Which Fastener Materials Work With Aluminum Without Corroding It?

- Coated Steel. With a thick enough coating, even a very reactive metal like brass can be used on an aluminum structure without corrosion.

- Electroplated Steel. One of the oldest ways of coating steel is through a process known as galvanization. ...

- Aluminum. One type of corrosion process is known as the two-metal reaction. ...

- Non-Metal Fasteners. Finally, fasteners made from the various high-strength plastics available today are also an option for preventing aluminum corrosion.

Which type of fastener should you use?

Which Type of Fastener Should You Use?

- Basic Screws. One of the most common types of fasteners is your basic screw. ...

- Basic Nails. Just as there are many types of screws, there are also many different types of nails. ...

- Bolts. While nails and screws are basically general-use products, bolts are a bit more heavy-duty and serious.

- Washers. Another more heavy-duty type of fastener is a washer. ...

What is the best screw for aluminum?

Screws Compatible With Aluminum

- Galvanic Corrosion. The process of galvanic corrosion occurs when two different metals are touching each other in the presence of an electrolyte, a fluid that allows the flow of electrons ...

- Aluminum Screws. ...

- Carbon Steel Screws. ...

- Stainless Steel Screws. ...

- Brass Screws. ...

What is the best coating for aluminum?

Types of Paint for Aluminum Siding

- Acrylic Paint Acrylic paint is a pick that's easy to work with that also happens to be widely available from all home improvement stores. ...

- Acrylic Latex Paint Most experts consider this hybrid paint the top choice for painting aluminum siding. Like 100% acrylic, acrylic latex is found at every home improvement store. ...

- Self-Etching Primer

What type of screws to use on aluminum hull?

Note that tensile loads on screws place shear loads on the threads, so in soft material like aluminum, you'll generally get greater holding power with thicker, i.e., coarser, threads. For example, select 1/4-20 rather than 1/4-28 screws for mounting hardware to a mast.

What metals work well with aluminum?

Coated Steel With a thick enough coating, even a very reactive metal like brass can be used on an aluminum structure without corrosion. Since stainless steel remains one of the least reactive metals without coating, it's smarter to use it as the base material.

Can stainless steel fasteners be used with aluminum?

When using stainless steel fasteners with aluminum surfaces, you can prevent corrosion by placing something between the two metals. Plastic or rubber washers or gaskets are good suggestions. Along with corrosion, discoloration of stainless steel may occur when combined with aluminum. This is also called 'tea staining'.

Can I use galvanized bolts on aluminum?

Aluminum. When used in mild-to-moderately corrosive environments and/or mild-to-moderate humidity, contact between a galvanized surface and aluminum is unlikely to cause substantial incremental corrosion.

Can you use steel screws on aluminum?

Carbon Steel Screws Unplated steel screws will cause corrosion in aluminum in a wet environment. They'll rust quickly themselves, as well, so they're not a good choice for fastening aluminum.

Can steel and aluminum be used together?

When aluminum and stainless steel are used in an assembly together, the electrons from the aluminum will begin to transfer into the stainless steel. This results in the aluminum weakening. This weakened aluminum causes it to deteriorate at a much faster rate. This can lead to an extended life of the stainless steel.

What are the best screws for Aluminium?

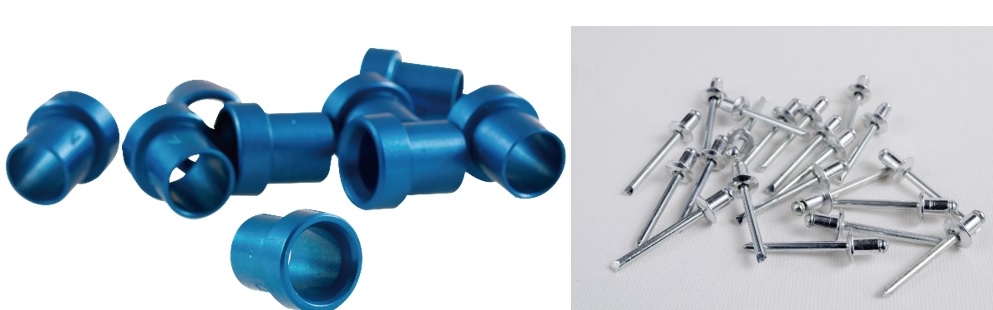

Self-tapping screws, also called sheet metal screws, are very versatile. They can be used to securely fasten metals together, including aluminum. They can also be used to efficiently fasten metal to other materials, such as wood or plastic, by creating a much stronger bond than a regular nail.

Will zinc screws react with aluminum?

The higher the electrical potential difference the greater the possibility of a reaction. In the case of zinc and aluminum, there is only a slight chance of a reaction because of the relatively small change in potential between the two metals and the formation of an insulating film on the surface of the aluminum.

Can you put Aluminium and Galvanised steel together?

Galvanizing and aluminum are not completely compatible, so you would not use such a combination on a critical structure like an airliner. But on the other hand they are fairly close galvanically, and rain water is 'distilled' and fairly non-conductive.

Can you put Aluminium with Galvanised steel?

Galvanized steel can be paired with many other metals. Specialized construction and fabrication needs may put galvanized steel in contact with stainless steel, aluminum, copper, and other weathering steel. The juxtaposition of galvanized steel with other metals can result in a condition called galvanic corrosion.

How do you attach something to aluminum?

Cyanoacrylate – also known as instant adhesives, super glue, crazy glue, ca glue, etc. All grades will bond aluminum well. For very high strength use a metal bonder such as 170 or the original 910®. For bonding aluminum to dissimilar surfaces with different coefficients of thermal expansion consider toughened 737.

Is brass compatible with aluminum?

Brass is incompatible with aluminum, per Mil-STD-889 [affil. link to spec at Techstreet] (and Notices 1, 2 & 3 thereof) DISSIMILAR METALS. Galvanized is your best choice.

How can we prevent galvanic corrosion between steel and aluminum?

Galvanic corrosion can be prevented by:Selecting materials with similar corrosion potentials.Breaking the electrical connection by insulating the two metals from each other.Applying coatings to both materials. ... Separating the two materials by inserting a suitably sized spacer.More items...

Does stainless react with aluminum?

Stainless steel is an alloy of carbon steel that is, itself, resistant to corrosion. However, stainless steel is reactive with aluminum, and when a stainless steel screw is in contact with an aluminum base metal, the aluminum is likely to corrode.

How can we prevent galvanic corrosion between steel and aluminum?

Galvanic corrosion can be prevented by:Selecting materials with similar corrosion potentials.Breaking the electrical connection by insulating the two metals from each other.Applying coatings to both materials. ... Separating the two materials by inserting a suitably sized spacer.More items...

Can you use self tapping screws in aluminum?

Self-tapping screws are good for use with metals, various types of plastics (plywood, fiberglass, polycarbonates), and cast or forged material, like iron, aluminum, brass or bronze. Self-tapping screws also work for surfaces where you can't secure the rear end with a nut.

Can I use stainless steel bolts on galvanized steel?

Miami Stainless, a supplier of high quality stainless steel products, explains why stainless steel should never be used with galvanised products. Stainless steel is one of the most corrosion resistant of all metals; hence there is usually a corrosion hazard for any metal used with it.

How to avoid two metal reaction corrosion?

One way to avoid two-metal reaction corrosion is to stick with aluminum throughout the project. The downside is that aluminum fasteners do not offer adequate shearing resistance for all but lighter-duty uses.

What are non metal fasteners?

Non-Metal Fasteners. Similarly, high-strength plastic fasteners lack the strength of metal varieties. Used in less heavy-duty applications such as medical and food-manufacturing, non-metal fasteners prevent aluminum corrosion. If you are still unsure which fasteners you can use with aluminum without corroding it, ...

What is electroplated fastener?

Electroplated Steel Fasteners. Also known as galvanization, steel fasteners that are electroplated with a layer of corrosion-resistant metal generally cost less than newer, high-tech coated fasteners. Although the electrical process secures the protective coating tightly to the surface of the metal, it can wear off over time. 3.

Which fastener will not corrode when in contact with aluminum?

To simplify the selection of an appropriate option, here is a breakdown of fastener that will not corrode when in contact with aluminum: 1. Coated Steel Fasteners. Even the most reactive metal is safe when encased in a thick enough coating.

Is stainless steel reactive?

Having said that, it is safest to avoid a metal that is very reactive, such as brass, and opt rather for one of the least reactive metals, such as stainless steel. That will give you peace of mind in case the coating peels away or disintegrates. 2. Electroplated Steel Fasteners.

Can you use aluminum fasteners without corrosion?

Which Fasteners You Can Use With Aluminum Without Corroding? Thanks to its properties - lightweight, flexibility, strength – aluminum is a popular choice of metal. Choosing fasteners for aluminum, on the other hand, is complicated by aluminum’s tendency to react negatively with other metallic substances, leading to corrosion.

Why does aluminum deteriorate?

As the process continues, one of the metals will deteriorate quickly as its electrons flow steadily to the other metal. When you fasten aluminum using screws made from a different metal, especially in situations where the metal is exposed to salt water, galvanic corrosion may cause significant deterioration of the aluminum base metal.

What is galvanic corrosion?

Galvanic Corrosion. The process of galvanic corrosion occurs when two different metals are touching each other in the presence of an electrolyte, a fluid that allows the flow of electrons from one metal to the other. As the process continues, one of the metals will deteriorate quickly as its electrons flow steadily to the other metal. ...

What causes corrosion in aluminum?

Exposure to salt water can cause corrosion of aluminum and its fasteners.

Can brass screws be used with aluminum?

Brass is very reactive with aluminum, and brass screws will cause substantial corrosion of an aluminum base metal in a wet environment. The process of galvanic corrosion depends on the presence of an electrolyte, though, so in a totally dry environment the risk of corrosion is low, even if you use uncoated brass screws. Advertisement.

Can stainless steel screws corrode aluminum?

As is the case with carbon steel screws, a plated stainless steel screw is less likely to corrode aluminum; screws treated with a high-quality coating consisting of zinc and aluminum flakes are especially resistant to corrosion. Advertisement.

Can you use unplated steel screws on aluminum?

Unplated steel screws will cause corrosion in aluminum in a wet environment. They'll rust quickly themselves, as well, so they're not a good choice for fastening aluminum. Galvanized steel screws, however, are plated with a corrosion-resistant coating, usually consisting of zinc, that is not nearly as reactive with aluminum.

Can aluminum screws cause corrosion?

Because galvanic corrosion happens when dissimilar metals come into contact with each other, the simplest way to prevent the process is to use screws made from the same metal as the metal you're fastening. Aluminum screws will not cause corrosion in aluminum base metal, even if the screws aren't plated or treated with any corrosion-resistant material.

What is the best screw to hold aluminum sheets together?

It is no doubt that stainless steel screws are the best when it comes to holding together materials such as aluminum sheets so that when faced with a variety of elements they do not break open.

How to protect connecting points from water?

Also, to reduce their contact with water, connecting points can be protected using tape or even paint depending on your preference. Check the surface area of metals. Always ensure that the aluminum part of the material is larger than the stainless steel screws to avoid it being eaten away.

How to reduce chances of metals getting corroded?

To reduce chances of the metals getting corroded reduce the contact the two metals have by creating a non-reactive barrier. The best barrier material is plastic washers which ensure that the metals are sealed at their point of contact.

Does aluminum disintegrate in salt water?

Aluminum which has an anodic nature will quickly disintegrate when it comes into contact with salty water, and will do the same when its surface area is less than that of stainless steel. Other products that Marsh Fasteners supplies to clients that work in the construction field all over the world include stainless steel threaded rod, ...

Can salty water corrode aluminum?

Salty water is an electrolyte that can easily corrode either the aluminum or stainless steel material when they come into contact with each other. Therefore, it is important to always separate the two metals as soon as possible especially if the environment has salty water or anything close to it.

Can Stainless Steel and Aluminum Be Used Together?

However, there are many dissimilarities in aluminum and stainless steel. But when the environment is dry and sheltered, there are fewer chances of the galvanic corrosion. Stainless steel and aluminum can be used together but in most cases, both metals catch corrosion. There can be several reasons behind the corrosion and they will be discussed in the next sections of the article.

How to Safely Use Stainless Steel Screws in Aluminum?

This section highlights the important steps that can help in the safe use of stainless steel screws in aluminum.

How to Prevent Galvanic/Bimetallic Corrosion?

After understanding that what happens when the aluminum and the stainless steel are used together and the details of the galvanic corrosion, this section will highlight the practices that can help in preventing the galvanic corrosion. The following points are very helpful for the prevention of corrosion:

What metals are used to stop corrosion?

The use of a metal that is anodic to aluminum and stainless steel in the galvanic contact with the sacrificial metal proves to be very helpful for stopping corrosion. The insulations and regular maintenance of the parts are very helpful in preventing the stainless steel screws from discoloration.

Why is aluminum important?

It is very important to make sure that the piece of aluminum has almost 10 times larger surface area than the stainless steel screw. The introduction of a non-reactive barrier between the metals reduces the chances of galvanic corrosion. The production of the galvanic current increases with the increase in the reduction of oxygen. And the reduction of oxygen increases when the cathodic part is larger than the anodic part.

How does galvanic corrosion occur?

Galvanic corrosion occurs when the potential difference between the two metals is more than 0.1 volts. The proper insulation of the stainless steel screws reduces the potential difference by restricting the electrical contact.

Why use anodic parts?

The use of replaceable anodic parts can also help in reducing galvanic corrosion. Moreover, increasing the thickness of the anodic parts ensures a long life for the stainless steel and aluminum assembly.

What is a galvanic cell?

The chart below shows the electrode potentials of metals in seawater. If two metals with different potentials are placed in contact and there is a conductive medium, such as sea water or condensation, there can be a reaction, commonly known as a galvanic cell.

What is the reaction between dissimilar metals?

One of the key factors in the reaction between dissimilar metals is the contact surface area. A severe reaction can occur when a large cathode (higher or more positive potential) is in contact with a small anode (lower or negative potential). In this situation, corrosion rates can increase dramatically.

Why is there a slight chance of a reaction between zinc and aluminum?

In the case of zinc and aluminum, there is only a slight chance of a reaction because of the relatively small change in potential between the two metals and the formation of an insulating film on the surface of the aluminum.

Does condensed water cause corrosion?

In many cases, condensed water does not provide enough conductance to start the corrosion process. Whenever possible, the best solution to this type of corrosion is to prove an insulation barrier between the two dissimilar metals.