Process variables for submerged arc welding

- Flux. The granular flux used in SAW has different compounds such as lime, silica, calcium fluoride, oxides of calcium and manganese, zirconium, aluminum, etc.

- Wire electrode. The composition of the wire electrode is solely dependent on the workpiece metal, and the wire electrode may have alloying elements as needed.

- Current and voltage. ...

- Travel speed. ...

What are covered electrodes in arc welding?

The covered sort of electrode is a kind of popular style of filler material in the arc welding process. The electrode covering’s composition determines the utility of the electrode, and specification deposited material decides the electrode. The category of electrode used largely depends upon the special properties within the weld deposit required.

What materials can a submerged arc welding machine Weld?

In addition, scientists used the SAW to weld certain copper alloys, nickel alloys, and even uranium in specific experiments. When there is no specific edge preparation, the submerged arc process can join materials 1/16 to 1/2 in thick. However, using an adequate edge preparation with constant voltage, single-pass on material from 1/4 to 1 in.

What type of electrodes are used for welding stainless steel?

Low hydrogen type electrodes are used for welding stainless steel. Iron oxide sodium (EXX20) – The high content of iron in the coatings produces a weld deposit that generates a bigger slag and is even difficult to control. This coating produces faster deposition with medium penetration and low spatter level and a very smooth finish in welding.

What are welding electrode coatings?

They base the formulation of welding electrode coatings on the established principle of metallurgy, physics, and chemistry. The coating is there to protect from damage, arc stabilization, improves the welding in the following ways.

What type of electrode is used in submerged arc welding Mcq?

Submerged arc welding: In submerged arc welding the arc is completely submerged into the granular flux powder and forming a blanket. Tungsten inert gas welding: In this type of welding non-consumable tungsten electrode will be used to generate the arc.

What equipment is used in submerged arc welding?

A welding machine or power source. Electrode material. Welding head and control system. Welding torch for automatic welding or the welding gun and cable assembly for semiautomatic welding.

What is submerged metal arc welding?

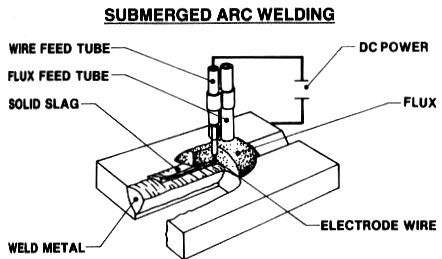

Submerged-arc welding (SAW) is a common arc welding process that involves the formation of an arc between a continuously fed electrode and the workpiece. A blanket of powdered flux generates a protective gas shield and a slag (and may also be used to add alloying elements to the weld pool) which protects the weld zone.

Which type of welding electrode is used?

Consumable Electrodes. The consumable electrode is the most common type of electrode and is used both by Metal Inert Gas (MIG) welders and Shielded Metal ARC Welders (SMAW, also known as stick welders, and arc welders). Unlike non-consumable electrodes, consumables melt during the welding process.

Where is submerged arc welding used?

What is the saw welding process used for? The industries where long wedding in the thick steels are required. The process involves making a joint between steel components using the electric arc submerged under a blanket of flux.

What type of electrode is used in SAW?

SAW strip-cladding utilizes a flat strip electrode (e.g. 60 mm wide x 0.5 mm thick). DC or AC power can be used, and combinations of DC and AC are common on multiple electrode systems.

What is the difference between arc welding and submerged arc welding?

The difference between submerged arc welding and regular arc welding is that the welding wire, arc, and weld joint are covered by a layer of flux. The flux creates a pathway for the arc to travel through to the material that is being welded.

What is the difference between DCEN and DCEP?

The DCEN mode is often used on open root runs to reduce the risk of burn-through, whereas DCEP is used to reduce the risk of lack of fusion defects. DCEN can also be used for surfacing applications in order to minimise penetration, and thin sheet welding.

Is submerged arc welding done underwater?

The underwater submerged-arc welding (USAW) process was innovatively developed. A mixture of epoxy resin and submerged-arc flux was employed. The process stability and weld formation was enhanced. Weld metal microstructure consists of pro-eutectoid ferrite and acicular ferrite.

What are the 5 types of electrodes?

Electrodes can be grouped into different types which include:Metal-metal ion electrode.Metal-insoluble salt electrode.Metal-amalgam electrode.Gas-ion electrode.Redox electrode.

What is 6010 welding rod used for?

Combined, these attributes are why E6010 electrodes are specified for pipe welding, as well as for applications such as field construction, ship yards, water towers, pressure vessels, pressure pipes, steel castings and steel storage tanks. Many of the applications for E6010 electrodes require 100 percent penetration.

What are the 2 types of electrode?

There are mainly two types of electrodes namely reactive and inert electrodes.

What is the current used in submerged welding?

The submerged arc welding process uses either direct or alternating current, but the direct current is used for most of the applications. Both direct current electrode positive (DCEP) and direct current electrode negative (DCEN) are used.

What is the most common method of welding?

The popular methods of SAW applications are Machine Method and Automatic Method. The machine method is the most common method where the operator keeps a watch on the welding operation. The automatic method is by push-button technique and the process applied semi-automatically but not a very popular method of SAW welding.

What is SAW welding?

Submerged arc welding (SAW) is a welding process where the tubular electrode is fed continuously to join two metals by generating heat between electrode and metal. The area of the arc and molten zone gets its protection from the atmospheric contamination by submerging under a blanket of granular flux.

What is the most important variable that affects welding heat?

The important variable that affects the welding heat includes the welding current, voltage, travel speed . The welding current is of prime importance as for single-pass weld the current should be enough for sufficient penetration without burning of the base metal.

What is the normal distance between the tip and arc of an electrode?

The normal distance between tip and arc is 25-38 mm.

What is the effect of travel speed on welds?

Travel speed has an influence on the weld bead and penetration. The higher the speed, the thinner is the bead with less penetration. This is an ideal situation in sheet metal where a small bead with minimum penetration is needed. Too fast speed may produce undercuts and porosity because of faster freezing. Too slow speed creates bad beads, excessive spatter, and flash.

Is a weld bead bigger than a submerged bead?

The weld bead is much bigger with submerged arc welding compared to any other arc welding. The heat input is much higher so its cooling takes longer. The gases have enough time to escape. The slag here has a lower density and floats out to the top of the bead. The automatic process offers uniformity and consistency.

What is the wire electrode used for welding?

Wire electrodes are available for welding mild steels, high or medium carbon steels, low, medium, special alloy steels, and stainless steels. Wire electrode is normally coated with copper to improve its electrical conductivity and to prevent rusting. The diameter of the wire electrode can be 1.6 mm to 6.4 mm. The approximate requirement of current to weld 1.6 mm electrode is 150-350 amps, 3.2 mm electrode is 250-800 amps, and 6.4 mm electrode is 650-1350 amps.

What is arc welding?

All arc welding processes, including the submerged arc welding, use the heat (thermal energy) generated by the arc between an electrode (consumable or non-consumable) and the workpiece to melt the workpiece surface and the filler metal, creating the molten weld metal pool. However, each arc welding process has its distinct features. An effort is made to compile the difference between submerged arc welding (SAW) and shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and gas tungsten arc welding (GTAW).

What happens to the weld before SAW?

Before starting the SAW process, the initial weld length is filled with a layer of flux. When the welding starts, the welding head starts pouring the granular flux, and the welding arc moves along the weld line completely submerged under cover of the flux. As the welding progresses along the length, the molten weld metal covered by the liquid flux cools and solidifies to create a weld bead with a protective slag above it.

How does a flux hoper work?

This system will have an automatic feed of flux, wire electrode and has a flux recovery system. The flux hoper is attached to the front of the welding head and has magnetically controlled valves that can be opened or closed by the control system. The wire electrode is continuously fed at a set (predetermined) speed. A separate drive system moves the welding head over the stationary workpiece, or the workpiece is moved or rotated below a stationary welding head.

Why is submerged arc welding bad?

These issues may happen due to the wrong settings of weld parameters or other issues.

Why is safety important in welding?

Hence, even in SAW, the welder has to wear his/her welding gear and strictly follow all the safety guidelines specified by the manufacturer of the SAW system and the local government safety laws .

What is travel carriage welding?

Travel carriage. The travel carriage can be a simple tractor or a complex, specialized system. In submerged arc welding, there can be two arrangements: The welding head mounted on the tractor moves over the weld length, and the workpiece is stationary.

What is a welding electrode?

A metal wire coated with a similar composition to the metal being joined is defined as a welding electrode. Several factors to consider before choosing the right electrode for any project. The arc welding electrode / SMAW is consumable as they become part of the weld fusion.

What is a light coated welding electrode?

There is always a definite composition of the light coated welding electrodes. They applied a light coating on the surface by dipping, washing, brushing, spraying, wiping, and tumbling. These coatings meant: to improve the arc stream.

How long should electrodes be dry?

It is mandatory to keep electrodes dry as moisture may destroy the characteristics of its coatings and may lead to excessive spatters. It may cause porosity and cracks development in the welded zone. Once electrodes are exposed to the damp environment for more than 2-3 hours, it should be advised to heat dry in a suitable oven for a minimum of 2 hours at 500 degrees F.

What is AC welding?

AC is used in atomic hydrogen welding and carbon arc processes where 2 carbon electrodes are used. It allows a uniform rate of welding and electrode consumption. In a carbon arc when one electrode is recommended then direct current straight polarity is the choice and here electrode consumption at a slower pace.

What is cellulose coating?

The cellulose coatings consisted of soluble cotton/ any other form of cellulose with a little amount of sodium, potassium, titanium, and some other added minerals . The cellulose coatings protect the molten metal with a gaseous section around the arc and the welding zone.

What is covered electrode?

The covered sort of electrode is a kind of popular style of filler material in the arc welding process. The electrode covering’s composition determines the utility of the electrode, and specification deposited material decides the electrode.

What is a welding rod made of?

The welding electrodes or welding rods are made from materials and composition similar to the metal being welded. The choice of welding rod depends upon a variety of factors for each and every project.

Click here to see our latest technical engineering podcasts on YouTube

A shielding gas is not required. The arc is submerged beneath the flux blanket and is not normally visible during welding.

Further information

If you have any questions or need help, email us to get expert advice: [email protected].