Here are a number of options I’ve come across that should suffice for basic soldering:

- 1 pound spool of lead-based solder wire with a diameter of 1.0mm

- Rosin Core for Lead-Free Solder

What is the best solder for electrical wiring?

Best Solder For Small Electronics: 60-40 Tin Lead WYCTIN Rosin Core Solder Wire Review

- It represents a good resin that easily sticks to a joint

- Offers free-flowing nature to fill up holes

- This is the best device for small electronics repair works

- Wire is so flexible

What type of solder should be used to repair electrical wiring?

There are three primary types of solder that are used frequently, namely:

- Acid core solder

- Rosin core solder

- Solid core solder

What kind of solder to use on circuit boards?

The three significant categories of solder suitable for your circuit board:

- Lead-based solders

- Lead-free solders

- Silver alloy solders

Can solder be used as wire?

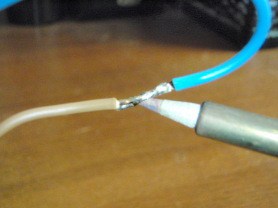

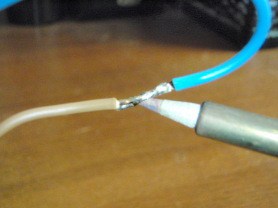

It cannot hold wires together. In this case, the solder is holding the wires, but I really wouldn't trust solder for electrical wires. Wires can get warmer when in use, which could weaken or break the solder. How do you solder wires without a soldering iron?

What is flux core solder wire?

Flux core solder wire means that there is flux inside the core of the solder wire. The flux prevents oxidation occurring when the oxygen in the air reacts with the hot metal. The oxide forms a covering layer over the metal and prevents the solder from sticking to it. Flux is the chemical that actively removes this oxide and prevents the build up ...

What is 60/40 solder?

A 60/40 solder is an alloy of 60 % tin and 40 % lead measured by weight. This type of solder has a melting point of around 190 °C. Another commonly used tin / lead solder alloy is 63/37, which has a melting point of 183 °C. I have compiled a Soldering Temperature Chart that might help determine the correct temperature for the type of solder used.

How to solder wires together?

First, strip the sections of wire you plan on soldering together. Then twist them around each other until secure. If you're using PVC shrink tube, slip this over one of the wires. Next, get ready with your solder and iron. Before you start working on the wire, you'll need to prepare the tip.

Why do you need to solder on the tip of a soldering iron?

You want to have some solder on the tip because it improves conductivity, which makes the task go faster, according to Instructables. It's best to get the wires soldered together quickly to avoid damaging the wires. When your soldering iron is all prepped and ready to go, it's time to solder the wires.

How to melt wire?

How to melt the wire. To turn the wire into a malleable and useful material, you'll need to apply some heat. The best tool for the job is a soldering iron, such as Master Appliance's EconoIron. Aside from your solder and soldering iron, you'll also need: Wire strippers.

How to clean solder tip?

Before you start working on the wire, you'll need to prepare the tip. Heat up the tip until it's hot enough to steam when wet, then clean off any old solder by wiping it with a damp sponge. After it's clean, tin the tip of the wire. This means coating it with the solder.

What is a 60-40 rosin core solder?

You'll want a 60-40 rosin-core solder, Popular Mechanics explained. This means it is 60 percent tin and 40 percent lead. The rosin core contains a flux, which will melt before the metal begins to. As the flux melts, it will coat the wire and allow it to weld together smoothly and strongly.