What are the different types of welding joints?

The five basic types of welding joints in the welding industry, acknowledged by the American Welding Society, are; Tee joint, Lap joint, Corner joint, Edge joint, and Butt joint. These types of joints are used in different welding applications and for other welding processes so the welder can deliver high-quality welds.

What is butt joint welding?

These types of welding joints form when the two metal pieces are placed end to end together in the same plane surface, it is known as butt joint welding. In welding, this is the most common type of joint.

What is an edge joint in welding?

A joint between the edges of two or more parallel or nearly parallel members. Often with this type of joint, one of the pieces is flanged. Although found in plate work, this joint is more common in sheet metal work. Use an edge type of welding joint only for joining members 1/4 inch or less that are not subject to heavy stresses.

How do I select the right joint design for my welding job?

Selecting the most appropriate joint design for a welding job requires special attention and skill. A butt joint, or butt weld, is a joint where two pieces of metal are placed together in the same plane, and the side of each metal is joined by welding.

What is the best joint welding?

A lap joint is when one plate overlaps another one, leaving two sections for fillet welds, one on the top and one underneath. This is often the most reliable welding joint due to the large surface area between the welds.

What types of welded joints used in welding?

There are five types of joints referred to by the American Welding Society: butt, corner, edge, lap, and tee. These configurations may have various configurations at the joint where actual welding can occur.

What are T joints used for?

As the name infers, the T-joint (Fig. 5.4b) is one where one member is positioned at approximately right angles to its partner with the most usual applications being plate to plate or branch connections.

What is the easiest type of joint to perform in welding?

Butt Joint A butt welding joint is also known as a square grove weld. It's the easiest and probably the most common weld there is. It consists of two flat pieces that are side by side parallel.

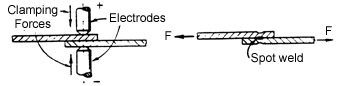

How does Spot welding work?

Spot welding works by applying pressure and heat to the weld area using copper alloy electrodes. These electrodes transport an electrical current through the weld segments. As the material melts the parts are fused. At this point, the current is turned off and pressure from the electrodes is upheld.

What are the 5 types of weld joints?

There are five basic welding joint types commonly used in the industry, according to the AWS:Butt joint welding.Tee joint welding.Corner joint welding.Lap joint welding.Edge joint welding.

What is L joint in welding?

Lap Joint Welding Lap welding joints are essentially a modified version of the butt joint. They are formed when two pieces of metal are placed in an overlapping pattern on top of each other. They are most commonly used to joint two pieces with differing thicknesses together. Welds can be made on one or both sides.

What is Britannia joint?

Joint, Britannia. A joint for uniting the ends of telegraph and electric wires. The ends of the wires are scraped clean and laid alongside each other for two inches, the extreme ends being bent up at about right angles to the wire.

What is edge joint welding?

Edge Welding Joint. Edge welding Joints are often applied to sheet metal parts that have flanging edges or are placed at a location where a weld must be made to attach to adjacent pieces. Being a groove type weld, Edge Joints, the pieces are set side by side and welded on the same edge.

Which weld joint is strongest?

TIG welding is often considered the strongest weld since it produces extreme heat, and the slow cooling rate results in high tensile strength and ductility. MIG is also an excellent candidate for the strongest type of weld because it can create a strong joint.

Which of the weld is most suitable for lap and T joints?

Fillet weldsWhich of the following type of weld is most suitable for lap and T-joints? Explanation: Fillet welds are suitable for lap and T-joints and groove welds are suitable for butt, corner, and edge joints.

What is the strongest joint?

The muscles and ligaments that surround the joint are also some of the largest and strongest in the body. So why does the biggest, strongest joint in the body become a problem?

What are the 4 different types of welding?

There are four main types of welding. MIG – Gas Metal Arc Welding (GMAW), TIG – Gas Tungsten Arc Welding (GTAW), Stick – Shielded Metal Arc Welding (SMAW) and Flux-cored – Flux-cored Arc Welding (FCAW). We dive deeper into each type of welding here.

What are the 3 types of fillet joints?

Fillet welded joints such as tee, lap and corner joints are the most common connection in welded fabrication. In total they probably account for around 70 to 80% of all joints made by arc welding. No edge preparation is needed and assemblies in piping systems are simpler.

What are the 4 basic welding positions?

What are the 4 basic welding positions?Flat (1)Horizontal (2)Vertical (3)Overhead (4)

What is 2F and 3G means?

2 refers to a horizontal position – either 2F or 2G. 3 is a vertical position – either 3F or 3G. 4 is an overhead position – either 4F or 4G.

What is a butt weld?

This type of joint is commonly used during the building of structures and in pipeline construction. It is an easy joint to pull off, as there are many different ways a welder can employ to get a good outcome. Butt welds are achieved through several means, and the various welding process has individual design purposes.

What are the different types of joints in welding?

The five basic types of welding joints in the welding industry, acknowledged by the American Welding Society, are; Tee joint, Lap joint, Corner joint, Edge joint, and Butt joint . These types of joints are used in different welding applications and for other welding processes so the welder can deliver high-quality welds.

What is AWS welding?

The AWS (American Welding Society) describes a welding joint as the way or manner workpieces are being fused. There are numerous welding applications, and all these applications require varying welding types, positions, and joints to achieve the best result.

What is the strongest welding?

The strongest weld is the TIG (Tungsten inert gas welding) called the GTAW welding. TIG is used in producing solid and clean welds; it is the most rigid type of welding and for diverse reasons. It is also a tedious process that is difficult to master than various types of welding. It is also a prolonged process.

What is the role of welding process?

The kind of welding process utilized has a significant role in selecting the right weld joint for the job. The welding process used affects the quality of the weld on some joints. Rate of deposition, travel rate, and penetration are also part of the affecting factors.

What is welding a craft?

Welding is a craft that can be pretty challenging to grasp fully. It requires a lot of training, patience, and creativity. To get the job done in the right and best way possible, a welder needs to have a deep knowledge of the various styles and techniques used in this profession. Knowing the different types of welding joints is also a vital part ...

What is edge jointing?

Edge Jointing. For a welder to get an edge joint, the two workpieces will be placed together to ensure equal edges. The two pieces or one of the pieces can be formed by bending them at the desired angle. A weld joint’s primary purpose is to join pieces together so the stresses can be evenly distributed.

How is welding heat generated?

The welding heat is generated by the electric current, which is transferred to the workpiece through copper alloy electrodes.

What is spot welding?

Spot welding (also known as resistance spot welding) is a resistance welding process. This welding process is used primarily for welding two or more metal sheets together by applying pressure and heat from an electric current to the weld area. It works by contacting copper alloy electrodes to the sheet surfaces, ...

What is the best material to use to spot weld copper?

Electrode materials typically used for spot welding copper include molybdenum and tungsten.

When spot welding zinc coated steels, electrodes must be frequently exchanged?

When spot welding zinc coated steels, electrodes must either be frequently exchanged or the electrode tip surface should be ‘dressed’, where a cutter removes contaminated material to expose a clean copper surface and reshapes the electrode.

Is steel a good material for spot welding?

Due to its lower thermal conductivity and higher electrical resistance, steel is comparatively easy to spot weld, with low carbon steel being most suited to spot welding. However, high carbon content steels (Carbon equivalence > 0.4wt%) are prone to poor fracture toughness or cracking in the welds as they tend to form hard and brittle microstructures.

How to weld lap joints?

Lap Joint. To get a lap joint weld, you place two plates together and then weld the edges of the plates together. The best weld results with plates that are 3 mm or less in thickness. Often, these types of welds can be found on exercise equipment and weight machines.

What is edge joint welding?

An edge joint weld occurs when two parallel plates are welded together. This type of weld is best used for plates that are 6 mm or less in thickness. This type of joint is commonly seen on sheet metal. Some of the types of welds you will find with an edge joint include: U groove. Square groove.

What type of welds are used for corner joints?

Some of the types of welds you will find with a corner joint include: Square groove. Fillet. Bevel groove.

How thick should a T joint be?

For the best results, you should only utilize plates up to 3 mm in thickness. If you do have plates that are thicker than the recommended 3 mm, you would need to complete the weld on both sides.

What is welding joint?

A welding joint, simply put, is where two or more pieces of plastic or metal are joined together. To get a welding joint, you must weld the pieces together by using specific geometric calculations.

What angle do you need to join two plates?

Corner Joint. To get a corner joint weld, you would need to join together the edges of two plates at a 90-degree angle . This type of welding is used primarily for light- and heavy-duty metal thickness.

How are edge joints formed?

The edge joints are formed by placing the blithe metal surfaces together so that their edges become even. You can also make them by bending and welding both plates at a suitable angle.

Is welding easy?

Want to know some basic welding joints types? The welding is not as easy as pie. It requires patience, attention, and the proper use of techniques to make perfect welds. The techniques of welding are limitless.

Why do welders use static and dynamic loading?

Engineers use static and dynamic loading computer programs to anticipate the weldment’s strength requirements. Today’s welders are expected to understand the types of forces being applied to the weldment and to determine the best joint design to prevent these forces from causing a structural failure.

What is welding a craft?

Welding is a complex craft that requires patience, an eye for detail and creativity. In order to do their job successfully, welders must have an in-depth understanding of the various techniques and practices used in the industry, which includes welding joint types.

Why do welders shape faying surfaces?

The faying surface can be shaped before welding to increase the weld’s strength, which is called edge preparation. The edge preparation may be the same on both members of the butt joint, or each side can be shaped differently. Reasons for preparing the faying surfaces for welding include the following:

What is a lap welding joint?

Lap welding joints are essentially a modified version of the butt joint. They are formed when two pieces of metal are placed in an overlapping pattern on top of each other. They are most commonly used to joint two pieces with differing thicknesses together. Welds can be made on one or both sides.

How does welding affect joint design?

Each welding process has characteristics that affect its performance. The rate of travel , penetration, deposition rate and heat input also affect the welds used on some joint designs.

Why are tee joints not grooved?

Tee joints are not usually prepared with groove, unless the base metal is thick and welding on both sides cannot withstand the load the joint must support. A common defect that occurs with tee joints is lamellar tearing—which happens due to restriction experienced by the joint.

How many types of welding joints are there?

The applications of welding are endless, and different jobs require different types of welds and joints. There are five major welding joint types, which are each made to stand up to the needs and forces of different applications. Keep reading to learn about each one and how this can apply to a career in the field:

What is the point where two or more base metals meet for welding?

Welders describe the point where two or more base metals meet for welding as the weld joint . The five main types of welding joints are: The design of each joint affects the quality and strength of the finished weld.

What is the root of a joint?

The root of a joint is the narrowest point in the gap between two members to be welded, or the point in the gap furthest removed from the electrode. Generally, these points are the same. As shown in Figure 7, the root may be a point, a line, or an area when viewed in a cross section.

What is the strongest type of joint?

Made by overlapping one piece of metal over another, the lap joint can be one of the strongest types of joints. Overlapping the metals at least three times the thickness of the thinnest member results in the most efficient joint (strongest relative to the base metal).

What is a weld symbol?

Weld symbols are a type of description used to help others understand the type of weld joint. They are commonly used by professionals. One of the most common ones is fillet welds, which are used to make tee joint, lap joint, and corner joint. There are the groove welds. This is mainly an edge to edge weld.

What is a tee joint?

When these metals are welded together, it is called a tee joint. Most often, they are addressed as a type of filler joint.

What is the task you must do if you want to join two pieces of metal together?

What is the task you must do if you want to join two pieces of metal together? The right answer is you weld. Not only does it helps bond different metals together, but you can also shape the metals and form what you want out of them.