Casing wire (wire for conduits/outer casings) This range of high carbon steel wires is suitable for the production of grease tight and dust proof conduits or outer casings. The wire features and excellent rest-ductility that withstands the flattening and wrapping processes that are part of producing the conduits.

What is the casing of electrical wire made of?

What is wire casing? Stripping. On Romex brand and other non-metallic cables, the casing is the heavy plastic sheathing that binds two or more individual wires. Each of these copper wires is coated with a thin layer of plastic. For this, you use a different device called a wire stripper. Click to see full answer.

What is casing and capping wiring?

Other Important Types of Electrical Wiring System

- Concealed Conduit Wiring. Concealed conduit wiring uses solid pipes that run internally through the walls because they are installed before the ball construction is completed.

- Cleat Wiring. It is easy and an old technique to install the wiring system. ...

- Batten Wiring. It is another old method for wiring management. ...

- Wooden Casing Capping Wiring. ...

Which wire to use for wire wrapping?

Which Wire to use for Wire Wrapping?

- Starting out. For just mucking around, it's good to play with "artwire" that can be bought cheaply and you won't feel heartbroken if you have to throw it away.

- Dead Soft Round Wire. This is my wire of choice. ...

- Half Hard Round Wire. As the name says, it's half hard, and a lot less flexible than dead soft. ...

- Half Round Wire. ...

- Fancy Wires. ...

- Gauges of Wire. ...

How to solder two small wires to a larger wire?

Part 2 Part 2 of 3: Applying the Solder

- Get 63/37 leaded solder for the easiest material to work with. ...

- Melt solder on the tip of your soldering iron to prevent oxidation. Put on a pair of safety glasses to protect your eyes.

- Hold the soldering iron against the bottom of the splice to heat the flux. ...

- Run the tip of the solder on top of the wire so it melts into the wires. ...

What is the casing around a wire called?

Most electrical wire is covered in a rubber or plastic coating called insulation.

How do you install a wire casing?

3. Installation of Casing Wiring SystemThe casing shall be fixed using suitable flat head screws to the asbestos or fiber fixing plugs, at intervals not exceeding 60 cm.On either side of the joints, the distance of the fixing arrangement shall not exceed 15 cm from the joint.More items...•

How do you wire a casing cap?

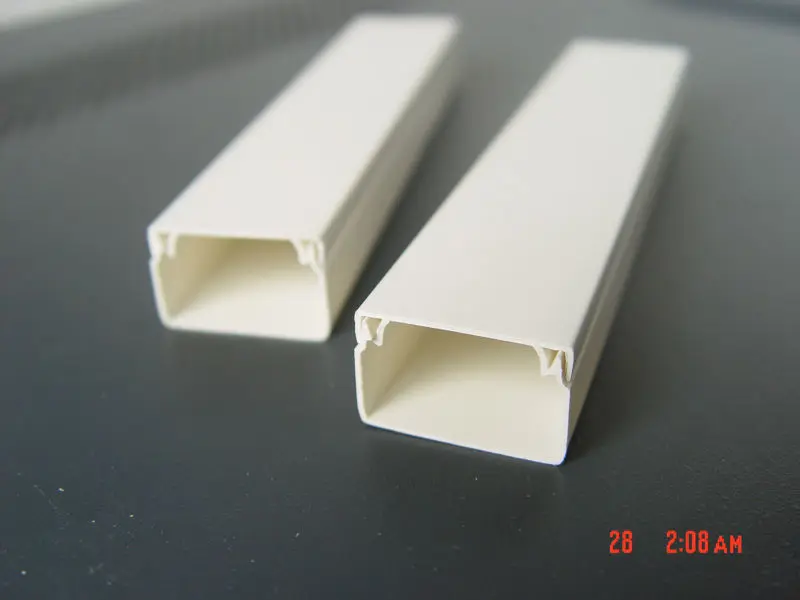

As the name referred in this wiring, PVC insulated wires are placed in plastic cashing and covered with cap. The cashing is of rectangular cross section as shown. The color of cashing channel and cap are normally white or grey.

Where is used casing and capping wiring?

Casing and Capping wiring applications The casing and capping are used as protection to some other wiring system. In offices and homes, this wiring system is used. In the case of devices that use low voltage, a casing and capping wiring system is used.

What is wooden casing?

This wiring is used for V-shaped grooves and usually two in number. These wires are laid in grooves and the casing is covered by a rectangular strip of the same width, that called capping and that was fitted by means of a screw. Capping and casing are made up of teak wood.

What is CTS or TRS wiring?

Tough rubber sheath (T.R.S) safety, first developed by the St. Helens cable Co., is typically lapped onto the already insulated conductor under the name C.T.S (cab tyre sheath). The conductor is insulated with vulcanized rubber insulation in the tough rubber sheathed cable.

What is PVC casing?

PVC Well Casing is primarily used to line wells for drinking water. Like other PVC piping systems, it is intended for applications where temperatures will not exceed 140° F.

What is PVC wiring?

PVC (Polyvinyl chloride) is widely used in electrical cable construction for insulation, bedding and sheathing. It was the 1950s when PVC started to replace rubber insulated and sheathed cables in general household wiring due to its ease of processing.

What is conduit wiring?

An electrical conduit is a tube used to protect and route electrical wiring in a building or structure. Electrical conduit may be made of metal, plastic, fiber, or fired clay. Most conduit is rigid, but flexible conduit is used for some purposes.

What are the advantages of casing capping wiring?

Advantages of casing capping wiring:This wiring system is way cheaper than a sheathed and conduit wiring system.It looks beautiful.There is no risk of mechanical shock.The alternation is possible in this system.It is cheaper compared to a steel conduit and sheeted wiring system.More items...

What are different types of wiring?

5 Different Types of Electrical House Wiring SystemsCleat Wiring. This wiring comprises of PVC insulated wires or ordinary VIR that are braided and compounded. ... Casing and Capping Wiring. ... Batten Wiring. ... Lead Sheathed Wiring. ... Conduit Wiring.

What is metal sheathed wiring?

In lead sheathed or metal sheathed wiring the cables used are insulated wires, TRS or PVC, with metal outer covering of about 1 mm. thick. The metal covering is known as sheathing and is made of lead – aluminium alloy containing about 95% of lead.

Published by

We provide tutoring in Electrical Engineering. View all posts by Electrical Workbook

Electrical Workbook

We provide tutoring in Electrical Engineering. View all posts by Electrical Workbook

What is electrical wiring?

The process of connecting different accessories for distributing electrical energy from supplier to home appliances such as lamps, fans and other domestic appliances is known as Electrical Wiring. It is one of the simplest forms of electric wiring systems. PVC insulated wires are placed in the plastic casing and covered with a cap, ...

Is casing capping better than conduit?

Advantages of Casing Capping Wiring. This wiring system is way cheaper than sheathed and conduit wiring systems. It is considered safe from smoke, dampness and humidity. Customized installation can be done in this wiring system. Reduced risk of electric shock can be expected.

What is a wood casing?

Wooden Casing Capping Wiring. These are the casing and capping wiring system that uses a V-shaped wooden casing. They are rear and generally have two grooves for two rest wiring. As they are more prone to get termites, they usually have a wooden varnished layer that has antibacterial properties.

What is casing cap?

Casing Capping is one of the simplest forms of electric wiring systems. In this system, a molded dome of different shapes and sizes are used to cover the wires. They are not just the covering wires but they are used as a decorative piece to make the external unconcealed circuit look clean.

What is a press and fit capping set?

Press and Fit. These are the most common types of casing and capping sets that are available in various colors and trunk sizes. They usually have two distant parts; the one layer that rests on the surface and the other part is the domed cover.

How many meters are there in a capping wire?

The slabs of casing and capping wire are generally available in meters such as 3 meters, 5 meters, etc. So, the first thing you should do is to find the roadmap for the installation. For this, you can use a regular measuring tape.

What is concealed conduit?

Concealed conduit wiring uses solid pipes that run internally through the walls because they are installed before the ball construction is completed. They are generally available in the metal, plastic, hard PVC, and fired clay .

Can you hide wires in a casing?

Use can hide any set of wires that are visible or has an open circuit. For this, you can use a casing-capping wiring system. They are available in a vast range of color and material options. So, based on your preferences, you can choose the best suitable wiring system.

Can you install wires over ceramic cleats?

In this wiring management system, the wires are installed over some ceramic cleats on a plastic or wooden surface without any cover.

3.1 Attachment to Wall and Ceiling

The casing shall be fixed using suitable flat head screws to the asbestos or fiber fixing plugs, at intervals not exceeding 60 cm.

3.2 Passing through Floors or Walls

When conductors pass through floors, the same shall be carried in an approved PVC conduit or heavy gauge steel conduit properly bushed at both ends.

3.3 Joints in Casing and Capping

The wireways in straight runs should be in a single piece as far as possible to avoid joints.

3.4 Attachment of Capping

Wherever required, capping shall not be fixed until the work has been inspected with the wires in position and approved.

3.5 Installation of Cables

For ease of maintenance, cables carrying direct current or alternating current shall always be bunched so that the outgoing and returning cables are drawn in the same casing.

3.6 Earth Continuity

A protective conductor shall be drawn inside the casing and capping for earthing of all metallic boxes of the installations and connections to the earth pin of the socket outlets.