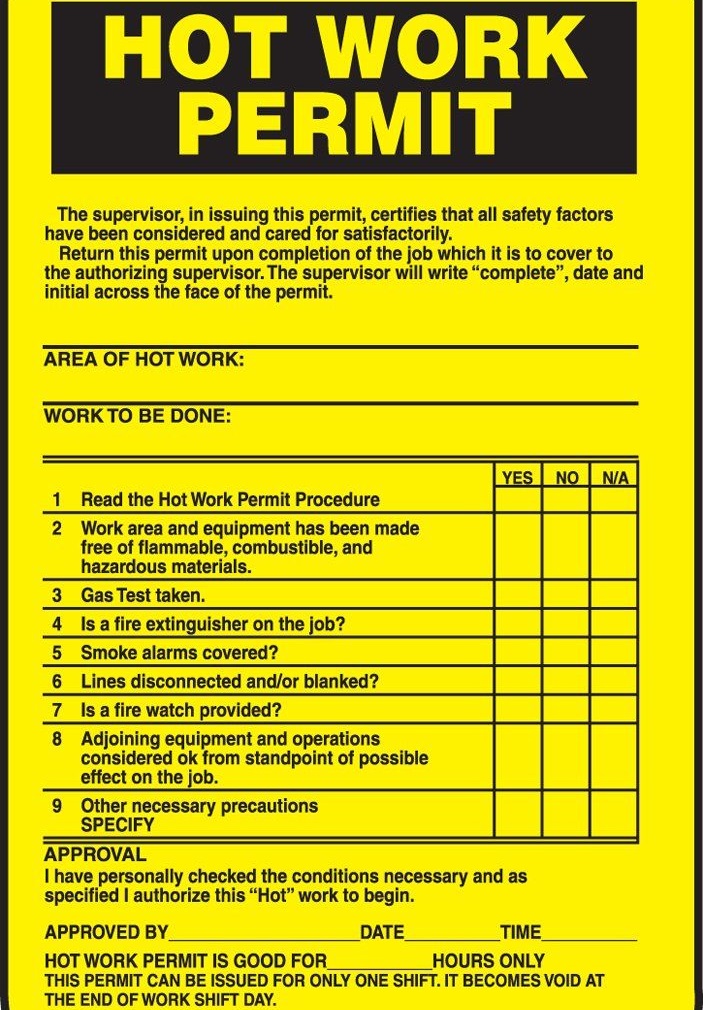

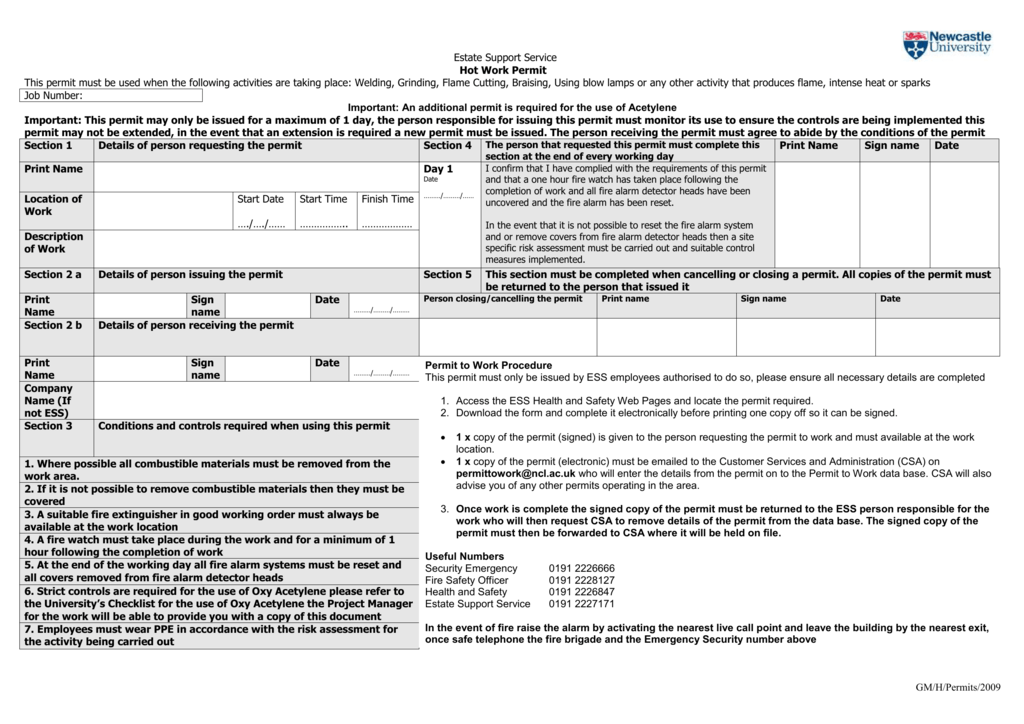

A hot work permit must consist of:

- The date

- The location of the job

- The duration of the job

- The exact nature of hot work

- Hazards and risks of the job

- PPE requirements

- Details of the person applying the permit and approving the permit

- Requirements for conducting the hot work monitoring and fire monitoring protocols

- Hot work checklist before starting the job

How long must a hot work permit be retained?

We always advise to maintain HW permits on a rolling 12 month schedule; however, at some very large facilities this can take a lot of filing cabinets! So I am asked by legal "what is officially required" and that is where I go to one of my most trusted sources...

What are hot work and cold work permits?

Cold work permits are green colored permids issued for hazardous maintenance work that does not involve the ignition hazards found in hot work. Cold work situations are determined by conducint a risk assessment for the task and the working environment. If no flammable or explosive risks are identified, a cold work permit is sufficient for ...

Is a hot work permit required by OSHA?

Yes. A permit system for Hot Work is required by the State Fire Prevention Code and OSHA. Is complying with code the only reason for having a Hot Work permit system? No. While it is important to comply with the codes, a Hot Work permit system helps the University maintain control of Hot Work operations to avoid injuries and losses from fires.

Do you have your hot work permit?

One of the most important 'parts' of performing hot works is conducting a risk assessment and safety check via a hot works permit. Hot works permits are required for all hot works, and must be completed before any work involving welding, grinding, gas-cutting, flame heating or any other flame / spark producing equipment is commenced.

What qualifies as hot work?

Definition. "Hot work" means riveting, welding, flame cutting or other fire or spark-producing operation. Hot work in confined spaces. Hot work shall not be performed in a confined space until a designated person has tested the atmosphere and determined that it is not hazardous.

Why might a hot work permit be required?

The Hot Work Permit system is intended to assure that the individuals involved in construction, renovation, repairs and maintenance of University facilities are aware of the hazards associated with hot work and welding and that they implement control measures to help mitigate them.

Which of the following is on a hot work permit?

(g) The hot work permit shall contain the following information: (1) The effective time and date. (2) The place of use. (3) The hours during which the source of ignition may be used, not to exceed 24 hours.

Is a hot work permit required for soldering?

A hot work permit is required for the following activities: brazing, cutting, heating, soldering*, welding, or similar type work in accordance OSHA 20 CFR 1910.252.

What is the OSHA standard for hot work?

29 CFR 1917.152OSHA defines hot work to include riveting, welding, flame cutting, or similar fire- or spark- producing operations. Requirements for hot work are in 29 CFR 1917.152.

At what conditions hot work permit are given in the industries?

Hot Work Operational Requirements Hot work is allowed only in fire-safe areas or either designated areas or permitted areas. A designated area is a specific area designed or approved for such work that consists of non-combustible or fire-resistive construction.

What are examples of hot work?

Hot Work: Any process that can be a source of ignition when flammable material is present or can be a fire hazard regardless of the presence of flammable material in the workplace. Common hot work processes are welding, soldering, cutting and brazing.

How many types of hot work permits are there?

4 Types of Permit-To-Work (PTW): The types of work for which PTW systems shall be applied include maintenance and repair, inspection, testing, construction, dismantling, modification and cleaning.

Who is responsible for issuing hot work permit?

A Hot Work Permit authorised by the Premise Responsible Person or their nominated representative and the Contractor/Person in control of the Hot Work will be required. You should use this Hot Work Permit when maintenance work is being undertaken, and you are the individual authorised to issue Hot Work Permits.

Is using a torch considered hot work?

Hot work is any operation that produces a flame, heat or sparks such as electric or gas welding, abrasive cutting, soldering, grinding, torch work, and brazing activities. This includes torches, arc welding equipment, portable grinders, and propane torches.

Is TIG welding considered hot work?

A HWP authorizes hot work operations to be performed outside a designated area established by an Operational Safety Procedure (OSP) including Tungsten Inert Gas/Metal Inert Gas (TIG/MIG) welding.

Are heat guns considered hot work?

Expanding on OSHA's definition, hot work means welding, brazing, cutting, soldering, thawing pipes, using heat guns, torch applied roofing and chipping operations, or the use of spark-producing power tools, such as drilling or grinding.

What are examples of hot work?

Hot Work: Any process that can be a source of ignition when flammable material is present or can be a fire hazard regardless of the presence of flammable material in the workplace. Common hot work processes are welding, soldering, cutting and brazing.

What is hot work permit on ship?

Hot Work Permit. A document issued by a Responsible Person permitting specific Hot Work to be done during a particular time interval in a defined area.

What is a hot work permit South Africa?

A hot works permit can be issued by the health and safety officer of the business or another senior person and is essentially just confirmation that certain specified risk management steps have been taken before any welding or other work with an open flame takes place.

WHO issues a hot works permit?

A Hot Work Permit authorised by the Premise Responsible Person or their nominated representative and the Contractor/Person in control of the Hot Work will be required. You should use this Hot Work Permit when maintenance work is being undertaken, and you are the individual authorised to issue Hot Work Permits. 1.

What are the requirements for a hot work permit?

A hot work permit must consist of: 1 The date 2 The location of the job 3 The duration of the job 4 The exact nature of hot work 5 Hazards and risks of the job 6 PPE requirements 7 Details of the person applying the permit and approving the permit 8 Requirements for conducting the hot work monitoring and fire monitoring protocols 9 Hot work checklist before starting the job 10 Hot work protocols for jobs in confined spaces and walls/ceilings 11 Final checkup after the job 12 Handover procedures and cancellation protocols

Why Do You Need a Hot Work Permit?

Let’s imagine a situation where a group of workers hasn’t obtained a hot work permit for a welding job. They can risk starting a fire, causing burns, excessive noise that can affect the work nearby and harm anyone in the vicinity.

Can a hot work permit be offline?

While a hot work permit can protect the workers from accidents, it can be quite tedious when the permit system is completely offline. You can save a lot of time and quicken the approval process when you use an online hot work permit checklist.

What should a hot works permit include?

You hot works permit format should include: Basic record keeping information - The issue and expiry data, instruction for permit applicants and a description or the type of hot works being performed. Hot works safety checks and measures - The next 'checklist' provides the list of checks and preventative measures necessary to begin hot works. ...

What is hot work?

Hot work is any work that may generate flames, heat or sparks and it includes any cutting (wet/dry), grinding, welding and use of open flames. Fire and open flame, as well as intense heat sources can be a powerful tool for getting work done, but they also come with plenty of inherent danger and hazards: Fire. Burns.

What are the hazards of hot works?

Oxygen-depletion. Toxic fumes. Many of these hazards are a constant in hot works, making your hot works permitting and procedures critical to ensuring none of them eventuate and turn into regrettable incidents. The intensity of hot works being performed can full on a wide spectrum, from using a grinder to split some steel to performing shielded ...

Why sign and mark areas and entry points near performed hot works?

Properly signing and marking areas and entry points near performed hot works ensures that parties moving through and around site aren't exposed to hot works without the right safety gear, and that they don't disrupt the concentration or work of the person doing the job.

Why should hot works not be taken for granted?

Hot works should not be taken for granted, as the consequences for a lack of conscious thought and safety effort can result in poor safety outcomes for companies and the individuals performing hot works.

What should be at the end of a permit?

At the end of the permit, there should be a section for signoff, confirming that all the 'steps' required to conduct hot works safely have been taken. Expand the example below by clicking on the button in the middle of the permit, opening up both pages and enabling you to take a closer look at the contents and purpose of each question.

Do you have to wear protective equipment when doing hot work?

In addition to these universal rules, the performer of hot works must have access to and wear personal protective equipment as required to complete the particular work (e.g. welding, grinding etc.).

Why do you need a permit for hot work?

Every job site involving Hot Work requires a permit to document the hazards and the safeguards in place to ensure the planned hot work does not cause a fire.

What is hot work?

Hot work is any activity or process that involves open flames or that generates sparks or heat and includes: Welding and allied processes; heat treating; grinding; thawing pipes; powder-driven fasteners; hot riveting; torch-applied roofing; and any similar applications producing or using sparks, flame or heat.

Is a hot work certificate required in Massachusetts?

Mandatory program in Boston and Massachusetts. The City of Boston requires a Hot Work Safety Certificate for all persons engaged in hot work operations on the work site. This is mandatory in the state of Massachusetts as of July 1, 2018.

Is hot work mandatory in Massachusetts?

Attending this training demonstrates your commitment to the highest safety standards. This is mandatory in the state of Massachusetts as of July 1, 2018.

Is hot work fire preventable?

Hot work fires are preventable. If you are an NFPA member, you can download our fact sheet on hot work safety. This fact sheet is also available in Spanish below.

What equipment is needed for hot work?

Equipment to be used (e.g. welding equipment, shields, personal protective equipment, fire extinguishers) must be in satisfactory operating condition and in good repair.

What is a permit required area?

A permit-required area is an area made fire-safe by removing or protecting combustibles from ignition sources.

How far away from a fire must a combustible floor be?

All combustible materials must be moved at least 35 ft away ...

What gas is used in welding?

After removal of the flame, the liquid metal cools to join the surfaces together. Gases used with oxygen or air are acetylene, MAPP gas and hydrogen.

What does "hot work" mean?

Definition. "Hot work" means riveting, welding, flame cutting or other fire or spark-producing operation. 1917.152 (b) Hot work in confined spaces. Hot work shall not be performed in a confined space until a designated person has tested the atmosphere and determined that it is not hazardous.

When is the hot work operation such that normal fire prevention precautions are not sufficient?

When the hot work operation is such that normal fire prevention precautions are not sufficient, additional personnel shall be assigned to guard against fire during hot work and for a sufficient time after completion of the work to ensure that no fire hazard remains. The employer shall instruct all employees involved in hot work operations as to potential fire hazards and the use of firefighting equipment.

What precautions are required for gas welding equipment?

Operational precaution. Gas welding equipment shall be maintained free of oil and grease.

When is hot work not performed in a confined space?

Hot work shall not be performed in a confined space until a designated person has tested the atmosphere and determined that it is not hazardous.

When openings or cracks in flooring cannot be closed, what precautions should be taken?

When openings or cracks in flooring cannot be closed, precautions shall be taken to ensure that no employees or flammable or combustible materials on the floor below are exposed to sparks dropping through the floor. Similar precautions shall be taken regarding cracks or holes in walls, open doorways and open or broken windows.