The textile industry has been a vital piece of the British economy for centuries. Through innovation and invention, the British led the world in textile production during the Industrial Revolution

Industrial Revolution

The Industrial Revolution, now also known as the First Industrial Revolution, was the transition to new manufacturing processes in Europe and the United States, in the period from about 1760 to sometime between 1820 and 1840. This transition included going from hand production methods t…

How did the British textile industry contribute to the Industrial Revolution?

With a wide range of new inventions that stretched from the availability of cotton to the steam engine, innovations to the British textile industry helped to propel Great Britain into the Industrial Revolution. The Industrial Revolution began in England in the late 18th century.

What was the textile industry like in the 1760s?

Before the 1760s, textile production was a cottage industry using mainly flax and wool. A typical weaving family would own one handloom, which would be operated by the man with help of a boy; the wife, girls and other women could make sufficient yarn for that loom.

Who invented textile machinery?

It was improved upon by William Horrocks, known for his invention of the variable speed batton in 1813. 1787 Cotton goods production had increased 10 fold since 1770. 1789 Samuel Slater brought textile machinery design to the US. 1790 Arkwright built the first steam-powered textile factory in Nottingham, England.

What was the most important textile in the 19th century?

Silk, wool, and fustian fabrics were being eclipsed by cotton which became the most important textile. Innovations in carding and spinning enabled by advances in cast iron technology resulted in the creation of larger spinning mules and water frames.

What inventions were made in England during the Industrial Revolution?

Inventors and Inventions of the Industrial RevolutionSpinning and weaving. ... The steam engine. ... Harnessing electricity. ... The telegraph and the telephone. ... The internal-combustion engine and the automobile.

What textile inventions were made during the Industrial Revolution?

1773 The first all-cotton textiles were produced in factories. 1779 Crompton invented the spinning mule that allowed for greater control over the weaving process. 1785 Cartwright patented the power loom. It was improved upon by William Horrocks, known for his invention of the variable speed batton in 1813.

What were the 5 major inventions in the textile industry?

Modern Textile Industry InventionsThe flying shuttle. This was an invention by John Kay in 1733 that used cords that were attached to a picking peg. ... The spinning jenny. ... The water frame. ... The spinning mule. ... The power loom. ... The cotton gin. ... The Jacquard loom. ... Synthetic dye.

What were three inventions most important in the textile production?

Which three inventions improved the textile industry? Several new inventions greatly increased productivity in the textile industry. They included the spinning jenny the spinning mule the cotton gin and the power loom. Steam power was also very important.

What were textiles in the Industrial Revolution?

Textile mills produced cotton, woolens, and other types of fabrics, but they weren't limited to just production. Textile mills brought jobs to the areas where they were built, and with jobs came economic and societal growth. During the Industrial Revolution, villages and towns often grew up around factories and mills.

How did the Industrial Revolution change textiles?

But, with the invention of the spinning wheel and the loom, cotton was produced quicker and eventually replaced wool in the textile field. This dramatically reduced production time and the cost to produce material and was the start of many drastic changes in the textile industry.

What was invented during Industrial Revolution?

Starting in the mid-18th century, innovations like the flying shuttle, the spinning jenny, the water frame and the power loom made weaving cloth and spinning yarn and thread much easier. Producing cloth became faster and required less time and far less human labor.

What were the specific inventions of the 1700s that revolutionized textile manufacture in Britain?

Elements of the Industrial Revolution Cotton spinning using Richard Arkwright's water frame, James Hargreaves' Spinning Jenny, and Samuel Crompton's Spinning Mule (a combination of the Spinning Jenny and the Water Frame). This was patented in 1769 and so came out of patent in 1783.

Why were inventions important in the Industrial Revolution?

New inventions and technologies played an important role in the Industrial Revolution. They changed the way things were powered, how goods were manufactured, how people communicated, and the way goods were transported.

What inventions transformed the textile industry quizlet?

Textile worker that invented the Spinning Jenny. It allowed spinning of 8 threads simultaneously. Combined both Arkwright's and Hargreaves's inventions to produce the Spinning Mule. It made stronger, finer, and more consistent thread.

How the inventions in the textile industry revolution is the production of cotton cloth?

The invention of Spinning Jenny, Spinning Mule leads to the revolutionising the production off the cotton cloth. At the time of Industrial Revolution, James Hargreaves invented a hand powered spinning wheel, the Spinning Jenny, to create multiple spools of thread at once.

When was the textile industry invented?

The industrial revolution started in Great Britain in the mid-1700s. Textile production was the first great industry created. The textile industry in America began in New England during the late 18th century.

What was the main industry of the Industrial Revolution?

Textiles were the main industry of the Industrial Revolution as far as employment, the value of output and capital invested. The textile industry was also the first to use modern production methods. The Industrial Revolution began in Great Britain and most of the important technological innovations were British.

Who covered the inventions of the Industrial Revolution?

Textile Industry and Machinery of the Industrial Revolution. Mary Bellis covered inventions and inventors for ThoughtCo for 18 years. She is known for her independent films and documentaries, including one about Alexander Graham Bell.

What was the Industrial Revolution?

The Industrial Revolution was the transition to new manufacturing processes in the period from about 1760 to sometime between 1820 and 1840. During this transition, hand production methods changed to machines and new chemical manufacturing and iron production processes were introduced. Water power efficiency improved and the increasing use ...

Who invented the power loom?

1785 Cartwright patented the power loom . It was improved upon by William Horrocks, known for his invention of the variable speed batton in 1813. 1787 Cotton goods production had increased 10 fold since 1770. 1789 Samuel Slater brought textile machinery design to the US.

Who invented the cotton gin?

1792 Eli Whitney invented the cotton gin : the machine that automated the separation of cottonseed from the short-staple cotton fiber. 1804 Joseph Marie Jacquard invented the Jacquard Loom that weaved complex designs.

Who invented the spinning Jenny?

1764 Spinning jenny invented by James Hargreaves: the first machine to improve upon the spinning wheel. 1764 Water frame invented by Richard Arkwright: the first powered textile machine. 1769 Arkwright patented the water frame. 1770 Hargreaves patented the Spinning Jenny.

Where was textiles made during the Industrial Revolution?

Textile manufacture during the Industrial Revolution in Britain was centred in south La ncashire and the towns on both sides of the Pennines. In Germany it was concentrated in the Wupper Valley, Ruhr Region and Upper Silesia, in Spain it was concentrated in Catalonia while in the United States it was in New England.

What were the most important textiles?

Silk, wool, and linen fabrics were being eclipsed by cotton which became the most important textile. Innovations in carding and spinning enabled by advances in cast iron technology resulted in the creation of larger spinning mules and water frames. The machinery was housed in water-powered mills on streams.

When was cotton spinning invented?

Cotton spinning using Richard Arkwright 's water frame, James Hargreaves' Spinning Jenny, and Samuel Crompton's Spinning Mule (a combination of the Spinning Jenny and the Water Frame). This was patented in 1769 and so came out of patent in 1783.

How did railroads improve the lives of people?

Railroads, steam boats, the telegraph and other innovations massively increased worker productivity and raised standards of living by greatly reducing time spent during travel, transportation and communications.

Why did steam engines work?

The steam engine also overcame the shortage of water power for iron works.

What was the first industrial action in Scotland?

At times, the workers rebelled against poor wages. The first major industrial action in Scotland was that of the Calton weavers in Glasgow, who went on strike for higher wages in the summer of 1787. In the ensuing disturbances, troops were called in to keep the peace and three of the weavers were killed.

How did the nature of work change during industrialisation?

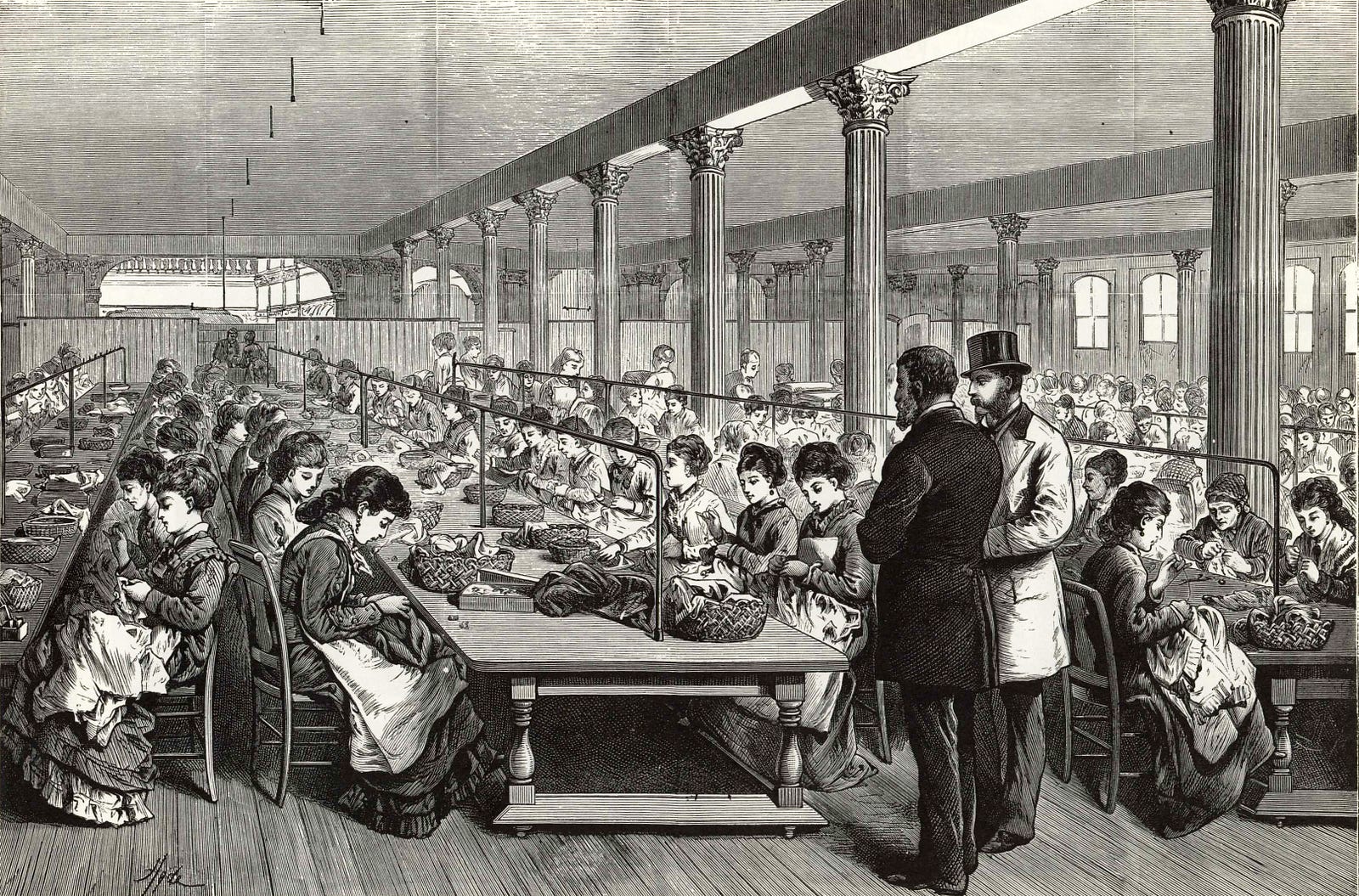

The nature of work changed during industrialisation from a craft production model to a factory-centric model. It was during the years 1761 to 1850 that these changes happened. Textile factories organized workers' lives much differently from craft production. Handloom weavers worked at their own pace, with their own tools, and within their own cottages. Factories set hours of work, and the machinery within them shaped the pace of work. Factories brought workers together within one building to work on machinery that they did not own. Factories also increased the division of labour. They narrowed the number and scope of tasks. They included children and women within a common production process. As Manchester mill owner Friedrich Engels decried, the family structure itself was "turned upside down" as women's wages undercut men's, forcing men to "sit at home" and care for children while the wife worked long hours. Factories flourished over manual craftsmanship because they had more efficient production output per worker, keeping prices down for the public, and they had much more consistent quality of product. The work-discipline was forcefully instilled upon the workforce by the factory owners, and he found that the working conditions were poor, and poverty levels were at an unprecedented high. Engels was appalled, and his research in Derby played a large role in his and Marx's book ' Das Kapital '. At times, the workers rebelled against poor wages. The first major industrial action in Scotland was that of the Calton weavers in Glasgow, who went on strike for higher wages in the summer of 1787. In the ensuing disturbances, troops were called in to keep the peace and three of the weavers were killed. There was continued unrest. In Manchester in May 1808, 15,000 protesters gathered on St George's Fields and were fired on by dragoons, with one man dying. A strike followed, but was eventually settled by a small wage increase. In the general strike of 1842, half a million workers demanded the Charter and an end to pay cuts. Again, troops were called in to keep the peace, and the strike leaders were arrested, but some of the worker demands were met.

Overview

Early inventions

Prior to the start of the Industrial Revolution in the late 18th century, Mughal India was the most important manufacturing center in world trade, producing about 25% of the world's industrial output, with the Mughal Bengal province prominent in the textile manufacturing industry. Real wages in 18th century southern India were also comparable to those in southern England at the time. In early …

Elements of the Industrial Revolution

The commencement of the Industrial Revolution is closely linked to a small number of innovations, made in the second half of the 18th century:

• Textiles – John Kay's 1733 flying shuttle enabled cloth to be woven faster, of a greater width, and for the process to later be mechanised. Cotton spinning using Richard Arkwright's water frame, James Hargreaves' Spinning Jenny, and Samu…

Industry and invention

Before the 1760s, textile production was a cottage industry using mainly flax and wool. A typical weaving family would own one handloom, which would be operated by the man with help of a boy; the wife, girls and other women could make sufficient yarn for that loom.

The knowledge of textile production had existed for centuries. India had a textile industry that used cotton, from which it manufactured cotton textiles. When raw cotton was exported to Europe it c…

Working practices

The nature of work changed during industrialisation from a craft production model to a factory-centric model. It was during the years 1761 to 1850 that these changes happened. Textile factories organized workers' lives much differently from craft production. Handloom weavers worked at their own pace, with their own tools, and within their own cottages. Factories set hours of work, and the machinery within them shaped the pace of work. Factories brought workers tog…

A representative early spinning mill 1771

Cromford Mill was an early Arkwright mill and was the model for future mills. The site at Cromford had year-round supply of warm water from the sough which drained water from nearby lead mines, together with another brook. It was a five-storey mill. Starting in 1772, the mills ran day and night with two 12-hour shifts.

It started with 200 workers, more than the locality could provide so Arkwright b…

A representative mid-century spinning mill 1840

Brunswick Mill, Ancoats is a cotton spinning mill in Ancoats, Manchester, Greater Manchester. It was built around 1840, part of a group of mills built along the Ashton Canal, and at that time it was one of the country's largest mills. It was built round a quadrangle, a seven-storey block faced the canal. It was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. Production finished in 1967.

Export of technology

While profiting from expertise arriving from overseas (e.g. Lewis Paul), Britain was very protective of home-grown technology. In particular, engineers with skills in constructing the textile mills and machinery were not permitted to emigrate — particularly to the fledgeling America.

Horse power (1780–1790)

The earliest cotton mills in the United States were horse-powered. The first mill to use this metho…