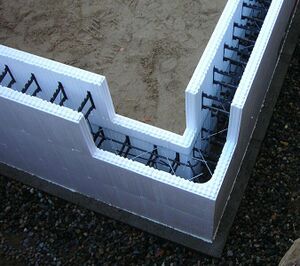

The materials needed to perform concrete block construction include:

- The blocks themselves

- Mortar

- Sand to add to the mortar

- Wall reinforcement material such as a ladder or truss-style joint reinforcement

- Standard block fill material, or

- Insulating block fill, to provide increased water repellency, fire resistance, and sound dampening

Full Answer

What are the materials needed to make concrete?

To make concrete there are four basic materials you need:

- Portland cement - You can buy this in a 94lb bag

- Sand - Course or Fine will work (course sand will give you a stronger mix)

- Aggregate (stone) You can use 3/8", 1/2", or 1/5" stone for aggregate

- Water - Clean cool water is best.

What materials are used to make concrete?

List of Materials Used in Reinforced Cement Concrete (R.C.C.) | Cement | Engineering

- Cement: Before the introduction of ordinary Portland cement, the lime was used as a cementing material. ...

- Aggregates: These are the inert or chemically inactive materials which form the bulk of cement concrete. These aggregates are bound together by means of cement.

- Steel: The steel reinforcement is generally in the form of round bars of mild steel. ...

Is there any material can we use instead of concrete?

Gravel is one of the more common alternatives to concrete. There are a few different types you can find in the home improvement store that can replace concrete cement used for driveways and walkways. These include pea gravel, crushed stone, and quarry process. Cheaper than other surface materials and low-cost to install.

Why is concrete such a widely used construction material?

Concrete is the most used material throughout the world, mainly thanks to its durability and strength. Concrete can handle almost ever climate and is resistant to erosion, rotting and rust- meaning that it requires minimal maintenance. Concrete can outlast wood and other common building materials and its strength improves over time.

What materials are required for concrete?

The principal ingredients that make up the concrete mix are: cement, fine aggregate, coarse aggregate, water, chemical admixtures, and mineral admixtures. Concrete used in construction may also contain reinforcing bars, welded wire fabric (wire mesh), and various reinforcing fibers.

What are three main materials in concrete?

Concrete is a composite material consisting of a binder, which is typically cement, rough and fine aggregates, which are usually stone and sand, and water. These comprise the constituent materials of concrete.

What is the most important materials used in concrete?

Portland cement is the basic ingredient of concrete. Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden.

What are the 4 main ingredients of concrete?

Concrete is a mixture of cement, air, water, sand, and gravel–it's as simple as that!

What is the mix for concrete?

The general concrete mix for concrete is 1:2:3, which means 1 part cement, 2 part sand, and 3 part is aggregate.

What are the 4 types of concrete?

Let's take a quick look at the most common types of concrete and what they are used for:Reinforced Concrete.Lightweight Concrete.High-Strength Concrete.High-Performance Concrete.Precast Concrete.

What is the difference between cement and concrete?

What is the difference between cement and concrete? Although the terms cement and concrete often are used interchangeably, cement is actually an ingredient of concrete. Concrete is a mixture of aggregates and paste. The aggregates are sand and gravel or crushed stone; the paste is water and portland cement.

How is concrete made step by step?

There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the burned product, known as “clinker,” together with some 5 percent of gypsum (to control the time of ...

What are the 3 types of concrete?

Concrete is made in different grades, including normal, standard and high-strength grades. These grades indicate how strong the concrete is and how it will be used in construction.

What are basic construction materials?

Wood, cement, aggregates, metals, bricks, concrete, clay are the most common type of building material used in construction. The choice of these are based on their cost effectiveness for building projects.

What are constituent materials?

The constituent materials are the matrix and reinforcing component.

What are the materials being used for making the building?

Building material is any material that can be used for construction purposes. It commonly includes wood, concrete, steel, cement, aggregates, bricks, clay, metal, and so much more. In the olden times, people have been using pure bricks, or wood, or straw.

What is the best SCM for cement?

Fly ash is the most common SCM and it improves finishability, although it tends to slow the set time, especially in cold weather. SCMs can be used to replace as much as 40% of the cement in a mix. Slag and metakaolin lighten the color of concrete which can be beneficial with integrally colored concrete. Metakaolin also helps to reduce the danger of efflorescence.

How to reduce shrinkage of concrete?

With our goal of reducing shrinkage though, aggregate becomes critical. To reduce shrinkage, we need to reduce the total amount of cement paste in the mix— the aggregate doesn't shrink. To reduce the cement paste, we need to minimize the spaces between the aggregate particles. That is accomplished with a "well-graded" aggregate mixture that starts with the largest aggregate size possible—ideally 1 ½ inches, although it should be less than 1/3 of the slab thickness and few stamping contractors will want to stamp a mix with aggregate that large. "I specify ¾ inch," says Bob Harris of the Decorative Concrete Institute. "Most of our stamp mixes are somewhere around ½ inch top size aggregate, but if we're pouring thick concrete we can successfully stamp ¾ inch or #57 stone."

What is the last ingredient in concrete?

One last ingredient in many concrete mixtures today is supplementary cementitious materials (SCM)--also called pozzolans. These materials include fly ash, slag cement (sometimes called ground granulated blast furnace slag—GGBFS or slag cement), silica fume, and metakaolin. SCMs are used as replacement for cement, and since they have a very small particle size, they reduce the permeability of concrete, which is good.

What is SCC in construction?

SCC is also ideal for producing glassy surfaces on sculpture, furniture, or countertops. Retarders and accelerators are also useful admixtures, especially when dealing with the variations in set time from cold or hot temperatures. One technique every decorative contractor should understand is set retardation (see Concrete Construction, July 2002, ...

What is a water reducer?

Water reducers can be used to maintain a specific slump with less water—reducing water content up to 30% or even turning concrete into self-consolidating concrete (SCC) that has a soupy consistency that is very useful for detailed decorative walls or when you want concrete to flow easily around embedded objects or congested reinforcing steel. SCC is also ideal for producing glassy surfaces on sculpture, furniture, or countertops.

What are the components of concrete?

What components go into the mix? Cool Climate Concrete. We all know that concrete is primarily portland cement, aggregate, and water. And in general it's best to keep it simple, since more ingredients can make it more difficult to control.

Does a low W/C ratio reduce shrinkage?

In that article he noted that a low w/c ratio "may increase strength and improve durability, but it is not likely to reduce shrinkage." He recommends lowering the total water content and even the cement content to reduce shrinkage, even if it means that the w/c goes above 0.5. Although this article was written specifically for industrial floors, it's wisdom applies equally to decorative floors.

What should be used for cement concrete?

The aggregates to be used for cement concrete work should be hard, durable and clean. The aggregates should be completely free from lumps of clay, organic and vegetable matter, fine dust, etc. The presence of all such debris prevents adhesion of aggregates and hence reduces the strength of concrete.

What is broken stone used for?

The broken stone is generally used as a coarse aggregate. The nature of work decides the maximum size of the coarse aggregate. For thin slabs and walls, the maximum size of coarse aggregate should be limited to one-third the thickness of the concrete section. The aggregates to be used for cement concrete work should be hard, durable and clean.

How are igneous rocks formed?

The igneous rocks are formed originally by cooling from a molten rock material known as magma. They are further classified as plutonic rocks, hypabyssal rocks and volcanic rocks. The plutonic varieties are brittle due to the presence of large crystals and the main types of rocks under this variety are granite, syenite, diorite, etc.

How are sedimentary rocks formed?

The sedimentary rocks are formed by the deposition of products of weathering on the pre-existing rocks. They are further classified as calcareous; siliceous and argillaceous. In calcareous variety, the calcium carbonate predominates and the main types include lime stones, dolomites and chalk.

What is natural aggregate?

The term natural aggregate is used loosely to designate aggregates which need only be removed from their natural deposits as unconsolidated sediments. The aggregates obtained from such deposits are called gravel and sand while those produced from ledge rock, boulders or cobble stones are known as crushed stone.

Why are dolomites and lime stones used?

The lime stones and dolomites are suitable because they have excellent adhesion to cement and bituminous binder. The chalk is unsuitable for construction purpose.

Why do you add admixtures to concrete?

It may be noted that sometimes the ingredients other than above are added in concrete to give it certain improved qualities or for changing different physical properties in its fresh and hardened stages. These ingredients or substances are known as the admixtures. The addition of an admixture may improve the concrete with respect to its strength, hardness, workability, water-resisting power, etc.

How to calculate concrete volume?

The formula for calculation of materials for required volume of concrete is given by: Where, V c = Absolute volume of fully compacted fresh concrete W =Mass of water C = Mass of cement Fa = Mass of fine aggregates Ca = Mass of coarse aggregates S c, S fa and S ca are the specific gravities of cement, fine aggregates and coarse aggregates respectively. The air content has been ignored in this calculation. This method of calculation for quantities of materials for concrete takes into account the mix proportions from design mix or nominal mixes for structural strength and durability requirement. Now we will learn the material calculation by an example.

What is the ratio of cement to water?

The water cement ratio required for mixing of concrete is taken as 0.45.

How to calculate volume of a cross sectional member?

The volume of a rectangular cross sectional member can be calculated as length x width x height (or depth or thickness). Suitable formula shall be used for different cross-sectional shapes of members.

How do I put concrete in a concrete slab?

Here is the list of tools you need to place the concrete: 1 Concrete screed or straightedge 2 A bull float - for smoothing the concrete 3 Kumalong or concrete rake - for pulling and pushing the concrete in place 4 Mag float - for smoothing the edges 5 Concrete boots - I know, not really a tool but you need them 6 Gloves - concrete will burn your skin, you need to protect them 7 Laser level, Tripod & Grade stick - to make sure the middle of the slab is level with the top of the boards

What tools do I need to put concrete in a concrete slab?

Here is the list of tools you need to place the concrete: Concrete screed or straightedge. A bull float - for smoothing the concrete. Kumalong or concrete rake - for pulling and pushing the concrete in place. Mag float - for smoothing the edges. Concrete boots - I know, not really a tool but you need them.

What tools do you need to build a form?

THE TOOLS YOU NEED TO BUILD THE FORMS. These are the tools we use to build the forms. We like to screw our forms together. You can use a hammer and nails if you want to. Dewalt drill driver - it's faster than hammering nails and holds the forms together better. 2 Pound sledge hammer - for driving in the stakes.

Can you fix concrete after it hardens?

Concrete is not easy to fix after it hardens. My course will explain to you in a video format how to easily set up the forms and prepare them for the pour. Then I will show and tell you all my secrets on how we pour concrete slabs. It's well worth the investment. GET IT NOW! Go to Concrete Slab.

Who owns Day's Concrete Floors?

My name is Mike Day, owner of Day's Concrete Floors, Inc.

Can you add videos to your watch history?

Videos you watch may be added to the TV's watch history and influence TV recommendations. To avoid this, cancel and sign in to YouTube on your computer.

What mix to use for concrete?

For very small projects, such as setting a mailbox post or doing repairs, you may want to purchase a packaged concrete mix. Such a mix combines cement, sand, and gravel in the correct mixing ratios and requires only the addition of water to create fresh concrete.

What is the best mix for concrete?

When making your own concrete it's important to use the correct concrete mixing ratios to produce a strong, durable concrete mix. To make concrete there are four basic materials you need: Portland cement, sand, aggregate (stone), and water. The ratio of aggregate to sand to cement is an important factor in determining the compressive strength ...

How much cement is needed to make 4000 PSI?

To produce a cubic yard of 4000 psi concrete, you have to adjust the concrete mixing ratio to: 611 pounds of cement or (277kg) 1450 pounds of sand or (657kg) 1600 pounds of stone or (725kg) 33- 35 gallons of water or (133L) As you can see a little more cement and a little less sand is required to produce this stronger concrete mix ...

How much cement is needed for 1 cubic meter of concrete?

Or... 1 cubic meter of concrete will require approximately 7.15 bags of Portland cement, .48 cubic meters of sand, and .51 cubic meters of gravel.

How to make smaller batches of concrete?

To make smaller batches of concrete, use the same proportions, but with smaller quantities, substituting buckets for cubic feet. (For the mix proportions given previously, you'd use 1 bucket of cement, 3 buckets of sand, 3 buckets of stone, and 1/2 bucket of water.) For any batch size, the most important thing is to keep the proportions ...

What is concrete edging?

Concrete edging for your lawn or garden. For very small projects, such as setting a mailbox post or doing repairs, you may want to purchase a packaged concrete mix. Such a mix combines cement, sand, and gravel in the correct mixing ratios and requires only the addition of water to create fresh concrete.

How much cement is in 1:3:3?

A 1:3:3 mixing ratio calculates to 115 lbs of cement to 343 lbs of sand and 343 lbs of stone. (Rounded off)