What kind of concrete is used for bench tops?

Concrete bench-tops should have a high-strength level, with the concrete mix having a compressive strength of 40Mpa minimum – therefore, the water-to-cement ratio should be kept to a minimum.

What kind of cement should I use for concrete countertops?

QUIKRETE® Countertop Mix (No. 1106-80, -81) is a specially formulated flowable high-strength concrete mix for pre-cast and cast-in-place concrete countertop applications. Super-plasticizer additive provides a flowable mix at low water/cement ratio.

Can you use regular concrete for concrete countertops?

Don't Use Regular Concrete Mix When it comes to concrete countertops, not just any mix will work. While traditional concrete mixes are great to have on hand, Quikrete Concrete Countertop Mix is specifically made for this type of project. Remember: There's no substitute for Concrete Countertop Mix.

How thick should a concrete benchtop be?

The standard concrete countertop slab thickness is 1 ½ to 2 inches, similar to countertops made of marble or granite. However, contractors can create the illusion of a thicker countertop by casting a drop-front edge.

Can I use Quikrete 5000 for countertops?

Owens uses Quikrete 5000 to make countertops because it is formulated to gain strength in a week while other products typically require 28 days to cure. You begin by cutting the wood to make the form, and using the screws to assemble it. Lay a bead of caulk on the inside edges to stop leaks.

Can lightweight concrete be used for countertops?

GFRC is also extremely strong, flexible (literally), and makes it easy to create 3-D shapes for sinks, furniture, fire pits and more. This is by far the easiest and most obvious way of making lightweight concrete countertops, and it is the technique of choice for the vast majority of concrete countertop professionals.

Can you DIY concrete countertops?

Concrete countertops can give the kitchen inside your home a distinctly industrial look or provide an outdoor kitchen with a slab that is both functional and durable. Making your own DIY concrete countertops may require some dedicated time, but the result of your effort can be gratifying.

Can I use portland cement for countertops?

A good general-purpose mortar mix for basic countertop applications is one part Portland cement with three parts sand packed into a form built on top of a cabinet. Just remember to make your mixture dry enough to hold together in a pile, without being sloppy.

Do I need rebar in concrete countertop?

Sufficient concrete cover is required to prevent corrosion and rust stains. Pro tip: Don't use rebar to reinforce countertops that are less than two inches thick. The rebar is too big and may even cause cracking rather than prevent it. However, rebar can be used in thicker countertops or to support daring overhangs.

Can I use high strength concrete for countertops?

The best concrete mix for countertops is one with high compressive strength, smaller, rounder stones and some flexibility. QUIKRETE® Countertop Mix (No. 1106-80, -81) is a specially formulated high-strength concrete mix for pre-cast and cast-in-place concrete countertops. It works really well and comes in 80pound bags.

How much does a concrete bench top cost?

about $1,000 - $1,800Concrete countertops made and installed by professionals cost about $1,000 - $1,800 for the whole kitchen. Is a DIY concrete benchtop an option? Installation of polished concrete benchtops is a complex job, involving heavy materials, as well as precise mixing, finishing, and curing processes.

How long does a concrete bench last?

Benches from The Cement Barn are cast out of quality concrete materials and are reinforced with rebar for extra support. These concrete benches will not blow over, will not rot, and they will last for decades! They are manufactured to withstand the outdoor elements and will be fine outside year round.

What is the difference between regular concrete and countertop concrete?

The countertop mix has additives formulated to make building countertops easier. A plasticizer additive allows the concrete to flow into the mold with ease. The plasticizer enables you to use less water while still maintaining a flowable mixture.

What is the best mix for concrete worktops?

Mix ratios are usually 1:1 cement/sand with the addition of 1-5% glass fibres. Polymers are also added for extra ductility and increased curing properties. GFRC is an excellent choice for concrete countertops as it is possible to fabricate very large, lightweight and 3 dimensional surfaces.

Can Portland cement be used for countertops?

A good general-purpose mortar mix for basic countertop applications is one part Portland cement with three parts sand packed into a form built on top of a cabinet. Just remember to make your mixture dry enough to hold together in a pile, without being sloppy.

What kind of slurry do you use for concrete countertops?

CHENG Pro-Formula Acrylic Slurry is ideal for quickly and easily filling both small and large voids that appear after polishing or after releasing concrete from the mold. With a “gel-like” consistency, this fast acting slurry can also be used to fill voids and make repairs on vertical surfaces.

What is the best sealer for concrete?

Sealers can be divided into two general categories: densifiers or penetrating sealers and topical sealers (though there are hybrids of the two available). Penetrating sealers or densifiers, as the name suggests, penetrate into the concrete closing the pores and strengthening it. They offer some stain resistance but greater scratch and abrasion resistance. These sealers are preferred by people who want to retain the natural beauty and feel of concrete and aren’t afraid of some staining or etching over the years. They welcome the patina of concrete in much the same way a wooden chopping board changes over time.

What is love concrete?

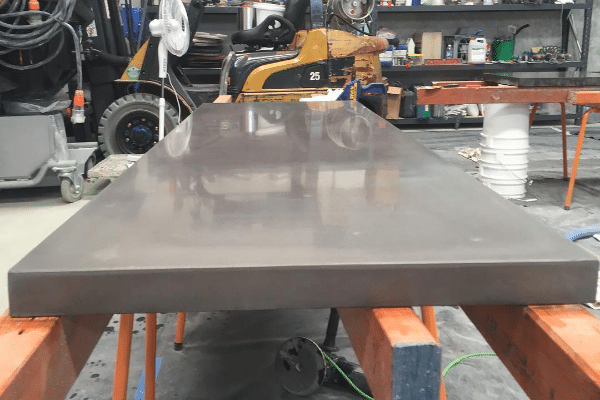

LOVE Concrete offers both traditional Wet Cast and Glass Fibre Reinforced Concrete (known as GFRC or GRC). There are benefits to both methods and the selection of the material will be driven by the design of the benchtop. We use GFRC for most pre fabricated bench tops due to its superior strength, durability and ability to make it lighter in weight and fabricate more complex designs. Wet Cast concrete is used in all cast in-situ benchtops and its main advantage is its absence of restrictions on size and shape as it is formed up and poured in a single piece which gets rid of the need for joins or grout lines. Both methods can be used to cantilever and span long distances without the need for support structures and both offer a wide range of customisable finishes and colours. Contact us with any design ideas and questions you may have.

What is wet concrete used for?

Wet Cast concrete is used in all cast in-situ benchtops and its main advantage is its absence of restrictions on size and shape as it is formed up and poured in a single piece which gets rid of the need for joins or grout lines.

How much does a square metre of concrete weigh?

The short answer is, generally no. One square metre of Wet Cast concrete at 40mm thickness weighs approximately 95kgs and GFRC can weigh as little as 45kg. This weight is usually spread over various points so it does not become an issue. Structural issues are discussed with the kitchen makers and designers to ensure the best result.

How thin can concrete be?

Because concrete is such a versatile product it can be made as thin as 25mm up to any thickness you want. Weight does not become a major issue as GFRC allows the weight to be kept at a minimum.

Why is concrete considered the new black?

It has moved beyond the cracked footpath and dirty driveway and is now seen by designers as the “new black” because it is possible to use it in interior and exterior contexts. Also because of its fluidity, concrete is able to be transformed into virtually any shape that becomes a solid mass therefore the design possibilities for creative expression are endless.

What is a topical sealer?

Topical sealers are a protective layer that sits over the concrete. Topical sealers, such as acrylics, epoxies and polyurethanes offer varying degrees of stain protection depending on price, but if not cared for properly are susceptible to scratching and chipping.

What are the basic properties of concrete?

The basic properties of concrete are fine and coarse aggregates (like sand and rocks or pebbles), Portland cement, and water. These three raw materials each play a different chemical role in the formation of concrete, as Portland cement is a hydraulic cement meaning it gets its strength from its chemical reaction with water.

How is concrete made?

Before concrete is made, the three raw materials must be proportioned correctly to ensure the outcome of a mixture that is strong and sturdy. The components of concrete react differently with each other based on the ratio of how much of each is added, and proportions will differ based on the type of concrete being made.

16 Common types of concrete

One of the reasons concrete is used to build so many different structures is due to how versatile it is and how it can be molded to any desired shape or design. There are many different types of concrete, however, and they are used for all different sorts of structures. Here are 16 types of concrete and how they are used.

Build Smarter

Get the latest updates about new courses, special trainings, resources, and more.