What kinds of materials would make good wind turbine blades?

- Light weight

- High tensile strength to bear higher wind speeds

- Relatively safer and abundant on earth (compared to several compound tried)

- Cheaper as aluminium and carbon fibre are both mined large amounts

- Both luminium & some carbon fibre can be easly cut to produce blades of required dimension

How big are the wind turbine blades?

Wind turbines come in a variety of sizes, depending upon the use of the electricity produced. A large, utility-scale turbine may have blades over 165 feet (50 meters) long, meaning the diameter of the rotor is over 325 feet (100 meters) – more than the length of a football field. (So, the blade located outside the building is a good reference).

Why do wind turbines have thin blades?

• Wind turbine blades are thin for the same reason that there are fewer foxes than rabbits – the hunter mustn’t consume all the hunted or there is nothing left to feed on. The blades extract power from the wind, thereby slowing it, and this slow wind behind the turbine causes the wind in front of the turbine to spill around it.

Should wind turbine blades be straight or on an angle?

This translates in a maximum conversion of 38.5% of the wind force into rotational motion. Therefore, the blades should be tilted at an angle of roughly 35.5 degrees from the oncoming air stream to obtain the optimal amount of energy using flat blade windmills.

What shape works best for wind turbine blades?

The faster the wind blows, the more lift that is produced on the blade, hence the faster the rotation. The advantages of a curved rotor blade compared to a flat blade is that lift forces allow the blade tips of a wind turbine to move faster than the wind is moving generating more power and higher efficiencies.

Why is the shape of the blade of a wind turbine very important?

Wind turbine blades generate lift with their curved shape. The side with the most curve generates low air pressure, while at the same time high-pressure air beneath forces on the other side of the blade-shaped aerofoil.

Why do turbine blades have a twisted shape?

As you learned on the page on stall , a rotor blade will stop giving lift, if the blade is hit at an angle of attack which is too steep. Therefore, the rotor blade has to be twisted, so as to acheive an optimal angle of attack throughout the length of the blade.

What is the angle of a wind turbine blade?

Thus, 5° pitch angle is optimum for a wind turbine when the operating velocity is 7 m/s for optimum power generation.

Why do wind turbines have only 3 blades?

This is because their angular momentum in the vertical axis changes depending on whether the blades are vertical or horizontal. With three blades, the angular momentum stays constant because when one blade is up, the other two are pointing at an angle. So the turbine can rotate into the wind smoothly.

How long does it take for a wind turbine to break even?

In medium winds, our V136-4.2 MW turbine hits this breakeven period within 6.1 months and in low winds, the V150-4.2 MW turbine will hit energy neutrality within 7.6 months. As this graph illustrates, a Vestas wind turbine (V117-4.2 MW, 136-4.2 MW, V150-4.2 MW) pays back more energy than it uses after 5 to 8 months.

Are windmill blades flat or angled?

But since wind turbine blades are set at an angle, the wind is deflected at an opposite angle, pushing the blades away from the deflected wind. This phenomenon can be viewed on a simple, flat blade set at an angle.

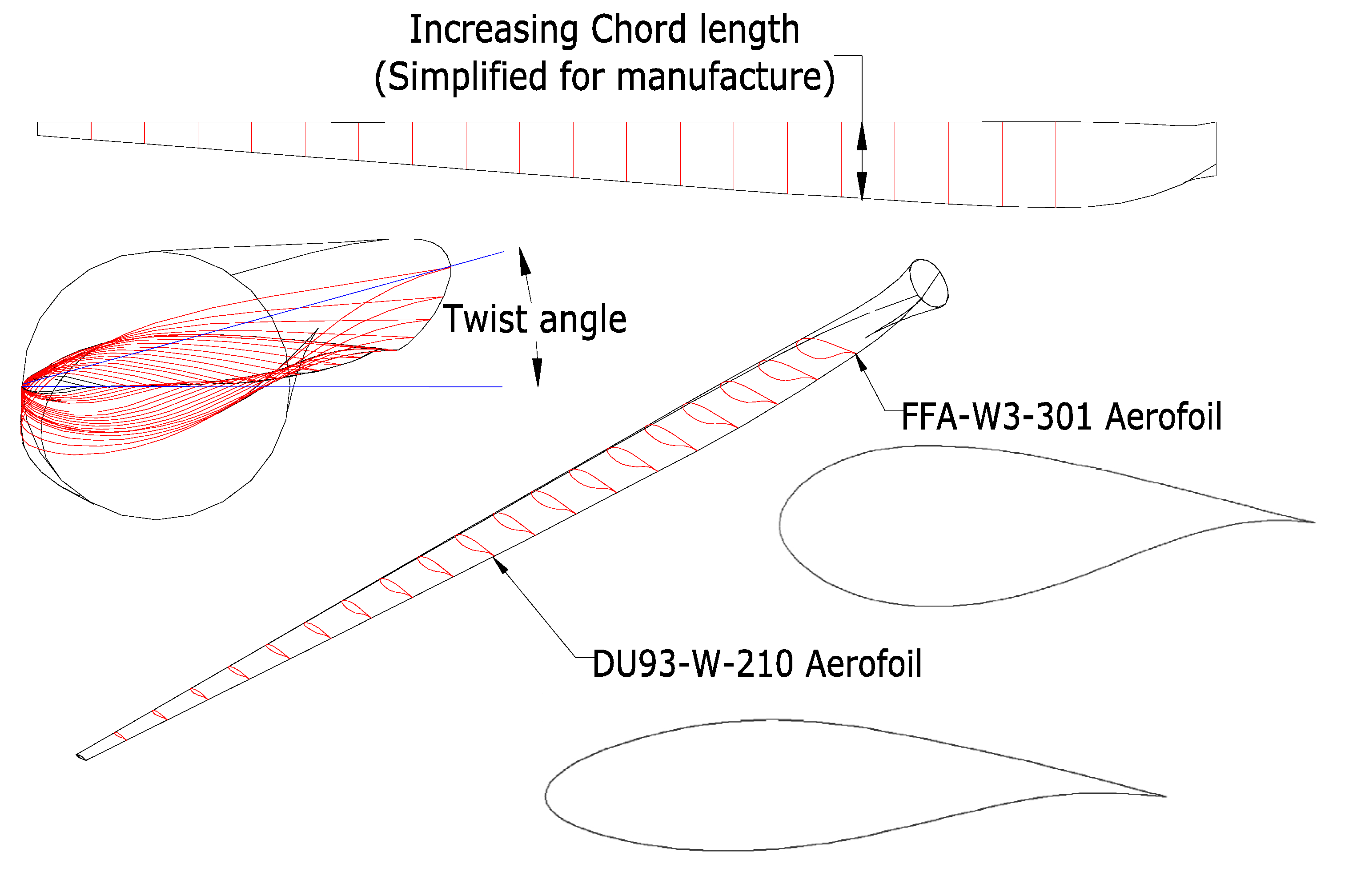

Why blades are tapered and twisted?

In the most of the application the rotor blades are tapered from hub to tip. This reduces the weight of the peripheral portions of the blade and hence the hub stress, which must be carried under the high rotational speeds, will be reduced [1].

Why are there teeth on wind turbine blades?

Halve the sound wind turbines make without any energy loss. Placing saw teeth on the blades of wind turbines is now possible. The saw teeth are designed by Stefan Oerlemans of the University of Twente and the National Aerospace Laboratory (NLR).

What is the best shape for turbine blades?

In generating electricity, a horizontal-axis turbine with a three-blade design is most efficient for energy production. However, other turbine and blade shapes may be better designed for production and durability in certain environmental conditions.

Can wind turbines have 4 blades?

With two blades you need significantly less material, construction and maintenance costs. A third or fourth rotor blade makes the wind turbine marginally more efficient, while the construction and material costs increase considerably. The four blades of our historic wind mills were more of a practical choice.

How fast do the blades on a wind turbine?

The rotational speed of the blades is usually between 30 and 60 revolutions per minute (rpm). This means that the tips of the blades are moving at between 1800 and 3600 rpm. The blades of a typical wind turbine are about 50 meters in length, so the tips of the blades are travelling at around 100 to 200 m/s.

How does the size and shape of the blade affect performance?

Blade designs may be altered in many ways, including overall size, shape, material, number of blades, and blade angle. These factors affect performance mainly by manipulating the surface area and mass of the blades. The greater the blade surface area, the greater the amount of energy that is captured by the blades.

Why is blade angle important?

Setting and maintaining the proper doctor blade angle is critical to maximize doctor blade performance. If a blade angle is not adjusted properly, the blade may wear too quickly or cause damage to the roll. It could even develop into a safety risk.

How does blades affect wind turbine?

The number of blades affected the rotation of the wind turbine. The results showed that by using more blades in the wind turbine, the wind turbine is easier to rotate at lower wind speeds, but a greater number of blades causes lower performance and higher torque [18].

Why is the blade twist important?

During the rotation the tips of the blades move at a faster pace than those areas near the hub. If the blade did not have twist all along from hub to the tip, there would be dissymmetrical rotation speed and consequently lift. Hence, the necessity for blade twist.

How heavy are wind turbine blades?

The blades of the Wikinger offshore wind farm, for example, have a lenght of 67.5 meters. The require specialised forms of transport that are capable of loading these structures and carrying them to their destination.

What is a blade made of?

Most blades are made with fibreglass-reinforced polyester or epoxy. Carbon fibre or aramid (Kevlar) is also used as reinforcement material. Nowadays, the possible use of wood compounds, such as wood-epoxy or wood-fibre-epoxy, is being investigated.

Why do wind turbines crack?

Wind turbine blades can suffer cracks, damage caused by the impact of lightning and birds or openings in the leading or trailing edge , among other damage. The repair tasks are performed by workers at height, who hang from the blades with ropes or are lifted up to them on suspended platforms.

What is the manufacturing phase of a blade?

Find out about the manufacturing phases of the blades. 1. Manufacturing of the beam: this is the inner part of the blade and is composed of materials formed of fibreglass and carbon pre-coated with epoxy resin - a thermostable polymer that hardens when mixed with a catalyst agent. 2.

Where is the Wind Farm in Spain?

Wind farm in Serra do Burgo (Orense, Spain).

What is a wind turbine blade?

Blades (wind turbine) Information. Wind turbine blades are airfoil-shaped blades that harness wind energy and drive the rotor of a wind turbine. The airfoil-shaped-design (which provides lift in a fixed wing aircraft) is used to allow the blades to exert lift perpendicular to wind direction. This force vector acts on the rotor and is ...

Why are wind turbine blades important?

Wind turbine blades are considered to be the most critical piece of a wind turbine. They are subject to enormous stresses and are manufactured to tight tolerances. They must be balanced and held to these tight tolerances in order to minimize any amount of vibration that would otherwise destroy the wind turbine.

Why do turbine blades have a twist?

As the tip of the blade travels much faster than segments of the blade closer to the hub of the rotor , the blades have incorporated a twist as to achieve an optimal angle of attack along the full length of the turbine blade. Straight blades are those that do not have a twist and are cheaper to manufacture. Image Credit: Murdoch University.

How does an oblique airfoil improve the life of a wind turbine?

The aerodynamics of wind turbine blades are optimized in a thin blade design, while the structural integrity of an oblique airfoil design increases the life expectancy and survival speed. These two extremes are carefully balanced as to optimize the efficiency of the turbine while increasing its life expectancy.

What is the tip speed ratio of a wind turbine?

The tip speed ratio of a wind turbine blade is the ratio of the speed of the tip of the blade to that of the wind. TSR is a vital design criterion for all lift-type wind turbines. As the blades of a wind turbine rotate they interact with the wind. If the rotation of the rotor is too slow, wind passes through the rotor swept area without interacting with the turbine blades. If the rotation is too fast then the rotor swept area acts as a barrier and deflects the wind, causing turbulence and loss of wind power. The optimal TSR for horizontal-axis, three blade turbines, which are predominantly used in onshore and offshore wind farms, is approximately 5:1 to 6:1.

What is a technical specification for wind turbines?

This technical specification provides guidelines for the full-scale structural testing of wind turbine blades and for the interpretation or evaluation of results, as a possible part of a design verification of the integrity of the blade.

How does wind affect airfoil?

Modern wind turbine blades have a twist along the length of the blade. The airfoil's optimal angle of attack is affected by the apparent wind direction. The apparent wind direction changes as the speed of blade increases, even when a uniform wind velocity exists across the rotor swept area. As the tip of the blade travels much faster ...

How are Wind Turbine Blades Made?

While the shape of the blade is made to specific standards, the actual crafting of the blade is made in a qualitative manner. That means that much is left to the discretion of the engineers and workers on site. Still, turbine manufacturers build their blades to rigorous standards to ensure maximum efficiency, as well as the safety of the workers both in the factory and on the field.

Why do turbine blades have slight twists?

This is to ensure that the blade captures the maximum amount of wind energy possible.

How are blades tested?

Once assembled, the blade goes through numerous tests and inspections. Engineers inspect the weak points of the blade for faults or cracks. The blades are then put through stress tests, where they are subject to a range of conditions they may experience while in use. This includes extreme temperatures, strong winds, and unusual movements.

How does the ratio of materials affect the size of a turbine?

The ratio of materials varies greatly according to the size of the turbine and its location. Turbines in areas with high wind speeds are going to be built much differently than turbines in low-wind speed areas. Furthermore, larger turbines are going to be built with stiffer blades. As the blades get longer, they are more likely to flex at the tips, so the ratio of materials must be adjusted to ensure that the blades don’t collide with the tower.

How does a wind turbine work?

Because of this, the cross-section isn’t entirely tubular; they have more of an oblong shape. The bottom of the blade deflects oncoming air, creating an area of high pressure. The top of the blade then cuts through the air as it’s pushed by the lift from the oncoming wind. This causes the rotor to spin.

What are blades subject to?

The blades are subject to immense pressures, and so must be built with materials that can withstand the stress. Source: Pixabay

What materials were used to make wind turbines?

Early wind turbine blades were made with aluminum. As time went on, engineers found that aluminum was too heavy and instead began using other materials like carbon fiber , glass fabric, and plastic.

How many blades are in a wind turbine?

The majority of wind turbines consist of three blades mounted to a tower made from tubular steel. There are less common varieties with two blades, or with concrete or steel lattice towers. At 100 feet or more above the ground, the tower allows the turbine to take advantage of faster wind speeds found at higher altitudes.

What is wind turbine?

What is a Wind Turbine? The concept of harnessing wind energy to generate mechanical power goes back for millennia. As early as 5000 B.C., Egyptians used wind energy to propel boats along the Nile River. American colonists relied on windmills to grind grain, pump water and cut wood at sawmills.

What is a lift based turbine?

Lift-based, or Darrieus, turbines have a tall, vertical airfoil style (some appear to have an eggbeater shape). The Windspire is a type of lift-based turbine that is undergoing independent testing at the National Renewable Energy Laboratory's. (link is external) National Wind Technology Center. (link is external) .

How does a wind turbine work?

Wind turbines operate on a simple principle. The energy in the wind turns two or three propeller-like blades around a rotor. The rotor is connected to the main shaft, which spins a generator to create electricity. Click NEXT to learn more.

What are vertical axis wind turbines?

While there are several manufacturers of vertical axis wind turbines, they have not penetrated the utility scale market (100 kW capacity and larger) to the same degree as horizontal access turbines. Vertical axis turbines fall into two main designs: 1 Drag-based, or Savonius, turbines generally have rotors with solid vanes that rotate about a vertical axis. 2 Lift-based, or Darrieus, turbines have a tall, vertical airfoil style (some appear to have an eggbeater shape). The Windspire is a type of lift-based turbine that is undergoing independent testing at the National Renewable Energy Laboratory's#N#(link is external)#N#National Wind Technology Center#N#(link is external)#N#.

What is the force of the wind on a rotor called?

When the wind blows, a pocket of low-pressure air forms on one side of the blade. The low-pressure air pocket then pulls the blade toward it, causing the rotor to turn. This is called lift. The force of the lift is much stronger than the wind's force against the front side of the blade, which is called drag.

How many kilowatts does a wind turbine produce?

Large wind turbines, most often used by utilities to provide power to a grid, range from 100 kilowatts to several megawatts. These utility-scale turbines are often grouped together in wind farms to produce large amounts of electricity.