho printing. Digital Printing. Screen printing.

What are the 6 major types of printing?

Digital Printing. Digital printing is the reproduction of digital images on to physical surfaces. ... Flexography. Flexography, often abbreviated to flexo, is a method of printing most commonly used for packaging. ... Lithographic (Offset) Printing. ... Rotogravure (Gravure) ... Large format printing. ... 3D Printing. ... Screen Printing.

What is the difference between water based and solvent based ink?

A drop of solvent based ink is composed of 35% pigment and 65% apolar solvents. A drop of water based ink, on the other hand, is composed of 33% pigment, 33% water and 33% non-toxic, water soluble polar solvents. The advantage is obtained during printing.

Is sublimation ink water based?

Sublimation on Cotton – Water based ink is special sublimation ink on water base used for printing applications and heat transfer to various white and light cotton garments by sublimation technique. After application the colors on T-shirts are igneous and very vivid.

What is a water based transfer?

Water-based heat transfers are a vibrant, soft, and lightweight alternative to traditional screen printing. They are an ideal way to print complex, multi-color designs on apparel, hats, tote bags, and coolers. Another advantage of heat transfer printing is the easy setup.

Is solvent ink water based?

In the world of ink, you mainly have two choices: water-based ink or oil-based ink. The term ink solvent refers to the ink containing an oil-based solution.

Why do we use water based ink?

We tend to use water-based ink as much as possible because it is a most sustainable option we have for printing. We add a mixing agent to the water-based ink to be able to print on darker garments. This ink, called Water-based Discharge, removes the dye within the image area of the garment and re-dyes it the color of the ink.

How many times does the right side of a printer get washed?

The right side was printed and washed once, while the left side was washed and dried about 15 times at various spin cycles and temperatures. Washout does occur at a faster rate for water-based inks than plastisol. Overall, water-base ink is still a great alternative to plastisol and has a better feel and greater impact on the environment.

Does water based ink fade faster?

DISCLAIMER: Because water-based ink is water-based instead of plastic-based, it tends to fade faster on some types of fabrics. This is the sacrifice of having the best hand feel versus a plastisol print with a higher durability. Above is an Allmade Eco shirt printed with a black water-based ink.

Is water base ink better than plastisol?

Overall, water-base ink is still a great alternative to plastisol and has a better feel and greater impact on the environment.

Is plastisol ink eco friendly?

It serves as a great alternative to plastisol ink in many circumstances. One of the most prominent features of this type of ink is that the base does not include plastic, which makes it a more eco-friendly options. The ink seeps into the garment and dyes the material rather than sitting on top of the fabric. This creates a more consistent feel ...

What is water transfer printing?

Water transfer printing, also known as immersion printing, water transfer imaging, hydro dipping, watermarbling, cubic printing, Hydrographics, or HydroGraphics, is a method of applying printed designs to three-dimensional surfaces. The resulting combinations may be considered decorative art or applied art. The hydrographic process can be used on metal, plastic, glass, hard woods, and various other materials.

What is the process of printing a substrate?

Process. In the process, the substrate piece to be printed first goes through the entire painting process: surface preparation, priming, painting, and clear coating. After painting but before clear coating, the part is ready to be processed.

Why is my ink not adhering to the base coat?

The adhesion is a result of the chemical components of the activator softening the base coat layer and allowing the ink to form a bond with it . One of the most common causes of a failure to achieve adhesion between the two layers is a poorly applied activator. This can be either too much activator being applied or too little.

What substrates can be used for film?

Films can be applied to all types of substrates including plastic, fiberglass, wood, ceramics, and metal. For the most part, if the item can be dipped in water and can be painted using traditional techniques then the hydrographic printing process can be used.

When was the hydrographic apparatus invented?

However, the first hydrographic apparatus registered for a US patent was by Motoyasu Nakanishi of Cubic Engineering KK on July 26, 1982. Its abstract reads, " [a] printing apparatus provided with a structure which supplies a transcription film into a transcription tub containing a liquid so that the transcription film is kept afloat on the liquid, ...

Can clear ink be washed off?

Any remaining residue is then rinsed off thoroughly. The ink adheres to the desired surface and it cannot be washed off easily.

What is water based ink?

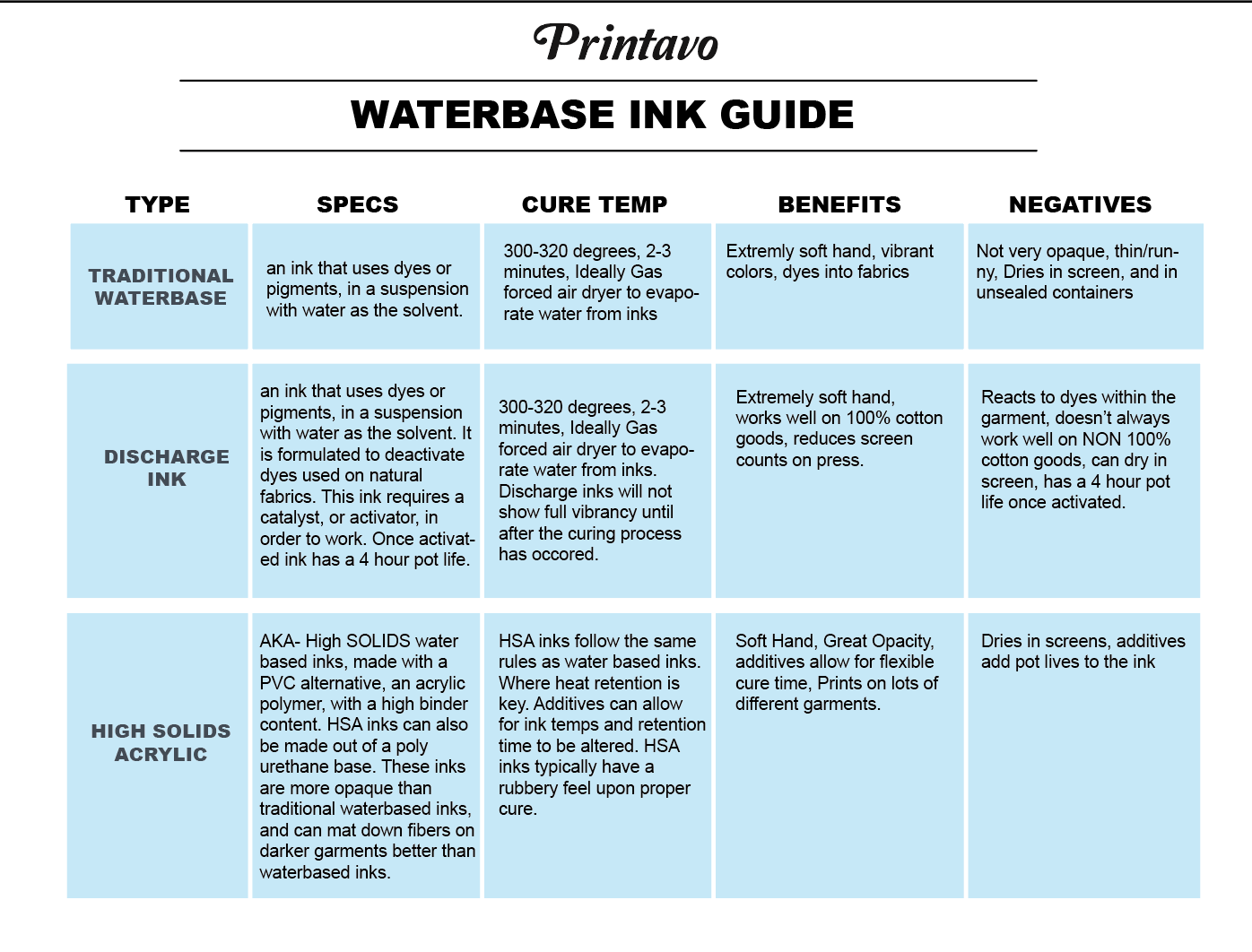

The simple answer is that water based ink is any ink which uses water as a solvent base to carry the pigment. But, there are a few different varieties of water based ink that make up the full list. From ready for use (RFU) inks, to newer formulations like High Solid Acrylic (HSA) inks. Here’s an overview of the wide array ...

Why do HSA inks have a thickening binder?

Developed to combat some of the problems of older water based inks (thin, runny, too transparent), these inks have a thickening binder added to create a formula more akin to plastisol ink. HSA inks don’t dry quickly on the screen, and can easily stretch and stack on top of each other.

What is RFU ink?

If you are new to water based inks, it’s easiest to start with ready for use inks (RFU). These inks come pre-mixed, and are offered in a large selection of the most commonly used colors.

Why do some printers use water based ink?

Others print with water-based inks because that’s what their customers want, which is what it comes down to in the end.

Why is water based ink good?

Intrigued by water-based inks? Water-based inks are great because they feel so soft on the garment and simple to print basic jobs, but it becomes challenging when printing complex art and it requires more legwork. Whether you’re ready for a new challenge or you received a request from a customer, printing with water-based inks is a whole new ball game compared to printing plastisol inks. Ink master Colin Huggins has shared helpful knowledge you need to know about water-based printing to help you decide if it’s right for you.

What is high solids water based ink?

High solids water-based ink is what you mainly see on the market today. The ink has a thicker body and has better coverage and opacity. It’s soft, but not as soft as low solids water-based ink — you can feel the ink on the shirt printed with high solids water-based ink. They also print more like plastisol inks (underbase and separations are almost interchangeable between the two). While some high solids inks are high solids acrylic (HSA), others have urethane included instead of acrylic. Urethane creates more plastisol-like properties while still being categorized as water-based ink.

Why do you flash a print?

Flashing a print will procure different results for plastisol versus water-based ink. For plastisol, you’d flash the print to get a partial crosslink in the ink system — gelling the ink. The chemical change in the ink makes the print more like a solid sheet. With water-based inks, you’d flash the print to evaporate the liquids. The print will not gel like a plastisol print. The point of flashing it is to dry the water-based ink. Usually printers print-flash-print when printing an underbase. During this process, water-based inks inherently will look more transparent when printing on the base white compared to plastisol. High solids water-based inks have a slightly lower opacity compared to plastisol, which is why you’d need to work a little harder compared to printing plastisol.

How to cure ink for printing?

Warp Drive is the cheapest insurance possible, and it pays off. You add it to the ink before you start printing. Use your flash or conveyor to evaporate the water. Set the garment aside for 48 hours and the additive will chemically cure the print. Low cure ink additives are great. They’ll cover up mistakes you didn’t even know you made. If you decide you want to print with water-based inks but don’t have the best curing devices, get something like Warp Drive. It’ll reduce the likelihood of angry customers returning because of prints washing off.

How long does it take to cure water based ink?

Lastly, but most importantly, curing. To cure water-based ink, you need to evaporate all the water, reach cure temp, and hold at the temp for at least 20 seconds. The most ideal situation is to have a minimum six-foot forced air conveyor dryer; you’ll be able to accomplish cure in the dryer in 1:30-2:00 minutes. Unfortunately, not everyone can get their hands on a big conveyor dryer, which is why it’s recommended that almost everyone uses Warp Drive .

What is the difference between discharge ink and low solids ink?

Low solids water-based ink is the softest ink because it goes into the fibers of the shirt. Discharge ink is a cousin to traditional water-based inks. While discharge ink has the agent that strips the color from the shirt, both have an incredible soft-hand feel.

How to keep ink from drying out?

If you live in a humid area, open a window. You can also pick up a humidifier if you live in a drier climate. Keep a spray bottle of water close by to mist the ink and keep it from drying out.

Can you print with water based ink?

Printing with water-based ink doesn’t have to be intimidating. With the right tools and know-how, you’ll be able to print professional-level designs without worry.

Does water based ink break down emulsion faster than plastisol ink?

Every time your squeegee runs across the screen, it wears your emulsion down a tiny bit. Water-based ink does break down emulsion faster than plastisol ink, but the rate at which it breaks down depends on how well your screen was created.

Is plastisol ink water based?

Before plastisol ink came along, there was only old-school water-based ink for printing on fabric. It dried fast. It was thin and not opaque. Frankly, it was a pain to print with. When plastisol came around, it solved all of those problems. But plastisol ink is essentially liquid plastic, and never quite could achieve that soft hand feel that water-based ink can.

Does plastisol ink dry out faster?

Water-based ink dries out quicker than plastisol ink. After all, plastisol ink doesn’t dry at all. You may think that you can’t do a long print run with water-based ink. There’s a few tricks to making your ink last longer.

Is water based ink better than plastisol?

Water-based ink is becoming more and more popular. With more shops turning to greener methods, printing with water-based ink can be nicer on the environment and your health. Many printers believe that water-based printing is more challenging than printing with plastisol. If you step into it the right way, water-based printing can actually be easier and save you time and money.

Can you print water based ink on light colored clothes?

A good way to start water-based printing is to print water-based ink only on your light colored garments, using darker ink colors.