A Mortise and Tenon joint is commonly used for tables, chairs, doors, beds, windows, frames, cabinets, paneling and any other kind of furniture. It comprises both a mortise (hole) and a tenon

Mortise and tenon

The mortise and tenon joint has been used for thousands of years by woodworkers around the world to join pieces of wood, mainly when the adjoining pieces connect at an angle of 90°. In its basic form it is both simple and strong. Although there are many joint variations, the basic mortis…

Full Answer

How tight should a mortise and tenon be?

Some say hand tight as above - that is the tenon should slide easily into the mortise, and some say it should be tight enough to require some kind of pounding to get it together. Most will argue that it should be at least snug. Visible gaps are not good.

How to make a wedged through mortise and tenon?

Make Super-Strong Through Mortises & Tenons

- Joint-sizing pointers. Through-mortise-and-tenon joints typically go together one of the two ways shown above. ...

- Begin with the mortises. Tenons can be fine-tuned easier than mortise widths, so cut your mortises first and match the tenons to them.

- Cut tenons to fit. ...

- Finish tenon and assemble. ...

How to cut a through mortice and tenon by hand?

Step – by – Step Instructions

- Prepare all the things you will need for the project. Make sure that everything you need is at hand and have been carefully maintained. ...

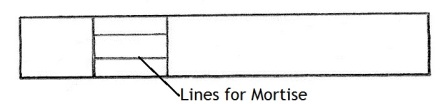

- Mark the wood in close approximation where the mortise hole is going to be placed and where the tenon joint will be. ...

- Use a square to make sure that everything lines up. ...

How do Morton and tenon joints work?

The mortise and tenon joint functions by inserting one end of a piece of wood into a hole in another piece of wood. It's that simple. The smaller end of the wood is the "tenon," and the wood with the hole in it is referred to as the "mortise."

How many parts are in a mortise and tenon?

While it may seem a bit over the top, there are at least nine parts to label when it comes to a run of the mill mortise and tenon. Do you need to know all these terms to make a successful mortise and tenon? The answer is no, but the nomenclature helps you to understand the geometry of the joint and how it can vary from use to use. For lack of a better term, we call this the anatomy of the joint, and some of the names are actually derived from our human anatomy. The specific name of the mortise/tenon piece depends on its use or function and its orientation. Most commonly, the mortise piece is usually an upright piece like a stile, while the tenon piece is usually a horizontal piece, such as a stretcher, rail or apron. This drawing will illustrate the various parts and where they occur.

What is the difference between a tenon and a mortise?

The specific name of the mortise/tenon piece depends on its use or function and its orientation. Most commonly, the mortise piece is usually an upright piece like a stile, while the tenon piece is usually a horizontal piece, such as a stretcher, rail or apron.

What is the best way to join end grain to long grain?

Joining end grain to long grain forms the king of joints. A mortise and tenon is one of the most ubiquitous and useful means to join wood together. Primarily used in solid wood woodworking to join end grain to edge grain, or long grain, it is a time-honored and proven technique. A mortise and tenon joint is, at its most basic, a peg fit into a hole.

Is the nomenclature of a joint derived from human anatomy?

For lack of a better term, we call this the anatomy of the joint, and some of the names are actually derived from our human anatomy.

What is the function of a mortise and tenon joint?

The mortise and tenon joint functions by inserting one end of a piece of wood into a hole in another piece of wood. It's that simple. The smaller end of the wood is the "tenon," and the wood with the hole in it is referred to as the "mortise.".

How long have mortise and tenon joints been used?

There's a reason the mortise and tenon joint has been used for thousands of years —it can be carved using basic woodworking tools and it'll last for ages. The mortise and tenon woodworking joint has been used around the world for thousands of years —for good reason. It's considered one of the strongest woodworking joints for attaching two pieces ...

What is the strongest joint?

The mortise and tenon woodworking joint has been used around the world for thousands of years—for good reason. It's considered one of the strongest woodworking joints for attaching two pieces of wood at 90 degrees. While not as visually appealing as dovetail joints, the mortise and tenon joint can be used by woodworkers ...

What tool is used to cut mortise?

A router with an upspiral bit is the preferred power tool for cutting a mortise, and an edge guide attached to the router base ensures a straight cut. A woodworking work bench with a vise makes this process much easier.

How thick should a tenon be for mortise?

A rule of thumb for cutting tenons is that they should be equal half the thickness of the board, and tenon length should be 4 to 5 times the thickness of the tenon.

What blade do you use to cut tenons?

For cutting tenons, a table saw with a dado blade and tenoning jig can cut the tenons quickly and accurately each time. This is essential when building larger pieces of furniture that need exact cuts each time.

Can you cut mortise and tenon by hand?

Like the dovetail joint, a mortise and tenon can be carved by hand, but that requires a certain skill level and aptitude for using a wide variety of hand tools. The easier and less time consuming way of cutting mortise and tenon joints is by using power tools.

Why did Chinese use mortise joints?

This is specified during the beginning of Linear Pottery Culture — literally when humans began fabricating dishware and art out of ceramic! In traditional Chinese architecture, the mortise and tenon joint was utilized because it allowed for the woods’ expansion during periods of great humidity.

Where were tusked joints used?

If we keep going back to about 7,000 years ago, tusked joints (which will be explained further right below) were used to create a wooden well near Leipzig – this is a place in Germany that hosts the oldest standing wooden architectures.

Where Are They Used?

They are one of the most common and strongest types of wood joinery. They can be used truly anywhere. It is after all a peg in a hole!

What is a half dovetail mortise?

Wedged Half Dovetail Mortise: a mortise that has a back that is wider or taller than the opening. This leaves space to insert the tenon and is reinforced to prevent withdrawal. Through Wedged Dovetail: exact same design as the mortise just explained, but it passes entirely through the workpiece.

What was the first wood joinery?

The mortise and tenon joint is probably the very first method of wood joinery ever used, and today we’re going to figure out all the details about it.

What is the second strongest joint?

Coming in second place next to the dovetail joint, the mortise and tenon joint is the second strongest joint there is! It is a joint that is made when bringing to union two pieces of material at a right angle. This is a method used for thousands and thousands of years by woodworkers due to its simplicity and strength.

How are tenon tongues connected?

Usually, in the shape of a square or rectangular, the two members’ ends are connected by glue or a locking mechanism. The tenon tongue usually comes equipped with shoulders the seat into place when joined with the mortise hole. (The mortise isn’t only dedicated to wooden pieces either!

What is a mortise and tenon joint?

A mortise and tenon joint is a means of joining two pieces of wood at an angle (usually 90°) to each other. A protruding tenon, cut at the end of one piece, fits into a corresponding recess, called a mortise, in the other.

What is a tenon cut?

The tenon, cut on the end of the mating piece, should be marked out to the same dimensions as the mortise, but cut a little “fat”, then pared down with a shoulder plane or wide chisel to fit the mortise exactly. The mortise and tenon joint is also commonly cut by machine.

What is a tenon shoulder?

The plain mortise-and-tenon joint has a tenon set back from the edges of the material. This setback, or ledge, is called a shoulder. The shoulders add strength to the construction and prevent wracking. They also cover up any flaw in the mortise. A mortise and tenon could have one, two, three, or four shoulders.

How many shoulders does a tenon have?

They also cover up any flaw in the mortise. A mortise and tenon could have one, two, three, or four shoulders. This variation on the joint might be employed when a smaller, narrower member is set into a larger member, surface or panel. The haunched tenon has a short projection in place of a short end shoulder (a portion of the tenon is cut away).

Why do you need a haunch on a plow?

Another reason for the haunch is to add strength and prevent the joint from twisting. For extra holding power, mortise and tenon joints also can be pinned or wedged. Pegs driven through offset holes make this drawbored mortise and tenon joint extra strong.

How thick should a mortise be?

Usually, the mortise is centered on the thickness of the material and is 1/3 its thickness. It should be set in 1/4 in. to 1/2 in. from the end of the workpiece. This “set-in” prevents the end of the mortise from splitting.

What makes a drawbored joint extra strong?

Pegs driven through offset holes make this drawbored mortise and tenon joint extra strong.

What are a mortise and tenon joint?

A mortise and tenon joint is a type of joint used in woodworking. It is made by cutting a hole in one piece of wood, then inserting a dowel or peg into the hole and turning it until the two pieces fit together.

Why use a mortise and tenon joint?

A mortise and tenon joint is a joint that is made between two pieces of wood by inserting a peg into a hole in one piece, then driving a tenon into the other piece. This joint is strong and can be used to build furniture, cabinets, and other items.

tips for making a perfect mortise and tenon joint

When making a mortise and tenon joint, it is important to follow a few simple guidelines to ensure a perfect fit.

Conclusion

Mortise and tenon joints are one of the most common joint types in woodworking. They are often used to join two boards of different thicknesses together. In this tutorial, we will show you how to make a mortise and tenon joint.

What is mortise and tenon joint?

It is very commonly used to join rails to the legs of tables or chairs, or fixed shelves to the sidewalls of cabinets or bookcases.

When creating mortise and tenon joints, what is the best rule of thumb?

A good rule of thumb when creating mortise and tenon joints is to cut the mortise first, then the tenon. Leave the tenon a little bit fat for the first test fitting. It's always better to shave down a tenon that is too large than to cut it too narrow and find that you have a sloppy fit.

What is a mortise bit?

Today, many woodworkers use a dedicated mortiser, which employs a drill bit encased inside a four-sided chisel. Many drill press manufacturers offer optional mortising attachments, making the drill press a much more versatile machine. There are also mortising attachments that can be used with a plunge router.

How to glue a mortise?

Once all joints have been formed and its time for assembly, apply glue to both the tenon and inside walls of the mortise. Coat all surfaces evenly with glue using a small brush. Assemble the pieces, tapping them together with a wooden mallet, if necessary. Let the glue dry completely before continuing assembly.

How to cut a mortise with a plunge router?

To cut a mortise using a mortiser, simply mark the position of the area to be cut, and then sink the bit into the material, taking small bites at a time.

Which joint is strongest when the two pieces of stock are at right angles to one another?

Bear in mind that the joint is strongest when the two pieces of stock are at right angles to one another. Mortise-and-tenon joints depend on great precision when outlining and cutting the tenon on one piece of the stock and the mortise on the adjoining piece.

Can a tenon be cut by hand?

Typically, the tenon is little more than a rectangular pin cut from the end of the stock. While tenons can be cut by hand, modern woodworkers will often employ a band saw or a tenoning jig on a table saw to safely form the tenon.

What Is a Wedged Mortise and Tenon Joint?

Before we go over what this type of joint is, it might help to know what a basic mortise and tenon joint is.

When making a mortise and tenon joint, is it better to cut the mortise first or?

When creating any mortise and tenon joints, it’s always better to cut the mortise first and the tenon second. It’s a lot easier to adjust a tenon to fit a mortise; you can always cut a tenon smaller if it’s too big or use larger wedges to compensate if it’s too small. A mortise can only be adjusted to make it bigger, not smaller.

How many wedges are used in a tusk tenon joint?

This is basically the same idea as the standard tusk tenon joint, except instead of one large wedge inserted through the tenon, this design uses two smaller wedges inserted from opposite sides of the wedge mortise.

What is the advantage of a wedged mortise?

The advantage of wedged mortise and tenon joints over basic ones is that because the pieces of wood are not glued together, you can easily disassemble the joint by removing the wedges.

How far should a tenon stick out from a joint?

As for how far your tenon should stick out from the joint, that’s up to you. For a basic wedged mortise and tenon joint, the tenon can either be flush with the joint or stand out. For other types of wedged mortise and tenon joints, the tenon needs to protrude a little bit from the joint. We’ll discuss these other types later.

How many kerfs do you need to cut a tenon?

After cutting the basic shape of the tenon, you need to cut two stress-relief holes and two kerfs. The kerfs allow you to slide wedges into the joint, while the stress-relief holes allow the tenon to flex without splitting.

What is a mortise in woodworking?

The mortise, which is a hole carved into one of the wood pieces. The mortise may be square-cut, or it may have flared edges depending on the type of tenon being used.

What is mortise and tenon joint?

The mortise-and-tenon joint is fundamental in woodworking. Along with the dovetail, this joint has been used for thousands of years. If you judge by the number of devices and methods developed to avoid making mortises, you might think it difficult and demanding. In truth, a mortise is just a square hole.

Which is stronger, mortise or tenon?

Through-mortise-and-tenon joints are the strongest, but if you can’t (or choose not to) go clear through, two-thirds the width of the mortised piece is a reasonable target.

How much thickness should a mortise be?

The width and depth of the mortise are equally important. When planning a joint, take no more than one-third the thickness of the mortised piece, and make the mortise as deep as you can. The strength of the joint is mainly a function of how far into the mortised piece the tenon goes.

How to make a mortise?

There are two steps to making a mortise – removing the waste and tidying up the edges. The mass of a mortise chisel helps considerably, and if the wood is soft and agreeable, you can hand-chop a mortise in a short amount of time. If the wood is hard, or the mortises many, you’ll find yourself in the position of your ancestors – wishing for a more expedient way.

Why does my mortise bit make a noise?

As the bit chews up the wood inside the mortise, the chips must move up through the chisel to escape. Leave enough of a gap to provide room and give the bit a head start on the chisel. If the machine makes a chattering noise or starts to burn, the bit is set too close; it’s choking off the escape route for the waste.

How strong is a tenon?

The tenon will be strongest the closer it is to the size of the piece on which it is made. Make the tenon as wide and thick as possible, and at least half as wide as the overall width of the workpiece. There are five surfaces in a typical mortise. Two of them need to fit just right for the joint to work.

What size drill do you use for a mortise?

Because you won’t have the control you would have with a stationary machine, use a bit that is 1⁄16“-1⁄8” smaller than the width of the mortise. As with the chisel, the important thing is to keep the bit plumb side-to-side, and you can easily see that from the end of the mortise.

Explaining The Mortise & Tenon

Okay But, How Long Have They Been Around…

- Y’know Stonehenge? Yes, that Stonehenge. Well, the whole reason behind why we still get to stand in front of those awe-inspiring and slightly creepy figures is thanks to the mortise and tenon joint. This type of joinery has clearly been around for a long time… Archeologists have fun mortise and tendon joints in water wells that were built in the Early Neolithic period… This is specified during …

The Types

- Types of Mortises

Open Mortise:a mortise that has 3 visible sides Stub Mortise:a mortise that does not pass through the workpiece, is rather shallow (its depth depends on the width of the workpiece) Through Mortise:very simple, a mortise that passes entirely through a workpiece Wedged Half Dovetail M… - Types of Tenons

Stub Tenon:a tenon shorter than the width of the mortised member, so that the tenon doesn’t show Through Tenon:tenon that passes through the workpiece and its end is entirely visible Loose Tenon:a separate limb of the joint that is later added on (not originally fabricated from the workp…

Where Are They used?

- They are one of the most common and strongest types of wood joinery. They can be used truly anywhere. It is after all a peg in a hole! We already learned all of the traditional ways in which they were used, but today the mortise and tenon joint is used in the construction of chairs, tables,frames, doors, windows, cabinets, you name it! It can be jo...

FAQ

- Is a mortise and tenon joint strong?

Absolutely! Second to the dovetail joint, it’s the strongest. This is due to the fact that weight and pressure are evenly distributed throughout the entire material, strain is not in one concentrated location. - What can a mortise and tenon joint be used for?

Almost any type of wood joinery can use the mortise and tenon joint. Any type of furniture making, doors, windows, etc..