What size OSB is used for walls?

What OSB to use on walls? Exterior Walls Minimum thickness to use on walls; 3/8″ plywood or 5/16″ OSB. If you are using fiber cement siding as a finish go with a min of 1/2″ plywood or 7/16″ OSB for the exterior walls.

What is a good wall thickness?

Though the building may still stand, 4″ thick walls offer minimum protection from weather, minimum thermal insulation, fire fire protection and earthquake resistance and is not recommended. All external walls should be at least 6″ thick. What is the minimum wall thickness?

What is the standard drywall thickness for interior walls?

What Is the Standard Drywall Thickness for Interior Walls?

- Standard Walls. The most common thickness of drywall used in residential interior construction is 1/2 inch. ...

- Curved Walls. Thin drywall, commonly 1/4- or 3/8-inch-thick, can be bent around curved surfaces. ...

- Fire Resistance. Fire-resistant drywall is available in both 1/2-inch and 5/8-inch. ...

- Wall Repair. ...

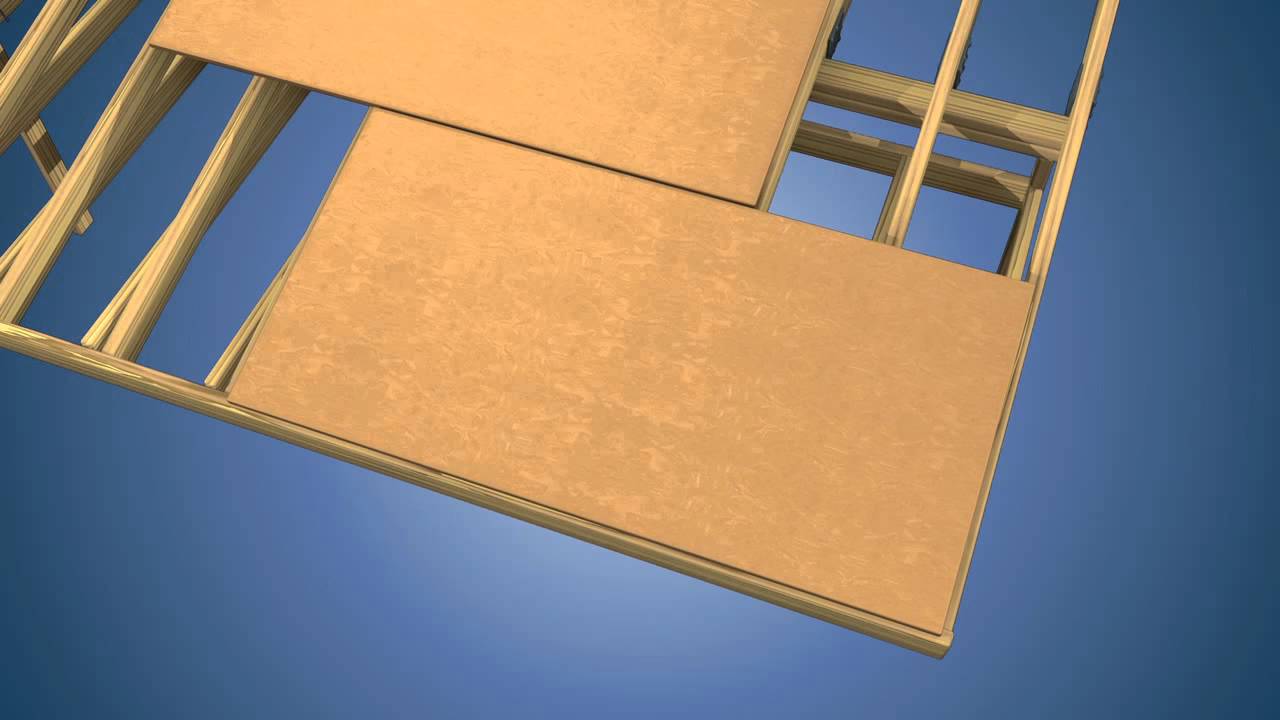

How thick should OSB subfloor be?

the subfloors need to be thicker. For joist spacing of more than 16 inches up to 19.2 inches on center, the minimum thickness for both plywood and OSB is 3/4 inch. For joists spaced more than 19.2 inches on center, the minimum thickness for plywood is 7/8 inch and for OSB, 1 inch.

What OSB thickness to use for the walls?

7/16”Minimum: 7/16” thickness. (Exception: 3/8” for gable end walls structural sheathing.)

Is 7/16 OSB good for exterior walls?

Exterior walls Minimum thickness of wall sheathing for use on walls; 3/8" plywood or 5/16" OSB. If you use fibre cement siding, go with 1/2" plywood or 7/16" OSB for the exterior walls. The wall sheathing can be nailed or stapled (check your local building code).

What size sheathing is standard for walls?

The International Residential Code specifies 3/8-inch plywood for sheathing walls with a standard stud spacing of 16 inches, if the siding is nailed to the studs through the sheathing.

Can you use 1/4 OSB for walls?

It's commonly used as an exterior sheathing and also offers benefits in a garage but can you actually use OSB for interior walls in your home? OSB can be used on interior walls since it is strong, durable, and provides structural support.

Which is stronger 3/8 plywood or 7 16 OSB?

OSB and plywood offer similar (and sufficient) performance in terms of strength and functionality, though plywood is about 7% stronger.

Can 7/16 OSB span 24 inches?

Wall panels 7/16 Category may be used on studs spaced up to 24” o.c.

What is the best sheathing for walls?

Plywood and OSB are largely considered the best wall sheathing choices because of their overall abilities to hold fasteners well, create a strong bond between studs, and provide some thermal advantages.

What thickness is wall sheathing?

For residential construction, the building code requirement typically is for a rated sheathing panel of either OSB or plywood of 0.95 cm (3/8 in) thickness when sheathing is required, as for shear wall sections; however, the common practice is to use sheathing thicknesses greater than code, which is referred to as “ ...

What is code for exterior wall sheathing?

1304.13 EXTERIOR WALL SHEATHING. (a) Wooden structural sheathing panels shall be installed on all exterior frame walls.

What is quarter inch OSB used for?

The most common uses are as sheathing in walls, flooring, and roof decking.

Can I use OSB instead of drywall?

OSB is a quite tough material compared to sheetrock. It is the best option in building structures like garages because of its resistance to damage. Normal garage activities will do very minimal damage to OSB. Thus, it would be advisable to go for OSB.

Why is there OSB behind drywall?

More than likely it was installed for backing for hanging garden tools, etc. or sound control between spaces. Remember, any wall between a garage and a habitable living space must have fire rated gypsum board (5/8” Type X or 1/2” Type C) on the garage side.

How thick are standard exterior walls?

External walls are generally 10 to 12 inches wide. Homes that are built with rammed earth or heavy exterior masonry will have thicker walls. There is no limit to how thick an exterior wall can be.

What type of sheathing is used for exterior walls?

Five common structural exterior sheathing options include wood-based, gypsum, glass mat, cement board, and Barricade® Thermo-Brace®. Plywood sheathing is made from whole sheets of wood that are cross-laminated, which give the boards strength and stiffness.

How thick is a 2x6 exterior wall?

This accounts for: 2x6 width: 5 ½ inches. Wall surface thickness on each side: 1 ¼ inches.

How thick are outside house walls?

However, the standard thickness of ICF exterior walls is 12 inches, reducing room sizes and minimizing the home's square footage. To maintain the original square footage of a building plan, you must increase the overall dimensions of the house, which also impacts the design of the roof and foundation.

What Is OSB?

It may lack a sleek polished veneer but exceptional engineering goes into making OSB. That said, OSB has a riveting texture that resembles a flattened hay bale, thanks to its unique construction process.

What is the best vapor barrier for sheathing?

Traditionally, fiberglass insulation and polyethylene were the go-to solutions. But OSB panels are increasingly becoming the most favored vapor barrier in the internal sheathing.

Why is OSB called oriented strands?

The strands are placed as alternating layers running parallel to each other; hence the name oriented strands. In essence, OSB uses the same manufacturing process as wafer boards, but the structure mimics the plywood. That’s because OSB panels are engineered to rival plywood’s stiffness and strength.

Why is OSB used in plywood?

That’s because OSB panels are engineered to rival plywood’s stiffness and strength. The engineering prowess that goes into making OSB makes it a more consistent and dependable construction material. Since each pile in OSB comprises bound stands, you can never have a soft spot on the panel.

How many NG is a perm?

The Canadian vapor barrier benchmark is expressed in Nanograms (NG). 1 US perm equals 57 NG, making for easier comparison.

What is OSB made of?

OSB is made from small, resinous fast maturing trees such as southern yellow pine, poplar, aspen, and some soft hardwoods, making it an eco-friendly building material. Soft hardwoods refer to physically soft hardwood species.

Why do you need interior wall sheathing?

An interior wall sheathing allows you to seal your home tightly, which improves your air exchanger’s efficiency. It also makes it easier for electricians, HVAC contractors, and drywall crew to carry out their work without punching holes into your air barrier.

How many inches of nailing on rim board?

Structural wood sheathing shall be nailed to the rim board if present with 8d ring shank or 10d nails at 4 inches on center along both the top and bottom edges of the rim board. See Figure 1.

What is a sheathed wall?

A fully sheathed wall of plywood or OSB, properly connected to the foundation below and roof above, is a strong barrier that resists the persistent forces of hurricanes, tornadoes, and high wind events. Wind loads are the most common loads that shear walls are designed to resist.

Why install plywood on exterior walls?

Install structural sheathing (plywood/OSB) in exterior walls to ensure the building will resist design wind pressures. This guide provides an overview of wood structural sheathing in exterior walls with a focus on applications in hurricane-prone regions or other high-wind areas.

What is coated sheathing?

Right – Coated sheathing is taped at all seams to serve as an exterior air barrier on the walls.

What is the wall impact resistance?

Wall Impact Resistance - Ensure that all exterior walls are constructed using a wall system that provides, at a minimum, the resistance to wind pressures and debris impact provided by 7/16-in.-thick OSB wood structural panels attached to wood wall framing.

How many fact sheets are there in the coastal residential report?

Report containing 37 fact sheets that provide technical guidance and recommendations concerning the construction of coastal residential buildings.

Do gable end walls need to be braced?

For Gable End Wall Bracing - Gable end walls need to be braced. See BASC Guide on Lateral Bracing Gable End Walls.

What is OSB?

You have probably seen OSB boards before when visiting your local home center or any construction site. Any home center will have OSB boards in different widths, thicknesses with some designed to be water-resistant and some just made to be dirt cheap.

Why use OSB instead of plywood?

Many people choose to use OSB instead of plywood because OSB is cheaper.

What is the standard OSB size?

Cut to size: OSB boards are cut to the wanted sizes. The most common size for OSB is 4x8ft (1220 x 2440 mm). But can be acquired in many different sizes depending on need and can even be custom ordered and cut.

What is OSB board?

OSB stands for oriented strand board and is an engineered wood used mainly in construction. OSB is made of large wood chips that are oriented in different directions, mixed with adhesives, and pressed to a board in a heat press. The standard size of OSB boards is 4 x 8 ft (1220 x 2440 mm ).

How much moisture is in OSB?

Stands Dried: The Wood strands of OSB are dried in huge tumble dryers to a moisture content of 4% to 8%

How thick are mats?

Mat Forming: The mix of adhesives and wood strands are formed into thick mats on conveyor belts. The mats are anywhere from 6 to 8 inches thick depending on the wanted thickness of the final board. The mat is separated at intervals and made ready for the press.

What is the first step in making OSB?

Logs Debarked: The first step of making OSB is acquiring the logs and debarking them. The bark is later used to create energy for the manufacturing process.